New AI-supported design methodology for power electronics converters

As previously reported [1], the British research institute CSA Catapult has worked with Zuken to develop optimized tools for creating 3D models of power modules. These have been incorporated into the EDA tool 'CR-8000 Design Force'. But the scientists at CSA took another important step: they created a new AI-supported methodology for the optimal electrical design of power electronics converters.

Fig. 1: The AI project involved scientists from different backgrounds from CSA and Cardiff University

Fig. 1: The AI project involved scientists from different backgrounds from CSA and Cardiff University

The UK government-funded non-profit organization Compound Semiconductor Applications (CSA) Catapult, based in South Wales, was founded to help the UK become a world leader in semiconductor interconnect technology, among other things. A press release from November 2022 reveals that the research organization's work is far broader than the successes in 3D design of compact power modules described in [1] [2]. It is also involved in researching the possibilities of using artificial intelligence (AI) to realize optimal electrical circuits for power electronics, here in the specific case of power converters (power converters, power converters) [3]. CSA is thus pursuing the goal of bringing progress to the entire design process of power electronics, i.e. enabling products with an optimized design from the circuit to the module construction. The further explanations show that, in addition to optimum electrical and design parameters, the aim is also to achieve the highest possible development efficiency, for example time economy. Scientists from CSA and Cardiff University worked together to solve the problem.(Fig. 1).

Power converter

A power converter is an electrical device for converting electrical energy. It can convert alternating current (AC) into direct current (DC) and vice versa or change the voltage or frequency of a current. Power converters have many different applications: Cell phones, computers, televisions, electric vehicles, renewable energy generation equipment, automation technology, aerospace and many more. This small list shows that the demand for power converters with a very diverse performance spectrum will increase enormously in the coming years. Not only that: the general technical requirements are also growing in many respects. Here are a few examples:

- Long-term stability

- reliability

- accuracy

- Miniaturization

- Power loss (efficiency, heat reduction)

- Temperature application ranges.

It is more than understandable that CSA, in cooperation with its partners, has made the optimization of the design and production efficiency as well as the usage parameters of power modules, including power converters, a focus of its work. This was supported by the Engineering and Physical Sciences Research Council, UK, under grant EP/T021969/1. The following are excerpts from publications by the project team, taken from various sources [3-5]. In particular, the publication in the 'IEEE Open Journal of Power Electronics' served as a source here. The scientific article is entitled 'Artificial Neural Networks-Based Multi-Objective Design Methodology for Wide-Bandgap Power Electronics Converters'. It should be remembered that the English term 'design' has a broader meaning than is usually the case in German. In the present case, it covers the range from circuit development to the construction of the module.

Basic problems in design

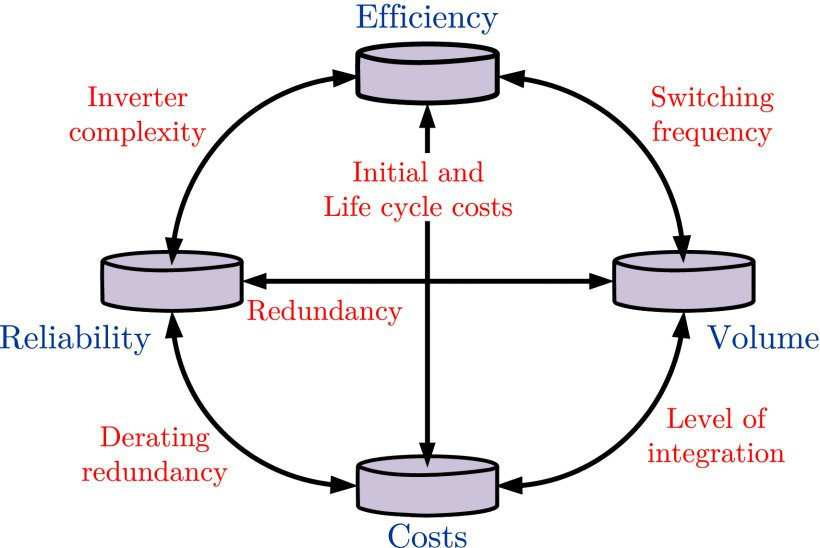

When designing power electronic converters, it should be noted that some of its performance parameters are coupled with each other. These include efficiency,

power density, cost and reliability(Fig. 2).

A well-designed electronic power converter must fulfill the following requirements:

- high efficiency

- small volume

- low weight

- low cost

- low failure rate.

Therefore, the main objective of a power converter design process is to find the best compromise between these performance indicators. For example, a design that focuses only on maximizing efficiency will inevitably sacrifice the power density, reliability and cost of the converter. In Figure 2, the texts in red are factors that primarily affect the performance of the converter. For example, switching frequency primarily affects efficiency and volume. Factors affecting performance include switching frequency, level of integration, derating redundancy, converter complexity, redundancy, but acquisition and life cycle costs must also be considered. The trade-offs depend mainly on factors such as converter topology, modulation scheme, converter components and design layout. Through careful design, the converter has high power density, reduced volume, low weight and low cost. Therefore, the main objective in selecting a design method is to identify the best compromise between mutually influencing parameters.

Fig. 2: Trade-off between performance parameters of power converters

Fig. 2: Trade-off between performance parameters of power converters

The CSA project

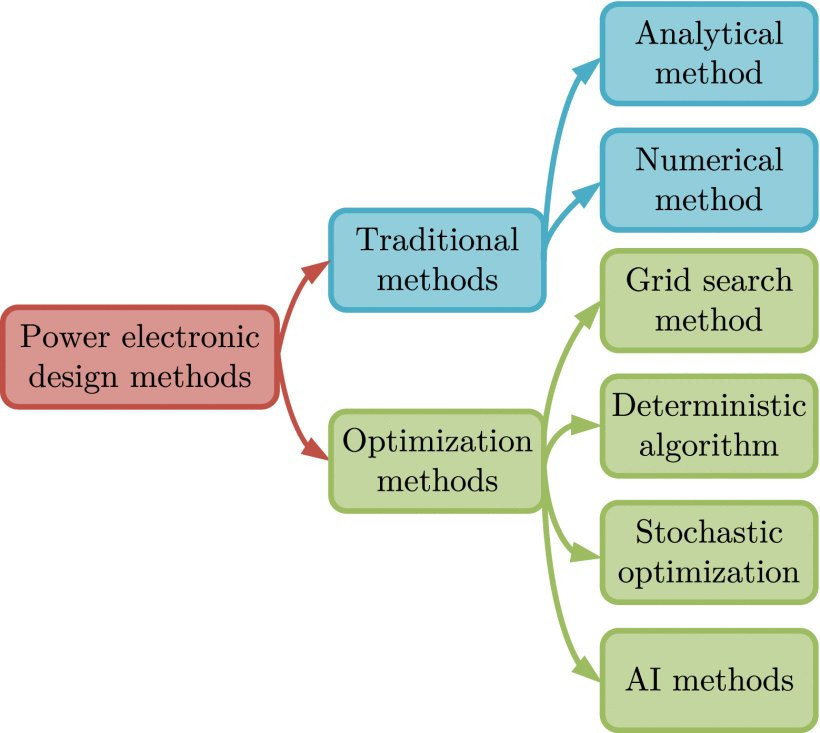

The design methodology for converters is critical to fully realize the potential of wide power semiconductors. The design methods are broadly classified into traditional and optimized methods(Fig. 3).

The analytical method is one of the traditional tools based on designing appropriate power dissipation models and solving analytical equations. Although the analytical models are easy to develop, the accuracy of the method proved to be low. Although the numerical methods give better results by including, for example, interactive functions and extended Langrange functions in the analytical equations, the final results are suboptimal in the researchers' experience. As the existing design methods are largely based on complex mathematical models, this considerably increases the computing time and complexity and leads to various problems. These include poor ability to take constraints into account, inaccurate design and difficult parameter tuning. Optimization methods are an alternative to the traditional approach. With them, the combination of design parameters is optimized with regard to the desired performance parameters of the converter. Fig. 3: Design methods for power electronics converters

Fig. 3: Design methods for power electronics converters

Use of AI for new design methods

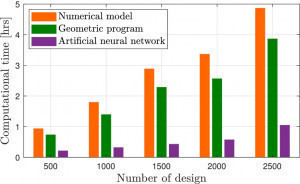

To overcome the aforementioned problems, the CSA scientists took a different approach. They created a new design method using a type of AI known as artificial neural networks (ANN), which uses algorithms and computer systems that mimic the interconnected neural networks of the human brain. The multi-objective design approach used offers significant advantages over the other methods mentioned in Figure 3, such as reducing the repeated use of complex mathematical models and thus the computational effort. This also leads to time savings in the development process. The computing time was reduced by up to 78% and 67% compared to the numerical modeling and geometric program (GP) methods also used.

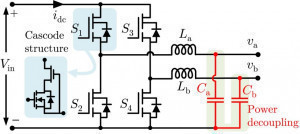

The proposed method was implemented in MATLAB/Simulink to design a single-phase 1 kW inverter with wide bandwidth. The inverter topology used to investigate the ANN-based design approach is shown inFigure4.Two identical DC-DC buck converters were used to form the inverter.Each converter generates the AC voltage with a DC offset and the sinusoidal output voltage is generated by combining both converter outputs. Figure 5 gives a rough overview of the entire ANN design approach and the processing sequence. The structure of the ANN for the proposed design approach can be found at the top right of the figure.

The ANN can be easily trained with a backpropagation algorithm and then applied to the design process. In the given case, it was trained with an existing dataset of over 2000 designs so that the team obtained the most suitable design for the desired efficiency and power density. Four main components were selected for the ANN-based design, including the power gallium nitrate (GaN) field-effect transistors (FETs), inductors, capacitors and heat sinks. The ANN was trained with the mathematical models of the power dissipation and volume of these components.

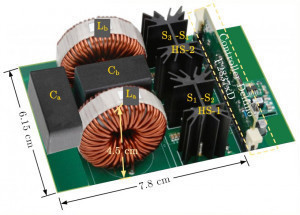

The design approach was validated by experimental tests on a GaN-based single-phase 1 kW inverter created using the specified design. For this purpose, the proposed method was implemented in MATLAB/Simulink. The efficiency and power density of the device were well matched to the design and range of existing devices, making it technically competitive and commercially viable. As a result of the work, a design with an optimized efficiency of 98.4% and a power density of 4.57 kW/dm3 was realized. The accuracy of the design was verified by experimental prototyping and the measured efficiency and power density were 98.02% and 4.54 kW/dm3 respectively, so that the errors of efficiency and power density compared to the simulated values were both around 0.38%. The new method reduced design times by up to 78% and a converter module with an efficiency of over 98% was created(Fig. 6).

Figure 7 shows that as the number of designs increases, the ANN AI method gains an increasing lead over the classic design methods in terms of cumulative time savings, and the researchers commented on the results of their work as follows: Study co-author Dr. Wenlong Ming, a lecturer at Cardiff University and senior research fellow at CSA Catapult, emphasized that accurate and fast transient modeling or simulation approaches are essential to efficiently and quickly optimize the performance of wide bandgap power electronics systems. It is foreseeable that the ANN "will gradually be used more for converter designs due to the advantages of fast calculation and high accuracy". According to another co-author of the study, Dr. Ingo Lüdtke, Head of Power Electronics at CSA Catapult, the automated optimization of power electronics design "enables the full benefits of wide bandgap power semiconductors compared to their silicon counterparts".

Further successes on the horizon

In a press release dated January 19, 2023, it was announced that Compound Semiconductor Applications (CSA) Catapult has signed a Memorandum of Understanding (MoU) with Cardiff University regarding the further expansion of scientific collaboration [6].

The MoU will lay the foundations for a long-term partnership to advance research in areas of shared strength and deliver lasting public impact in the UK and beyond.

The MoU was signed during an event at the CSA Catapult Innovation Center by Martin McHugh, CEO of CSA Catapult, and Professor Rudolf Allemann, Pro Vice-Chancellor, International and Student Recruitment and Head of the College of Physical Sciences and Engineering at Cardiff University.

The MoU sets out a framework to develop joint research projects and funding bids, exchange staff, share facilities and equipment, develop teaching initiatives and create a pipeline of skills and talent. The collaboration recognizes CSA Catapult and Cardiff University's joint strengths in power electronics - the processing of high voltages and currents to provide electricity for a range of applications, from domestic electronics to electric vehicles and space technology.

www.zuken.com, https://csa.catapult.org.uk

International research team

In addition to the technical description of the KI-ANN project, a brief look should be taken at the research team. The published short biographies show that all five co-authors come from different countries:

- Dr. Rajesh Rajamony, India

- Dr. Sheng Wang, China

- Dr. Ingo Lüdtke, Germany

- Dr. Gerardo Calderon-Lopez, Mexico

- Dr. Wenlong Ming, China

They studied in their respective home countries and then moved to the UK for further academic qualifications (doctorate). As can be seen from [7], a scientific publication from January 2022, Dr. Ingo Lüdtke and Dr. Wenlong Ming are also active in the field of simulation of SiC power MOSFETs. This also underlines that power electronics is a broad and important focus of CSA's work.

References

[1] Hartmut Poschmann, PLUS 1/2023, p. 30ff.

[2] https://csa.catapult.org.uk/advanced-packaging/

[3] https://csa.catapult.org.uk/blog/2022/11/09/

[4] https://ieeexplore.ieee.org/document/9887949/authors#authors

[5] R. Rajamony; S. Wang; G. Calderon-Lopez; I. Ludtke; W. Ming: Artificial Neural Networks-Based Multi-Objective Design Methodology for Wide-Bandgap Power Electronics Converters, IEEE Open Journal of Power Electronics, Vol. 3/2022, pp. 599-610 (CC BY 4.0)

[6] www.csa.catapult.org.uk/blog/2023/01/19/

[7] P. Yang; W. Ming; J. Liang; I. Lüdtke; S. Berry; K. Floros: Hybrid Data-Driven Modeling Methodology for Fast and Accurate Transient Simulation of SiC MOSFETs, IEEE Transactions on Power Electronics, vol. 37, no. 1, pp. 440-451, Jan. 2022, doi: 10.1109/TPEL.2021.3101713. (CC BY 4.0)