German IMAPS Conference October 20-21, 2022

Munich University of Applied Sciences

Every autumn, IMAPS Germany organizes the annual conference on current topics in packaging technology in many different fields of application. IMAPS Germany would like to see the annual conference as an important platform for the necessary close-meshed technical discussion between industry and universities as well as production and research in order to secure, strengthen and further develop Germany as a business location. We therefore cordially invite you once again this year to come to Munich for our conference on the following microelectronic packaging topics. The proven open atmosphere between speakers, exhibitors and participants offers good conditions for specialist information, establishing contacts, networking, exchanging views on current topics or initiating new project ideas.

Meet specialist colleagues from research, product development, mechanical engineering, services, consumers, material suppliers, experts from sales, universities, quality assurance or application!

Thursday, October 20, 2022

9:00-9:10 Opening and welcome

Chair: Martin Schneider-Ramelow, Fraunhofer IZM

9:10-10:25 AVT soldering

Chair: Martin Schneider-Ramelow, Fraunhofer IZM

New technological approach for soldering technology based on the argumentation of thermodynamic influences in soldering processes, Landulf Skoda, Privat

Challenges in soldering large-area substrates, Ventzeslav Rangelov, REK Innovation GmbH

Investigations into the soldering of fine-pitch SMD components on printed polymer substrates, Lukas Auer, Artem Ivanov, University of Applied Sciences Landshut

10:25-10:45 Presentation of the exhibitors

Chair: Dirk Schade, XYZTEC

10:45-11:30 Exhibition and coffee break

Chair: Ernst J. M. Eggelaar, Microtronic M. V. GmbH /IMAPS

11:30-12:45 Sensors & Actuators

Chair: Artem Ivanov, University of Applied Sciences Landshut

Copper Pillar Bumps for Microacoustic High Frequency Filters Gregor Feiertag1, Constanze Eulenkamp1, Jakob Schober21: Munich University of Applied Sciences, 2: RF360 Europe GmbH a Qualcomm Company

Presentation of a high-precision platinum temperature sensor for purity analysis of gases in the ppm range, Lukas Mennicke, Klaus Hofmann, TU Darmstadt

In-situ monitoring of the degree of cross-linking and kinetic analysis of epoxy resins for encapsulation processes in electronic packaging Corinna Niegisch1, Sabine Haag1, Tanja Braun2, Ole Hölck2, Martin Schneider-Ramelow3

1: Robert Bosch GmbH, 2: Fraunhofer Institute for Reliability and Microintegration

3: Berlin University of Technology

12:45-13:45 Lunch break and trade exhibition

Chair: Ernst J. M. Eggelaar, Microtronic M. V. GmbH /IMAPS

13:45-15:00 High-frequency technologies

Chair: Indira Käpplinger, CiS Forschungsinstitut für Mikrosensorik GmbH

Printing technologies as a solution for mmW packages above 100 GHz, Georg Gramlich, Thomas Zwick, Karlsruhe Institute of Technology (KIT)

THz Components and Module Technology, Robin Kress, Christian Preuss, Nils Weimann, University of Duisburg-Essen, Components for High Frequency Electronics

Miniaturized and Ultra-Broadband Fan-out Wafer-Level Package-based Modules for 6G Wireless Communication Michael Kaiser, Thi Huyen Le, Tanja Braun, Friedrich Müller, Ivan Ndip, Martin Schneider-Ramelow, Fraunhofer Institute for Reliability and Microintegration

15:00-15:30 Exhibition and coffee break

Chair: Ernst J. M. Eggelaar, Microtronic M. V. GmbH /IMAPS

15:30-17:10 Reliability & Simulation

Chair: Stefan Härter, Siemens AG / IMAPS- e.V.

Transient electro-thermally coupled simulation with LTspice models Model extensions and experimental validation Gregor Wiedemann, Ralph Schacht, BTU Cottbus - Senftenberg

Thermal reliability study using fluxfree and flux based solder pastes for SMD components Nihesh Mohan, Hannes Schwan, Gordon Elger, Institute of Innovative Mobility (IIMo), Technische Hochschule Ingolstadt

Application of Neural Networks to Solder Joint Reliability Prediction Andreas Zippelius1, Maximilian Schmid2, Gordon Elger1

1: Ingolstadt University of Applied Sciences, 2: Fraunhofer Institute for Transportation and Infrastructure Systems IVI

Evaluation of sintering interconnection by using µ-Raman Spectroscopy (µRS) and Finite Element Method E Liu, Sri Krishna Bhogaraju, Gordon Elger, Technische Hochschule Ingolstadt

17:15-18:00 General meeting

In the afternoon of the first conference day, the IMAPS association members will meet for the general meeting.

Chair: Martin Schneider-Ramelow, Fraunhofer IZM,

Ernst J. M. Eggelaar, Microtronic M. V. GmbH /IMAPS

19:00-23:00 Joint dinner in the Augustiner Gaststätten

Neuhauser Straße 16, 1st floor, green hall

Friday, October 21, 2022

9:00-10:15 Emerging Technologies

Chair: Thomas Bartnitzek, MicroHybrid

Wafer Level Chip Scale Package - from design to product realization Daniel Lieske, AEMtec GmbH

Approaches for the reduction of bonding pressure and temperature in Aluminum thermocompression wafer bonding Silvia Braun, Kevin Diex, Dirk Wünsch, Maik Wiemer, Harald Kuhn, Fraunhofer ENAS

Adhesive bonding - reliable integration of electronic modules in textiles Lars Stagun, TU Berlin

10:15-11:00 Exhibition and coffee break

Chair: Ernst J. M. Eggelaar, Microtronic M. V. GmbH /IMAPS

11:00-13:00 Growth core HIPS - High Performance Sensors

Chair: Jens Müller, TU Ilmenau

Potentials of Si-LTCC composite substrates from an industrial point of view Speaker: K. Baumgärtel | Micro-Hybrid Electronic GmbH, Hermsdorf

A new technology platform of silicon-ceramic composite substrates for high performance sensors, Speaker: F. Bechtold | VIA electronic GmbH, Hermsdorf

Development of a continuous film casting process for the production of a SiCer-capable LTCC ceramic, Speaker: C. Motzkus, B. Capraro | Fraunhofer IKTS, Hermsdorf

Microstructural investigations at the interface between LTCC and silicon wafer in microsystem substrates designed with SiCer technology Speaker: H. Engelhardt, C. Motzkus, K.E. Freiberg, M.Seyring, S. Lippmann, B. Capraro, A.L. Görne | Fraunhofer IKTS, Hermsdorf

Impedance sensor module in SiCer technology - structure, fluidics and characterization M. Fischer 1, K. Schilling 2, M. Krojer 2, S. Lörracher2, M. Frant 3, S. Gropp 1 and J. Müller11: Ilmenau University of Technology, IMN MacroNano®, 2: Ilmsens GmbH, Ilmenau, 3: IBA e.V. Heilbad Heiligenstadt

Packaging of piezoresistive pressure sensors based on SiCer technology Speakers: A. Cyriax 1, M. Hintz 1, C. Kleinholz 2, R. Koppert 3, U. Krieger 4, T. Ortlepp 1 1: CiS Forschungsinstitut für Mikrosensorik GmbH, Erfurt, 2: Ilmenau University of Technology, Ilmenau, 3: Siegert Thinfilm Technology GmbH, Hermsdorf, 4:Via electronic GmbH, Hermsdorf

13:00-13:15 Closing remarks and outlook

Chair: Martin Schneider-Ramelow, Fraunhofer IZM

TU Ilmenau completes dew point sensor project for acidic gases

Fig. 1: Removal of the gold electrode from the LTCC after the acid testIna joint project with two SMEs, the Ilmenau University of Technology developed a sensor element based on LTCC, which will make it possible to determine the dew point of acidic gases from exhaust systems in-situ. Such sensors help to keep the exhaust gas temperature of industrial fossil fuel plants low without running the risk of acid condensing in the exhaust gas line and destroying the chimney. This makes it possible to lower combustion temperatures, which leads to lowerCO2 emissions.

Fig. 1: Removal of the gold electrode from the LTCC after the acid testIna joint project with two SMEs, the Ilmenau University of Technology developed a sensor element based on LTCC, which will make it possible to determine the dew point of acidic gases from exhaust systems in-situ. Such sensors help to keep the exhaust gas temperature of industrial fossil fuel plants low without running the risk of acid condensing in the exhaust gas line and destroying the chimney. This makes it possible to lower combustion temperatures, which leads to lowerCO2 emissions.

The challenges faced by the Electronics Technology department during development were as follows:

- Continuous operation at over 250 °C

- Acid-resistant sensor surface for impedance measurement

- Large signal range in the event of condensation to avoid distortion due to supply lines

- integrated temperature sensor and

- low heat capacity in the sensor area for efficient cooling.

The high-temperature AVT and the sensor control were part of the work of the industrial partners.

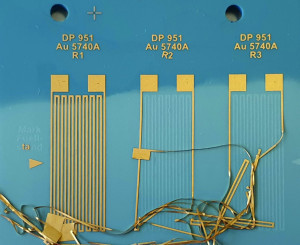

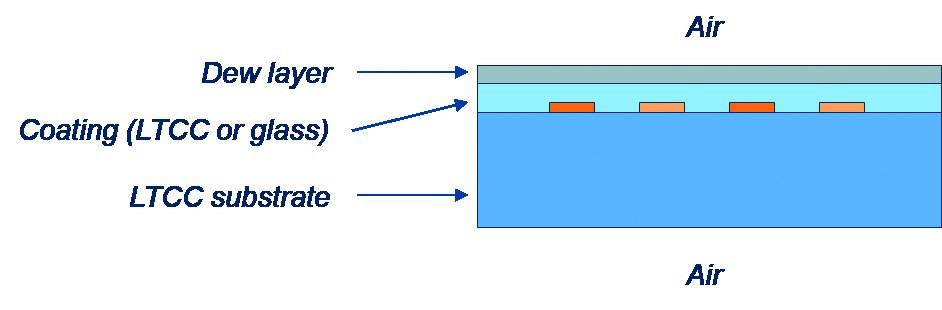

Due to the operating conditions, a ceramic system based on low-temperature ceramics (LTCC) was the obvious choice. A locally lower heat capacity can be achieved by reducing the number of LTCC layers. Screen-printed platinum structures can be used for temperature detection and typical LTCC systems are suitable for high-temperature applications. The focus of the development work was therefore on the acid resistance of the LTCC, including the sensor structure, and the optimization of the signal stroke in the event of condensation. At the beginning of the project, it was not clear whether a resistive or capacitive measuring principle should be used. When measuring on a resistive basis, the metallic electrodes are in direct contact with the acidic medium, while in capacitance measurement there is a covering layer between the electrode structure and the dew layer. Interdigital electrodes are used in both cases. The acid resistance was therefore tested in an initial experiment. Over a period of 30 days, samples of two commercial LTCC materials with different screen-printed precious metal electrodes were stored in solutions with different concentrations of nitric and sulphuric acid. In all material combinations, there were color changes in the LTCC and the structures detached from the LTCC (loss of adhesion, Fig. 1). The metallic structures themselves remained intact. As a result, the resistive measuring principle was not considered further. In the second acid resistance test, a glass coating was identified from a large number of cover glasses that offered stable protection under the test conditions. Figure 2 shows a schematic structure.

Fig. 2: Schematic structure of the capacitive sensor (simulation model)

Fig. 2: Schematic structure of the capacitive sensor (simulation model)

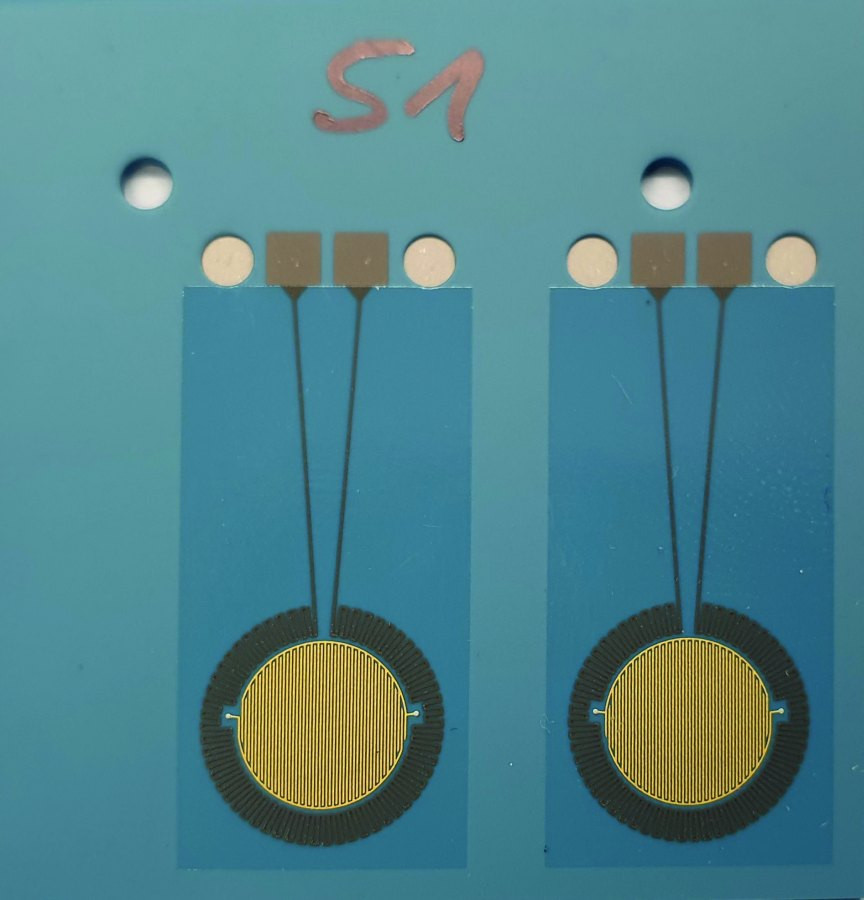

Fig. 3: Demonstrator of the dew sensor

Fig. 3: Demonstrator of the dew sensor

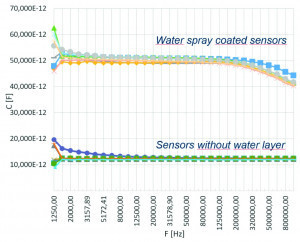

Fig. 4: Measurement of capacitance change through water layerTooptimize the sensor signal for a given area, it was initially assumed that a high resolution of the interdigital structure is required. Using screen printing, a resolution of 70 µm line width and spacing was reliably achieved with the selected electrode paste. Laser structuring was used to reduce the resolution to 30 µm, which led to a significant increase in capacitance. However, the electromagnetic simulation of the electrodes including the covering layer revealed that a narrower electrode spacing with an identical covering layer thickness leads to a lower signal deviation in the case of condensation. The demonstrator was therefore manufactured and characterized in the more cost-effective screen-printed version. Figure 3 shows a glass-covered sensor element with a circular interdigital structure and temperature sensor in meander format. The measurement of the signal stroke was simulated using a water atomizer(Fig. 4). A detailed presentation of the project results was given at the CICMT 2022 in Vienna. The project participants would like to take this opportunity to express their gratitude for the project funding under the BMBF-ZIM program "Central Innovation Program for Small and Medium-sized Enterprises (SMEs)" under contract number FKZ: ZF4030903WM9.

Fig. 4: Measurement of capacitance change through water layerTooptimize the sensor signal for a given area, it was initially assumed that a high resolution of the interdigital structure is required. Using screen printing, a resolution of 70 µm line width and spacing was reliably achieved with the selected electrode paste. Laser structuring was used to reduce the resolution to 30 µm, which led to a significant increase in capacitance. However, the electromagnetic simulation of the electrodes including the covering layer revealed that a narrower electrode spacing with an identical covering layer thickness leads to a lower signal deviation in the case of condensation. The demonstrator was therefore manufactured and characterized in the more cost-effective screen-printed version. Figure 3 shows a glass-covered sensor element with a circular interdigital structure and temperature sensor in meander format. The measurement of the signal stroke was simulated using a water atomizer(Fig. 4). A detailed presentation of the project results was given at the CICMT 2022 in Vienna. The project participants would like to take this opportunity to express their gratitude for the project funding under the BMBF-ZIM program "Central Innovation Program for Small and Medium-sized Enterprises (SMEs)" under contract number FKZ: ZF4030903WM9.

Calendar of events

|

Location |

Period |

Event name |

Organizer |

|

Berlin |

Sept. 26-29, 2022 |

ESREF 2022 |

IZM / TU |

|

Boston, MA |

October 3-6, 2022 |

International Symposium |

IMAPS US |

|

Munich, Germany |

October 20-21, 2022 |

Fall Conference |

IMAPS D |

|

Munich, Germany |

November 15-18, 2022 |

SEMICON EUROPE |

SEMI Europe |

|

Tours |

November 24, 2022 |

Power electronics and packaging workshop |

IMAPS France |

This calendar is subject to change. Please refer to the information and notes of the organizers on the respective websites!

IMAPS Germany - Your association for packaging and packaging technology

IMAPS Germany, part of the 'International Microelectronics and Packaging Society' (IMAPS), has been the forum in Germany for all those involved in microelectronics and packaging technology since 1973. With almost 300 members, we essentially pursue three important goals:

- we connect science and practice

- we ensure the exchange of information among our members and

- we represent the point of view of our members in international committees.

Imprint

IMAPS Germany e. V.

Kleingrötzing 1, D-84494 Neumarkt-St. Veit

1st Chairman: Prof. Dr.-Ing. Martin Schneider-Ramelow, Director of the Fraunhofer Institute for Reliability and Microintegration (IZM),

Treasurer

(for questions about membership and contributions):

Ernst G. M. Eggelaar,

You can find detailed contact information for the board members at www.imaps.de

(Board of Directors)