Invitation for spontaneous participants!

IMAPS Fall Conference October 20-21, 2022

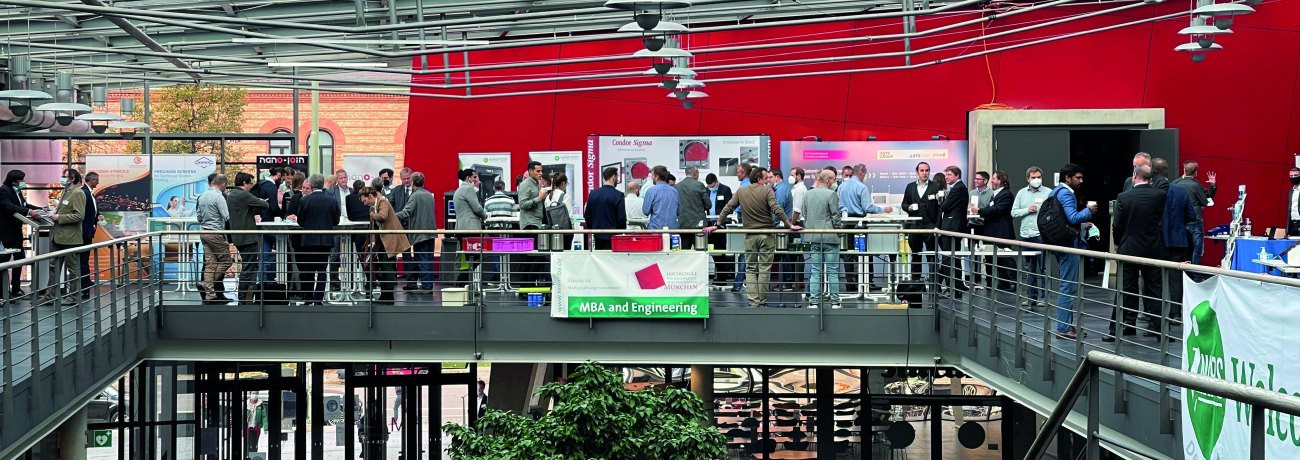

Come to Munich for the annual fall conference of IMAPS Germany. Meet representatives from the fields of microelectronics and related packaging. Experts from both industry and research will be present to exchange specialist information, initiate joint work or develop future project ideas. Exchange ideas and take the opportunity to discuss the latest trends and current research priorities with representatives from the individual universities. The program again includes interesting presentations on the topics of AVT soldering, sensors & acoustics, high-frequency technology, reliability & simulation and emerging technologies.

You can find more information about the program on our website at https://imaps.de OR directly at: www.conftool.net/imaps-herbstkonferenz-2022/sessions.php

Fig. 1: Coffee break between the presentations - opportunity to visit the individual exhibitors and to discuss

Fig. 1: Coffee break between the presentations - opportunity to visit the individual exhibitors and to discuss

This year we are looking forward to a new series of lectures. Research institutions and industrial partners from the HIPS - High Performance Sensors growth core will present their joint results from past collaborations. In various consecutive presentations you will be informed about the potential of Si-Cer technology (combination of silicon technology with ceramic multilayer technology) but also about difficulties encountered and solutions adopted.

Fig. 2 and 3: Talks at the exhibition stand of the companies Nano-Join GmbH and Nanotec International GmbH (taken in 2021)

As every year, Dirk Schade will introduce the exhibitors during the generous breaks between the presentations. In addition to PacTech GmbH, Via electronic GmbH, UniTemp GmbH, LaserJob GmbH, Indium Corporation, Amadyne GmbH and Budatec GmbH, young industry partners such as Nanotec International GmbH and Nano-Join GmbH will remain loyal to us and will also present their latest developments this year.

We look forward to your visit!

Development of protective functions and barriers for the production of tamper-proof and trustworthy electronics

Motivation and goals

The key to trustworthy electronics is secure knowledge of the origin and functions of the electronic system. This presupposes that components and supply and value chains can be traced and that (sub)systems have not been copied or manipulated by third parties. The VE-CeraTrust research project focuses on innovative hardware solutions by developing integrated structures to ensure the trustworthiness of electronic systems. The targeted innovations are intended to ensure the unique identification of assemblies and subsystems during production and use. Modular protective functions and barriers also make it difficult or impossible to manipulate the electronic system and its sensitive subcomponents.

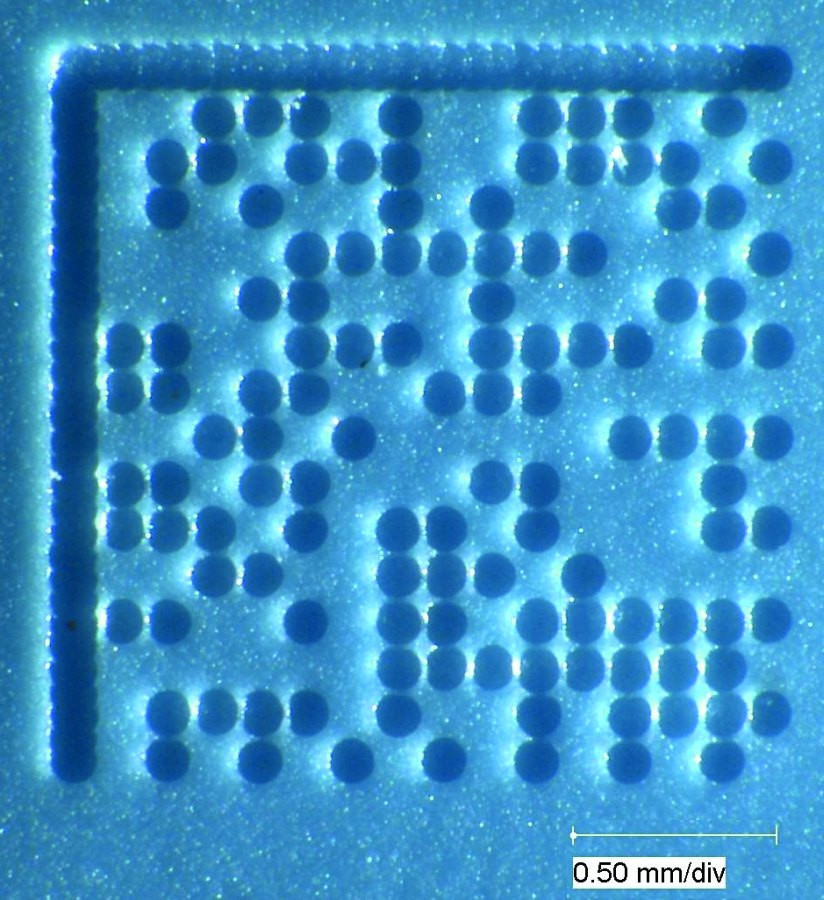

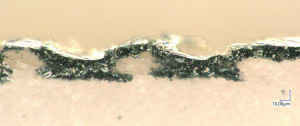

Fig. 4: Sections of microprofiles after sintering a) Green Tape 951TM DuPont Nemours, b) KOA Corporation 'KLC-Tape', connected or interrupted conductor path depending on the embossing depth

The technological core of the project is the ceramic multilayer technology Low Temperature Cofired Ceramics (LTCC), which due to its specific material properties is already established in reliable and robust electronic assemblies (e.g. multi-chip modules, system-in-package) in safety-critical areas such as automotive, aerospace, telecommunications and medical technology. In VE-CeraTrust, technological assembly concepts are to be tested and extended with specific protection functions, e.g:

- Development of high-resolution microprofiles to realize obvious as well as hidden security features, comparable to the security features of banknotes

- Protection against tampering and reverse engineering through modular, substrate-integrated barriers that prevent third parties from analyzing the system, detect tampering based on sensors and, if necessary, protect security-critical IP or components in the system against fraudulent handling.

For example, optical features that can be identified using existing measurement methods in production are used for implementation. Individual material-specific structures are suitable for fingerprint-like identification. Hidden components that can be networked along the production chain can be used to create scalable security levels.

Results

Miniaturized DMC codes were created using standard tools available in the production process. They were embossed into the LTCC tape as well as combined with a metallic layer on the surface (silver paste). These DMC codes can be used to add specific security features before sintering, which are later used for identification in the supply chain by subsequent processing partners. Due to the existing work steps, the additional effort is extremely low and therefore only incurs very low costs. At the same time, security is increased as additional features are available for identification on each individual product. Figure 4 shows a top view of a DMC code in the sintered state and, depending on the embossing depth, a connected or interrupted conductor track (material KOA Corporation 'KLC tape').

Applications

The modular, integrative solution approach of the protection functions and the generation of an assembly library should ensure that the results from VE-CeraTrust can be widely utilized, as they can also be transferred to other technologies (thick film, hybrid and PCB technology). The consortium's target markets include automotive, Industry 4.0, sensor and medical technology as well as safety-related applications.

Partners

ANDUS ELECTRONIC GmbH, Fraunhofer IKTS, IMST GmbH, KMS Technology Center GmbH, PRIGNITZ Mikrosystemtechnik GmbH, VIA electronic GmbH, associated partner: EKRA

The project is funded by the Ministry of Education and Research as part of the ZEUS initiative (FKZ:16ME0330K). We would like to thank all partners for their support.

Contact

VIA electronic GmbH, Dr.-Ing. Uwe Krieger

Robert-Friese-Straße 3, D-07629 Hermsdorf

E-mail:

Calendar of events

|

Place |

Period |

Event name |

Organizer |

|

Munich |

October 20-21, 2022 |

Fall Conference |

IMAPS D |

|

Munich, Germany |

November 15-18, 2022 |

SEMICON EUROPE |

SEMI Europe |

|

Tours |

November 24, 2022 |

Power electronics and packaging workshop |

IMAPS France |

This calendar is subject to change. Please refer to the information and notes of the organizers on the respective websites!

IMAPS Germany - Your association for packaging and packaging technology

IMAPS Germany, part of the 'International Microelectronics and Packaging Society' (IMAPS), has been the forum in Germany for all those involved in microelectronics and packaging technology since 1973. With almost 300 members, we essentially pursue three important goals:

- we connect science and practice

- we ensure the exchange of information among our members and

- we represent the position of our members in international committees.

Imprint

IMAPS Germany e. V.

Kleingrötzing 1, D-84494 Neumarkt-St. Veit

1st Chairman: Prof. Dr.-Ing. Martin Schneider-Ramelow, Director of the Fraunhofer Institute for Reliability and Microintegration (IZM),

Treasurer

(for questions about membership and contributions):

Ernst G. M. Eggelaar,

You can find detailed contact information for the board members at www.imaps.de

(Board of Directors)