Laser welding is a sensible alternative to conventional joining methods for e-mobility machining processes such as rotor welding or battery production due to its non-contact and precise machining technology.

However, highly reflective materials such as copper and aluminum are used. Their low surface absorption and high thermal conductivity make a special design of the laser system necessary in order to prevent scattered radiation and an increase in material temperature to over 80 °C, as welding generates a lot of heat.

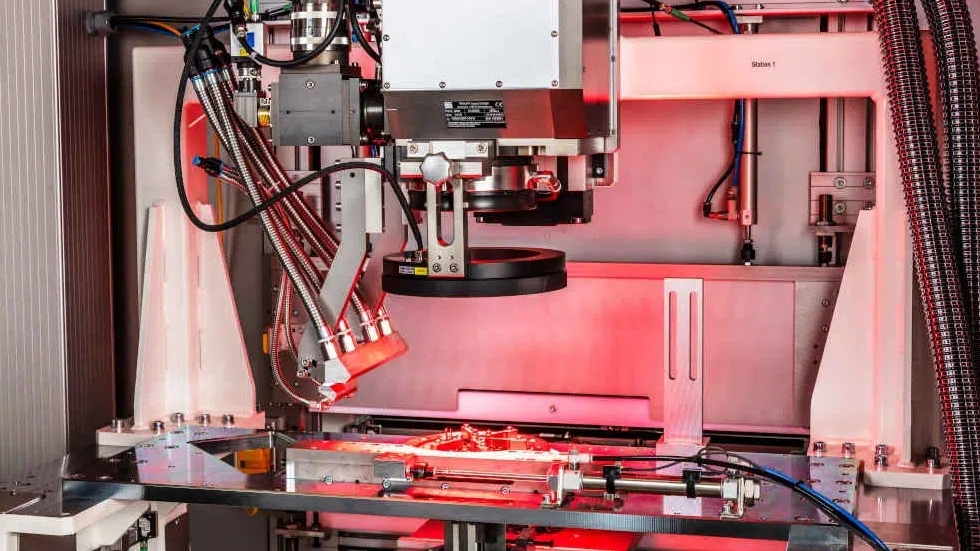

If this value is exceeded, the lithium in the battery, for example, can ignite and cause a fire or explosion. In addition to temperature control and a suitable laser, special optics with intelligent image processing are required so that the laser can reach all welding points without restriction despite the different types of battery. In order to meet all these requirements, LMB Automation GmbH develops, among other things, systems specially designed for laser welding the contact connections on batteries. They generally have an adapted housing design containing a combined movement unit with a fast, scanner-optics-based beam guidance system. This is supplemented by intelligent image processing and temperature probes.

In the manufacture of batteries, the connections between the battery cells at the electrodes must be welded in order to achieve higher performance. The main advantage of laser welding is the precise and short energy input, which significantly reduces heating of the surrounding material