The following article is dedicated to the provision of renewable heat in surface treatment companies, with a focus on the provision of solar process heat.

Starting with a presentation of the necessity of this topic, the authors discuss the potential of solar thermal heat supply in industry as well as trade, commerce and services. The broad field of application and possible heat sinks are discussed below, before the technical background on the design and operation of a solar thermal system is presented. The integration of renewable heat in particular represents a major challenge, which is why the authors also discuss this in detail. In addition to the technical issues, the economics must also be right. The information on subsidies and turn-key costs leads to the calculation of solar heat production costs and the contracting business model. In the section on preliminary design and feasibility assessment, the reader learns how a system should actually be sensibly designed, before current market developments and best-practice systems are presented.

Introduction

The energy supply in Germany has been undergoing a massive transformation since the turn of the millennium. In the coming years and decades, the current path of a coal, gas and nuclear-based energy supply must be fundamentally changed towards a renewable energy supply. The previous concept of fossil energy supply is increasingly giving way to a decentralized and renewable energy supply. In recent years, discussions and transformation processes have focused heavily on the electricity sector. Wind turbines and photovoltaic systems dominate the landscape. Despite the ongoing debate about the pros and cons of individual technologies and whether climate protection targets have been achieved or missed, the energy transition in the electricity sector can be considered a success overall. In 2017, for example, one third of electricity was already supplied from renewable sources. However, a cross-sectoral view of German energy consumption reveals that electricity only accounts for around 20 % of total energy consumption.

Heating sector consumes the largest share of energy

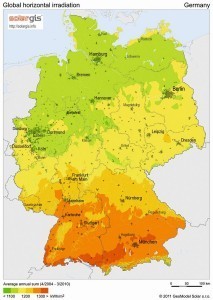

Fig. 1: Irradiation map for GermanyMorethan 50 % of energy consumption in Germany is attributable to the heat supply. Despite this enormous relevance of the heating sector, the urgently needed start of the heating transition has been overslept. Not waking this sleeping giant is particularly fatal in view of the fact that electricity can be generated, transported and distributed throughout Germany or even Europe, meaning that all electricity consumers are consuming more and more green electricity without any action on their part. However, heat must be generated locally, which means that companies from industry and commerce in particular have an individual responsibility to ensure that their own heat supply is aslow in CO2 emissions as possible in the coming years. German industry alone requires more than 520 TWh of heat per year, which is roughly equivalent to the total electricity consumption in Germany. Currently, this heat is provided almost exclusively by fossil fuels. Renewable heat generation is largely restricted to the limited fuel biomass, which has a very broad field of application, but should be used for more demanding applications (transport sector, high-temperature heat) in the future. However, mature technologies for renewable process heat are already in the starting blocks. Solar thermal energy and heat pumps can provide the heat required below 150 °C without emissions and at lower prices than fossil fuels. A possible futureCO2 tax will increase the pressure to switch to a production infrastructure that is as climate-friendly as possible. With its high heat demand below 100 °C, the surface industry is a particularly suitable sector for the use of renewable process heat.

Fig. 1: Irradiation map for GermanyMorethan 50 % of energy consumption in Germany is attributable to the heat supply. Despite this enormous relevance of the heating sector, the urgently needed start of the heating transition has been overslept. Not waking this sleeping giant is particularly fatal in view of the fact that electricity can be generated, transported and distributed throughout Germany or even Europe, meaning that all electricity consumers are consuming more and more green electricity without any action on their part. However, heat must be generated locally, which means that companies from industry and commerce in particular have an individual responsibility to ensure that their own heat supply is aslow in CO2 emissions as possible in the coming years. German industry alone requires more than 520 TWh of heat per year, which is roughly equivalent to the total electricity consumption in Germany. Currently, this heat is provided almost exclusively by fossil fuels. Renewable heat generation is largely restricted to the limited fuel biomass, which has a very broad field of application, but should be used for more demanding applications (transport sector, high-temperature heat) in the future. However, mature technologies for renewable process heat are already in the starting blocks. Solar thermal energy and heat pumps can provide the heat required below 150 °C without emissions and at lower prices than fossil fuels. A possible futureCO2 tax will increase the pressure to switch to a production infrastructure that is as climate-friendly as possible. With its high heat demand below 100 °C, the surface industry is a particularly suitable sector for the use of renewable process heat.

Potential for renewable process heat

Solar thermal collectors convert incident solar radiation into usable heat. Figure 1 shows the total annual irradiation in Germany, which averages around 1,200 kWh/(m2a). As the figure makes clear, the radiation potential shows a slight north-south gradient, even if the differences are only in the region of 10 %. The slightly lower irradiation values in the north-west are still sufficient for solar thermal systems to be used sensibly throughout Germany. In areas near the equator, the annual irradiation sum can be significantly higher at up to 2700 kWh/(m2a). In contrast to photovoltaic systems, thermal solar collectors use the entire radiation spectrum, which is reflected in higher specific yields.

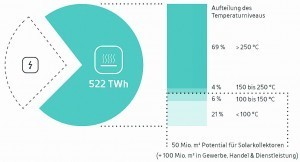

Around 750 TWh of energy was required in German industry in 2017 (BMWi, 2018). Figure 2 illustrates that only a quarter of this is attributable to electricity, while around three quarters was used to provide heat. Much of this heat is required at a relatively high temperature level above 250 °C, which is due to the great importance of heavy industry in Germany. Although the heat in this temperature range can theoretically be provided using solar thermal energy, this would require concentrating solar collectors, which make little sense in Germany from a technical and economic perspective. The same applies to the temperature range between 150 and 250 °C. For the use ofCO2-free heat supply technologies, the focus should therefore be on the temperature range below 150 °C, which accounts for more than a quarter of industrial heat demand. Taking into account efficiency measures, limited (roof) space for collectors and the divergence between heat demand and solar radiation supply, there is a potential of 50 millionm2 of collector area in Germany. If the heat demand in the trade, commerce and services sector is also taken into account, there is a further 100 millionm2 of potential to be tapped. At first glance, this may seem like a mammoth task, but a comparison with other orders of magnitude shows that these are quite realistic dimensions. In Germany, for example, opencast lignite mines cover an area of 2,300 millionm2 (BMU 2006) and even freeways cover an area of 570 millionm2 (ADAC n.d.). As already mentioned at the beginning, the electricity sector is well ahead of the heating sector. To date, around 450 millionm2 of PV collectors have already been installed.

Fig. 2: Breakdown of electricity and heat demand in German industry as at: 2017

Fig. 2: Breakdown of electricity and heat demand in German industry as at: 2017

According to the German government's targets, at least 50 % of the total heat consumed should come from renewable sources by 2050. In view of the Paris Climate Agreement, even this does not seem ambitious enough. Nevertheless, the share of renewable technologies in heat consumption in Germany has been stagnating at a low double-digit level (currently 13 %) for years. The majority of this is accounted for by biomass combustion, whereby the already limited biomass potential in Germany is being reduced even further due to competition for space (food) and use (e.g. liquid fuels). Heat pumps will also make their contribution in the future, but it must be emphasized here that they will only reduceCO2 emissions if electricity from renewable energies is used and a suitable heat source is available. Renewable electricity for direct heating should only be used for the high-temperature range. Solar thermal systems can be used sensibly with all the technologies mentioned and can also be combined with CHP systems. In the future, a successful heat transition will depend on the right mix of technologies in integrated heat supply systems.

One advantage over photovoltaic systems for electricity generation is the fact that solar thermal systems are regarded as efficiency measures and therefore do not incur any administrative costs. Neither the installation and commissioning of a solar thermal system has to be registered, nor do solar yields have to be transmitted to a central office.

Industries and areas of application

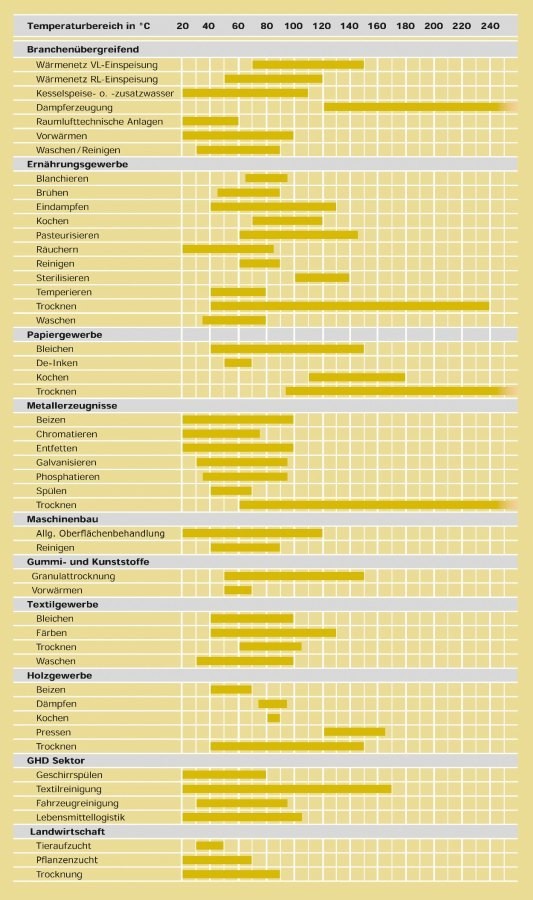

Solar process heat can be used in many different ways. Applications and processes with a suitable temperature level can be found in almost all industries. Figure 3 provides an overview of some particularly relevant industrial sectors in Germany and the respective processes with significant heat requirements.

Fig. 3: Overview of industries and relevant processes with temperature range

Fig. 3: Overview of industries and relevant processes with temperature range

There are many suitable processes in surface technology companies that can be heated using solar thermal energy. Heated baths (e.g. for any spraying or dipping process), which are found particularly in electroplating but also in other sectors for pre- and post-treatment, offer very good framework conditions. In addition, the ventilation systems should always be kept in mind. Although the temperature level here is very low, the enormous air requirement often results in considerable heat consumption. In almost all companies in the surface treatment industry, there is a dryer at the end of the process chain. Here too, solar heat can be integrated very efficiently, either by using air collectors to generate warm air directly or by using water-guided collectors in conjunction with an air-water heat exchanger to heat the drying air. If drying takes place via ventilation systems, a further heat exchanger can be integrated into the system itself or a solar heat exchanger can be integrated into the conventional heating circuit. Last but not least, solar heat can be used to provide hot water, e.g. for any cleaning and washing processes. In addition, excess heat can be used for space heating purposes at any time during the heating period so that no heat is lost.

Technology

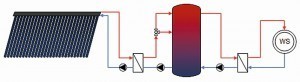

Fig. 4: Diagram of a solar thermal system for supplying a heat sink (WS) with the most important components collector and buffer cylinder. Pumps, heat exchangers and a three-way valve are also shown The solar thermal system is only ever a "fuel saver". This means that it does not replace conventional boiler output, but only reduces the running time of the boiler and thus the use of fossil fuels. The conventional heating system is still required in any case as a backup for periods of low radiation. However, depending on the size of the solar thermal system and the design of the components, the final energy consumption (gas, wood, oil, electricity, etc.) is typically reduced by 20 to 50 %.

Fig. 4: Diagram of a solar thermal system for supplying a heat sink (WS) with the most important components collector and buffer cylinder. Pumps, heat exchangers and a three-way valve are also shown The solar thermal system is only ever a "fuel saver". This means that it does not replace conventional boiler output, but only reduces the running time of the boiler and thus the use of fossil fuels. The conventional heating system is still required in any case as a backup for periods of low radiation. However, depending on the size of the solar thermal system and the design of the components, the final energy consumption (gas, wood, oil, electricity, etc.) is typically reduced by 20 to 50 %.

The basic structure of a solar thermal system is shown in Figure 4. The heart of the system is the collector, which, together with a heat storage tank, can provide a considerable proportion of the heat requirementCO2-free, especially in the summer months. The functional principle of a solar thermal system is always the same. The solar radiation is converted into heat in the collector by the absorber. This heat is then transferred to the heat transfer fluid in the solar circuit. For frost protection reasons, a glycol-water mixture is usually used. In cases where frost-free conditions can be guaranteed due to the ambient conditions or an active heating system, there are now sophisticated systems on the market that use water as the medium. This results in a corresponding reduction in costs. In the case of very high collector temperatures, thermal oil can also be used in the collector circuit. In addition to the collector, a buffer cylinder is usually required, as the solar radiation supply rarely coincides with the heat demand. With the help of a storage tank, solar heat can be stored, for example, during the day for the night or at the weekend for the next working day, so that high solar coverage rates can be achieved despite the temporal shift between irradiation and demand. In most cases, water storage systems are used, which are particularly cost-effective and environmentally friendly compared to other energy storage technologies. Water storage tanks are operated unpressurized up to 95 °C or pressurized up to 120 °C and are available on the market with virtually any storage volume. Due to the different media (glycol-water mixture in the collector circuit and water in the storage circuit), the storage tank and collector are usually hydraulically separated by a heat exchanger.

If water is used as the heat transfer medium in the solar circuit, the heat exchanger can be dispensed with. Three-way valves in the flow allow temperature-dependent stratification of the solar heat. A heat exchanger is also usually installed between the storage tank and the heat sink. This enables the controlled and demand-based heating of the distribution medium on the heat sink side, as the capacity flows can now be specifically regulated on both sides of the heat exchanger. Depending on the application, the fluid on the heat sink side can also be an acid or alkali, which also makes hydraulic separation necessary.

Selection of a suitable collector

Fig. 5: Suitable collectors with the respective temperature range for the provision of solar process heatThetemperature that a solar thermal system is to provide isdecisivefor the selection of a suitable collector. The higher the required temperature, the more complex the design of the collector must be. Uncovered collectors, such as those used in outdoor swimming pools or for pool heating, do not play a role in industrial applications due to the low possible temperature level. Thanks to their simple design, flat-plate collectors are particularly cost-effective and the method of choice for low temperatures and preheating processes. Temperatures of up to 80 °C can be achieved with standard flat-plate collectors (see Fig. 5). With the help of a double transparent cover, the heat losses of flat-plate collectors can be reduced and temperatures of up to 110 °C can be provided efficiently. Vacuum tube collectors use the insulation principle of a thermos flask to reduce heat losses, allowing even higher temperatures to be provided than in flat-plate collectors. Depending on whether this type of collector is fitted with a mirror on the back (CPC collector) or not, the sensible application range for these collectors is between 80 ... 150 °C. These collectors are particularly interesting for the industrial sector, as new developments enable very low roof loads. The individual tubes can be rotated individually so that they can be perfectly aligned to the south regardless of the roof orientation. This avoids the usual need for the collectors to be tilted, resulting in lower wind loads, which are generally more problematic than the static loads of the collector itself when checking the load-bearing capacity of the building. Concentrating collectors work on the principle of a burning glass. They are continuously aligned in the direction of the sun, bundle the incoming sun rays at the focal point on the absorber and can therefore provide temperatures of up to 400 °C. However, as these collectors can only use direct solar radiation and a large proportion of the radiation arriving in Central Europe is diffuse, concentrating collectors are more suitable for Southern Europe.

Fig. 5: Suitable collectors with the respective temperature range for the provision of solar process heatThetemperature that a solar thermal system is to provide isdecisivefor the selection of a suitable collector. The higher the required temperature, the more complex the design of the collector must be. Uncovered collectors, such as those used in outdoor swimming pools or for pool heating, do not play a role in industrial applications due to the low possible temperature level. Thanks to their simple design, flat-plate collectors are particularly cost-effective and the method of choice for low temperatures and preheating processes. Temperatures of up to 80 °C can be achieved with standard flat-plate collectors (see Fig. 5). With the help of a double transparent cover, the heat losses of flat-plate collectors can be reduced and temperatures of up to 110 °C can be provided efficiently. Vacuum tube collectors use the insulation principle of a thermos flask to reduce heat losses, allowing even higher temperatures to be provided than in flat-plate collectors. Depending on whether this type of collector is fitted with a mirror on the back (CPC collector) or not, the sensible application range for these collectors is between 80 ... 150 °C. These collectors are particularly interesting for the industrial sector, as new developments enable very low roof loads. The individual tubes can be rotated individually so that they can be perfectly aligned to the south regardless of the roof orientation. This avoids the usual need for the collectors to be tilted, resulting in lower wind loads, which are generally more problematic than the static loads of the collector itself when checking the load-bearing capacity of the building. Concentrating collectors work on the principle of a burning glass. They are continuously aligned in the direction of the sun, bundle the incoming sun rays at the focal point on the absorber and can therefore provide temperatures of up to 400 °C. However, as these collectors can only use direct solar radiation and a large proportion of the radiation arriving in Central Europe is diffuse, concentrating collectors are more suitable for Southern Europe.

Special case of air collectors

Air collectors are a special case. These do without a liquid heat transfer medium and use air instead, which completely changes the system design. The collectors are suitable wherever large quantities of warm air are required, e.g. for drying or ventilation applications. They are available as flat-plate (up to 80 °C) or tube collectors (up to 180 °C). Although it is possible to store the hot air, this is usually only possible with great effort. Air collectors are characterized by low system costs and high specific yields.

- to be continued -

Literature

[1] ADAC, n.d., Share of roads in Germany in the total area of the country in 2014, Statista, accessed May 7, 2019, available at https://de.statista.com/statistik/daten/studie/163401/umfrage/anteil-der-strassen-in-deutschland-an-der-gesamtflaeche/

[2] Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, Energy Policy 20 Years after Chernobyl, Documentation of the Conference Chernobyl 1986-2006: Experiences for the Future, Berlin, April 24-25, 2006

[3] Federal Ministry for Economic Affairs and Energy, Facts and Figures Energy Data, 2018

[4] Federal Ministry for Economic Affairs and Energy, Prozess wärme aus erneuerbaren Energien: Umsteigen und von Förderung profitieren, available at https://www.deutschland-machts-effizient.de/KAENEF/Redaktion/DE/Foerderprogramme/energieeffizienz-in-der-wirtschaft-modul-2-prozesswaerme.html, accessed on May 14, 2019

[5] Federal Network Agency, Federal Cartel Office, n.d., Gas prices* for commercial and industrial customers in Germany in the years 2008 to 2018 (in euro cents per kilowatt hour), Statista, available at https://de.statista.com/statistik/daten/studie/168528/umfrage/gaspreise-fuer-gewerbe-und-industriekunden-seit-2006/, accessed on May 14, 2019,

[6] Association of German Engineers, VDI 3988, Solar thermal process heat (green print), Beuth Verlag, Berlin, 2018