In the field of autonomous driving, design and testing are increasingly taking place in an integrated process. The Darmstadt-based Fraunhofer Institute LBF Autonomous Driving presented an example of this a fortnight ago at the Hannover Messe. So-called XiL tests make it possible to test real components - such as cameras - in virtual vehicle designs and deployment scenarios.

With simulation-based testing, the behavior of automated driving functions can be tested in many traffic situations at low cost and riskIn orderfor future autonomous driving to actually arrive in everyday life, it must be ensured that all relevant components of a vehicle function reliably. This is a challenge for system developers for a number of reasons, which is once again driving integrated design trends: To ensure this safety, the individual components are tested comprehensively and realistically as early as the vehicle design phase.

With simulation-based testing, the behavior of automated driving functions can be tested in many traffic situations at low cost and riskIn orderfor future autonomous driving to actually arrive in everyday life, it must be ensured that all relevant components of a vehicle function reliably. This is a challenge for system developers for a number of reasons, which is once again driving integrated design trends: To ensure this safety, the individual components are tested comprehensively and realistically as early as the vehicle design phase.

X-in-the-loop tests (XiL) of the sensors make it possible to realistically simulate vehicles and scenarios and test the real components in their operating environment. This makes influences on road safety visible that cannot be detected with other test methods or can only be detected when the entire vehicle is released. At the Hannover Messe, researchers from the Fraunhofer Institute for Structural Durability and System Reliability LBF presented pioneering results.

For example, a camera-in-the-loop test environment makes it possible to investigate the influence of vehicle vibrations on the classification of objects in different virtual traffic situations. This makes it possible to ensure the safety and functionality of camera-based sensor systems. This validation and verification of camera-based sensor systems represents a decisive development step in the development of highly autonomous driving functions.

Autonomous driving functions validated and verified

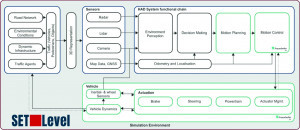

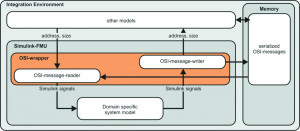

In a virtual test environment for automated vehicles, different environmental and vehicle components are represented by networked simulation models. Interfaces for the exchange of standardized data messages enable the flexible use of different models and simulation environments in standardized, digital verification processesAutomatedvehicles are probably the biggest change in the field of individual transport since the invention of the internal combustion engine. In the foreseeable future, vehicles will participate in road traffic fully autonomously (level 4 and 5 of the SAE scale). As a research partner, the Darmstadt-based Fraunhofer Institute supports manufacturers and suppliers in the development of these vehicles with analyses of system reliability (e.g. FMEA) and methods for validating virtual prototypes in multi-scale simulations. The decisive factor here is that this approach not only integrates the design phase and validation/verification, but also means that the boundary between real and only virtually existing, but largely or fully functionally modeled components no longer plays a role in development.

In a virtual test environment for automated vehicles, different environmental and vehicle components are represented by networked simulation models. Interfaces for the exchange of standardized data messages enable the flexible use of different models and simulation environments in standardized, digital verification processesAutomatedvehicles are probably the biggest change in the field of individual transport since the invention of the internal combustion engine. In the foreseeable future, vehicles will participate in road traffic fully autonomously (level 4 and 5 of the SAE scale). As a research partner, the Darmstadt-based Fraunhofer Institute supports manufacturers and suppliers in the development of these vehicles with analyses of system reliability (e.g. FMEA) and methods for validating virtual prototypes in multi-scale simulations. The decisive factor here is that this approach not only integrates the design phase and validation/verification, but also means that the boundary between real and only virtually existing, but largely or fully functionally modeled components no longer plays a role in development.

The advantages of increased individual comfort for passengers, who can use their travel time for other things than before, are just one aspect. It is also important that automated vehicles enable more efficient and smoother road traffic. Up to now, ensuring active and passive vehicle safety has played a dominant role in vehicle development. This is being replaced by the more far-reaching aspect of safe vehicle behavior. In fully automated road traffic, crashes will no longer be mitigated by crumple zones or airbags, but avoided. This will lead to enormous savings in resources and completely new functional concepts - here too, the new approaches to mobility will have far-reaching effects on vehicle development and design.

However, in order to achieve this goal, not only the safe function, but also the safe behavior of the vehicle within every conceivable driving situation must be proven. This includes the correct perception and interpretation of the traffic situation, the correct decision on vehicle behavior and the implementation of this decision by the vehicle as an overall mechatronic system.

The LBF is laying important foundations for the holistic verification and validation required for this, as well as for simulation-based development. The researchers in Darmstadt have developed key innovations in the interaction of virtual and real tests, which are based on a scenario-based and data-driven approach. The results are already being applied to highway traffic and urban traffic situations.

The SET Level project (simulation-based development and testing of automated driving) is creating the basis for efficient, development-accompanying testing and comprehensive, reliable testing of automated vehicles in complex traffic situations. The main result of the SET Level project is an open, flexible and easily expandable platform for simulation-based investigations and tests of SAE Level 4 and 5 vehicles in urban traffic situations.

The Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt has stood for the safety and reliability of lightweight structures since 1938. With its expertise in the fields of structural durability, system reliability, vibration technology and polymer technology, the institute today offers solutions for three important cross-cutting topics of the future: lightweight system design, functional integration and cyber-physical, mechanical engineering systems. The focus is on solutions for social challenges such as resource efficiency and emission reduction as well as future mobility, such as electromobility and autonomous, networked driving. Clients come from sectors such as vehicle construction, aviation, mechanical and plant engineering, energy technology, electrical engineering, medical technology and the chemical industry. They benefit from the proven expertise of around 390 employees and state-of-the-art technology in more than 17,900m2 of laboratory and testing space.