Dear IMAPS members,

Thanks to the coronavirus vaccines, the pandemic situation has fortunately eased somewhat over the past year, which has made it possible to hold significantly more face-to-face events again. However, as the pandemic is not yet over, we are of course still keeping an eye on the infection figures and regulations. Most importantly, however, we managed to keep creating opportunities to stay in touch with fellow campaigners in the field of advanced packaging. However, before I look back on the past year, I would like to announce some extremely good news. I am pleased to welcome back a member of the IMAPS Germany Board after a break due to parental leave. Saskia Lange, Group Leader at Fraunhofer ISIT, will be actively supporting us again from January 2023. Welcome back, dear Saskia!

The event year 2022

The event year 2022 kicked off with the 11th DVS/GMM symposium at EBL 2022 in Fellbach (June 14-15, 2022), where everything revolved around "Intelligent Design, Intelligent Manufacturing, Testing and Application" and IMAPS Germany appeared as a partner as usual. Our first major highlight followed a few weeks later with the International Conference and Exhibition on Ceramic Interconnect and Ceramic Microsystems Technologies (CICMT 2022). The conference, held in Vienna for the first time, was organized by IMAPS Germany in collaboration with IMAPS USA and ACerS as well as the Vienna University of Technology and took place from 13 to 15 July 2022 on the premises of the Austrian Federal Economic Chamber in Vienna. The 80 participants from 12 countries were treated to a varied program with 40 presentations covering all areas of ceramics in electronics, from new materials and applications to process technologies and additive manufacturing. In addition, seven exhibitors - Lithoz, Wachstumskern HIPS, Micro-Hybrid Electronic, Keko Equipment, Microtronic, Budatec and F&S BONDTEC - supported the event and presented their products and services at the accompanying trade exhibition.

In addition to the CICMT, IMAPS Germany organized another major conference in 2022 with the traditional autumn conference at Munich University of Applied Sciences. To the great delight of everyone involved, the event was able to take place from October 20 to 21, 2022 without any restrictions. With almost 90 participants, 21 speakers and 12 exhibitors, the conference was a complete success and lived up to its reputation as the most important exchange platform for the German IMAPS community. As always, the lecture program covered a wide range of topics in assembly and connection technology: from soldering and sintering, sensors and actuators to high-frequency technologies, reliability and simulation to emerging technologies. The breaks were used for networking and visiting the exhibition.

The 'Best Presentation Award' for outstanding scientific papers went this time to Lars Stagun from the Technical University of Berlin for his presentation on "Adhesive Bonding - A reliable integration of electronic modules in textiles". Congratulations once again on this well-deserved award! With AEMtec, Budatec, EKRA, Hesse, Indium and Via Electronic, six well-known sponsors supported the conference. Of course, there was also a joint Bavarian evening at the Augustiner pub, which the participants used for a lively exchange of ideas.

In addition to the events mentioned above, IMAPS Germany also supported the ESTC 2022 in Sibiu (September 13-16, 2022), the 55th International Symposium on Microelectronics in Boston (October 3-6, 2022) and the Advanced Packaging Conference at SEMICON EUROPA in Munich (November 15-18, 2022). Further information on our activities and events can be found on our website www.imaps.de

What can we expect in the new year?

After having to do without the spring seminar in recent years due to the pandemic, it will finally celebrate its revival on March 23, 2023 at the Ilmenau University of Technology. The spring seminar will focus on the topic of "Sustainability in current electronics production". We have asked renowned companies such as BMW, VW, Infineon, Siemens, Heraeus, Hella and ERSA to participate in the event in order to present you with a top-class conference program. We have already received confirmations from the TU Ilmenau, the Research Fab Microelectronics Germany, the Fraunhofer IZM, Turck Duotec and the TU Darmstadt. You will find the full program on our website and in the next issue of PLUS. So make sure you save the date!

We can also look forward to the 24th European Microelectronics and Packaging Conference & Exhibition organized by IMAPS UK in Hinxton (near Cambridge) from 11 to 14 September 2023. The call for papers has already started in fall 2022 and I would be delighted to meet many of you there as presenters or exhibitors. I am sure that EMPC 2023 will seamlessly join the list of successful EMPC conferences of recent years!

Of course, as usual, you can count on the IMAPS Fall Conference taking place in Munich in October. The exact date and more details about the event will be announced on our homepage soon. Other event highlights in the new year include CICMT 2023 in Albuquerque (18-20.04.2023), the 56th International Symposium on Microelectronics in San Diego (02-05.10.2023) and the Advanced Packaging Conference at SEMICON EUROPA in Munich (14-17.11.2023).

The last few years have not been easy and the fact that we have managed to keep membership numbers stable and organize exciting events despite the adverse circumstances is mainly thanks to the dedicated cooperation of our IMAPS community. I would like to express my sincere thanks for their support in the form of specialist presentations, participation in exhibitions and sponsorship.

The entire extended Executive Board wishes you and your families a happy new year with health, happiness and success for you and your loved ones! Stay with us and take good care of yourselves!

Yours sincerely,

Yours

Martin Schneider-Ramelow

Announcement IMAPS seminar on March 23, 2023 in Ilmenau at the Technical University

"Are electronics for sustainability really sustainable (production aspects, materials, design, application)?" After a three-year break, IMAPS Germany is resuming its tradition of offering a spring seminar on a current topic in microsystems technology. This year, we would like to use various presentations to create a basis for discussion on a pressing contemporary issue relating to sustainability in electronics production. How can we manage to make production or individual stages of production sustainable and which aspects must be taken into account. On the other hand, microelectronic components can be used in control and regulation technology so that resources are only consumed when necessary or can be used or reused optimally and over the long term.

Directions to the Curie Building of the Ilmenau University of Technology

Directions to the Curie Building of the Ilmenau University of Technology

We were able to attract speakers from a wide range of industrial and research fields to speak on this topic.

The following presentations, for example, will provide a general overview of which aspects need to be taken into account against the background of a sustainable economy and which measures can be taken in production:

- Fraunhofer IZM, Karsten Schischke "On the road to climate neutrality: where are the hotspots in the electronics industry's supply chain and what options for action exist?"

- Duotec GmbH, Artur Rönisch "Measures to reduce energy costs in production".

The current situation and the challenges we face as a result are described in the following presentation:

- Solderpunks e. V., Marco Dörr "From ore to scrap - a look behind the scenes of the electronics industry".

The following contributions will describe in more detail and give concrete examples of how a production line or individual production stages can be made climate-neutral(er):

- Aisler B. V., Felix Plitzko and Patrick Franken "Climate-neutral and yield-optimized printed circuit boards for prototypes and small series"

- Research Fab Microelectronics Germany, Stephan Guttowski "Competence center for resource-conscious information and communication technology - Green ICT @ FMD"

- TU Ilmenau, Martin Ziegler "Bio-Inspired Information Pathways"

Furthermore, we were able to win Stefan Merlau from Heraeus Deutschland GmbH & Co. KG for a presentation as well as Klaus Hofmann from the Technical University of Darmstadt.

The detailed program with the specific daily schedule will be available shortly on our homepage, where you can already register now either via https://imaps.de/events/ (and follow the further link for registration) or directly at https://www.conftool.net/imaps-seminar-2023/index.php?page=login.

This year's seminar will take place on March 23 at the Ilmenau University of Technology. We would like to invite you to the Curiebau (formerly "Technikum") on the city campus (Weimarer Straße 25).

If the journey is a little longer, the Mara Hotel, which is less than five minutes' walk from the Curiebau, can be used as accommodation. The smaller hotel on Kirchplatz is also not far away.

Adhesive bonding - reliable integration of modules in textiles

Textile-integrated sensors and electronic components are essential for many e-textiles applications (hybrid textile products that are equipped with additional functions through integrated electronics) such as heating surfaces, vital data recording, ergonomic monitoring, lighting or innovative operating concepts. The resulting demands on e-textiles in terms of wearer comfort, washability, freedom of design, signal stability and cost-effective manufacturing processes are very high.

The integration of electronic components and assemblies into textile circuit carriers is still one of the biggest hurdles in the industrial manufacture of reliable e-textile products. The processes and components involved from the fields of textiles and electronics could not be more different. Manufacturing, process and material requirements differ greatly, making the combination of both sides a major challenge. High process temperatures during soldering, which already cause the textile to degenerate, or machines that cannot handle the flexible properties of textiles are just a few examples. Conventional integration technologies from electrical engineering such as soldering and crimping offer low contact resistance, but do not adapt sufficiently to the nature of the textile and therefore do not offer reliable mechanical contacting. Textile methods such as sewing on electronic modules with conductive yarns or connecting with press studs also do not provide a permanently stable electrical and mechanical connection. A special solution is required to combine these contrasting industries and create reliable contacts. One possibility is a connection technology adapted to the physical properties of textiles, in which electronic modules are applied to textile substrates using a non-conductive adhesive (NCA) [1].

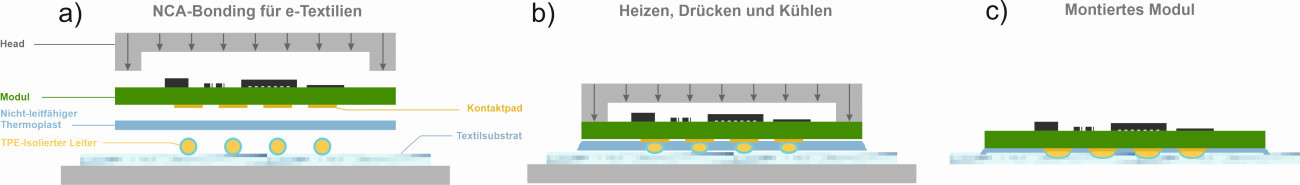

Fig. 1: Description of the NCA bond process for e-textiles; a) The modules are positioned with an NCA film between them and the textile substrate; b) The adhesive softens and the contact partners come into contact due to the pressure and heat applied. During subsequent cooling, the NCA solidifies again; c) Finally realized, mechanically and electrically contacted module

Fig. 1: Description of the NCA bond process for e-textiles; a) The modules are positioned with an NCA film between them and the textile substrate; b) The adhesive softens and the contact partners come into contact due to the pressure and heat applied. During subsequent cooling, the NCA solidifies again; c) Finally realized, mechanically and electrically contacted module

Fig. 2: CT image of a bond contact - interposer on textile conductorThebonding technology developed at the TU Berlin (at the Research Center for Microperipheric Technologies) and the Fraunhofer Institute for Reliability and Microintegration IZM offers great advantages for the special requirements of textile-integrated electronic systems. During the NCA bonding process, the non-conductive adhesive and the optional thermoplastic conductor insulation soften and are displaced in the area of the contact points. After cooling, the adhesive hardens and the modules are mechanically and electrically connected in a single process step(Fig. 1). The highly temperature-sensitive textiles are only subjected to localized thermal stress. As the contact pads are located on the underside of the modules, the contact points are better protected from external influences and the mechanical stress at the connection point between the soft textile and rigid electronics is reduced.

Fig. 2: CT image of a bond contact - interposer on textile conductorThebonding technology developed at the TU Berlin (at the Research Center for Microperipheric Technologies) and the Fraunhofer Institute for Reliability and Microintegration IZM offers great advantages for the special requirements of textile-integrated electronic systems. During the NCA bonding process, the non-conductive adhesive and the optional thermoplastic conductor insulation soften and are displaced in the area of the contact points. After cooling, the adhesive hardens and the modules are mechanically and electrically connected in a single process step(Fig. 1). The highly temperature-sensitive textiles are only subjected to localized thermal stress. As the contact pads are located on the underside of the modules, the contact points are better protected from external influences and the mechanical stress at the connection point between the soft textile and rigid electronics is reduced.

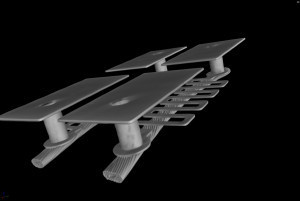

Figure 2 shows a computed tomography (CT) image of such a bond connection: an FR4 interposer with contact pads facing downwards was bonded to a textile-integrated conductor.

The bonded contacts show very good reliability under cyclic temperature and humidity loads as well as good washability [2].

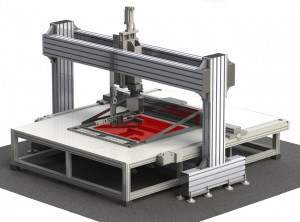

Further advantages of the contact process are the absence of additional additives, such as flux or conductive particles, and the fact that the adhesive can be repaired and recycled by re-melting. The NCA bonding technology is suitable for metallized yarns and flat goods as well as for strands that can be embroidered, knitted or woven into the textile substrate. In addition, it has been validated that the bonding technology also works with thermoplastic insulated conductors. In contrast to the flip-chip soldering process, it is not necessary to add an underfiller, as the adhesives already involved in the process also take on this stabilizing function. To date, there are no machines for producing e-textiles on a large scale. In the course of process development, the e-textile bonder was designed and constructed(Fig. 3) [3]. This was developed to bring the bonding technology up to industry standard and to typical textile sizes.

Fig. 4: TheraTex modular e-textile for hemiparesis therapy; ZiM project with futureTEX

Fig. 4: TheraTex modular e-textile for hemiparesis therapy; ZiM project with futureTEX

Fig. 3: Overview of the relevant parts of the E-Textile BonderIn addition,it is adapted for a wider range of applications and enables alternative process parameters, new materials and other contacting technologies such as sintering to be investigated on a large-scale system. The E-Textile Bonder enables the bonding of multi I/O modules of up to 50 mm x 50 mm edge length on textile carrier substrates of up to 1 m x 1 m.

Fig. 3: Overview of the relevant parts of the E-Textile BonderIn addition,it is adapted for a wider range of applications and enables alternative process parameters, new materials and other contacting technologies such as sintering to be investigated on a large-scale system. The E-Textile Bonder enables the bonding of multi I/O modules of up to 50 mm x 50 mm edge length on textile carrier substrates of up to 1 m x 1 m.

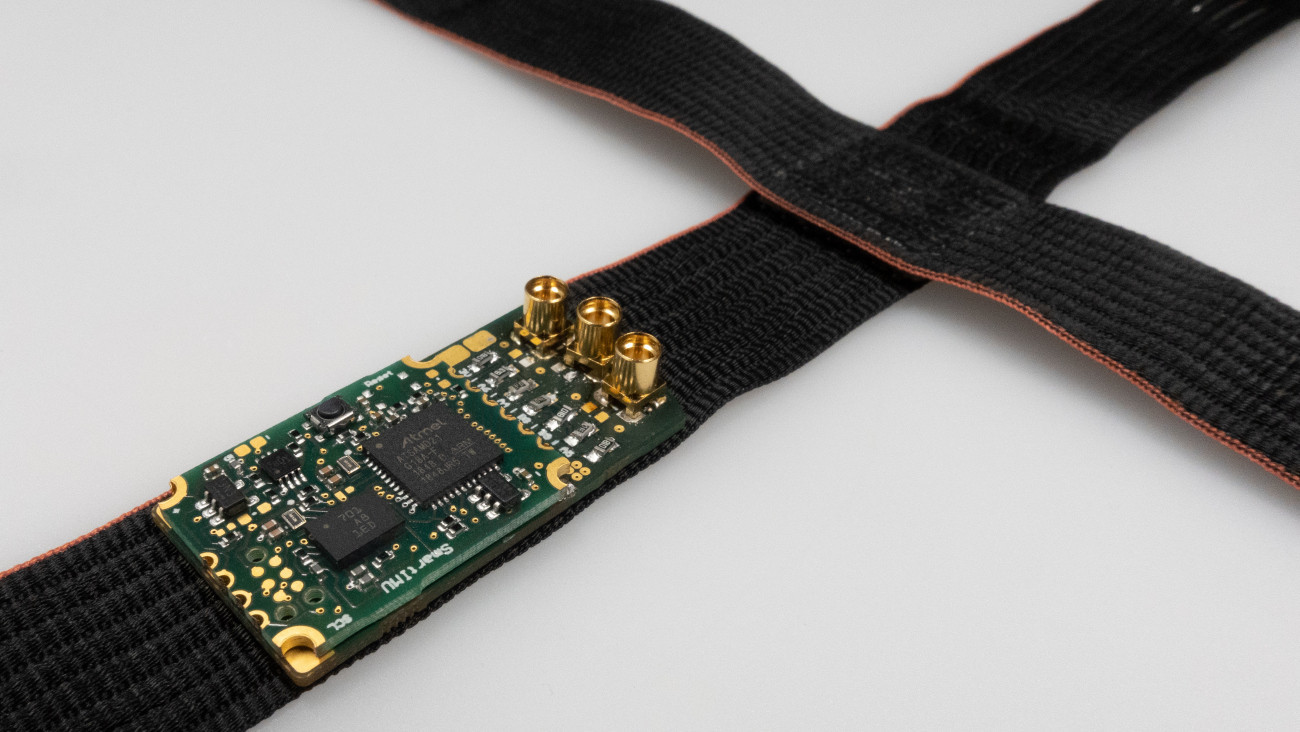

Textile bonding has already been used successfully in various projects. With bonding as a reliable contacting technology for highly conductive strands in textile tapes together with actuators and sensors, various sensor applications close to the body with feedback function can be realized. For example, the tracking of movements over the entire body using inertial sensor technology for the evaluation of therapeutic movement therapies for hemiparesis patients [4, 5].

The Ghost-Feel-it project pursues a different therapeutic approach [6]. Here, direct haptic feedback is given back to the person wearing the e-textile. By integrating modules with vibration motors, irreparable nerve damage and the associated loss of sensation, e.g. in the hands, can be transferred to other parts of the body. Using a special glove, the gripping movement and the force profile of the closing hands are transmitted to the back by means of a special vibration pattern, thus providing the user with newly learned feedback on movements. Bonding technology can also be used successfully in other areas such as sports and protective clothing, fashion(Fig. 5), textile interiors, vehicle interiors, lighting, textile facades and high-performance sails.

Fig. 5: EU project: Re-Fream 'Second Skin' Malou Beemer; www.maloubeemer.com/project/second-skins-re-fream/

Fig. 5: EU project: Re-Fream 'Second Skin' Malou Beemer; www.maloubeemer.com/project/second-skins-re-fream/

References

[1] Linz, T.; von Krshiwoblozki, M.; Walter, H.; Foerster, P.: Contacting electronics to fabric circuits with nonconductive adhesive bonding, J. Text. Inst. 2012, 103:10, 1139-1150, DOI: 10.1080/00405000.2012.664867

[2] Von Krshiwoblozki, M.; Linz, T.; Neudeck, A.; Kallmayer, C.: Electronics in Textiles - Adhesive Bonding Technology for Reliably Embedding Electronic Modules into Textile Circuits. Adv. Sci. Technol. 2013, 85, 1-10, DOI:10.4028/www.scientific.net/AST.85

[3] Garbacz, K.; Stagun, L.; Rotzler, S.; Semenec, M.; von Krshiwoblozki, M.: Modular E-Textile Toolkit for Prototyping and Manufacturing, Proceedings 2021, 68, 5, https://doi.org/10.3390/proceedings2021068005

[4] Brunner, B.; Dils, C.; Garbacz, K.; Stagun, L.: Electronics in e-textiles: how to combine electronics and textiles, In Proceedings 3rd Symposium Electronics and System Integration (ESI), Landshut, Germany, April 06, 2022, pp. 10-21

[5] Betz, G.; Danckwerth, J.; Brunner, B.; Dils, C.; Garbacz, K.; Leher, I.; Sesselmann, S.: Knitted e-textiles for Innovative Prevention and Therapy Systems, In the proceedings of the Aachen Dresden Denkendorf International Textile Conference (ADDITC), Aachen, Germany, December 2, 2022

[6] Buecheler, L.; Hillmer, I.; Reimer, V.; Jiang, Y.; Angelmahr, M.; Schade, W.; von Krshiwoblozki, M.; Pawlikowski, J.; Garbacz, K.; Stagun, L.; Fischer, M.; Guttowski, S.: Non-invasive rehabilitation system for irreparable nerve damage in the wrist area, In Proceedings MikroSystemTechnik Kongress (MST), Berlin, Germany, October 28-30, 2019

Calendar of events

|

Venue |

Period |

Name |

Organizer |

|

Ilmenau |

23 Mar 2023 |

IMAPS Germany Spring Seminar |

IMAPS DE |

|

Albuquerque |

18 - 20 Apr 2023 |

CICMT 2023 |

IMAPS/ACerS |

|

Oslo |

12 - 14 Jun 2023 |

NordPac 2023 |

IMAPS Nordic |

|

Cambridge |

11 - 14 Sep 2023 |

EMPC 2023 |

IMAPS UK |

|

San Diego |

Oct 02 - 05, 2023 |

56th International Symposium on Microelectronics |

IMAPS US |

|

Munich, Germany |

Oct 19 - 20, 2023 |

IMAPS Germany - Fall Conference |

IMAPS DE |

|

Munich, Germany |

Nov 14 - 17, 2023 |

SEMICON EUROPE |

SEMI Europe |

This calendar is subject to change. Please refer to the information and notes of the organizers on the respective websites!

IMAPS Germany - Your association for packaging and interconnection technology

IMAPS Germany, part of the 'International Microelectronics and Packaging Society' (IMAPS), has been the forum in Germany for all those involved in microelectronics and packaging technology since 1973. With almost 300 members, we essentially pursue three important goals:

- we connect science and practice

- we ensure the exchange of information among our members and

- we represent the position of our members in international committees.

Imprint

IMAPS Germany e. V.

Kleingrötzing 1, D-84494 Neumarkt-St. Veit

1st Chairman: Prof. Dr.-Ing. Martin Schneider-Ramelow, Director of the Fraunhofer Institute for Reliability and Microintegration (IZM),

Treasurer

(for questions about membership and contributions):

Ernst G. M. Eggelaar,

You can find detailed contact information for the board members at www.imaps.de

(Board of Directors)