Is it possible to convertCO2 back into fuels or other useful chemicals? Absolutely, but we can't yet control exactly which chemicals are produced. Empa researcher Alessandro Senocrate is looking for material defects that could help us do this.

Can we simply reverse the burning of oil, natural gas and coal? With a renewable energy source, some water and a suitable catalyst, the excessCO2 from the Earth's atmosphere could become a valuable resource, for example for the production of synthetic fuels or "synfuels". This promising idea is being researched worldwide, including at the Swiss Federal Laboratories for Materials Science and Technology (Empa), as it is not easy to implement. For example, if you take a copper catalyst - the best-researched type of catalyst for the conversion of carbon dioxide - you get up to 20 different molecules, from carbon monoxide and methane to propanol and acetic acid. "Some of these compounds are liquid at room temperature, others are gaseous," says Empa researcher Alessandro Senocrate. "It is extremely difficult to separate all these products from each other."

Senocrate, who works in the "Materials for Energy Conversion" laboratory under the direction of Corsin Battaglia, intends to research the solution to this problem over the next four years. The project is funded by an "Ambizione Grant" from the Swiss National Science Foundation (SNSF) and is embedded in the National Center of Competence in Research "NCCR Catalysis". The aim of the project is to develop novel catalysts forCO2 conversion. Senocrate does not start with the material itself, but with so-called defects. A defect forms in a crystalline material, for example, when an atom is missing in its crystal lattice or is replaced by a foreign atom. These sites give the original material different properties and can therefore act as active centers in which chemical catalysis takes place.

Where batteries are not enough

First of all, the researcher wants to investigate which defects lead to which reaction products. "Ideally, we can use this knowledge to design catalysts that deliver specific molecules instead of a mixture during the conversion ofCO2," he explains. Some potential target molecules are of particular interest to industry. These include carbon monoxide and ethylene. These molecules are so-called platform chemicals: they are the starting materials for numerous chemical processes, including the production of most plastics. "We already have a complete value chain for such platform chemicals," says Senocrate. "However, today they are almost exclusively produced from crude oil." Alternative, more environmentally friendly sources for carbon-based chemicals - whether fromCO2 conversion or from biomass - are therefore in demand. In addition to plastics, fuels can also be produced from these platform chemicals. Other Empa research projects are focusing on the production of synfuels. "Cars can be electrified very well," says Alessandro Senocrate. "The situation is different for aircraft and many energy-intensive industrial processes." Synfuels make a lot of sense here.

The advantage of liquid fuels such as kerosene is their enormously high energy density, which can exceed that of batteries by a factor of almost 100. Fuels produced with renewable energy are therefore also a particularly attractive option for seasonal energy storage. The infrastructure for the transportation and storage of synfuels is already in place, as they hardly differ from fossil fuels in terms of their composition. The only thing missing is the ability to produce them on a large scale. Senocrate, however, is optimistic: "I've only been researching this field for a few years, and yet I've already seen massive progress," says the scientist. "Of course, it will also require major political and social change. But from a materials science perspective, progress is rapid."

Perfecting the technology

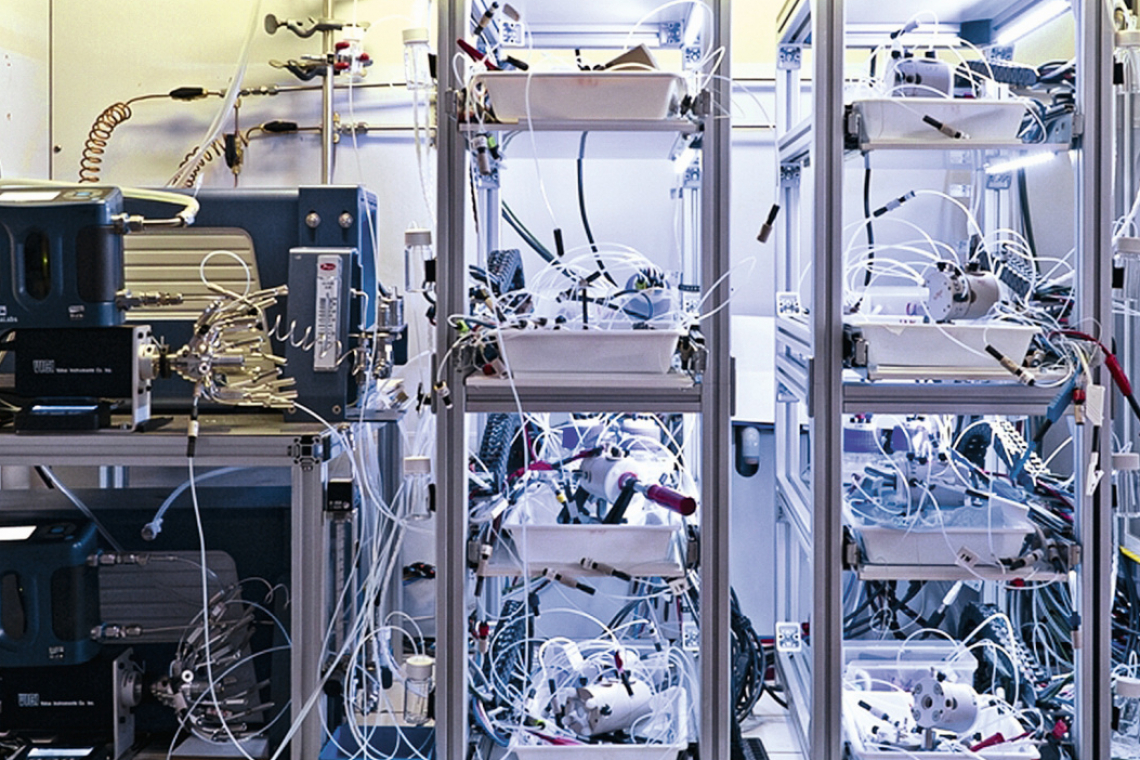

Before Senocrate can contribute to this progress with his "Ambizione" project, he still has a few challenges to overcome. One of the biggest: introducing enough defects into the target material to achieve a measurable catalytic effect. This is because the researcher deliberately uses an inert starting material that has no influence on the electrochemical reaction without the defects. "This allows me to determine very precisely what effect the respective defects have," he explains. Once the defects have been characterized, they can also be incorporated into existing catalytic materials. "Ideally, at the end of the project we will be able to specifically improve an existing system forCO2 conversion," says Senocrate. Such systems are already in use in the "Materials for Energy Conversion" laboratory, where researchers are already testing various catalysts and electrode materials.

The demands placed on these materials are high: "For industrial use, the catalyst must be selective, active and stable," explains Senocrate. Selectivity means that it only delivers one chemical reaction product - or at least a few that can be easily separated. High activity is necessary in order to produce as much fuel or chemicals as possible with as little energy as possible. And, of course, a market-ready catalyst should maintain its functionality over thousands of operating hours, i.e. be stable. "We still need to improve a lot on all three of these properties," says the researcher. "But we are on the right track."