However, highly reflective materials such as copper and aluminum are used. Their low surface absorption and high thermal conductivity make a special design of the laser system necessary in order to prevent scattered radiation and an increase in material temperature to over 80 °C, as welding generates a lot of heat. If this value is exceeded, the lithium in the battery, for example, can ignite and cause a fire or explosion.

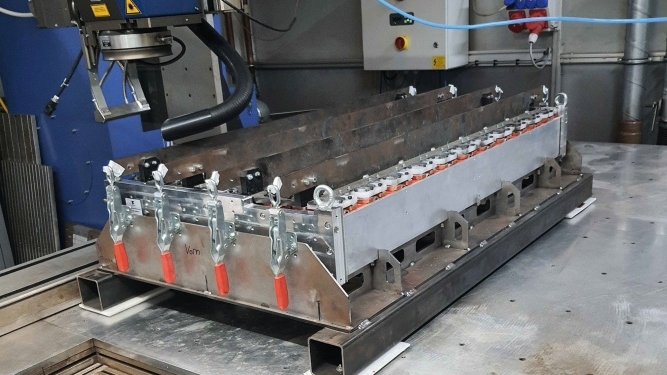

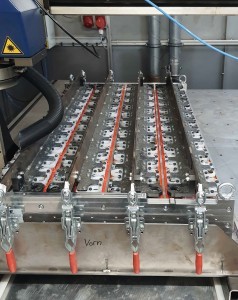

Due to their special geometries, the use of reflective materials and their dimensions, e-batteries for industrial trucks or HGVs require the laser welding system to be adapted In addition to temperature control and a suitable laser, special optics with intelligent image processing are required so that the laser can reach all welding points without restriction despite the different battery types. In order to meet all these requirements, LMB Automation GmbH develops, among other things, systems specially designed for laser welding the contact connections on batteries. They generally have an adapted housing design containing a combined movement unit with a fast, scanner-optics-based beam guidance system. This is supplemented by intelligent image processing and temperature probes.

Due to their special geometries, the use of reflective materials and their dimensions, e-batteries for industrial trucks or HGVs require the laser welding system to be adapted In addition to temperature control and a suitable laser, special optics with intelligent image processing are required so that the laser can reach all welding points without restriction despite the different battery types. In order to meet all these requirements, LMB Automation GmbH develops, among other things, systems specially designed for laser welding the contact connections on batteries. They generally have an adapted housing design containing a combined movement unit with a fast, scanner-optics-based beam guidance system. This is supplemented by intelligent image processing and temperature probes.

"When manufacturing batteries, the connections between the battery cells at the electrodes have to be welded in order to achieve higher performance. The main advantage of laser welding is the precise and short energy input, which significantly reduces heating of the surrounding material," explains Peter Schlüter, Managing Director of LMB Automation GmbH. "Using precise guidance systems, precise positioning to less than 0.05 mm can be achieved in a very short time, which is completely sufficient in battery technology." Other joining methods such as crimping, screwing or ultrasound are significantly slower, more cost-intensive or unsuitable for thicker materials. However, when designing a laser welding system for batteries, there are a number of things to consider, as reflections, inclusions and heating of the welding environment must be avoided due to the difficult material properties and the heat sensitivity of the lithium used. In addition, uncleanly machined component areas such as milled edges can impair the welding result, so it makes sense to integrate good image processing to support the laser optics.

This is why LMB Automation GmbH develops special laser welding solutions that are adapted to different battery sizes as well as for trucks and industrial trucks. However, the company also offers systems for other e-mobility tasks such as welding rotors. The key parameters such as the materials used and material thickness, the welding requirements and the component geometry are defined with the customer in advance of a project. Thanks to its many years of experience in the field of laser system construction and the welding of aluminum or copper, LMB can determine the various machine components for positioning, monitoring and safety and link them together efficiently.

Laser welding technology for demanding materials

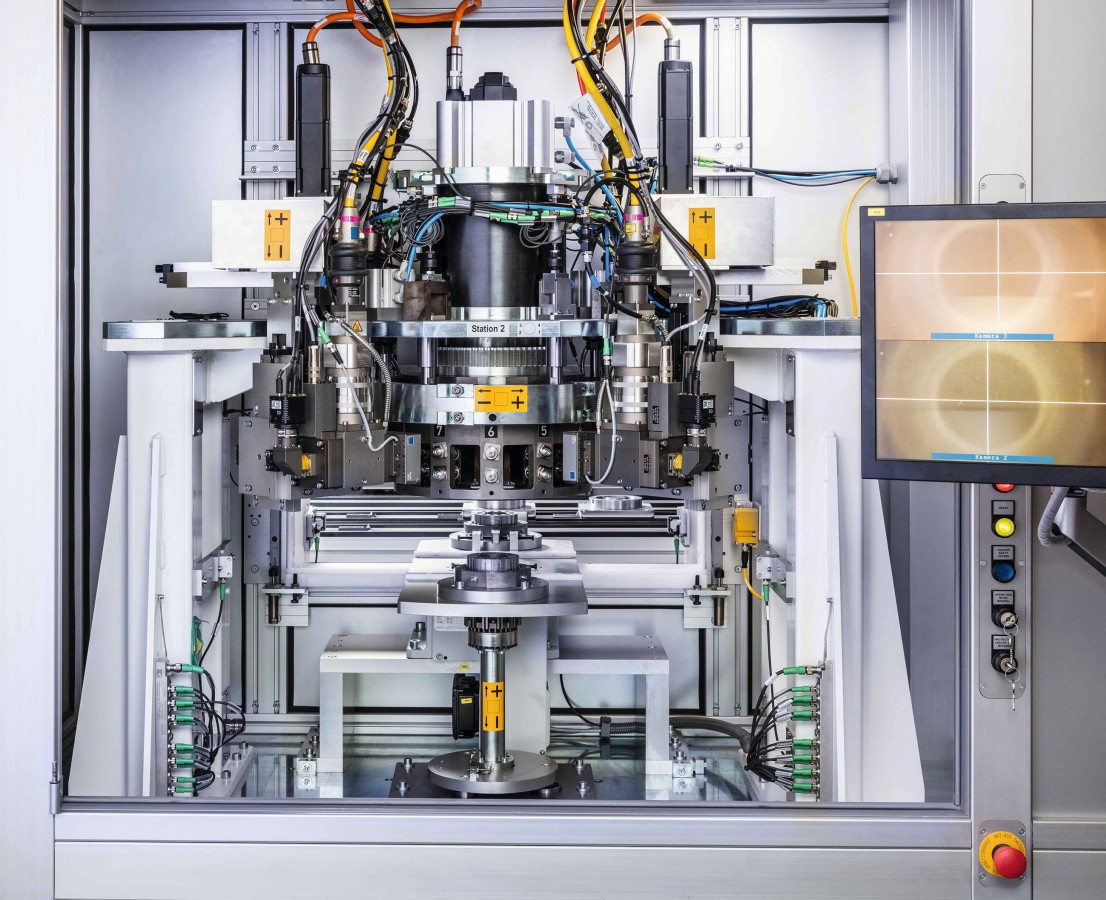

In the production of batteries, the connections between the battery cells must be welded to the electrodes in order to achieve higher performance. The main advantage of laser welding is the precise and short energy input, which significantly reduces heating of the surrounding material "Safe and effective laser welding of batteries essentially depends on the right combination of laser tool and monitoring. A machine design with a special housing design, a combined movement unit with a fast optical precision guidance system and an additional fast beam guidance system with scanner optics therefore makes sense," explains Schlüter. The laser used should work with a high beam quality and still provide sufficient power, as welding must be carried out quickly to avoid heat build-up at the welding point. Overall, the material in the vicinity of the weld must not heat up to over 80 °C, as otherwise the lithium in the battery could ignite. Fiber or disk lasers with an average power of 4 to 6 kW have proven their worth with LMB, as they have a good and reproducible beam quality so that their power can be coupled into a fiber with a diameter of 0.1 to 0.2 mm. This ensures very precise and reproducible spot and seam welding, which is an advantage for seam lengths of up to 30 mm per component.

In the production of batteries, the connections between the battery cells must be welded to the electrodes in order to achieve higher performance. The main advantage of laser welding is the precise and short energy input, which significantly reduces heating of the surrounding material "Safe and effective laser welding of batteries essentially depends on the right combination of laser tool and monitoring. A machine design with a special housing design, a combined movement unit with a fast optical precision guidance system and an additional fast beam guidance system with scanner optics therefore makes sense," explains Schlüter. The laser used should work with a high beam quality and still provide sufficient power, as welding must be carried out quickly to avoid heat build-up at the welding point. Overall, the material in the vicinity of the weld must not heat up to over 80 °C, as otherwise the lithium in the battery could ignite. Fiber or disk lasers with an average power of 4 to 6 kW have proven their worth with LMB, as they have a good and reproducible beam quality so that their power can be coupled into a fiber with a diameter of 0.1 to 0.2 mm. This ensures very precise and reproducible spot and seam welding, which is an advantage for seam lengths of up to 30 mm per component.

A movement unit with scanner optics is ideal for positioning the laser, as it can execute very different geometries and movement profiles smoothly, even in confined spaces. This means that circular paths or figure-eight lines, for example, can be realized precisely at up to 10 m/s, even in a small area. A scanner system can position the laser beam in the processing position by an order of magnitude more precisely than conventional optics. The system engineers at LMB supplement this flexible movement unit with an image processing system developed in-house, which ensures the correct positioning of the specified welding points. "As the position of the welding points on modern batteries is not always directly visible due to the connecting plate on the individual cells, the defined welding strategy must be compared with real-time images before the laser is positioned," explains Schlüter. "The software-based image processing ensures that the actual and target positions are compared, after which the laser is automatically aligned."

Shielding gas and temperature control prevent material reaction with the ambient air

A motion unit with scanner optics is ideal for positioning the laser to weld a rotor Since temperature-sensitive aluminum, copper and lithium are used in batteries, safety and monitoring components such as shielding gas supply and temperature probes must be integrated into the system without hindering the laser or oversizing the housing. Here, LMB draws on material experience from other welding work on these materials in its own contract manufacturing. For example, the shielding gas, which is intended to prevent the supply of oxygen to the aluminum, should be introduced into the welding area without turbulence. This is because swirling entrains air, which causes oxygen to reach the welding area. To prevent ignition of the lithium, which is very difficult and costly to extinguish, temperature sensors in combination with high welding speeds of the laser ensure that the material temperature does not rise above 80 °C. In addition, the housing of the work area is designed so that it can be completely sealed off to isolate the source of the fire and deprive it of oxygen.

A motion unit with scanner optics is ideal for positioning the laser to weld a rotor Since temperature-sensitive aluminum, copper and lithium are used in batteries, safety and monitoring components such as shielding gas supply and temperature probes must be integrated into the system without hindering the laser or oversizing the housing. Here, LMB draws on material experience from other welding work on these materials in its own contract manufacturing. For example, the shielding gas, which is intended to prevent the supply of oxygen to the aluminum, should be introduced into the welding area without turbulence. This is because swirling entrains air, which causes oxygen to reach the welding area. To prevent ignition of the lithium, which is very difficult and costly to extinguish, temperature sensors in combination with high welding speeds of the laser ensure that the material temperature does not rise above 80 °C. In addition, the housing of the work area is designed so that it can be completely sealed off to isolate the source of the fire and deprive it of oxygen.

As with the crucial components for positioning, monitoring and safety, LMB also adapts the systems to customer requirements in terms of component type and location. In addition to the laser station, this also includes peripheral additions for sorting, feeding, clamping and quality assurance. "As we operate contract manufacturing with 16 laser systems, we can simulate the processing of the individual battery components in production test runs in advance," reports Schlüter. "This allows us to adapt the process and the system components precisely to the component. At the same time, we can check how the laser behaves and whether gaps occur due to possible distortion." In addition, micrographs are produced in consultation with the customer to ensure the seam quality and exclude inclusions and pores. Dummies with the same material properties and geometries are often used as component replacements. LMB also advises its customers both before and after the order is placed. This includes remote maintenance after approval by the customer, for example to isolate faults and carry out calibrations. "Our aim is to be a partner at the customer's side in this growing sector. Starting with the project planning, including the preparation of the electrical plan, through to the construction and delivery of the system and on to further support," concludes Schlüter.

The laser used should work with a good beam quality and provide sufficient power, as the welding must take place quickly to avoid a large build-up of heat at the welding point

The laser used should work with a good beam quality and provide sufficient power, as the welding must take place quickly to avoid a large build-up of heat at the welding point

INFO

LMB Automation GmbH

LMB Automation GmbH has been offering solutions for laser-based material processing of various materials and components since 1994. The three application areas of welding, cutting and marking are covered. Since 2000, the company has also been developing industrial production systems - as stand-alone models or as part of a production line - in which the laser is the key tool. These are completely designed, constructed, assembled and adapted to the customer's specific requirements at the company site. In addition to lasers with different outputs, manual workstations, multi-axis systems and robots are used for in-house contract manufacturing. In addition, R&D projects are implemented together with partners in photonics and universities. The company currently employs 55 people.