Minimization and robustness are a challenge not only, but above all, in the development of printed circuit boards in the automotive sector. Electronic components in this area have to fulfill a whole range of special criteria. Surface mount technology (SMT) has largely established itself here - 'floating' elements are now providing new impetus.

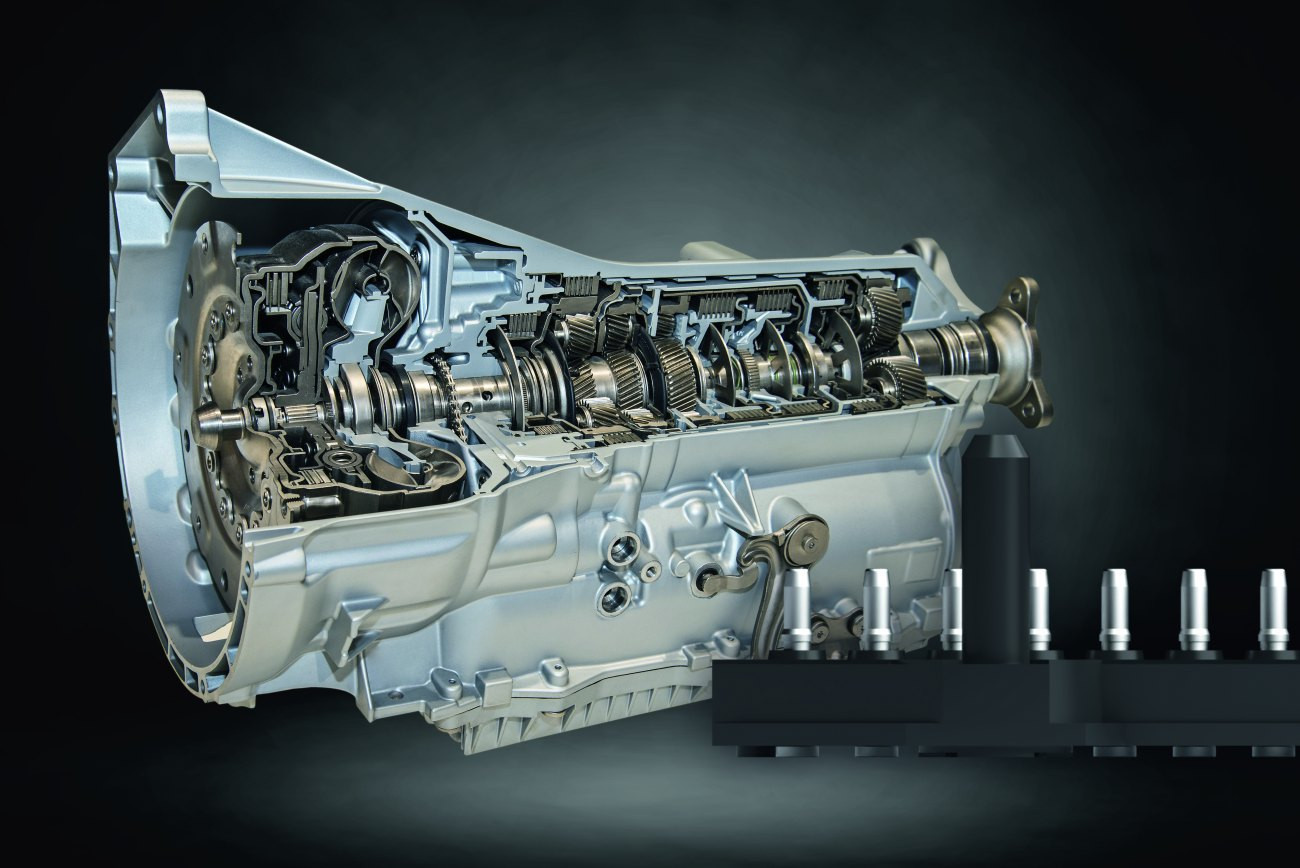

Petra Adamik, freelance IT author from MunichTheautomotive industry is undergoing dynamic change. New generations of vehicles are leaving the production halls with alternative drive systems and offer highly automated driving. Added to this is the user's desire for even more gadgets, even more comfort, even more intelligence, connectivity and services. The electronic components installed in the transmissions are expected to deliver more and more power in ever smaller spaces. This is one reason why surface mount technology (SMT) has become a permanent fixture in automotive electronics. In addition to its technical advantages, SMT can also score with its cost-effectiveness.

Petra Adamik, freelance IT author from MunichTheautomotive industry is undergoing dynamic change. New generations of vehicles are leaving the production halls with alternative drive systems and offer highly automated driving. Added to this is the user's desire for even more gadgets, even more comfort, even more intelligence, connectivity and services. The electronic components installed in the transmissions are expected to deliver more and more power in ever smaller spaces. This is one reason why surface mount technology (SMT) has become a permanent fixture in automotive electronics. In addition to its technical advantages, SMT can also score with its cost-effectiveness.

However, classic SMT components are also reaching their limits, particularly in the automotive industry. Up to now, this has affected connectors above a certain size and with a pitch of more than 2.54 mm. Through-hole mounting was necessary in order to attach components to the PCB. This is because the conductor connection and power supply need sufficient dimensions to meet the physical requirements for higher currents and voltages. PCB terminals are also exposed to greater mechanical loads than other passive or active electronic components. Enormous forces are generated during the assembly process, whether by connecting electrical conductors or attaching a corresponding connector strip. In some cases, this leads to the adhesive forces of the terminal not always being able to withstand the installation requirements and the terminal becoming detached from the PCB.

Ways out of the assembly dilemma

WECO's "floating pin" technology aims to solve this dilemma. "Floating pins compensate for the different expansion coefficients of components, absorb PCB unevenness and compensate for solder joint tolerances. The so-called floating contact elements offer a wide range of applications: they are freely movable in all directions and sit reliably on the PCB surface. According to Detlef Fritsch, Managing Director of WECO Contact, one hundred percent coplanarity is achieved with SMD components. The size of the components or the number of poles have no influence on the final result.

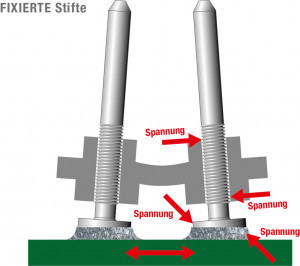

Permanently installed contact elements lead to stresses at the solder joints and to changes in the pitch in the event of temperature fluctuations and different expansion coefficients of the materials. Counterparts can then either not be plugged in at all or only with difficulty and in turn generate further stresses at the solder joints and housingFloating meansthat components are not firmly connected to the PCB as a completely rigid product. They can move flexibly up and down as well as sideways. In order to increase the compressive and tensile strength, the company has developed movable, floating solder anchors for some of its pin headers and connection terminals. These solder anchors are able to absorb the compressive and tensile forces that occur before deformation occurs at the solder joints. In automotive engineering, this has the advantage that components can absorb strong temperature fluctuations, for example. Each component has its own coefficient of expansion, which is why the circuit board and plastic part can expand separately. The expansion coefficients do not coincide, which significantly increases the flexibility of the components in the environment in which they are used. The air between the components in the part provides sufficient room for expansion. Due to cohesion, the metal part to be applied moves exactly into the center of the solder and thus lies perfectly on the surface. In this way, high strength can be achieved because the component is automatically always in the center of the soldering point. This reduces the supposed disadvantage of SMT to absurdity, because in this case the component is always perfectly centered and strength is achieved.

Permanently installed contact elements lead to stresses at the solder joints and to changes in the pitch in the event of temperature fluctuations and different expansion coefficients of the materials. Counterparts can then either not be plugged in at all or only with difficulty and in turn generate further stresses at the solder joints and housingFloating meansthat components are not firmly connected to the PCB as a completely rigid product. They can move flexibly up and down as well as sideways. In order to increase the compressive and tensile strength, the company has developed movable, floating solder anchors for some of its pin headers and connection terminals. These solder anchors are able to absorb the compressive and tensile forces that occur before deformation occurs at the solder joints. In automotive engineering, this has the advantage that components can absorb strong temperature fluctuations, for example. Each component has its own coefficient of expansion, which is why the circuit board and plastic part can expand separately. The expansion coefficients do not coincide, which significantly increases the flexibility of the components in the environment in which they are used. The air between the components in the part provides sufficient room for expansion. Due to cohesion, the metal part to be applied moves exactly into the center of the solder and thus lies perfectly on the surface. In this way, high strength can be achieved because the component is automatically always in the center of the soldering point. This reduces the supposed disadvantage of SMT to absurdity, because in this case the component is always perfectly centered and strength is achieved.

With permanently installed parts, on the other hand, both the circuit board and the components expand, resulting in extreme stress on the soldering point. In extreme cases, the soldering as well as the circuit board and the component can crack. Press-fit technology, a solderless connection technique for printed circuit boards, requires significantly more complex and precise processing of the components, as the tolerances have to be matched extremely precisely. This leads to higher costs for the components. And even minor deviations increase the number of rejected products. In addition, the major advantage over SMT technology is lost, namely the production of PCBs without solder holes and double-sided assembly.

Independent tests and certificates as proof of quality

In vehicles that are used in extreme temperatures, it is essential that a transmission unit functions smoothly in a wide range of temperatures. In the Siberian winter, for example, outside temperatures of -40° are reached, while the operating temperature of the transmission oil can rise to 90-100°. The integrated system must be able to withstand these fluctuations without any problems. The electrical connector solutions are explicitly designed for use in unforgiving outdoor environments. The robust technology works in heat, rain, sleet and snow. It is also insensitive to gear oil, gases and other chemical influences. High strength and coplanarity ensure durability, which is a basic requirement for use in vehicles.

For the "floating pin" process, the components are no longer soldered, but pass through a soldering oven. A special foil is applied to the base board in advance, which shows a negative image of the components. The solder paste is applied to predetermined points. The components are assembled using a robot arm. The whole thing then travels through the soldering oven, where the solder paste melts at 260°. During this process, the metal components of the connector bond with the circuit board. After cooling, all components are firmly connected. Robustness is ensured by heat testing with the plastic.

Vibration tests, tests on temperature ranges and resistance to solvents, oils or gases are carried out by an independent, external laboratory. The customer receives a neutral test report. Cleanliness is another important issue in the automotive environment. An independent laboratory also tests the products in this area. Cleanliness is of particular importance in vehicle technology, as contamination poses a risk to the transmission. This can cause the transmission oil to clump together, which accelerates wear. The IATF certification also certifies that the manufacturer complies with all quality standards, which are a must for suppliers to the automotive industry.

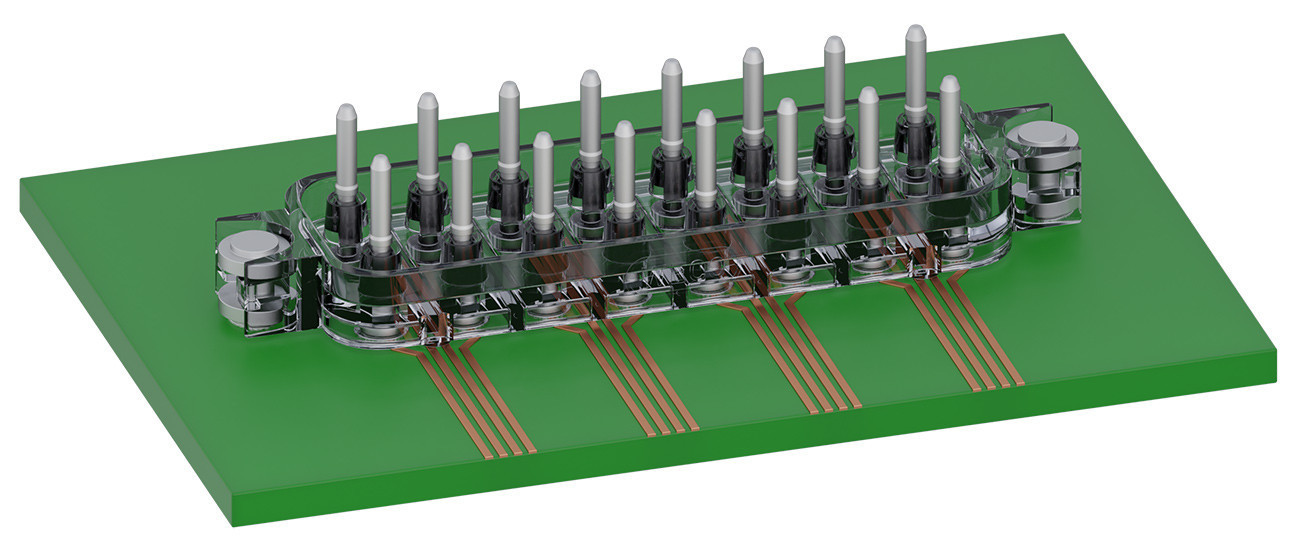

Male connector for transmission control units

Male connector for transmission control units

Robust technology in many sizes

A solder anchor also helps to absorb any pushing and pulling forces that occur, thus reducing the load on the important release pointsTheproduct range now includes a number of solutions in different sizes. The 930-D-SMD-DS connection terminal with a 3.5 mm pitch, for example, is suitable for a conductor cross-section of up to 1 mm². The terminal body is movable in the housing. A special feature of this variant is that no lateral soldering flange is required to enlarge the soldering surface. Thanks to this technology, the two-pole version already has a PCB breakaway force of over 100 N.

A solder anchor also helps to absorb any pushing and pulling forces that occur, thus reducing the load on the important release pointsTheproduct range now includes a number of solutions in different sizes. The 930-D-SMD-DS connection terminal with a 3.5 mm pitch, for example, is suitable for a conductor cross-section of up to 1 mm². The terminal body is movable in the housing. A special feature of this variant is that no lateral soldering flange is required to enlarge the soldering surface. Thanks to this technology, the two-pole version already has a PCB breakaway force of over 100 N.

WECO's 140-A-126-SMD PCB terminal block is one of the components on offer with a 5.0 mm pitch. In this model, the clamping bracket with the solder lug is made from a single piece and firmly integrated into the housing. The solder tags, which create a coplanar connection after reflow soldering, are aligned parallel to the PCB. The housings have two lateral mounting flanges, in which soldering elements are located that can be moved slightly in a vertical direction. This makes it possible to compensate for height differences that can occur if the solder paste is applied unevenly to the PCB. According to the manufacturer, the optimum adjustment to the solder paste thickness ensures that this version is securely mechanically fixed to the PCB, which has been tested using the standard number of six poles. Accordingly, the PCB terminal can withstand tear-off forces of up to 320 N. Additional drill holes, plated-through solder connections or screw connections are not necessary.

The circuit board developed for the automotive sector has a size of around 6 cm and has 19 plus three or 24 plus three pins, which are required for the supply or removal of the control signals in the gearbox. If all the necessary pins were rigidly integrated into the plastic carrier, the component would not be able to adequately absorb the mechanical pressure when expanding or contracting due to the temperature range. The result would be a high mechanical force acting on the individual solder points of the circuit board. Errors could therefore not be ruled out.

As the pins are not rigidly fixed in the plastic of the housing that encloses the PCB, they can move up and down or sideways to a sufficient extent. By installing this solution, users can be sure that the electronics will function smoothly and maintenance-free over the entire service life of the gearbox. There is no need for time-consuming and expensive maintenance work. The circuit board can be controlled externally and does not need to be removed. The "floating pin" technology also has the advantage that the required components can be mounted on smaller circuit boards. Previously, larger PCBs were used with THR technology, which had to be drilled through in order to fit the necessary components. This was cumbersome and time-consuming. Assembly using the "floating process" is less time-consuming. Automotive suppliers thus achieve greater flexibility and faster production of the circuit boards.

As the pins are not rigidly fixed in the plastic of the housing that encloses the PCB, they can move up and down and sideways to a sufficient extent

As the pins are not rigidly fixed in the plastic of the housing that encloses the PCB, they can move up and down and sideways to a sufficient extent