Smart networking can reduce companies' electricity requirements by up to 80%, according to industry associations. Integrated IoT concepts not only reduceCO2 emissions, but also energy-related operating costs. The latest low-power wireless area network (LPWAN) mobile radio standards for machine-to-machine communication are therefore deliberately tailored to energy efficiency. For a better understanding of the abbreviations used, please read the background information in the box.

Even without the crisis, energy has always been a decisive cost factor for companies. The dena speaks of price increases for electricity, natural gas and heating oil for industry of 160 to 490 % between 1999 and 2014 [1]. In a survey conducted by the Family Business Foundation, 82% of the companies surveyed therefore stated that they wanted to invest in energy efficiency or had already done so [2].

Even without the crisis, energy has always been a decisive cost factor for companies.

According to the Federal Statistical Office, the bottom line is that the energy consumption of industrial companies increased by 15% between 2003 and 2021 [3]. According to Destatis data [3], German industry consumed 918 petajoules of energy in 2021. This was 4.6% more than in 2020 and 2.6% more than in 2019. 88% of this was used to generate electricity and heat. The remaining 12% was used as a raw material for the manufacture of products such as chemicals, fertilizers or plastics. At 21%, electricity in particular is the most important energy source after natural gas (30%). However, electricity is around four times more expensive than natural gas (Fig. 1).

INFO

Background information

- The 3rd Generation Partnership Project (3GPP) is a global cooperation of standardization bodies for standardization in mobile communications; specifically for UMTS, GSM, LTE and 5G/NR. The 3GPP was founded on December 4, 1998 by five Organizational Partners.

- eSIM is the abbreviation for Embedded Subscriber Identity Module. eSIMs are based on eUICC technology and are usually integrated as a fixed chip on the circuit board. However, SIM cards with conventional form factors can also have eSIm functionality with OTA provisioning.

- eUICC is the abbreviation for Embedded Universal Integrated Circuit Card and refers to the software with which tariffs can be provided on an eSIM with the mobile network, e.g. new tariffs or updates.

- LPWAN stands for Low Power Wide Area Network and comprises various mobile radio transmission standards that are intended exclusively for industrial use.

- LTE-M is the abbreviation for Long Term Evolution for Machines. It is a mobile communications standard that is particularly energy-efficient and intended for industrial use.

- NB-IoT is the abbreviation for Narrowband Internet of Things and refers to a mobile communications standard that is the most energy-efficient alternative for transmitting small amounts of data of up to 5 MB per month.

- OTA is the abbreviation for Over the Air. In the context of mobile communications standards, OTA offers the option of transferring tariffs and transmission standards contactlessly via the existing mobile network on eSIMs.

Savings potential in building automation

Of course, energy consumption also depends on production volumes, the type of products manufactured and the technologies and raw materials required. However, regardless of the industry in question, factory buildings are a fixed cost factor. According to dena, non-residential buildings account for around 36% of the energy consumption of all buildings in Germany. "It is not always worth the effort to completely restore the outer shell or it is not technically feasible," says Dennis Paul, Head of IoT Projects at Wireless Logic mdex GmbH. "Networking building functions can nevertheless open up considerable energy-saving potential by making resources and functions available as required."

This is based on measures that seem simple at first glance. The heating of large factory halls, for example, is particularly inefficient due to the size of the room: there are temperature differences of 10 degrees or more between the hall floor and ceiling due to the rising heat. These transmission losses can be largely avoided by installing industrial fans to recirculate warm air.

In industrial halls in particular, building ceilings tend to heat up. At a room temperature of 14 °C near the floor, the hall ceiling quickly heats up to 26 °C due to rising heat, calculates fan manufacturer Fenne KG [4]. With appropriate ceiling fans, the room air near the floor can be raised by 5 degrees without additional heating. This reduces heating costs by around 30 %. Fans become particularly cost and energy efficient when they are networked and their function is constantly optimized by collecting sensor data. The hall can only be fully heated during operating times using an intelligent operation control system. The fans shorten the required pre-heating and extend the night setback time.

In an assembly hall at the Volkswagen plant in Emden, for example, 20 ventilation systems were optimized, resulting in electricity savings of 80 %. At the heart of this was the use of frequency converters and measurement and control technology to operate the ventilation system in line with demand. With an investment of 1.4 million euros, Volkswagen was able to achieve savings of 1 million euros per year [5]. Electricity consumption fell by 7.1 GWh.

Light monitoring for smart lighting systems

Lighting in companies is particularly important, regardless of the sector. It is estimated that up to 15 % of a company's total costs are caused by inadequate and inappropriate use of light sources [6]. It is known that an LED saves around 15 euros in electricity costs per year compared to a 60 watt incandescent lamp. In addition, however, needs-based lighting saves energy, particularly in delivery zones, workplaces and traffic routes. On the one hand, the temporary use of lighting can be implemented through the simple use of light-sensitive sensors or motion detectors. The calculation of optimized walking and traffic routes also plays a role in the IoT approach.

It is known that an LED saves around 15 euros in electricity costs per year compared to a 60 watt light bulb

This leads to the concept of light monitoring, which adapts a networked lighting system to fixed schedules, shifts, presence or times of day. The room lighting can be dimmed automatically depending on the amount of daylight or activity in the room. In addition, the energy consumption of each individual luminaire can be collected in a data pool and evaluated via a dashboard. Presence sensors show which areas are unnecessarily illuminated during operation. In addition, light monitoring provides valuable data for predictive maintenance of the lighting and uses the performance data of each individual light point to signal the need for replacement and repair at an early stage.

Even by simply replacing and repositioning energy-saving fluorescent tubes, Würzburger Verkehrsbetriebe (WVV) was able to significantly reduce the electricity consumption of the company's own underground car park. On the one hand, the old fluorescent tubes were replaced with 116 more energy-efficient and better-positioned neon tubes. The decisive factor, however, was the use of electronic ballasts with 10 to 20 % less power loss. These ballasts are networked with sensors and dim the lighting as required: When there are no vehicles or people moving in the underground garage, the lamps are reduced to 10% of their light intensity. These measures have enabled WVV to save 76% on electricity costs per year and increase the service life of the lamps threefold [7].

Intelligent networking as a starting point

Networking buildings, systems and end devices with the control centre makes it possible to use machine learning to optimize usage profiles, demand times and routes. In addition, necessary maintenance can be predicted and thus personnel and material deployment can be optimized.

"The core of energy-saving measures is the needs-based use of resources," says Dennis Paul. "This includes the timely provision of energy-intensive resources and corresponding forecasting models. Comprehensive company networking via mobile communications makes it possible to connect the relevant machines, systems and buildings." With 4G, 5G and various LPWAN technologies, there are now numerous mobile communications standards for setting up industrial IoT environments. "It doesn't matter whether it's a system in the open field or an end device hidden deep in the core of a building," says Dennis Paul. "There is tailor-made connectivity for every required data volume, latency requirement or indoor penetration."

LPWAN as an energy-saving IoT alternative

The latest technology is 5G, which enables transmission rates of more than 1 Gbit/s in the high-band frequency of 3.6 GHz and can transmit at least twice the amount of data compared to 4G. Despite the short range of between 300 and 1000 meters per radio cell in this frequency range, this technology is particularly useful for limited, private company networks. For time-critical control of production facilities, autonomous factory traffic or transportation systems in particular, 5G makes sense due to the low latency of less than one millisecond in the high band.

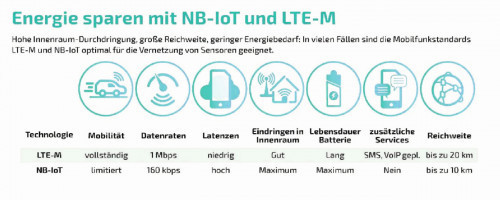

In contrast, 4G, a mobile technology originally designed for consumers, achieves transmission rates of no more than 500 Mbit/s with latencies of between 15 and 80 ms. Today, most IoT applications can be easily implemented via 4G. However, 4G is not optimized for industrial purposes and, in particular, is not energy-efficient. The new LPWAN technologies are specifically designed for communication between machines and systems. The standardization committees had industrial application scenarios and minimal power consumption in mind. The LPWAN standards LTE-M and NB-IoT are part of the 4G network and therefore have the widest network coverage (Fig. 2).

Fig. 2 (Graphic: Wireless Logic mdex GmbH)

Fig. 2 (Graphic: Wireless Logic mdex GmbH)

NB-IoT and LTE-M are consistently trimmed for energy efficiency. This means that the battery life in networked sensors, for example, can be up to 10 years. This is made possible by two key technologies. Extended discontinuous reception (eDRX) switches the device off between receiving data, even over longer periods of time. In addition, the Power Saving Mode (PSM) can shut down the radio module completely. However, the device does not have to reconnect to the network when it is switched on again.

However, NB-IoT is only suitable for sporadic transmission of small amounts of data up to approx. 5 MB per month, where high latencies of between 1.6 and 10 seconds can be tolerated. The maximum data transfer rate of NB-IoT is only approx. 128 Kbit/s. However, this is often perfectly adequate for transmitting silo fill levels, temperatures or consumption data. Due to its high indoor penetration and low susceptibility to interference, NB-IoT is particularly suitable for smart metering, parking lot monitoring and building management. In addition, up to 50,000 sensors or end devices can be addressed per radio cell.

Fig. 3 (Graphic: Wireless Logic mdex GmbH)

Fig. 3 (Graphic: Wireless Logic mdex GmbH)

The disadvantage of NB-IoT is that there is no handover between the radio cells and it is therefore only suitable for stationary use. The standard is therefore not suitable for mobile applications with higher data throughput. LTE-M meets the need for more powerful data connections with simultaneous mobility. This LPWAN technology offers a data rate of up to 1 Mbit/s with latencies of between 10 and 15 milliseconds. Similar to NB-IoT, LTE-WAN uses the energy-saving technologies eDRX and PSM. This means that LTE-M is almost as economical in terms of power consumption as NB-IoT and has a similar building penetration. In the future, LTE-M will also support voice transmission (VoLTE). This makes the standard suitable for higher-value applications such as elevator emergency call systems, where indoor penetration and near real-time data transmission are required (Fig. 3).

Old SIM cards as a bottleneck

With the new transmission technologies and intelligent, demand-oriented IoT networking, energy can already be saved to a considerable extent. However, conventional SIM chips on plastic cards are not only susceptible to moisture and vibrations, but also have to be replaced manually when operators and tariffs change. The manpower and travel required for on-site service, for example when equipping local network stations or smart meters, is immense.

With the eUICC technology (Embedded Universal Integrated Circuit Card) of eSIM chips, however, it is possible for the first time to avoid manual maintenance. The eSIMs, which are only 6 x 5 mm in size, are already permanently installed on the circuit boards of the end devices, are resistant to moisture and vibrations and are therefore perfect for networking in production and warehouse logistics and for mobile applications. The highlight, however, is future-proofing: the data connection can be imported and managed over-the-air with eSIMs. This means that a change of operator can be carried out without physical effort and is therefore energy-neutral.

"The problem is that the uncomplicated change of operator is not in the interest of mobile phone providers," explains Dennis Paul. "All mobile phone companies offer eUICC technology and eSIMs. However, in the event of a change of operator, a traditional mobile phone company either does not provide support at all, charges for it or excludes it from the outset by contract." This eliminates a key advantage of eUICC technology: the contactless provision of mobile connections over the air.

"This is exactly where the Conexa virtual mobile network comes in," explains Dennis Paul. "With Conexa, Wireless Logic mdex offers all network standards and operators with just a single contract. This includes OTA provisioning, management and ongoing advice on the optimum data connection, without having to replace the SIM card stock as in the past."

This has considerable advantages in terms of energy consumption, especially for OEM manufacturers operating internationally. Instead of having to install a different SIM card in the end product for each sales territory, just one is sufficient. The eSIM chip or the eUICC-capable SIM card is supplied with a preconfigured profile, which is used to provide the desired tariff via this mobile connection on site. Conexa and the integrated SIM management portal can then be used to monitor all mobile connections in terms of on-SIM and on-device behavior, performance and costs via a single user interface.

As Conexa is a full-service solution, the most energy and cost-efficient connectivity is available depending on the area of application, without being tied to a provider or having to provide internal resources for connectivity management. "The eUICC in conjunction with a Conexa virtual mobile network not only saves energy, but also that of the responsible employees," says Dennis Paul.

Sources and literature

[1] German Energy Agency (dena), https://www.dena.de/themen-projekte/energieeffizienz/unternehmen/

[2] Cf.: Family Business Foundation, Energy Survey, https://www.familienunternehmen.de/de/pressebereich/meldungen/2022/2022-10-24/energiepreisumfrage

[3] Cf. Federal Statistical Office, https://www.destatis.de/DE/Themen/BranchenUnternehmen/Energie/Verwendung/_inhalt.html

[4] Cf. Fenne KG; https://fenne-kg.de/warmluft-rueckfuehrung/

[5] Cf. dena, https://www.dena.de/newsroom/publikationsdetailansicht/pub/broschuere-energieeffizienz-inkleinen-und-mittleren-unternehmen/

[6] Cf.: Saxonia, https://www.saxonia-licht.de/energie-sparen-in-der-industrie/

[7] Saving energy in the workplace, https://www.energieeffizienz-im-betrieb.net/energiesparen-betrieb/energiesparhallenbeleuchtung.html