Call for Abstracts: German IMAPS Conference in Munich

October 20/21, 22: IMAPS Germany invites you to the annual conference in Munich

The IMAPS fall conference is seen by all participants as an important platform for professional discussions between industry and academia as well as production and research in order to further strengthen and promote Germany as a business location. After many virtual conferences and meetings, it is time for personal contacts again. We - IMAPS Germany - would like to support you in this and are currently planning this year's Fall Conference 2022 as an in-person event.

|

Design, modeling, simulation |

Materials and processes |

|

|

|

System integration technologies |

Quality and reliability |

|

|

We therefore cordially invite you again this year to present your results on the above-mentioned topics in the field of microelectronic packaging at our conference in front of representatives from industry and science and to discuss them together (presentation duration 15-20 min, no paper only presentation).

With half a year to go, we currently expect to be able to continue the proven mix of professional exchange, personal interaction, exhibition, lecture series and consolidation of networks in a joint and justifiable manner. If the conference cannot take place as a face-to-face event, we will hold the event virtually, which will give you the opportunity to present your results in this way as well.

Please submit your abstract for evaluation by July 15 (approx. 200 words). Please use the following link for submission: https://www.conftool.net/imaps-herbsttagung-2022(activation from May 2022).

We will also be presenting a Best Presentation Award this year!This only applies to the face-to-face event! |

Expert meeting showcases the latest electronics developments in research and practice

At the 3rd Symposium on Electronics and System Integration, around 130 experts from science and industry met virtually at Landshut University of Applied Sciences to exchange and discuss the latest technological developments in this field, which is particularly important for the future-relevant topics of digitalization.

In his welcoming address, event initiator Prof. Dr. Artem Ivanov (spokesperson for the Electronics and System Integration research focus at Landshut University of Applied Sciences) emphasized the broad range of topics. Registrations from eight federal states as well as participants from Austria and Switzerland demonstrated the great interest in the event. In his welcoming speech, University President Prof. Dr. Fritz Pörnbacher pointed out that the exchange between scientists and experts from industry was of great importance and could provide valuable impetus for future technological developments. The ESI symposium is organized by the Microsystems Technology Cluster together with the Electronics and System Integration research focus at Landshut University of Applied Sciences.

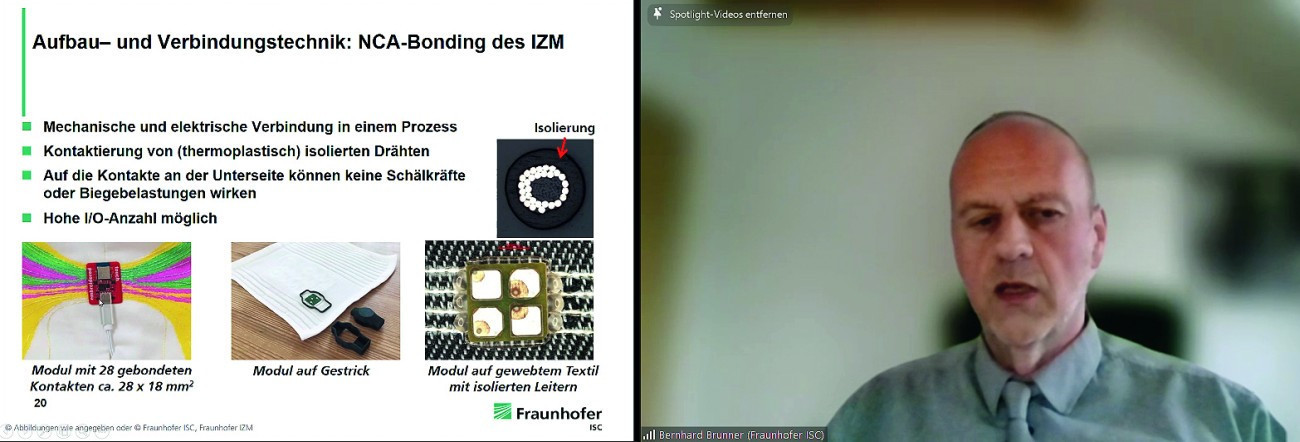

Electronics in e-textiles with high potential

Combining electronics with textiles is being used in more and more fields, as Dr. Bernhard Brunner (Fraunhofer Institute for Silicate Research ISC) explained in his plenary lecture on "Electronics in e-textiles". The global market volume in 2020 was around 2.1 billion US dollars, and the estimated growth rate is 18.5% by 2027. Not only does sensor technology offer many areas of application, from posture, movement or ECG sensors to welding analysis or pressure measurement fields in shoes or seats, but electricity can also be introduced into the body, as in electro-muscle stimulation (EMS). This places high demands on electrical conductors in textiles: they must be thermally and chemically resistant, have good conductivity, be washable, abrasion-resistant, flexible/stretchable, skin-friendly and recyclable. The Fraunhofer ISC is working on silicones as sensor and actuator materials. Elastic, insulating and conductive layers can also be applied to highly curved components using screen printing. Fraunhofer has developed new solutions for assembly and connection technology, including NCA bonding (Nonconductive Adhesive Bonding), an adhesive process in which pressure and high temperatures are used to fuse and thus create the electrical and mechanical connection in a single process.

In his plenary lecture, Dr. Bernhard Brunner (Fraunhofer ISC) emphasized the potential of electronics in e-textiles

In his plenary lecture, Dr. Bernhard Brunner (Fraunhofer ISC) emphasized the potential of electronics in e-textiles

Printed and flexible electronics was also the topic of a separate session. Johannes Jehn (Munich University of Applied Sciences) presented an inkjet-printed resistive humidity sensor based on tungsten oxide. Anette Wimmer (Hof University of Applied Sciences) spoke about the production of three-dimensional assemblies using high-pressure forming and back-injection, while Nesrine Naziri (Ilmenau University of Technology) reported on flexible thermoelectric generators. A comparison of methods and materials to optimize electrical connections of printed electronics on often temperature-sensitive substrates was presented by Prof. Dr. Artem Ivanov (Landshut University of Applied Sciences).

Practical application in power electronics

In the second plenary lecture, Markus Böhmisch (Elec-Con technology GmbH) demonstrated the hybrid implementation of a power supply with digitally configurable control for embedded systems. The controller for the converter is implemented using a microcontroller with analog components. Measurement data is recorded directly via converters that are monitored by the higher-level digital system. The high reliability of analog control combined with digital monitoring and control offers many fields of application, from Industry 4.0 to predictive maintenance or increasing the service life of various batteries. He demonstrated the use of a hybrid system using the example of a step-down converter or step-down converter. For correct dimensioning, it is just as important to estimate undershoots or overshoots during load jumps as it is to determine how quickly the system reacts (step-through frequency). The complex frequency characteristic method makes it possible to set a control system precisely and to regulate load jumps.

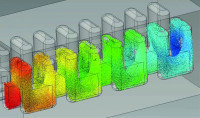

Prof. Dr. Till Huesgen (Kempten University of Applied Sciences) dealt with the PCB embedding of power electronics in his presentation

Prof. Dr. Till Huesgen (Kempten University of Applied Sciences) dealt with the PCB embedding of power electronics in his presentation

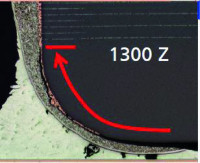

The power electronics session provided further valuable input. For example, Prof. Dr. Till Huesgen (Kempten University of Applied Sciences) gave an overview of the state of the art and current challenges in PCB embedding of power semiconductor components. This offers advantages such as shorter current paths and improved heat dissipation, but also challenges such as insulation resistance, moisture-induced copper corrosion or fractures, as the components used must be adapted to the material expansion coefficient of copper. Janusz Wituski (Landshut University of Applied Sciences) presented a gallium nitride (GaN) power module based on a 3-level flying capacitor topology to stabilize the vehicle electrical system voltage and set the desired voltage level for hybrid and fuel cell vehicles.

Developments in networked systems, assembly and connection technology and sensor technology

Two further sessions on networked systems offered a focus with a wide range of topics. Ralf Eckhardt (Texas Instruments Deutschland GmbH) demonstrated the potential of two-wire Ethernet applications for the automotive and industrial sectors. Dirk Linnenbrügger (FlowCAD EDA-Software Vertriebs GmbH) explained how antennas and RF circuits can be efficiently designed for industrial applications on printed circuit boards. Alexander Krutwig (Mixed Mode GmbH) presented a platform for peer-to-peer energy trading via blockchain. Reactive soldering with selective heat input in the bond interface with an ignitable layer as an internal heat source promises new areas of application and improved integration capability for LTCC ceramics. This soldering method, which is suitable for temperature-sensitive components, was highlighted by Thomas Herbst (VIA Electronic GmbH). The reliability of SAC+ solders under thermomechanical stress was discussed by Maximilian Schmid (TH Ingolstadt), Nihesh Mohan (TH Ingolstadt) presented some variants of copper-based sinter pastes for use in power and printed electronics.

Reactive soldering for LTCC ceramics was presented by Thomas Herbst (VIA Electronic GmbH)

Reactive soldering for LTCC ceramics was presented by Thomas Herbst (VIA Electronic GmbH)

A presentation by Prof. Dr. Gordon Elger (Fraunhofer Institute for Transportation and Infrastructure Systems - IVI) dealt with ensuring the functionality of sensors and the storage of data for environment recognition in the field of autonomous driving. Presentations in the field of sensor technology included the determination of the thermal parameters thermal conductivity and thermal capacity of a lithium-ion pouch cell (Felix Gackstätter, Landshut University of Applied Sciences) and nano-3D printing for sensor development (Prof. Dr. Matthias E. Rebhan, Munich University of Applied Sciences).

Further information on the symposium can be found in the conference proceedings with 15 scientific papers. Individual contributions can be requested by e-mail

Further information on the symposium - as well as the table of contents of the conference proceedings - can be found on the event homepage at www.symosium-esi.de.

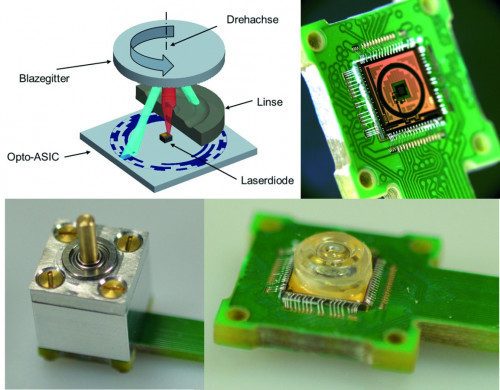

Miniaturized, intelligent, optical rotation angle sensors

The miniaturization of sensors does not stop at optical rotary sensors. In addition, more and more measured variables are to be recorded simultaneously and in the smallest of spaces, and additional functionalities and analyses are to be integrated into sensors.

In the IGF project X-MIND (17898 N), the Sensors+Actuators group at Hahn-Schickard in Stuttgart developed a concept for a miniaturized, absolutely coded, optical rotation angle sensor with a resolution of 10 bits, which corresponds to 1024 individual angle positions, and successfully implemented it together with IMS CHIPS.

Miniaturized, intelligent, optical rotation angle sensorAplastic angle disk is attached to a rotating shaft. The incident beam from a laser diode is focused by a plastic lens. Thanks to hybrid assembly and connection technology, both elements are located directly on an opto-ASIC. The focused light beam is reflected by a specially designed diffraction structure in the angled disk, a blazed grating, so that two points of light of different intensities are created on the Opto-ASIC that circle around the laser diode. There are photodiodes on the Opto-ASIC so that the position of the rotating light points can be detected.

Miniaturized, intelligent, optical rotation angle sensorAplastic angle disk is attached to a rotating shaft. The incident beam from a laser diode is focused by a plastic lens. Thanks to hybrid assembly and connection technology, both elements are located directly on an opto-ASIC. The focused light beam is reflected by a specially designed diffraction structure in the angled disk, a blazed grating, so that two points of light of different intensities are created on the Opto-ASIC that circle around the laser diode. There are photodiodes on the Opto-ASIC so that the position of the rotating light points can be detected.

The Opto-ASIC itself is mounted directly on a printed circuit board. The angled disk can be manufactured cost-effectively and in large quantities using injection moulding. The plastic lens was first turned from plastic using ultra-precision machining. Two concepts were pursued for the opto-ASIC, one with 1024 individual photodiodes arranged in a circle and a differential gray code variant. Both variants were successfully tested.

In the IGF project InoSens (20944 N), this basic functional principle was taken up again and extended. For this purpose, the 10 bit gray code variant was pursued further and extended by additional incremental tracks, so that in addition to the absolute coding of 10 bit, an interpolation with 5 bit is also available. Position resolutions of up to 15 bit can thus be realized. The Opto-ASIC has dimensions of 4.8 mm x 4.8 mm and is manufactured at XFab. The lens is now also produced cost-effectively by injection molding and therefore in scalable quantities. The lens is mounted on the chip with high precision using Active Alignment during assembly.

Another special feature of the new rotation angle sensor is its additional sensor technology and intelligent functions. A powerful microcontroller and an acceleration sensor with 6 degrees of freedom are located on the back of the circuit board. A temperature sensor is also on board. At the same time, the current is regulated and monitored by the laser diode. The microcontroller can be freely programmed by the user and allows numerous analyses, the provision of additional information such as speeds or acceleration monitoring as well as long-term storage of ageing data. This makes condition monitoring possible for the first time with this sensor, which is only 1 cm³ in size. Communication with the sensor takes place via SPI.

In order to extend the possible application range of the rotation angle sensor, special attention was paid to temperature resistance when selecting the components. The concept also offers the advantage of extremely simple installation technology. For example, the rotation angle sensor is insensitive to eccentricity of the sensor shaft. In conjunction with the intelligent functions, the increased temperature range and the design consisting of a small number of low-cost optical components, the low-cost rotation angle sensor with speeds of up to 12,000 rpm offers the potential to open up completely new applications, e.g. in medical technology or in the consumer sector.

Author: Dipl.-Ing. André Bülau

Contact Dr.-Ing. Jonathan Seybold, Hahn-Schickard, Stuttgart and Alexander Frank, IMS Chips

Calendar of events

|

Location |

Period |

Event name |

Organizer |

|

Gothenburg, S |

June 12-14, 2022 |

NordPac 2022 |

IMAPS Nordic |

|

Fellbach, D |

14/15 Jun. 2022 |

EBL 2022 |

IMAPS D |

|

California, USA |

June 21-23, 2022 |

SiP 2022 |

IMAPS USA |

|

Vienna, AT |

July 13-15, 2022 |

CICMT 2022 |

IMAPS |

|

Oxford, UK |

July 18-20, 2022 |

HITEN 2022 |

IMAPS UK, IMAPS USA |

|

Sibiu, RO |

Sep 13-16, 2022 |

ESTC 2022 |

IEEE-CPMT, IMAPS Europe |

|

Berlin, D |

Sep 26-29, 2022 |

ESREF 2022 |

IZM / TU |

|

Boston, USA |

Oct. 3-6, 2022 |

International Symposium |

IMAPS USA |

|

Munich, Germany |

Oct. 20/21, 2022 |

Fall Conference |

IMAPS D |

|

Munich, Germany |

Nov. 2022 |

SEMICON EUROPE |

IMAPS Europe |

IMAPS Germany - Your association for packaging and packaging technology

IMAPS Germany, part of the "International Microelectronics and Packaging Society" (IMAPS), has been the forum in Germany for all those involved in microelectronics and packaging technology since 1973. With almost 300 members, we essentially pursue three important goals:

- we connect science and practice

- we ensure the exchange of information among our members and

- we represent the point of view of our members in international committees

Imprint

IMAPS Germany e. V.

Kleingrötzing 1

D-84494 Neumarkt-St. Veit

1st Chairman:

Prof. Dr.-Ing. Martin Schneider-Ramelow,

Deputy Director of the Fraunhofer Institute for Reliability and Microintegration (IZM),

m

Treasurer (for questions about membership and contributions): Ernst G. M. Eggelaar,

You can find detailed contact information for the board members at www.imaps.de

(Board of Directors)