The Airbus subsidiary Tesat-Spacecom relies on collaboration tools from Siemens to speed up the development of devices for communication satellites: Xpedition-Flow reduces design time and ensures the quality of the design.

Like so many other sectors, space communications is undergoing rapid change. The telecommunications satellite sector demands products with higher functionality and integration density at lower cost and faster time to market. These required shorter development cycles and the introduction of commercially available parts in space.

Therefore, a constant challenge for the electrical engineering team at the company's headquarters in Backnang is to bring their designs to market with a minimum number of iterations while ensuring design quality. To achieve these goals while designing more complex products, Bastian Diehm (Methods and Processes - Development and Design), Dominik Vogel (PCB Design Engineer) and their team have adopted the Xpedition software flow from Siemens EDA.

Key user team for development and design: As the majority of products contain one or more PCBs manufactured by Tesat, the work of the 200-strong development and design department is crucial to success

Key user team for development and design: As the majority of products contain one or more PCBs manufactured by Tesat, the work of the 200-strong development and design department is crucial to success

Concurrent engineering support from the Xpedition family and the integrated development database enable faster design iterations, while integrated constraint management together with HyperLynx verification ensures design correctness. The resulting solution significantly reduces design time for the user's high-density space designs.

The electronic systems focus on HDI (High Density Interconnect) PCBs with high layer counts for data communication products. These are usually impedance-controlled high-speed PCBs with LVDS (Low Voltage Differential Signaling) and layouts with serializers/deserializers (SERDES) using ball grid array (BGA) and ceramic column grid array (CCGA) packages.

"We were able to achieve our design time targets because we were able to make extensive use of concurrent engineering through the schematic, constraint and layout functions in Xpedition," says Dominik Vogel.

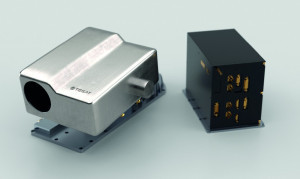

Tesat's laser communication terminal for constellations (ConLCT): Due to the development with step-by-step simulations - electrical and thermal - the development time could be accelerated and the development cycles shortenedConventionaldesigns include PCBs for high-power amplifier applications and ion drives, with a focus on high-voltage PCBs. Their RF substrates are based on low temperature ceramic (LTCC) and PCB technologies (e.g. MEGTRON7N) for high frequency applications. The designs include both rigid-flex PCBs (with up to 10 rigid layers and three flexible layers) and thermomechanically stress-compensated PCBs (with ceramic and molybdenum inserts). These boards have a size of up to 450 x 280 mm, with up to 24 layers and 4000 parts per board, AC/DC voltage up to 20 kV, RF up to 40 GHz and data rates up to 10 Gbit/s.

Tesat's laser communication terminal for constellations (ConLCT): Due to the development with step-by-step simulations - electrical and thermal - the development time could be accelerated and the development cycles shortenedConventionaldesigns include PCBs for high-power amplifier applications and ion drives, with a focus on high-voltage PCBs. Their RF substrates are based on low temperature ceramic (LTCC) and PCB technologies (e.g. MEGTRON7N) for high frequency applications. The designs include both rigid-flex PCBs (with up to 10 rigid layers and three flexible layers) and thermomechanically stress-compensated PCBs (with ceramic and molybdenum inserts). These boards have a size of up to 450 x 280 mm, with up to 24 layers and 4000 parts per board, AC/DC voltage up to 20 kV, RF up to 40 GHz and data rates up to 10 Gbit/s.

Tesat has a huge product range with many variants. To manage these variants, it is even more important to reduce the number of rework that occurs on repurposed IP for many reasons, mainly electrical design changes, component replacement and extensive testing. This broad product portfolio also leads to a variety of design areas, which requires collaboration in an interdisciplinary team. Depending on the product, this mix of heterogeneous areas includes PCB (schematic and layout), mechanical, RF, manufacturing and software teams. In addition, system integration or system-of-systems teams may be involved, as Tesat also supplies its customers with subsystems.

"We tell others who are interested in this process that Xpedition EDM is very valuable for its traceability and collaboration features alone, and that the integrated design database is a huge improvement for concurrent engineering." Dominik Vogel, Tesat-PCB-Design.

Interdisciplinary design teams with a laser focus

A recent project, the new laser communication terminal for constellations, was the first complete system developed with Xpedition. The highly integrated and very complex product required a high level of integration expertise and had to be brought to market quickly to gain a competitive advantage. In this respect, it was a good testing ground for the optimal use of the new functions of the Siemens software suite.

"The high-intensity integration aspect of the design was particularly exciting," Diehm recalls. For Tesat, but also for the space community in general, this terminal has a very high integration density and is very complex - up to 20 layers and 3500 digital components. "I think this level of integration and complexity in the context of the space business is remarkable."

In the first iteration, the team used the verification functions in Xpedition EDM. For the schematic review, the designers could make notes directly in the web browser, and the developer could make his reviews and annotations directly from the browser and then mark them as done.

Diehm: "The Xpedition tools helped us to achieve an unprecedented level of interdisciplinary collaboration. Everything is integrated into the Xpedition EDM system, everything happens in the same web browser. They can access it from anywhere and don't have to send emails or files."

The hybrid production line from Tesat

The hybrid production line from Tesat

For the design and production team, this type of continuous management of electronic devices and systems was increasingly necessary in customer projects. A digital transformation of the entire design and manufacturing flow requires continuous and centralized data management that results in a single, living and shareable source of design and library data: a unified data source - which Diehm and Vogel refer to as a single source of truth. Among other things, this single source of truth protects data integrity and accelerates iterations.

In addition, Xpedition also supports collaboration between the PCB and mechanical sides so that they can move forward together and speed up iterations. "Repeated design checks in the Siemens NX mechanical tool also helped to minimize the number of design iterations," notes Vogel.

Concurrent engineering

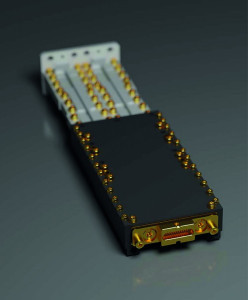

HDI TR module from TesatWhileprevious tools forced them to design sequentially - from schematic to layout to design - Xpedition enabled concurrent engineering by supporting parallel schematic and layout development. This shortened the development time from schematic input to production data release.

HDI TR module from TesatWhileprevious tools forced them to design sequentially - from schematic to layout to design - Xpedition enabled concurrent engineering by supporting parallel schematic and layout development. This shortened the development time from schematic input to production data release.

All layouts on the PCBs for this project were done with Xpedition. Supporting collaboration and data exchange between schematic and layout was important because although Tesat normally uses one designer for the layout and one for the schematic, there are also designs with multiple schematic designers and one layout designer, and in both cases they need to work simultaneously.

"We were able to achieve our design time targets through the extensive use of concurrent engineering enabled by the schematic, constraints and layout features in Xpedition," says Vogel. "The automated routing functionalities in Xpedition have saved a lot of time in the layout phase. Now we are trying to make more use of the new functions and possibilities that Xpedition offers." The traceability and collaboration functions alone make the system very valuable. "The integrated design database is also a huge improvement for concurrent engineering."

Manage circuit components and constraints

Tesat can have up to 50 variants for a design. Designs are reused in many products - even from one generation to the next. This is why variant management is particularly important. "Especially if you use a circuit often in the same PCB, it's a pretty cool Xpedition feature to copy a part and instantiate it correctly maybe five, six or seven times," says Diehm.

The Xpedition Constraint Manager also helped to reduce iteration cycles between the development and design teams and shorten development time. "Previously, we could only include a few constraints in our tool," Diehm recalls. "Now we can include all our constraints in the Constraint Manager. "Since everything is digital and in a single tool cockpit, the schematic designer can view the design at any time as it progresses and change things as needed, so we don't have as many iterations."

In addition, the management features of the EDM library not only made it easier to assign elements of a component library, but also helped to improve design quality.

"The library manager performed more checks and was more intuitive to use than our old tool. They were carried out graphically with the Library Manager," continues Vogel. In addition, the checks in Xpedition's EDM library manager are more complex, so they find more errors before the PCB is finalized and sent to production. So we have correctness by library or correctness by design."

Verification during design

Laser products from TesatOneof the most difficult challenges in the development of the new laser communication terminal was the use of a PCB with second-generation DDR4 memory. Signal integrity, electrical, thermal and radiation analysis, supported by Xpedition, helped the company to quickly solve this challenge while avoiding rework and improving design quality.

Laser products from TesatOneof the most difficult challenges in the development of the new laser communication terminal was the use of a PCB with second-generation DDR4 memory. Signal integrity, electrical, thermal and radiation analysis, supported by Xpedition, helped the company to quickly solve this challenge while avoiding rework and improving design quality.

"It was a challenge to meet the requirements of PCB DDR4," Vogel recalls. "For the simulation, we used Hyper-Lynx signal integrity analysis and checked it during the design phase. This would not have been possible with our old tool. This allowed us to meet all the requirements in the first design iteration."

Diehm adds: "As part of our project process, we also carried out radiation analysis, which ensured that the schematic was also checked by an appropriate specialist - another good example of concurrent engineering, as the analyst is usually involved not only at the end when a radiation document has to be produced for the customer, but also during the development of the schematic to find the circuit options that are intolerant to radiation."

The electrical and thermal simulations have also helped to minimize the number of reworks. Diehm: "Through the development accompanied by step-by-step simulations - electrical and thermal - we were able to further accelerate the development time and at the same time shorten the development cycles."

To summarize, the Xpedition flow enabled faster design iterations through its concurrent design capabilities and integrated database, while its constraint management features ensured the correctness of the design.

"In the development of our new laser telecom terminal, we saw improved quality, fewer design changes between the plug-in board and the flight model, and higher design quality by eliminating design errors," Vogel reports. The developers were also able to meet stringent differential mode delay requirements and meet a tight project schedule. The more efficient design activities increased engineering throughput, meaning more designs could be created in the same amount of time.

Tesat has an internal production defect tracking system that is also used to track defects related to engineering and design. It was found that the new solution obviously improved the quality of the PCB design as the defect tracking system showed fewer errors.

www.tesat.de, www.eda.sw.siemens.com

Business benefits of Xpedition

- 20% increase in development and design productivity

- 35% reduction in the cost of quality defects due to incorrect schematic and layout data

- Reduce the cost of quality defects due to incorrect data processing and better version management by 25% (expected)

- Increase in productivity due to more efficient communication by 30% (expected)

- 25% reduction in costs for quality defects due to inconsistent library information (expected)

Space time in total: > 650 million h

Tesat-Spacecom GmbH & Co KG, a subsidiary of the Airbus Group, has developed extensive expertise in the manufacture of payload equipment for communication satellites over six decades and has established itself as the market leader. The approximately 1000 employees at the headquarters in Backnang, Baden-Württemberg, have developed, assembled, integrated and tested systems and devices for more than 700 space projects. The following figures illustrate the company's experience and importance: Over 30,000 units in orbit, over 650 million operating hours of space use. Tesat maintains close business relationships with almost all satellite manufacturers worldwide.