The combination of newly functionalized aluminium surfaces with innovative copper printing opens up new optimisation potential for electromobility, printed electronics, power electronics, heating and cooling, LED lighting systems and renewable energies.

Advanced materials play a decisive role in the search for solutions for sustainable electromobility and resource efficiency. The companies Automoteam GmbH (Germany) and PrintCB (Israel) present the new multi-material system with new mechanical, electrical and thermal properties.

Copper has been the most widely used conductive material in electronics and communications for half a century. Nevertheless, despite its obvious advances, printing copper has been a major technological challenge for many years.

PrintCB is tackling the copper challenge with a completely new approach. Through advanced chemistry and materials science, the company has been able to develop CopPair, a platform that utilizes conventional printing technologies to print conductive copper at low drying temperatures and ambient conditions to overcome oxidation.

The ability to print copper at temperatures up to 110°C using traditional industrial processes and dry in hot air opens up new possibilities for combinations of printed electronics in plastics as well as other less sensitive materials.

Contradictory material properties

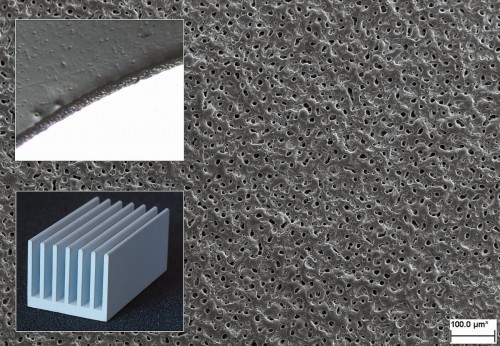

Metaker Surface is a process for the electro-plasma-chemical modification of light metal surfaces by dipping. The process transforms the surface layers of a workpiece into a new type of micro-composite material under electrolyte plasma and under the influence of millions of micro-arcs (Fig. 2).

Aluminum components with Metaker surface layers are microstructured, microporous, chemically activated, graded and multifunctional in a unique way. The following new surface properties of modified aluminum would be of interest for electromobility and renewable energies:

- Very good to extreme wear resistance

- Very good corrosion resistance

- Very good electrical insulation

- Very good thermal conductivity

- Very good heat radiation

- Very good light reflection or light absorption

- Microstructuring with very high specific surface area

- Microporosity, chemical activation and enormous compatibility with other materials

- Very good decorative properties.

Any aluminum components such as solid components, sheets, foils, layers, fabrics, wire, wire coils, open-pored foams and even water-resistant material hybrids with an aluminum component can be modified using the Metaker process. Their geometry can be as complex as desired.

The new material properties of aluminum edge layers allow the substitution of expensive aluminum alloys, steel, titanium, brass, bronze, PEEK or ceramics. At the same time, the functionality and efficiency of a wide range of products can be improved. Furthermore, such substitution makes the production processes independent of conventional, environmentally harmful surface technologies such as phosphating, anodizing, chromating, chromium plating, burnishing, cathodic dip coating, powder coating, electroless nickel plating, CVD, PVD and many others.

The Metaker process control system allows the production of hundreds of different property profiles. Some of these have been in series production since 2010, but most are still unknown and unexplored by the general public.

The technological combination of Metaker surfaces with innovative copper printing opens up a whole new field of application.

Copper printing on aluminum

The multifunctional, microporous, microstructured and chemically activated Metaker surfaces can be printed with copper inks using various processes.

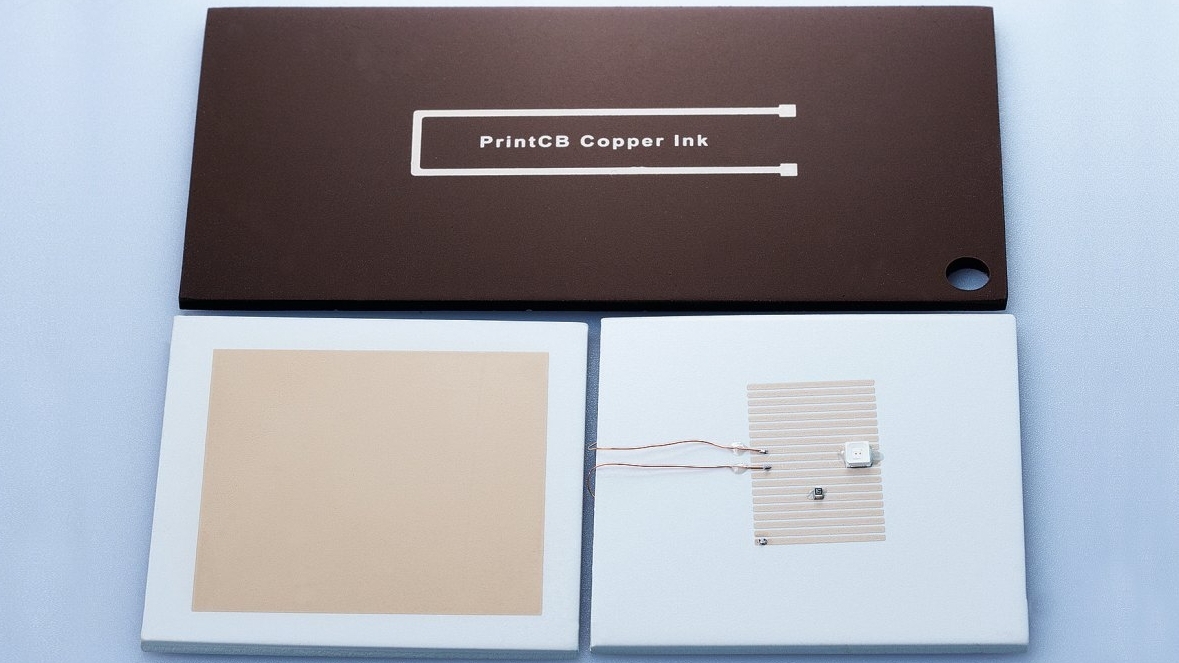

Fig. 2: The large image shows light microscope images of a Metaker surface. The small image above shows the cross-section of an aluminum part (white in the image) with a Metaker layer. Small picture below shows a modified aluminum heat sink Figure 1 shows various Metaker surfaces printed with PrintCB's copper ink. These surfaces are screen-printed and then dried at 140 °C, resulting in strong adhesion and good electrical conductivity of approx. 0.07 Ohm per square. The thermal conductivity of the copper-metaker composite was also evaluated and found to be in the range of 30-40 W/m*K. Soldering to copper ink was also demonstrated using Sn-Bi solder paste. The Metaker surfaces and the copper inks can be adapted to different applications.

Fig. 2: The large image shows light microscope images of a Metaker surface. The small image above shows the cross-section of an aluminum part (white in the image) with a Metaker layer. Small picture below shows a modified aluminum heat sink Figure 1 shows various Metaker surfaces printed with PrintCB's copper ink. These surfaces are screen-printed and then dried at 140 °C, resulting in strong adhesion and good electrical conductivity of approx. 0.07 Ohm per square. The thermal conductivity of the copper-metaker composite was also evaluated and found to be in the range of 30-40 W/m*K. Soldering to copper ink was also demonstrated using Sn-Bi solder paste. The Metaker surfaces and the copper inks can be adapted to different applications.

The sample on the right shows an arrangement of copper tracks printed on a white, decorative Metaker substrate including soldering of wires and LED.

The example on the left shows a 50 x 50 mm copper surface printed on a white decorative Metaker substrate. This example demonstrates a potential Thermal Interface Material (TIM) for application in power electronics. Such a surface can be soldered to attach power devices. Thermal measurements performed on this surface showed a thermal conductivity of 30-40 W/m*K.

The combination of copper and functionalized aluminium opens up new possibilities and uses the best of these two technical materials. Aluminum is a lightweight, low-cost metal with high thermal conductivity and is the metal of choice for the automotive industry. However, bonding to aluminum is challenging due to its native oxide. The functionalization of aluminum can help overcome this challenge.

Printing conductive copper enables cost-effective production of circuits, electrodes, pads and conductive surfaces for a variety of applications. The ability to solder power electronic devices such as LEDs, inverters and others onto a copper surface printed on aluminum ensures excellent heat dissipation and opens up many new possibilities in the design of next-generation power electronics in electric vehicles and renewable energy.

Innovation development

With the help of the new technologies, existing products and processes can be optimized and disruptive product and process innovations can be developed in a wide range of technical fields. Intelligent hybrid solutions with Metaker surfaces and copper are developed and realized in cooperative collaboration between specialized partners from science, industry and services. They are designed for specific applications and developed from functional prototypes in several iterations through to series production.

Before a project idea can be developed, interdisciplinary development teams need a holistic understanding of the technology. The new knowledge is imparted to interested companies in customer-specific technology workshops.