The following article is dedicated to the provision of renewable heat in surface treatment companies, with a focus on the provision of solar process heat.

The temperature is crucial

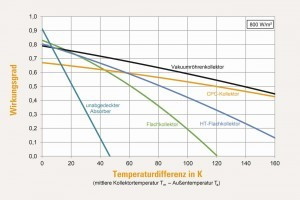

Fig. 6: Exemplary efficiency curves of the various collector technologies The (process) temperature level is significant for the efficiency of the collector and therefore also for the entire solar system. Figure 6 illustrates how heat losses increase with rising temperatures, thus reducing collector efficiency. This is accompanied by lower yields and savings from the solar thermal system, which consequently results in poorer economic efficiency. Solar thermal systems can also supply heat for industrial processes at temperatures above 100 °C at competitive prices.

Fig. 6: Exemplary efficiency curves of the various collector technologies The (process) temperature level is significant for the efficiency of the collector and therefore also for the entire solar system. Figure 6 illustrates how heat losses increase with rising temperatures, thus reducing collector efficiency. This is accompanied by lower yields and savings from the solar thermal system, which consequently results in poorer economic efficiency. Solar thermal systems can also supply heat for industrial processes at temperatures above 100 °C at competitive prices.

Nevertheless, when choosing the integration point, care should be taken to ensure that the solar thermal system can operate at the lowest possible temperature level under the given conditions.

Integration of renewable heat into the existing infrastructure

Domestic hot water and space heating are the main heat consumers in households. Solar system concepts can be easily standardized for these applications, as the heat supply requirements remain largely the same from household to household. This means that essentially only the size of a solar thermal system needs to be adapted to the number of occupants and the energy standard of a building. In industry and commerce, the requirements for heat supply vary from company to company due to the large number of different production processes. This results in a variety of integration concepts for solar heat. As a rule, integration takes place via an additional heat exchanger, which is heated on the primary side using the solar-generated heat. The selected heat sink is connected on the secondary side in order to transfer the heat to the process medium accordingly.

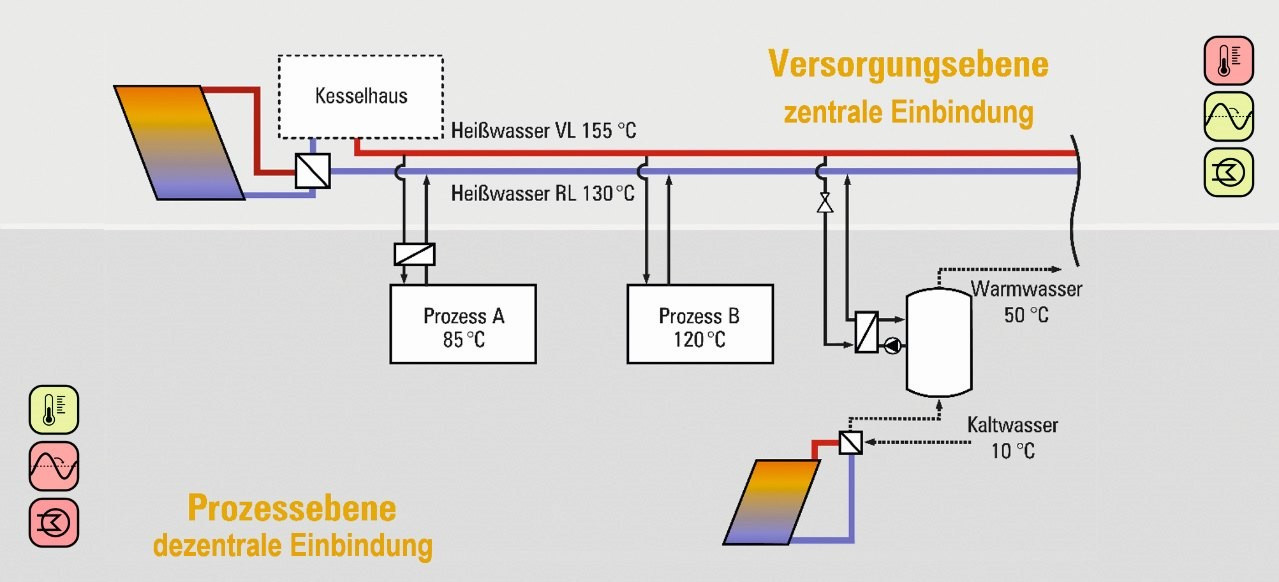

The heat supply infrastructure in companies traditionally comprises the actual heat generator (usually based on the combustion of fossil fuels) and a heat network that can be divided into supply and return lines. This is referred to as the supply level. On the other hand, there is the process level, which comprises the individual processes. The two levels are often separated by a heat exchanger, although this is not absolutely necessary. The temperature level in the heat distribution network is determined by the highest process temperature and represents the maximum temperature in the system. The solar system can be integrated both centrally at the supply level and decentrally at the process level. The latter refers to the direct supply of solar heat to individual processes or heat consumers, such as the provision of hot water or ventilation. This has the advantage that only those processes that offer good framework conditions are selected for the supply of solar heat. These are, for example, low temperatures and a high heat demand all year round, which means that a high level of efficiency and a high proportion of solar coverage in relation to the process heat demand can be achieved. On the other hand, only a small proportion of the total heat requirement can be supplied with solar heat, as the heat is only available to individual processes.

When integrating at process level, the existing conventional heating of the process plays a decisive role in the choice of integration concept. In particular, the question of whether the process is heated internally or externally is significant. If, for example, immersion baths are heated via an external heat exchanger, then in most cases a solar heat exchanger can be installed cost-effectively in parallel or in series with the heat exchanger of the conventional heat supply system. If process baths are heated internally (e.g. by electric heating cartridges), an additional heat exchanger can be suspended in the immersion bath to provide solar heating for the process medium in parallel with the conventional system. Special, space-saving heat exchangers (e.g. "pillow plates") are available for such cases. Depending on the complexity of the integration, the costs for the integration can make up a large proportion of the overall project costs. In most cases, internal heating is more complex and therefore more expensive than external heating.

The major advantage of central integration is that all processes can be supplied with solar heat. The first approach to integration here is always to use the solar heat to preheat the return flow of the heating network (solar system in series with the conventional boiler). The boiler then does not need to start on sunny days. On less sunny days, the boiler maintains the set temperature after preheating. In addition to this serial integration, the solar thermal system can also be operated in parallel with the boiler. In this case, the solar thermal system must always reach the flow temperature of the heating network, which means that a lower level of efficiency is generally achieved in the solar thermal system. However, the advantage of parallel integration can be that the conventional heat generator can remain completely switched off for longer periods in summer, resulting in an overall efficiency advantage.

The solar provision of process steam at temperatures of up to 250 °C is also technically possible. However, due to the high temperatures involved, the provision of solar-generated steam is only recommended for southern European locations with a high proportion of direct solar radiation, which enables the use of concentrating collectors. For central or northern European companies with steam networks, it is advisable to heat individual processes with a lower temperature level and suitable system technology using solar energy.

One example of this is the heating of make-up water, which only needs to be heated up to 100 °C before degassing and fed into the system to compensate for steam, desalting and blowdown losses.

Fig. 7: Distinction between supply and process level with centralized or decentralized integration

Fig. 7: Distinction between supply and process level with centralized or decentralized integration

Promotion of renewable heat

The sun does not send a bill. This bold way of speaking makes it clear that a solar process heat system is a long-term and strategic investment. Although the installation and integration of the system requires a comparatively high initial investment, it then enables the use of solar heat over a period of at least 20 years at virtually zero cost. In Germany, investments in renewable process heat are extensively funded by the Federal Ministry for Economic Affairs and Energy as part of the "Energy efficiency and process heat from renewable energies in industry" program (BMWi, 2019). Since the beginning of 2019, heat pumps and biomass have also been covered by this funding, which means that the technologies can be funded much more extensively than before. In this funding guideline, process heat is interpreted as the heat required to manufacture, process or refine products and to provide services. When submitting an application, proof must be provided that more than 50% of the renewable heat fed into the grid is actually used for process heat. However, other heat sinks, such as the provision of space heating or sorption-based cooling processes, can also be supplied. The investment is subsidized with 45% or even 55% in the case of an SME company. Funding is provided in the form of an investment grant from BAFA or a low-interest loan with a corresponding repayment subsidy from KfW. It should be emphasized that in the case of solar process heating systems, not only the investment in the components themselves, but the entire project volume is included in the funding. This means that in addition to the hardware, all costs from the feasibility assessment and planning through to installation and commissioning are also subsidized. Even costs for necessary conversions for the integration of renewable heat, such as any necessary conversion of production facilities, are taken into account when calculating the eligible costs. The only thing that cannot be taken into account is any investment required to improve the structural load-bearing capacity of the roof.

Turn-key costs of solar process heating systems

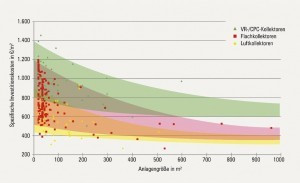

Fig. 8: Overview of specific net investment costs (before subsidies, incl. planning & installation) of realized solar process heat systems in Germany Real project costs (net, without subsidies) for solar process heat systems are shown in Figure 8. For better comparability, the specific investments are given in relation to the area. It can be seen that large systems result in significant economies of scale towards cheaper systems. Particularly in the area of small systems, the projects have very different specific costs. This is mainly due to the fact that the integration costs are particularly high for small systems and can vary greatly depending on the process integration. In addition, solar thermal system technology can differ significantly depending on the application, which makes it difficult to provide generally valid information on necessary investments. Standard market turn-key costs for somewhat larger solar thermal systems (> 100m2) are between 350 and 900 €/m2. In case of doubt, it may be worth obtaining a further offer from a second provider in order to check the plausibility of the cost estimate. Air collectors have the lowest costs, as the system structure is very simple and installation can be carried out more quickly than with water-based systems. Flat-plate collectors are correspondingly cheaper than higher-quality vacuum tube collectors, which can also be used at higher temperatures.

Fig. 8: Overview of specific net investment costs (before subsidies, incl. planning & installation) of realized solar process heat systems in Germany Real project costs (net, without subsidies) for solar process heat systems are shown in Figure 8. For better comparability, the specific investments are given in relation to the area. It can be seen that large systems result in significant economies of scale towards cheaper systems. Particularly in the area of small systems, the projects have very different specific costs. This is mainly due to the fact that the integration costs are particularly high for small systems and can vary greatly depending on the process integration. In addition, solar thermal system technology can differ significantly depending on the application, which makes it difficult to provide generally valid information on necessary investments. Standard market turn-key costs for somewhat larger solar thermal systems (> 100m2) are between 350 and 900 €/m2. In case of doubt, it may be worth obtaining a further offer from a second provider in order to check the plausibility of the cost estimate. Air collectors have the lowest costs, as the system structure is very simple and installation can be carried out more quickly than with water-based systems. Flat-plate collectors are correspondingly cheaper than higher-quality vacuum tube collectors, which can also be used at higher temperatures.

Solar heat generation costs

Thanks to extensive subsidies, the achievable solar heat generation costs are often between 3 and 5 € cents/kWh, which means that heat is generally produced more cheaply than with fossil fuels. In particularly favorable conditions, such as those often found in companies in the electroplating and surface technology sector, solar heat generation costs of less than 3 € cents/kWh are even possible. By comparison, the average price that companies paid for gas in 2017 was € 2.7 cents/kWh for industrial customers and € 4.5 cents/kWh for commercial customers (Federal Network Agency n.d.). The solar heat generation costs are calculated in accordance with VDI 3988 Solar Thermal Process Heat1 and represent the average price over the entire service life, including all operating and usage-related costs and taking discounting into account.

It is important to emphasize here that the gas price does not correspond to the actual useful heat price. With conventional heat supply, exhaust gas losses occur during combustion as well as heat losses in the boiler and during heat distribution, which must also be taken into account. In total, the actual annual efficiency of conventional heat supply is often in the range of 70 to 80 %, which means that even without a price increase over the years, the real useful heat price is between 3.4 and 6.4 €-ct/kWh. Even taking into account a moderate price increase of 2 %/a and an annual utilization rate of 80 %, fossil-based useful heat costs are between 4.0 and 6.6 €-ct/kWh.

This means that the conventional heat generation costs are usually significantly higher than the solar heat generation costs. When using more expensive final energy sources such as oil, wood or electricity, the economic advantage of a solar thermal heat supply increases further. In most cases, it is even worth switching the entire heat supply to a system with solar thermal energy and a gas boiler (average electricity costs in 2017: 14.9 € cents/kWh for industrial customers and 21.7 € cents/kWh for commercial customers).

ExcursusCO2 tax

The introduction of aCO2 tax has been called for by climate researchers and environmental associations for years and has been discussed at a political level. In some countries such as France, Switzerland, Canada and Sweden, there are already examples of this. It is probably only a matter of time before a similar tax is introduced in Germany. The only thing that seems unclear at present is the amount and the final form it will take. In the current discussions, amounts in the range of €20 to €80/t are being mentioned. The combustion of natural gas releases 0.22 kg/kWh. This means that this would result in a levy in the range of 0.4 to 1.76 € cents/kWh, which could lead to a significant increase in view of the comparatively low gas prices. With this in mind, companies should already be thinking about how this potential increase in heating costs can be absorbed.

Wrong key figures result in wrong decisions

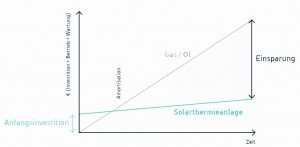

Fig. 9: Profitability and potential savings of an investment in a solar process heat system over its lifetime compared to the short-term payback periodInindustrial companies, investment decisions are often made solely on the basis of the payback period. However, this is too short-sighted for such an investment. The payback period is a key figure for risk assessment and indicates when the capital invested will be refinanced. However, it does not provide any information about the profitability of the investment over its lifetime (see Fig. 9). This crucial difference is illustrated below using a simple example. Two investments with different lifetimes are compared. Investment A requires an investment volume of € 10,000 with annual savings of € 5,000 and a service life of three years. Investment B, on the other hand, requires an investment of € 25,000 with the same annual savings but a significantly longer service life of 10 years. Investment A pays for itself after just two years, but due to the short service life, only a profit of € 5,000 remains before a new investment is required. Investment B, with the higher initial investment, is only refinanced after 5 years, but costs are also saved in the following years, so that a profit of € 25,000 is achieved at the end of the service life. This highly simplified example is intended to show that the payback period cannot be the sole key figure for an investment in renewable process heat. Instead, the internal rate of return or the net present value should also be used for the evaluation. Solar thermal systems generally achieve double-digit returns and therefore prove to be a very profitable investment.

Fig. 9: Profitability and potential savings of an investment in a solar process heat system over its lifetime compared to the short-term payback periodInindustrial companies, investment decisions are often made solely on the basis of the payback period. However, this is too short-sighted for such an investment. The payback period is a key figure for risk assessment and indicates when the capital invested will be refinanced. However, it does not provide any information about the profitability of the investment over its lifetime (see Fig. 9). This crucial difference is illustrated below using a simple example. Two investments with different lifetimes are compared. Investment A requires an investment volume of € 10,000 with annual savings of € 5,000 and a service life of three years. Investment B, on the other hand, requires an investment of € 25,000 with the same annual savings but a significantly longer service life of 10 years. Investment A pays for itself after just two years, but due to the short service life, only a profit of € 5,000 remains before a new investment is required. Investment B, with the higher initial investment, is only refinanced after 5 years, but costs are also saved in the following years, so that a profit of € 25,000 is achieved at the end of the service life. This highly simplified example is intended to show that the payback period cannot be the sole key figure for an investment in renewable process heat. Instead, the internal rate of return or the net present value should also be used for the evaluation. Solar thermal systems generally achieve double-digit returns and therefore prove to be a very profitable investment.

Contracting as a way out of the investment dilemma

In practice, it is often the case that such investment decisions fall through the usual cracks due to the one-sided focus on the payback period and projects are therefore not implemented. Contracting companies have recognized this gap. In recent years, numerous companies have specialized in offering solutions to this problem. As part of a contracting agreement, the contractor takes on the entire project management from planning and financing through to implementation. The contractor is then also the operator of the system and only sells the heat to the company. The contractually agreed price is lower than the fossil heat price and is usually linked to the development of the gas price. The contract also stipulates whether the plant will automatically become part of the company's assets at some point or whether it will be dismantled after an agreed period. This means that the company benefits from reduced heating costs andCO2 emissions from day one, without having to invest and without the risk of system failure.

- to be continued -

Literature

[1] ADAC, n.d., Share of roads in Germany in the total area of the country in 2014, Statista, accessed May 7, 2019, Available at https://de.statista.com/statistik/daten/studie/163401/umfrage/anteil-der-strassen-in-deutschland-an-der-gesamtflaeche/

[2] Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, Energy Policy 20 Years after Chernobyl, Documentation of the Conference Chernobyl 1986-2006: Experiences for the Future, Berlin, April 24-25, 2006

[3] Federal Ministry for Economic Affairs and Energy, Facts and Figures Energy Data, 2018

[4] Federal Ministry for Economic Affairs and Energy, Prozess wärme aus erneuerbaren Energien: Umsteigen und von Förderung profitieren, available at https://www.deutschland-machts-effizient.de/KAENEF/Redaktion/DE/Foerderprogramme/energieeffizienz-in-der-wirtschaft-modul-2-prozesswaerme.html, accessed on May 14, 2019

[5] Federal Network Agency, Federal Cartel Office, n.d., Gas prices* for commercial and industrial customers in Germany in the years 2008 to 2018 (in euro cents per kilowatt hour), Statista, available at https://de.statista.com/statistik/daten/studie/168528/umfrage/gaspreise-fuer-gewerbe-und-industriekunden-seit-2006/, accessed on May 14, 2019,

[6] Association of German Engineers, VDI 3988, Solar thermal process heat (green print), Beuth Verlag, Berlin, 2018