Altium and the Swedish company Hexagon have entered into a strategic partnership with the aim of significantly advancing sustainability in the electronics sector. To this end, suitable design tools and production solutions are to be offered to the industry. By founding the Sustainability Leadership Council at the same time, the IPC has decided to step up its commitment to sustainability in the international electronics industry. Altium will contribute its experience to this new body.

The Australian software company Altium, headquartered in San Diego (USA), has achieved a leading, if not global, position in tools for electronics development in the more than 35 years of its existence. The focus is on software for the automation of electronic design, especially for printed circuit boards and electronic assemblies. In specialist circles, the company is best known for its PCB design tool Altium Designer [1]. This combines circuit diagram, layout and everything else needed to design PCB assemblies in a standardized design environment.

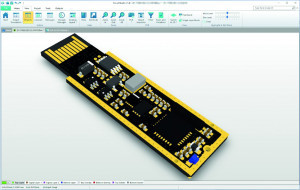

Fig. 1: Zymbit used CircuitStudio to develop a new class of IoT security modulesAnothertwo tools as 'offshoots' or 'economy variants' of the fee-based, rather complex Altium Designer tool have been offered to interested parties for several years as a supplement for electronics development:

Fig. 1: Zymbit used CircuitStudio to develop a new class of IoT security modulesAnothertwo tools as 'offshoots' or 'economy variants' of the fee-based, rather complex Altium Designer tool have been offered to interested parties for several years as a supplement for electronics development:

- CircuitStudio

- CircuitMaker

CircuitStudio is a professional but inexpensive PCB design tool for beginners. It is used by many companies that develop sophisticated electronics. The engineers at Californian company Zymbit, for example, used the DRC and 3D modeling functions in CircuitStudio to create the first prototypes of safety modules, which were then functional and virtually ready for production in less than six weeks(Fig. 1).

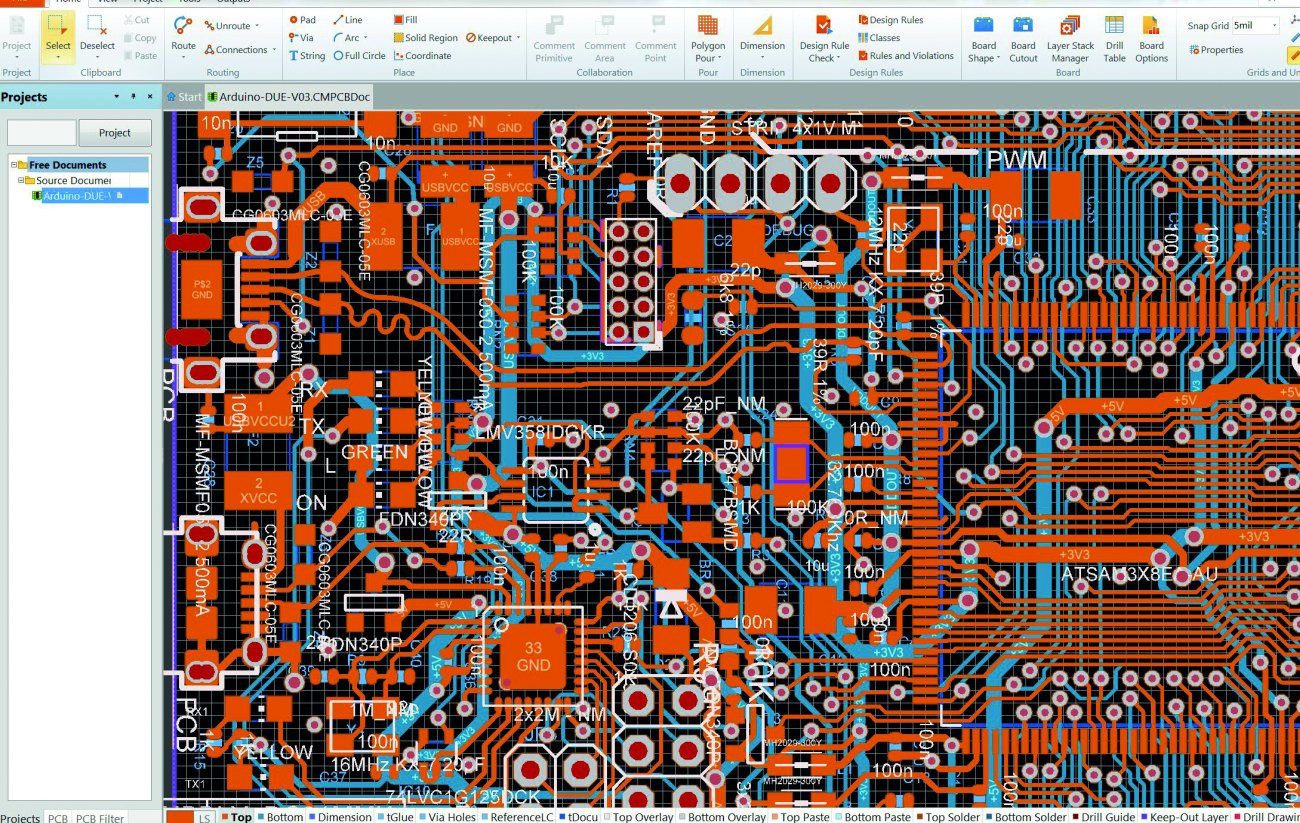

CircuitMaker includes free schematic and PCB design software based on Altium Designer technology. It is primarily provided for manufacturers, open source and non-profit organizations and uses an appropriately optimized user interface and a powerful engine(Fig. 2). This should provide an equivalent for free 'competitor' tools such as Eagle, KiCAD, gEDA and DesignSpark since 2015.

Fig. 2: Screenshot of a design edited with CircuitMaker

Fig. 2: Screenshot of a design edited with CircuitMaker

Steady progress

Anyone who has followed Altium's press releases over the years has witnessed the determined development of the tools, which is reflected in their regular updates. In 2019, for example, Altium launched the Altium Designer 20 release on the market. With this release, the company took a significant step towards even simpler, modern and powerful PCB design software. The new version of Altium Designer incorporated more than two decades of experience. This was reflected, for example, in a faster schematic editor, high-speed design and enhanced interactive router functions. In total, over 200 improvements suggested by users of the tools were integrated into Altium Designer 20.

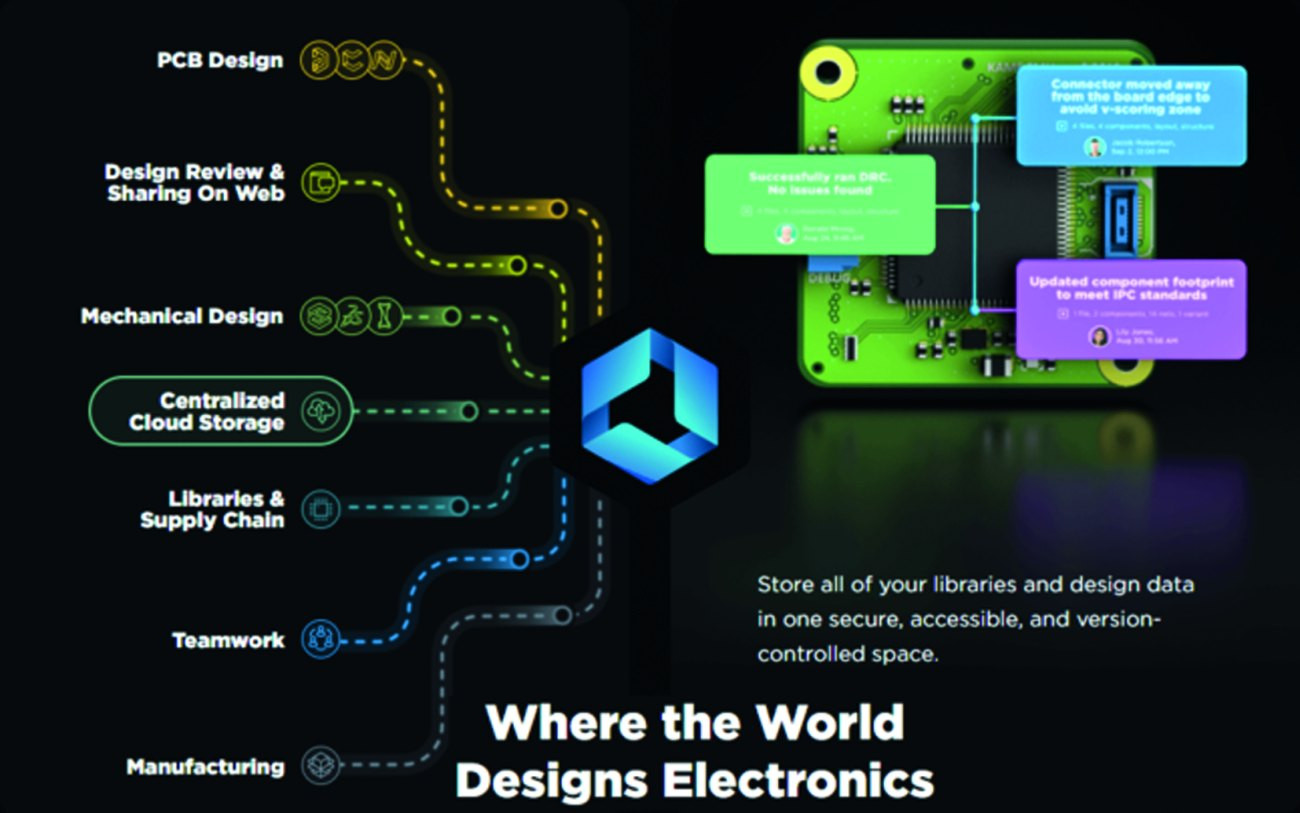

As of 2018, Altium LLC was working on a qualitatively new goal, namely to transform the electronics industry through a cloud-based digital platform. It would connect design with the supply chain and manufacturing and enable collaborative working. By introducing Altium 365, the software provider was responding to the global trend towards cloud use in complex work processes. For practical implementation, AWS (Amazon Web Services) was chosen as the host for the Altium 365 cloud platform in 2021. This combines PCB design, MCAD, data management, component procurement and production [2, 3].

The platform thus opened up a new dimension of development work at the time. It enables seamless collaboration between multiple remote teams across the entire PCB design and production process and connects electronics design with manufacturing in a new way(Fig. 3). As it is cloud-based, there is no need to install anything at the companies themselves, no servers to configure and no updates to install. You can work from anywhere and be connected remotely with every team member, which should have proven to be an advantage during the coronavirus pandemic at the latest.

Fig. 3: Symbolization of the advantages and possibilities of Altium 365Thecompany now goes so far as to call Altium 365 the 'world's most trusted PCB design system' on its website, which is of course an extremely high self-importance [2]. This is to offer software tools that connect PCB designers, component suppliers and manufacturers even more closely and enable them to develop and manufacture electronic products faster and more efficiently than ever before. But times are changing and new challenges are on the horizon.

Fig. 3: Symbolization of the advantages and possibilities of Altium 365Thecompany now goes so far as to call Altium 365 the 'world's most trusted PCB design system' on its website, which is of course an extremely high self-importance [2]. This is to offer software tools that connect PCB designers, component suppliers and manufacturers even more closely and enable them to develop and manufacture electronic products faster and more efficiently than ever before. But times are changing and new challenges are on the horizon.

Environment - new future requirements

On closer inspection, it can be seen that the releases of Altium Designer and Altium Designer 365 to date have mainly related to the further development of the technical and organizational capabilities of the tools. In the period from January to March 2023, Altium Designer 365 focused on the following topics, among others

- Altium 365 comparison functions for schematic, parts list and Gerber files

- Export of the project history

- Version control for part selection

- ODB++ in the Altium 365 Standalone Viewer

- Simulation uploads in Altium 365

So far, however, little can be found in Internet searches regarding Altium on topics such as the inclusion of artificial intelligence (AI) and environmental issues in the development and production process. However, this trade journal has reported several times since 2021, for example in [4], how intensively the integration of AI into the design process (circuit development, board and assembly design, production) is already being worked on internationally. In the upcoming Plus 5/2023, the example of power converters will be used to explain how the use of AI in the design process can significantly improve their parameters (efficiency, reliability, volume, material consumption ...), i.e. ultimately their environmental footprint. From a sustainability perspective, Altium therefore still has great potential for the further development of its tools. If advances in sustainability issues are made accessible to as many companies as possible via Altium 365 in the cloud, the EDA tool provider could achieve a major leverage effect in the electronics industry from an environmental perspective.

In recent years, increasing environmental problems and the environmental targets adopted by many governments have increased the pressure on companies to take much greater account of environmental issues in their work, both in their products and in their development and production processes. Sustainability is steadily becoming a decisive competitive factor.

Although notable activities to improve the environmental footprint of both their production facilities and their products (3R: Reduce, Reuse, Recycle) have been undertaken since the mid-1990s, particularly by Japanese electronics companies, it has not yet been possible to extend these activities to the global electronics industry to the extent required. Because product parameters that are essential for the environment are already defined in the design process, the developers of design tools such as Altium have a key role to play.

As a press release published by Altium at the beginning of March 2023 indicates, the software provider intends to focus more on environmental issues in the future. According to a press release also published by the IPC in March 2023, the American trade association considers it desirable for Altium to take on an important role as a mediator for environmentally friendly electronics in the entire electronics industry, regardless of its customer base, e.g. by helping to shape corresponding standards [5].

Cooperation between Hexagon and Altium for more sustainability

The Altium press release mentioned above announces that Hexagon's Manufacturing Intelligence Division and Altium have entered into a strategic partnership to improve the environmental sustainability of electronics design and manufacturing. The partnership combines Hexagon's expertise in utilizing data from design and engineering, manufacturing and metrology with Altium's strengths in PCB design and the electronics supply chain. The aim is to help Altium's customers better understand the impact of product development decisions on the sustainability of electronics and smart products in particular.

The partners recognize the significant impact that the electronics industry has on the environment. Their collaboration aims to help the industry become more sustainable by introducing new tools and solutions to bring about positive change.

The partnership will integrate Hexagon's Nexus platform and the Altium 365 platform to address four key areas:

- Manufacturing sustainability: helping manufacturers identify and implement more sustainable manufacturing processes and technologies that help reduce waste and minimize environmental impact through continuous improvement

- Design for sustainability: supporting engineers with data-driven workflows that use advanced simulation-based design, virtual prototyping and quality testing techniques to develop sustainable products with the right materials, design and manufacturing processes

- Fostering innovation: working with the market to develop new solutions that meet changing market needs and address current and future challenges, for example through Hexagon's start-up ecosystem and Sixth Sense support program

- Enterprise solutions: Providing solutions that offer compelling business differentiators to the electronics industry and address the higher demand for innovation for sustainability from the smart-intensive businesses

The cooperation is far-reaching. Development work for 2023 and beyond will focus on delivering initial solutions to reduce eWaste by tracking carbon footprint and recyclability improvements. These will be made available through Hexagon's Nexus Digital Reality platform and the Altium 365 platform electronics design. Increasing recyclability means developing and implementing tools that provide recommendations for more recyclable components and materials on the one hand, and recommendations for more recyclable design of assemblies and devices on the other. However, these are also the areas of work that have been significantly neglected at the IPC to date.

"Sustainability is a key discussion point on the agenda of executives at almost every company in our industry," said Ted Pawela, Chief Ecosystem Officer at Altium. "Our partnership with Hexagon will enable real progress in tracking and reporting - and most importantly - improvements in the key sustainability metrics that our customers need to consider. We look forward to continuing to work with IPC and Hexagon to help create a more sustainable future for the industry."

IPC aims for broad impact

Unsurprisingly, the US global industry association IPC has declared its support for the announced partnership between Altium and Hexagon, as Altium is already active on several of the association's committees. John Mitchell, President and CEO of the IPC, stated in a press release: "The IPC congratulates Altium and Hexagon on their partnership to help improve sustainability. Altium's expertise in PCB design and supply chain, combined with Hexagon's measurement and analysis capabilities, strengthens the company's position as a leading authority on environmental sustainability for the electronics industry." The IPC sees Altium as a valued partner in future IPC initiatives, particularly for new standards and as a member of the IPC Sustainability Leadership Council established in March 2023 [6]. It is probably no coincidence that Altium announced its new partnership with Hexagon and the IPC announced the formation of the Council at the same time. It looks like a concerted effort to finally make significant progress on these issues.

The reasons for the appointment of this new international working body were briefly explained by the IPC in the press release:

- Recognizing the need to identify, understand and address the most pressing sustainability challenges facing the electronics industry

- Creating a strategic plan to address the issues identified by the Council based on an industry-wide materiality assessment

- Creating a corresponding work plan for the detailed tasks to be solved

Representatives of the following companies were appointed to the Leadership Council:

- AT&S

- Altium

- BAE Systems

- Flex

- Intel

- Jabil

- NGC

- Siemens

- TTM Technologies

- Zollner

Tight Council work program

The Leadership Council is cross-industry. It consists of sustainability experts from PCB design and manufacturing companies, electronics manufacturing service providers and original equipment manufacturers from various product sectors. The Council plans to meet every two weeks to develop strategy and roadmap recommendations to address the industry's sustainability challenges.

Dr. Kelly Scanlon, Lead Sustainability Strategist at the IPC, said: "We are hearing from the industry that there needs to be a balance between current and evolving regulatory requirements with practical and realistic solutions, such as specific training, advocacy and standards that harmonize the industry's ability to achieve its sustainability goals." The committee has set itself the goal of presenting recommendations for a sustainability strategy plan by August 2023. This is a very ambitious project.

Strong European component

It can be seen that the ten major companies, some of which are known worldwide, include four well-known European corporations: AT&S, BAE Systems, Siemens and Zollner. Altium will probably have to take on a leading role in the consortium from a design perspective, although if AI is also included in the steering committee as an important point of reference for achieving greater sustainability, AT&S could already contribute experience in the use of AI in PCB production. On the other hand, board, component and device manufacturers would have the opportunity to provide Altium with any necessary tailwind in the environmental sector. Hexagon, with its experience in the increasingly important field of sustainability, should also be closely involved in the Council's work via Altium indirect. As an aside, it should be noted that the ten companies also include pioneers in other important sectors. For example, Flex was recognized as one of the World's Most Ethical Companies 2023 in the "Industrial Manufacturing" category by Ethisphere, a leading global analysis and assessment firm based in Scottsdale, Arizona, in defining and promoting standards for ethical business practices. It is easy to understand that sustainability and business ethics are closely intertwined and must be considered as a necessary unit in business practice in the future. In fact, according to the author, ethics, sustainability and AI form a 'holy trinity' that should underpin ambitious future corporate strategies.

Who is Hexagon AB?

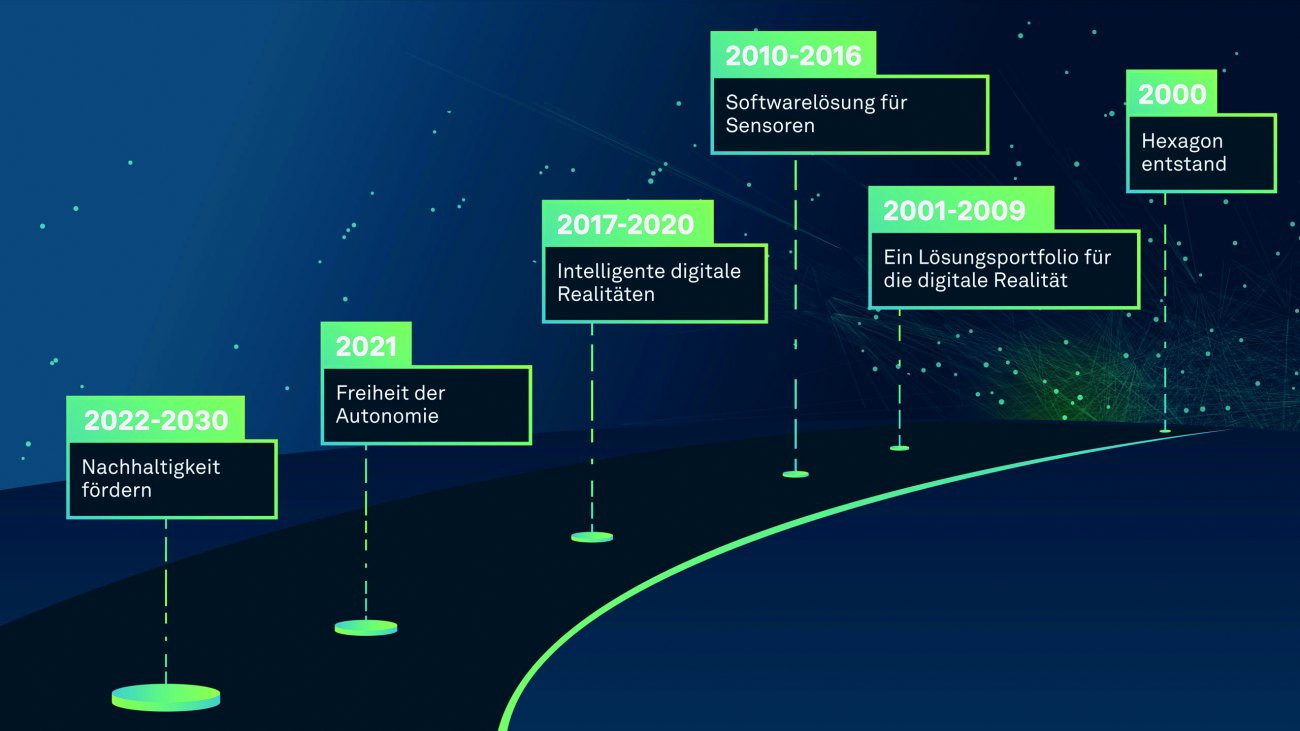

Founded almost 25 years ago, the Swedish company headquartered in Stockholm has developed into the world's leading provider of digital reality and autonomous solutions. It has set itself the goal of leading the world into a sustainable future and carries out this work in eight business areas. These cover large areas of the economy. The Manufacturing Intelligence Division selected by Altium as a partner is one of the eight. The company has offices in many countries around the world, 24 in Germany alone. Figure 4 shows the stages in which the company has 'worked its way up' to its current main area of work, sustainability.

Fig. 4: Hexagon's development stagesHexagoncreates, captures and delivers added value for two mega-ecosystems: people and production. The ecosystems that have the most direct impact on people include cities and nations, defense, buildings and infrastructure. Production ecosystems include manufacturing facilities, industrial plants, mines and farms(Fig. 5).

Fig. 4: Hexagon's development stagesHexagoncreates, captures and delivers added value for two mega-ecosystems: people and production. The ecosystems that have the most direct impact on people include cities and nations, defense, buildings and infrastructure. Production ecosystems include manufacturing facilities, industrial plants, mines and farms(Fig. 5).

Fig. 5: Hexagon works for two mega-ecosystemsToconclude this article, let's take a brief look at Hexagon's Manufacturing Intelligence Division, which intends to play a significant role for Altium and thus for large parts of the electronics industry in the coming years. At least that is what can be gleaned from the following ambitious statements by company managers. They also underline the direction Altium intends to take in the future.

Fig. 5: Hexagon works for two mega-ecosystemsToconclude this article, let's take a brief look at Hexagon's Manufacturing Intelligence Division, which intends to play a significant role for Altium and thus for large parts of the electronics industry in the coming years. At least that is what can be gleaned from the following ambitious statements by company managers. They also underline the direction Altium intends to take in the future.

"Sustainability is a top priority for Hexagon," stated Parth Joshi, Chief Product and Technology Officer of Hexagon's Manufacturing Intelligence division. "We are excited to partner with Altium and leverage their electronics expertise and software to provide more comprehensive solutions to our customers. Together, we have a vision to change the way sustainability is viewed, implemented and adopted in the electronics industry. We are committed to developing and implementing sustainable manufacturing processes and open digital technologies that help our customers address inefficiencies, reduce theircarbon footprint and adopt a circular economy."

It continues: "Hexagon's Manufacturing Intelligence division enables manufacturers to innovate and create without limits. Our solutions support optimization throughout the product lifecycle, empowering designers to make better products in new, innovative ways for people and the planet. Whether employees are inventing, designing, manufacturing, testing or maintaining products, Hexagon's Manufacturing Intelligence division empowers them to create without limits."

It continues: "Our technologies remove the limits of what is possible, empowering manufacturers to redefine the world we know through manufacturing innovation. From concept to end of life, our solutions deliver optimization across the value chain by transforming design, simulation, testing, material selection, engineering for manufacturing, production, inspection and performance in the real world."

Hexagon's smart manufacturing portfolio supports the entire product and production lifecycle, unlocking potential, solving problems before they occur and delivering significant gains. By bringing the physical and digital worlds together through hardware and software, we give makers the freedom to develop ideas, explore, get it right first time and scale production sustainably. Our goal is to close the loop of cost, quality, innovation and sustainability to create better products in new innovative ways.

References

[1] www.altium.com/de/altium-designer

[2] www.altium.com/documentation/altium-365

[3] www.altium.com/company/newsroom/press-releases/altium-and-aws-collaborate-advance-electronic-design

[4] Plus 9-11/2021

[5] https://hexagon.com/company/newsroom/press-releases

[6] www.ipc.org/news-release/new-ipc-sustainability-electronics-leadership-council-address-industry-sustainability