THT solder joints: Why DfM rules alone are not enough - Hidden risks and costs of Through Hole Technology

by Dr.-Ing. Reinhardt Seidel, DEEPTRONICS GmbH

Hidden THT risks

PCB designers know the problem: even if all DfM rules are strictly adhered to, unexpected THT soldering problems arise in series production. Especially with high-power electronics with several copper layers and thick PCBs (>1.6 mm), the limits of conventional design-for-manufacturing approaches become apparent.

The reality is that the majority of THT risks are not covered by standard DfM checks. This gap is particularly wide in the case of sophisticated high-power assemblies, because the effects of PCB design are particularly pronounced here.

This leads to costly prototype loops, rework and delays.

The physics behind the problem

THT solder joints are complex multi-physical systems. Their quality depends on numerous factors that influence each other:

- Thermal mass: copper layers, PCB thickness and component size

- Process parameters: Soldering time, temperature profiles, flux and alloy

- Geometric influences: Pin-to-hole ratio, bumper connection and distribution

- Machine specifics: process type, nozzle configuration, wave height, preheating

Conventional DfM rules do not consider these factors adequately, but define simple rules that usually only define minimum distances or a hole diameter. However, it is the interaction between the assembly design and the soldering process that determines the actual solderability.

Identify risks through process-based calculation instead of estimation

What if you knew at the design stage which solder joints would be problematic? What if you could quantify how design changes affect manufacturability?

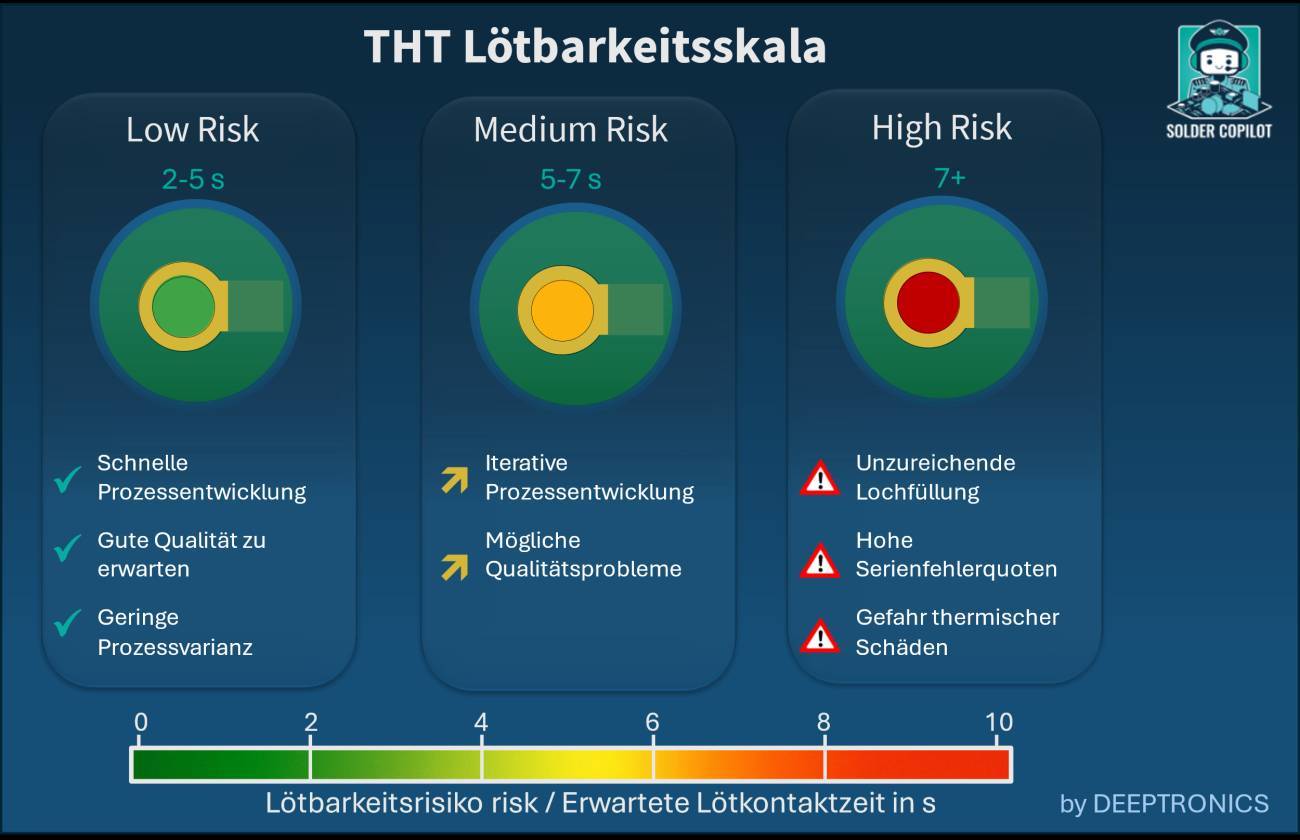

A digital twin of the THT soldering process makes exactly that possible. It simulates the process physics and evaluates each solder joint individually:

- Green solder joints: < 5 s robust process window

- Yellow solder joints: 5-7 s iterative process development required

- Red solder joints: > 7 s high risk of insufficient soldering

Risk minimization at the design stage for high quality requirements

The physics-based approach of the Solder Copilot supplements the subjective assessment by manual checking with quantified risk assessment. Critical THT solder joints are identified before layout freeze and prototype ordering and defects are corrected before they become costly.

The result

Fewer prototype loops, faster time to market and higher production quality.

Indications of hidden risks can be identified using simple rules of thumb:

- Thick PCBs (>1.6 mm) with many copper layers (>4 layers)

- Thick copper layers > 35 µm

- High-power components (electrolytic capacitors, shunts, transformers)

- Use of solder masks for wave and selective wave soldering with dense placement

About the author

Dr. Reinhardt Seidel founded DEEPTRONICS GmbH as a spin-off from his research work at the FAPS chair at FAU Erlangen-Nuremberg. He is an expert in THT layout, THT soldering processes and digital twins in electronics production.

Contact:

www.deeptronics.io

Program Autumn Conference at Munich University of Applied Sciences

We are once again inviting you to the fall conference in Munich on October 16 and 17, 2025. As usual, the venue will be the "Roter Würfel" lecture hall at Munich University of Applied Sciences. We look forward to your participation. You can find the detailed program at https://www.conftool.net/imaps-herbstkonferenz-2025/sessions.php (see QR code)

| Thursday 16.10.2025 | |

| 9:00 - 9:10 | Opening and welcome: Martin Schneider-Ramelow, IZM | IMAPS |

| 9:10 - 10:25 | Ultrasonic bonding and soldering, Chair: Martin Schneider-Ramelow, IZM | IMAPS |

| Model-based optimization of an ultrasonic torsional welding system Markus Dohmen, Peter Bornmann, Walter Littmann, Tobias Hemsel, Walter Sextro |

|

| Influence of Different Control Strategies on the Heavy Wire Bonding Quality Bernhard Rebhan, Josef Sedlmair |

|

| New flux-free solder paste systems for wash-free soldering processes Andreas Karch |

|

| 10:25 - 10:45 | Presentation of the exhibiting companies, Chair: Matthias Lorenz, AEMtec | IMAPS |

| 10:45 - 11:30 | Break & exhibition in the gallery, Chair: Ernst J. M. Eggelaar, Microtronic GmbH | IMAPS |

| 11:30 - 12:45 | Ceramic substrates, Chair: Jens Müller, TU Ilmenau | IMAPS |

| Integration of functional materials in ceramic multilayer technology Arno Görne, Tina Block, Qaisar Khushi Muhammad, Uwe Krieger |

|

| Feasibility study on LTCC inserts sintered into silicon to extend substrate functionality Michael Fischer, Cathleen Kleinholz, Alexander Schulz, Björn Müller, Jens Müller |

|

| Contact thermography and multi-energy X-ray diagnostics as non-destructive testing methods for soldered semiconductor dies on DCB substrates Martin Oppermann, Oliver Albrecht, Thomas Zerna |

|

| 12:45 - 13:45 | Break and exhibition in the gallery |

| 13:45 - 15:00 | Simulation and modeling, Chair: Indira Käpplinger, CiS | IMAPS |

| Generic Transient Thermal FE based Digital Twin for Automotive High Power LEDs to predict Solder Joint Reliability Gokulnath Vellaisamy Muniyandi, Hannes Schwan, Gordon Elger |

|

| AI Driven Model for Optimizing Active Metal Brazed (AMB) Ceramic Substrates Reliability Abdel Rahman Alkasabreh, Gordon Elger |

|

| Simulation of mechanical stresses in MLCC components due to thermal gradients during desoldering processes for the purpose of repair or reuse Steffen Wiese |

|

| 15:00 - 15:35 | Break and exhibition in the gallery |

| 15:35 - 16:50 | Polymers in microsystems technology, Chair: Matthias Lorenz |

| Influence of total encapsulation of white-light mid-power LED packages over the correlated colortemperature Edward Olivera, Matthias Hien, Mahmoud Beker, Markus Zankl |

|

| Advancing sustainability of PCB manufacturing for next-generation green electronics Nihesh Mohan, Pratheep Kumar Annamalai, Gordon Elger |

|

| Innovative assembly concepts of MEMS IR emitters Toni Schildhauer, Michael Hintz, Manuel Kermann, Christian Maier, Andreas Winzer |

|

| 17:00 - 18:00 | General meeting of IMAPS Deutschland e.V., Chair: Martin Schneider-Ramelow |

| 19:30 - 23:00 | Joint dinner in Augustiner Gaststätten, Neuhauser Str. 27, 1st floor, Grüner Saal |

| Friday, 17.10.2025 | |

| 9:00 - 10:40 | Enabling Technologies I, Chair: Artem Ivanov, Landshut University of Applied Sciences |

| Fabrication and characterization of nanoporous copper structures for contacting applications in wafer level packaging Jordis Take, Markus Wöhrmann, Morten Brink, Martin Schneider-Ramelow |

|

| Progress in mmW packaging above 100 GHz Janis Blank, Thomas Zwick |

|

| Thermal laser processes in printed electronics: sustainable and rapid post-processing for high volume production Alexander Görk |

|

| Assembly and connection technology of an 800 V high-current power module with TO-263 SiC MOSFETs on a metal core PCB Bernhard Jahn, Alexander Kleimaier |

|

| 10:40 - 11:30 | Break and exhibition in the gallery |

| 11:30 - 13:10 | Enabling Technologies II, Chair: Alexander Hensel, Siemens AG |

| Condition monitoring powered AI for repair and reuse in electronics Andreas Zippelius |

|

| Flexible coding of chip-less RFID tags in the manufacturing process using direct laser exposure Peter Uhlig, Lynn Möhring, Enrico Tolin, Martin Ihle, Birgit Manhica |

|

| High-frequency interference sensitivity of micromechanical microphones Margarita Chizh |

|

| Power electronics packaging - New perspectives with Compression Molding Marcus Voitel |

|

| 13:10 - 13:15 | Closing remarks by the Chairman of IMAPS Deutschland e.V., Martin Schneider-Ramelow |

Calendar of events

| Venue | Period | Event name | Organizer |

| Grenoble, France | Sept. 16-18, 2025 | IMAPS Europe EMPC 2025 | IMAPS France |

| San Diego, USA | Sept. 29-Oct. 2, 2025 | IMAPS Symposium 2025 | IMAPS USA |

IMAPS Germany - Your association for packaging and packaging technology

IMAPS Germany, part of the "International Microelectronics and Packaging Society" (IMAPS), has been the forum in Germany for all those involved in microelectronics and packaging technology since 1973. With almost 250 members, we essentially pursue three important goals:

- we connect science and practice

- we ensure the exchange of information among our members and

- we represent the point of view of our members in international committees.

Imprint

IMAPS Germany e. V.

Kleingrötzing 1, D-84494 Neumarkt-St. Veit

1st Chairman: Prof. Dr.-Ing. Martin Schneider-Ramelow, Director of the Fraunhofer Institute for Reliability and Microintegration (IZM),

Treasurer

(for questions about membership and contributions):

Ernst G. M. Eggelaar,

You can find detailed contact information for the members of the Executive Board at www.imaps.de

(Executive Board)