In a pilot project with Eplan and Cideon, esmo AG has merged data from mechanical and electrical design. This mechatronic parts list brings considerable advantages not only in the design of complex systems. In the semiconductor industry, esmo is known for its testing and handling systems and other equipment. As a highly specialized manufacturer of special machines and systems, the company is known internationally in many other industries.

Anyone watching a testing system from esmo at work, for example, can hardly comprehend the movement sequences. Depending on the application requirements, the index time can be as short as 0.6 seconds. In this short time, the components to be tested are contacted and tested for their electrical, optical, thermal or other testable properties. The Rosenheim-based company plans both the production of the actual test systems and their integration into existing systems/plants.

Broad range of expertise in automation technology

Fig. 2: The automation technology division designs highly complex systems esmo also has a broad spectrum of expertise, ranging from image processing (for optical 3D inspection) and complete testing and handling to parts feeding and integration into complete production lines.

Fig. 2: The automation technology division designs highly complex systems esmo also has a broad spectrum of expertise, ranging from image processing (for optical 3D inspection) and complete testing and handling to parts feeding and integration into complete production lines.

For the latter tasks, the company founded its own esmo automation division (automation technology) in 2011 - with the clear aim of opening up new areas of application. This goal has been achieved. As a result, esmo is less dependent on the volatile and cyclical business with the semiconductor industry. At the same time, however, the range of automation systems, which are always individually designed and manufactured, has become even broader. Consequently, this means that design, procurement and production in control cabinet construction are becoming more complex.

Goal: Combining mechanical and electrical design

Against this background, the desire arose to simplify the design processes. Florian Peter, administrator in the electrical design department: "We work with functional assemblies - these are sub-assemblies of the entire system. The functional assemblies contain the respective components, such as sensors and electric motors, which are represented in both the mechanical and electrical design." However, the comparison between the two trades or between Solidworks and Eplan was originally only possible manually: "The individual assemblies of our systems can contain up to 500 mechatronic components. The parts list comparison using Excel lists therefore often took several days. If the user requested a 'last-minute change', the lists had to be updated and synchronized manually. Errors can occur and inconsistencies can be overlooked in all of these work steps."

PDM creates the connection

Fig. 3: The mechanical and electrical design are divided into functional assembliesTheobjective was therefore clearly defined: The two trades were to be linked automatically and connected to the ERP system for mapping the commercial functions (purchasing, production planning ...).

Fig. 3: The mechanical and electrical design are divided into functional assembliesTheobjective was therefore clearly defined: The two trades were to be linked automatically and connected to the ERP system for mapping the commercial functions (purchasing, production planning ...).

The prerequisites were already in place with the introduction of the Pro.File PDM system from Procad. Peter Herr: "We now have a platform that brings together the data from both trades." However, the required information from MCAD and ECAD was not yet linked. This link was only established with the introduction of the 'Eplan Pro.File-Connector'.

Result: Consistent data management

This interface supplements the product models in the PDM system with ECAD-specific data such as connection lists, circuit diagrams and parts lists. This actually enables consistent data management and if, for example, a sensor or an electric motor is replaced in the mechanical design, this change is visible in a web report created in Pro.File.

That sounds very simple, and in practice it is, and that was the aim. However, implementation is not always easy in practice, as this is a very comprehensive interface. At esmo, the conditions were ideal, as a joint workshop with Eplan and Cideon showed: the customer had already created comparable structures in MCAD and ECAD in advance. Peter Herr: "We developed the concept and implementation strategy ourselves. We were able to use the standard version of the Pro.File Connector, whereby the workshops and implementation of the interface were professionally implemented by a team from Cideon, Eplan and Procad."

Inconsistencies are displayed

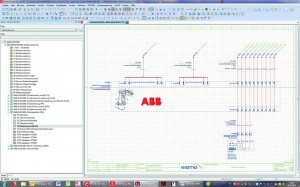

Fig. 4: esmo uses Solidworks for mechanical design - and has created a powerful interface to electrical design with Eplan via the PDM systemWhatdoes the interaction of the trades look like in practice? esmo designs in - quite large - functional assemblies. The electrical parts list for each assembly is transferred from Eplan to Pro.File via the connector. The PDM system performs the automatic comparison with Solidworks and provides a list of the inconsistencies found. Florian Peter: "We check these differences manually and correct the errors. It's a manageable task."

Fig. 4: esmo uses Solidworks for mechanical design - and has created a powerful interface to electrical design with Eplan via the PDM systemWhatdoes the interaction of the trades look like in practice? esmo designs in - quite large - functional assemblies. The electrical parts list for each assembly is transferred from Eplan to Pro.File via the connector. The PDM system performs the automatic comparison with Solidworks and provides a list of the inconsistencies found. Florian Peter: "We check these differences manually and correct the errors. It's a manageable task."

Result: the mechatronic parts list

However, the benefits go beyond the automatic comparison and consistent storage of the design data in a single mechatronic parts list. Peter Herr: "Both the data generated in Eplan and in Solidworks are not only merged in Pro.File. They are also available - via Pro.File - in our ERP system and can be easily accessed there. This function is important for sales, for example."

The esmo designers have thus achieved their goal. Some of the advantages of the mechatronic parts list are only now becoming apparent during operation. For example, assemblies of existing machines that the customer has ordered as a repair part can be rebuilt much more easily because there is only one CAD data set and not two.

Conclusion: It pays to break new ground

Fig. 5: The mechatronic parts list brings together the data from mechanical and electrical design With the mechatronic parts list, esmo has broken new ground: Hardly any other company has such a tool in the CAD landscape. The advantages are - as shown - great, but the effort involved is small. One reason for this is the high degree of maturity of CAx-supported design and the high level of IT expertise. The example presented here should encourage other CAD users to follow the same path and check whether an interface between ECAD and MCAD (via PDM) is feasible. If so, the recommendation to implement a project is the logical consequence: the mechatronic parts list as a central data platform really does advance design. It saves time and increases the quality of the design work performed.

Fig. 5: The mechatronic parts list brings together the data from mechanical and electrical design With the mechatronic parts list, esmo has broken new ground: Hardly any other company has such a tool in the CAD landscape. The advantages are - as shown - great, but the effort involved is small. One reason for this is the high degree of maturity of CAx-supported design and the high level of IT expertise. The example presented here should encourage other CAD users to follow the same path and check whether an interface between ECAD and MCAD (via PDM) is feasible. If so, the recommendation to implement a project is the logical consequence: the mechatronic parts list as a central data platform really does advance design. It saves time and increases the quality of the design work performed.

Fig. 6: The 'architects' of esmo's design platform: Dipl.-Ing. (FH) Peter Herr, Manager Design & Engineering (left), and Florian Peter, Administrator in Electrical Design

Fig. 6: The 'architects' of esmo's design platform: Dipl.-Ing. (FH) Peter Herr, Manager Design & Engineering (left), and Florian Peter, Administrator in Electrical Design