- Part 2 - Results and conclusions/ continued from Galvanotechnik 2/2024

Geothermal energy is an energy source that can be used to replace fossil fuels and reduceCO2 emissions. Technologies exist to utilize geothermal energy, but the operating conditions in geothermal plants are in many cases extremely corrosive due to the chemical composition of the hydrothermal fluids and the high temperatures. It is therefore essential to select materials on the basis of prior material qualification by means of corrosion tests.

Results of ageing tests

Except in water with a low pH value, all materials tested showed corrosion rates below the previously defined limit value of 0.3 mm/year after 24 weeks of ageing. All materials showed sufficient or very good corrosion resistance in the selected synthetic geothermal waters. No signs of susceptibility to SpRK were found. At a pH value of 2, the carbon steel showed corrosion rates of more than 1 mm/year.

The carbon steel tested showed uniform corrosion in all synthetic geothermal waters. The corrosion rate increased with increasing salinity and decreasing pH (Figure 2). Signs of crevice corrosion susceptibility were observed in the area of fixation.

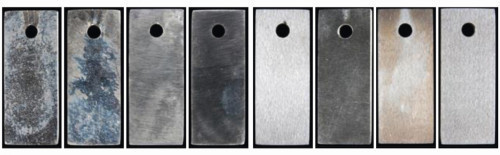

Fig. 3: Materials after 6 months of ageing in synthetic ORG geothermal water at different temperatures; from left to right: X2CrNiMo22 5 3, X2CrNiMoCuWN25 7 4, X1CrNiMoCu32 28 7 and NiCr23Mo16Al

Fig. 3: Materials after 6 months of ageing in synthetic ORG geothermal water at different temperatures; from left to right: X2CrNiMo22 5 3, X2CrNiMoCuWN25 7 4, X1CrNiMoCu32 28 7 and NiCr23Mo16Al

Test specimens made of the materials X2CrNiMo22-5-3 and X2CrNiMoCuWN25-7-4 showed some signs of crevice corrosion in the area of fixation by PTFE cord in both high-salinity synthetic geothermal waters, and X1CrNiMoCu32-28-7 only in NDB [5], but not in ORG(Figure 3). Therefore, specific electrochemical tests for susceptibility to crevice corrosion were performed. According to the aging results, the nickel-based alloy NiCr23Mo16Al can be considered suitable at 100 °C and 150 °C.

Electrochemical tests

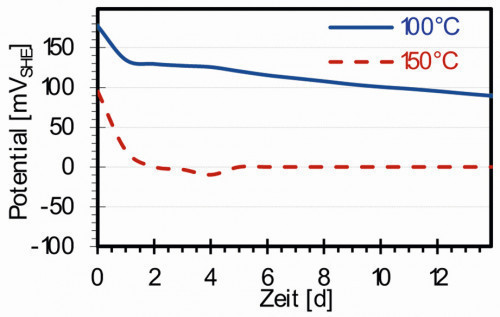

All measured values are summarized in Tables 3 and 4. Some of the NDB results have already been described elsewhere [5, 8]. In the following, selected test results in ORG geothermal water are described in more detail. The resting potential (RP) of the super duplex steel X2CrNiMoCuWN25-7-4 in ORG synthetic geothermal water at 100 °C stabilizes after 8 to 10 days and reaches values around 100 mVSHE after 14 days. Increasing the temperature to 150 °C leads to a more negative resting potential around 0 mVSHE (Figure 4).

|

Material |

RP [mVSHE] |

KLP [mVSHE] |

KSP |

REP [mVSHE] |

|||

|

100 °C |

150 °C |

100 °C |

150 °C |

100 °C |

100 °C |

150 °C |

|

|

X2CrNiMoCuWN25-7-4 |

75 - 125 |

-50 |

280 - 30 |

25 - 50 |

150 |

≤ RP |

< RP |

|

X1CrNiMoCu32-28-7 |

170 - 180 |

120 - 150 |

550 - 580 |

425 - 450 |

275 |

330 - 380 |

< RP |

|

NiCr23Mo16Al |

90 - 160 |

125 - 300 |

> 900 |

500 - 590 |

325 |

CPP ≅ CPP |

420 - 450 |

|

Material |

RP [mVSHE] |

KLP [mVSHE] |

REP [mVSHE] |

|||

|

MB 150 °C |

LHD 175 °C |

MB 150 °C |

LHD 175 °C |

MB 150 °C |

LHD 175 °C |

|

|

25CrMo4 |

-350 - -200 |

-450 |

200 - 300 |

(active) |

n. repass. |

(active) |

|

X2CrNiMo17-12-2 |

254 - 348 |

-65 - -55 |

586 - 784 |

302 - 394 |

91 - 261 |

-44 - -0 |

|

X2CrNiMo22-5-3 |

177 - 207 |

867 - 901 |

245 - 295 |

|||

|

X1CrNiMoCu32-28-7 |

-50 - 250 |

725 - 775 |

325 - 375 |

|||

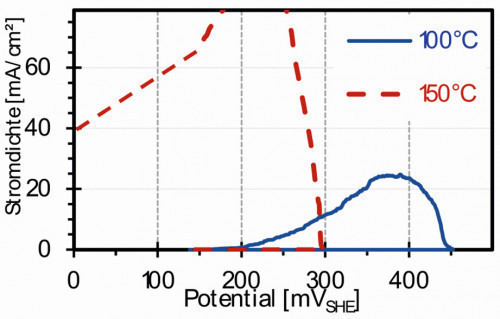

The critical pitting potential (CPP) and the repassivation behavior of the materials were determined by potentiodynamic measurements. Figure 5 shows an example of the polarization curves of X2CrNiMoCuWN25-7-4 in synthetic ORG geothermal water. Despite slight current fluctuations, the critical pitting corrosion potential of X2CrNiMoCuWN25-7-4 at 100 °C is between 350 and 450 mVSHE. In addition, X2CrNiMoCuWN25-7-4 has a repassivation potential (REP) that is more positive than its resting potential and lies between 150 and 250 mVSHE.

Fig. 4: Resting potential of X2CrNiMoCuWN25-7-4 in synthetic ORG geothermal water at different temperatures

Fig. 4: Resting potential of X2CrNiMoCuWN25-7-4 in synthetic ORG geothermal water at different temperatures

When the temperature is increased to 150 °C, the critical pitting potential of X2CrNiMoCuWN25-7-4 shifts slightly in the cathodic direction. It was then between 300 and 350 mVSHE. The repassivation potential could not be determined as it shifted to values much more cathodic than the resting potential. Once hole formation had started, it was difficult to repassivate the active sites under resting potential conditions. Consequently, the super duplex stainless steel X2CrNiMoCuWN25-7-4 is also considered unsuitable in ORG geothermal water at 150 °C.

Fig. 5: Current density-potential curves of X2CrNiMoCuWN25-7-4 in synthetic ORG geothermal water at different temperatures

Fig. 5: Current density-potential curves of X2CrNiMoCuWN25-7-4 in synthetic ORG geothermal water at different temperatures

The duplex steel X2CrNiMo22-5-3 generally shows similar behavior to the super duplex steel in ORG geothermal water, so it was also not acceptable for this. It should be noted that this also applies to the results in NDB geothermal water, where X2CrNiMo22-5-3 was not tested, but X2CrNiMoCuWN25-7-4 was.

The higher alloyed materials show a different behavior.

Tables 3 and 4 summarize the electrochemical parameters obtained from the resting potential and potentiodynamic measurements on the different materials.

The duplex steel X2CrNiMo22-5-3 showed limited corrosion and repassivation properties at both temperatures. The critical pitting potential was certainly more anodic than the resting potential at 100 °C, but decreased with increasing temperature up to 150 °C and approached the resting potential. This means that, for example This means that even small fluctuations within the operating conditions trigger the corrosion of this material. The repassivation potentials were in the range of the resting potential or were more cathodic than the resting potential. So once corrosion has started, repassivation at 100 °C is very unlikely and can also be ruled out at 150 °C under resting potential conditions. However, there is no difference between the onset of crevice and pitting corrosion. Both critical potentials were close to the resting potential.

A slightly better behavior was observed for the super duplex steel X2CrNiMoCuWN25-7-4. It was able to repassivate at 100 °C, as the repassivation potential had slightly more positive values than the resting potential. The critical pitting potential was also slightly more anodic than the resting potential. At 150 °C, it behaved similarly to the aforementioned duplex stainless steel.

The superaustenitic steel X1CrNiMoCu32-28-7 exhibited significantly better resistance. The critical pitting corrosion potential and the repassivation potential were close to each other and were relatively far away from the resting potential at 100 °C (in the anodic direction). This means that very strong changes in operating conditions are required to initiate corrosion. In addition, very rapid repassivation takes place. Crevice corrosion occurs before pitting corrosion, as can be seen from the lower critical crevice corrosion potential (CCP) compared to the critical pitting corrosion potential. The critical pitting corrosion potential and the repassivation potential shift to more cathodic values at 150 °C, but are still more anodic than the resting potential. Therefore, a good corrosion resistance can be concluded.

As already shown in NDB geothermal water, the nickel-based alloy NiCr23Mo16Al is the most resistant material. Here too, the critical pitting corrosion potential and the repassivation potential at 100 °C were within the transpassive range, far from the quiescent potential, which indicates that the alloy is capable of rapid repassivation. The critical crevice and pitting corrosion potentials determined in long-term tests were also far more anodic than the resting potential. The temperature increase shifts the critical pitting corrosion and repassivation potential in a cathodic direction, but only slightly. Rapid repassivation also occurs here.

In ORG geothermal water, only the nickel-based alloy and the super austenite offer sufficient corrosion resistance, while the duplex and super duplex steel only exhibit a certain resistance up to 100 °C.

For MB conditions, the critical potentials of the low-alloy steel were far enough away from the resting potential so that no critical corrosion rates were to be expected during operating fluctuations. The stainless steel X2CrNiMo17-12-2 showed large differences between quiescent and critical pitting potentials, which means that it is quite stable and therefore suitable. In LHD geothermal water, electrochemical methods showed that the resting potential of the material 25CrMo4 was in the critical range, indicating active conditions (i.e. corrosion) [9].

Low alloy steels showed good resistance to pitting corrosion due to the large difference between critical pitting potential and resting potential. However, the possibility of repassivation was limited. Therefore, special care must be taken during the process to prevent the onset of localized corrosion in these alloys. In acidic geothermal water, the poor repassivation behavior must be taken into account.

Conclusions

The corrosion behavior of various metallic materials can be assessed by means of aging and electrochemical tests in the laboratory. The following conclusions can be drawn from the test results obtained in various synthetic geothermal waters in the laboratory:

- Susceptibility to crevice corrosion was found to be the most important aspect for material qualification.

- The low-alloy steel 25CrMo4 showed uniform corrosion below the accepted threshold of 0.3 mm/year at low salinity in MB geothermal water. Therefore, it can be considered suitable for low salinity geothermal conditions as tested for MB. There is no need to switch to higher alloyed (more expensive) materials. Lower pH (as with LHD) results in corrosion rates above acceptable limits, so the low alloy materials are not suitable for low pH fluids.

- Highly saline geothermal waters require higher alloyed materials as the corrosion rate of low alloy steel is too high.

- The duplex steel X2CrNiMo22-5-3 and the super duplex steel X2CrNiMoCuWN25-7-4 were not considered suitable for geothermal applications in geothermal waters with a composition comparable to NDB and ORG due to their critical susceptibility to localized corrosion in the form of pitting and crevice corrosion under operating conditions.

- The super austenitic steel X1CrNiMoCu32-28-7 is suitable for ORG and low-salt waters. In NDB geothermal water it was considered suitable at 100 °C. However, its susceptibility to crevice corrosion limits its applicability. In addition to its good corrosion resistance, its repassivation behavior is responsible for its limited applicability in low pH geothermal waters.

- The nickel-based alloy NiCr23Mo16Al was found to be suitable and represents a safe option for use in geothermal plants, even when working with highly saline geothermal water.

Acknowledgments:

The results of this publication were obtained with the support of the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety and the German Federal Ministry of Education and Research.

Literature

[1] Bäßler R., Burkert A., Kirchheiner R., Saadat A., Finke M.: Evaluation of Corrosion Resistance of Materials for Geothermal Applications, NACE International Conference, Corrosion (2009), New Orleans, USA, paper 09377

[2] Regenspurg S., Feldbusch E., Saadat A.: Corrosion processes at the geothermal site Groß Schönebeck (North German Basin), NACE International Conference, Corrosion (2013), Orlando, USA, paper 2606

[3] Herzberger P., Münch W., Kölbel T., Bruchmann U., Schlagermann P., Hötzl H., Wolf L., Rettenmaier D., Steger H., Zorn R., Seibt P., Möllmann G.-U., Sauter M., Ghergut J., Ptak T.: The Geothermal Power Plant Bruchsal, Proceedings World Geothermal Congress (2010), Bali, Indonesia, paper 0619

[4] Mundhenk N., Huttenloch P., Schreiber J., Genter A., Zorn R., Kohl T.: Corrosion and scaling in the geothermal cycle of Soultz-sous-Forêts (France), NACE International Conference, Corrosion (2014), San Antonio, USA, paper 3897

[5] Sarmiento Klapper H., Bäßler R., Saadat A., Asteman H.: Evaluation of Suitability of Some High-Alloyed Materials for Geothermal Applications, NACE International Conference, Corrosion (2011), Houston, USA, paper 11172

[6] Keserovic' A., Bäßler R.: Material evaluation for application in geothermal systems in Indonesia, NACE International Conference, Corrosion (2013), Orlando, USA, paper 2269

[7] German Institute for Standardization (DIN): German Standard DIN 50905/4: "Corrosion of metals; corrosion testing; corrosion testing in liquids under laboratory conditions without mechanical stress", (1987)

[8] Stoljarova A., Bäßler R., Regenspurg S.: Influence of Precipitating Brine Components on Materials Selection for Geothermal Applications, Proceedings World Geothermal Congress (2020+1), Reykjavik, Iceland, paper 27003

[9] Keserovic' A., Bäßler R., Kamah Y.: Suitability of alloyed steels in highly acidic environments, NACE International Conference, Corrosion (2014) San Antonio, USA, paper 4031