Together with other project partners, the Fraunhofer Institute for Solar Energy Systems ISE has developed a technical plant concept and a design for a hydrogen production plant optimized for use at sea. The results show that hydrogen production directly at sea with a PEM electrolyzer is technically and economically feasible. The work was carried out as part of the two-year "OffsH2ore" project funded by the German Federal Ministry for Economic Affairs and Climate Protection (BMWK).

Green hydrogen from renewable energies plays a key role in achieving climate targets. Hydrogen produced from offshore wind energy can help to meet future hydrogen demand and contribute to the diversification of the hydrogen supply. In the "OffsH2ore" project, the project partners PNE, Silica Verfahrenstechnik, Wystrach, Kongstein and Fraunhofer ISE developed a technical plant concept for offshore hydrogen production in conjunction with a ship-based transportation concept for compressed hydrogen. In addition, concepts for operation, logistics and plant design were developed and the overall concept was subjected to a techno-economic analysis. Scientists from Fraunhofer ISE contributed their expertise and research achievements in the fields of modular PEM electrolysis systems and the design of balance-of-plant components, seawater desalination using waste heat from electrolysis, power electronics and techno-economic analysis.

The team developed a blueprint for a 500 MW offshore hydrogen production platform including a transportation concept for compressed hydrogen, a detailed technical concept and a techno-economic analysis. They showed that offshore hydrogen production with PEM electrolysis is technically and economically feasible and contributes to the diversification of European hydrogen production.

Such offshore hydrogen production on the scale of 500 MW has not yet been realized. With the concept presented by the consortium, rapid and large-scale implementation has become realistic.

Project partners from the entire value chain

In addition to Fraunhofer ISE, the consortium included PNE AG as project coordinator, an international project developer and operator of renewable energy plant projects; Silica Verfahrenstechnik GmbH, an engineering and plant construction company; Kongstein GmbH, which provides consulting services for offshore wind and hydrogen technologies, and Wystrach GmbH, a supplier of high-pressure hydrogen storage systems. The "OffsH2ore" project brought together an experienced and complementary consortium of industrial partners and scientists from the entire value chain.

Hydrogen production without land use competition

"Green hydrogen produced sustainably from renewable energies will become an important pillar for the defossilization of our energy systems. For countries like Germany, where the large-scale production of green hydrogen is already a challenge due to land use competition, for example, hydrogen production at sea with the help of offshore wind energy is an additional option," explains Marius Holst, who was in charge of coordinating the work packages for Fraunhofer ISE. "Hydrogen production at sea simultaneously offers high full-load hours and the opportunity to cover the entire value chain at national level, while at the same time decoupling offshore wind expansion and grid expansion," continues Holst.

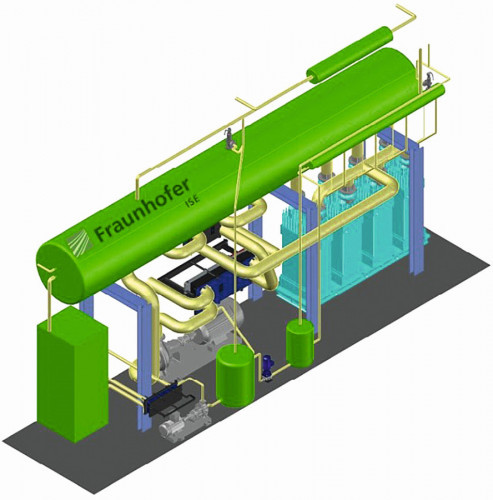

Scientists at Fraunhofer ISE have designed an electrolysis system as part of the OffsH2ore project (Photo: Fraunhofer ISE)

Scientists at Fraunhofer ISE have designed an electrolysis system as part of the OffsH2ore project (Photo: Fraunhofer ISE)

The concept is based on an offshore wind farm that is directly connected to a 500 MW electrolysis platform. This can produce up to 50,000 tons of green hydrogen per year. The system has a scalable, modular design that can be easily adapted to different hydrogen production capacities. The fresh water for the PEM electrolyzer is provided by desalinating seawater, using the waste heat from electrolysis. The hydrogen produced is purified and dried, compressed to up to 500 bar and transferred to a transport ship. The ship delivers up to 400 tons of hydrogen per transport from the offshore platform to land. This concept is independent of hydrogen transport pipelines and offers flexibility in the choice of location.

PEM electrolysis offshore is technically and economically feasible

ISE's work packages included the projection of a proton exchange membrane (PEM) electrolysis module. The scientists showed that offshore hydrogen production with PEM electrolysis is technically and economically feasible. "PEM electrolysis is the preferred technology for the offshore environment. With this electrolyser, we can react appropriately to the limited space available on the platform and take advantage of the dynamic operating behavior of this electrolysis variant," explains Anna Wunsch, who supervised this work package and calculated the technical design of the system. With PEM electrolysers, operators can react quickly to fluctuations in the energy supplied and also operate the electrolyser at partial load without any problems.