The following article is dedicated to the provision of renewable heat in surface treatment companies, with a focus on the provision of solar process heat.

How great is the potential in my company?

Planning a solar process heat system is comparatively complex. However, with newly developed tools, it is possible to estimate the technical potential with just a few details as part of a feasibility study. To begin with, it should be checked whether roof or open spaces are available for the installation of solar collectors. Ideally, the areas should face south, although an east/west orientation will only result in slightly lower solar yields. In addition, there should also be a relevant heat requirement in summer at a suitable temperature level up to a maximum of 150 °C. When designing the solar thermal system, it must be decided which heat sinks are actually to be supplied. The average daily heat demand in summer as well as the flow and return temperatures should be determined for these. With the help of this data and by specifying the location via the zip code, the pre-dimensioning tool at www.solare-prozesswärme.info/vorauslegung can be used.

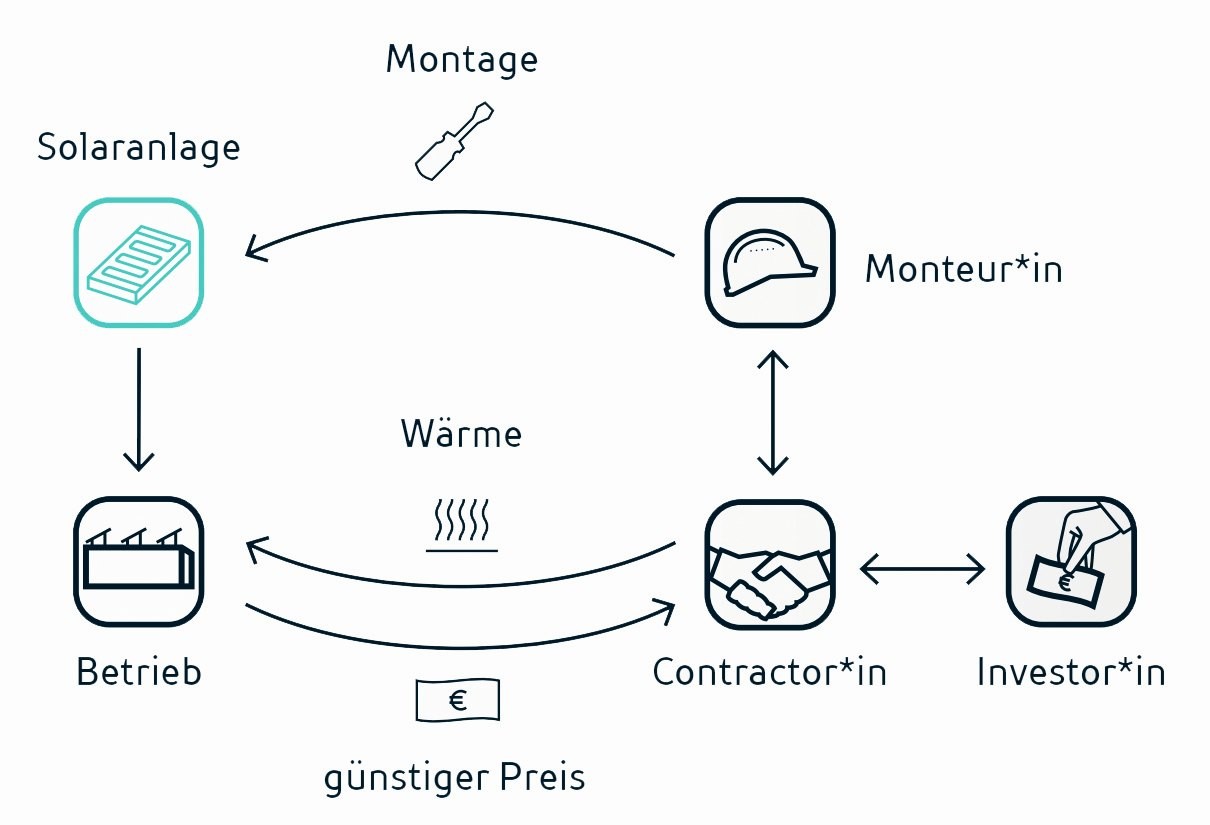

Fig. 10: Diagram of heat supply contracting

Fig. 10: Diagram of heat supply contracting

A solar thermal system is most economical when it substitutes the largest possible amount of fossil energy with the lowest possible investment. In other words, this means that a solar thermal system should have the highest possible specific  Fig. 11: Example of a design based on the summer heat demand for a given load profile (black) and the solar yield curve over the year under the given conditions (yellow)Annual yield (= annual yield per collector area in kWh/(m2a)). To achieve this, as much of the annual solar radiation supply as possible must be utilized without producing significant heat surpluses. Therefore, in a first step, solar thermal systems for industry and commerce are dimensioned so large that the collectors can just about cover the entire heat demand on a working day in summer with a predominantly blue sky.

Fig. 11: Example of a design based on the summer heat demand for a given load profile (black) and the solar yield curve over the year under the given conditions (yellow)Annual yield (= annual yield per collector area in kWh/(m2a)). To achieve this, as much of the annual solar radiation supply as possible must be utilized without producing significant heat surpluses. Therefore, in a first step, solar thermal systems for industry and commerce are dimensioned so large that the collectors can just about cover the entire heat demand on a working day in summer with a predominantly blue sky.

The amount of energy irradiated on a good summer day is approx. 7..8 kWh/(m2d) worldwide. Depending on the collector technology selected and the required temperature, around 50 % of this, i.e. 3..4 kWh/(m2d), can be utilized. With the help of this so-called design value and the heat requirement on a summer day, the recommended collector area can be calculated in the next step.

This dimensioning strategy is explained below using an example:

Figure 11 shows an example of the course of the daily heat demand of an electroplating plant over the course of the year. The increased heat demand in winter for ventilation and space heating purposes can be clearly seen. It is also clear that there is still a relevant thermal base load at weekends, which can be easily covered by the solar thermal system. The average daily heat demand in summer, which was set at 5.3 MWh/d for the design, is indicated by the red line. The temperatures in the electroplating heating network are 80 °C in the flow and 60 °C in the return.

If this data is used in the aforementioned preliminary design tool (see Fig. 12 left), the design value of 3 kWh/(m2d) determined in the tool results in a possible collector area of 1766m2. In combination with a storage volume of 135m3, this results in a specific yield of 346 kWh/m2 at the given temperatures (see Fig. 12 right). The result of a simulation of the daily solar yield with this design is shown in Figure 11. It can be seen that surpluses are not produced on any day, so that the entire solar yield can be used. In summer, significantly higher yields are possible due to the increased irradiation values, but the solar thermal system can also provide a relevant proportion of the heat requirement in the transitional period and on winter days, thus reducing the boiler running time and the use of fossil fuels.

Fig. 12: Left: Input of the necessary information into the tool, right: Output of the design and yield estimateDependingon the collector area, temperature range and temporal progression of the heat demand, different storage volumes may be required for efficient system operation. The aim should always be to achieve the required volume with a single storage tank within the building. In this way, in addition to optimum charging and discharging and lower heat losses, the system costs can also be kept as low as possible. There are a number of manufacturers on the market who offer preconfigured, locally welded or modular storage tanks, e.g. made of steel, plastic or GRP. In a first approach, the storage tank is designed so that at least the irradiation of a good summer day (3 ... 4 kWh/(m2d) can be stored. If several storage units are necessary under the given circumstances, they should not be connected in parallel but in series.

Fig. 12: Left: Input of the necessary information into the tool, right: Output of the design and yield estimateDependingon the collector area, temperature range and temporal progression of the heat demand, different storage volumes may be required for efficient system operation. The aim should always be to achieve the required volume with a single storage tank within the building. In this way, in addition to optimum charging and discharging and lower heat losses, the system costs can also be kept as low as possible. There are a number of manufacturers on the market who offer preconfigured, locally welded or modular storage tanks, e.g. made of steel, plastic or GRP. In a first approach, the storage tank is designed so that at least the irradiation of a good summer day (3 ... 4 kWh/(m2d) can be stored. If several storage units are necessary under the given circumstances, they should not be connected in parallel but in series.

The methodology stored in the tool has also found its way into the new VDI guideline 3988 Solar thermal process heat.

Market

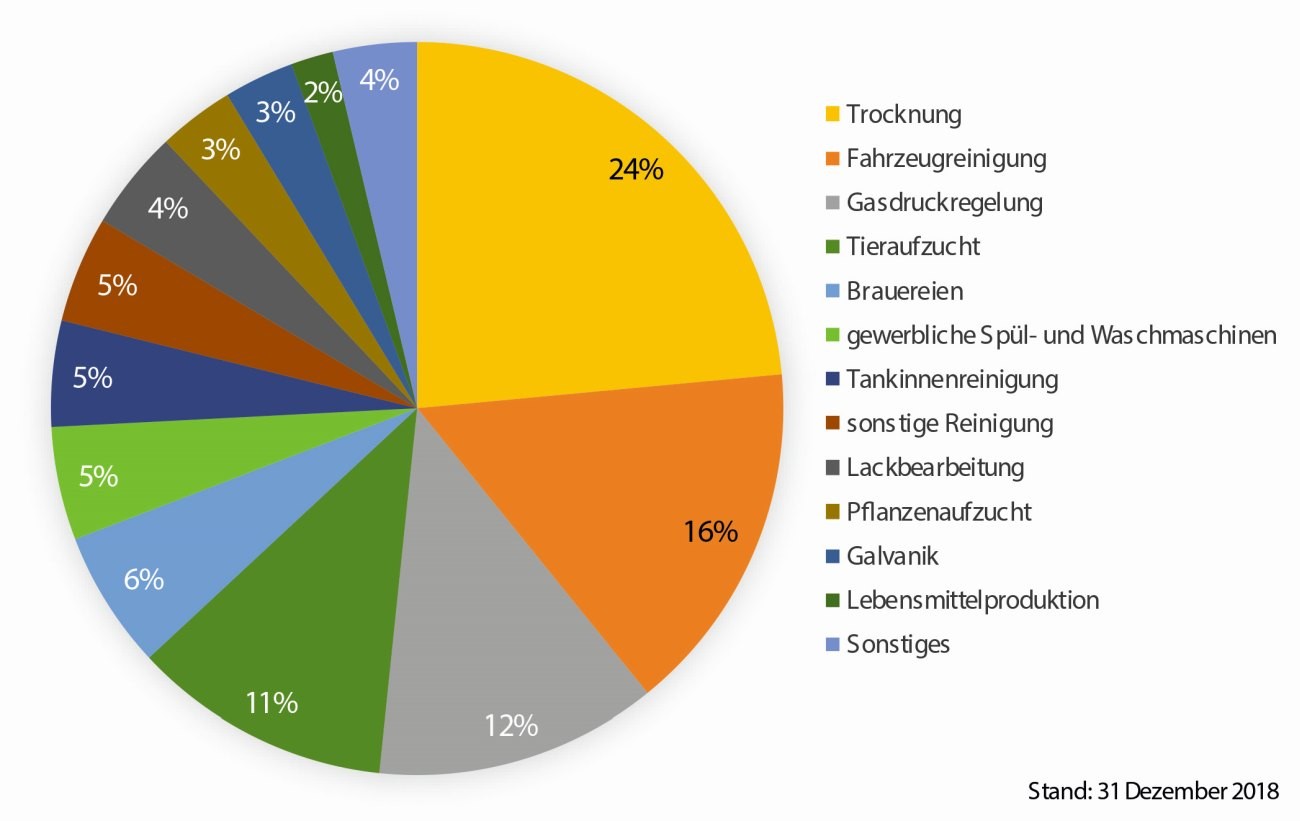

As of the end of 2018, 33,000m2 of collector area in more than 300 solar process heat systems are under construction and in operation in Germany. The implemented systems are dominated by agricultural applications in which biomass (e.g. wood chips, pellets, hay) is dried using air collectors. Smaller collector areas in the region of 60m2 tend to be used here. At the same time, however, the currently largest solar process heat system in Germany with a good 1,300m2 is also used for drying wood chips. Overall, however, the market has shown a trend towards larger collector fields in many areas of application in recent years. As Figure 13 shows, the range of applications is enormous. Drying processes can be found in many industrial companies at different temperature levels. Particularly in drying processes with a high air exchange rate, it often makes sense to preheat the air with the solar thermal system and, if necessary, to have the boiler ensure the target temperature. However, HVAC systems for air conditioning and recirculating air dryers in combination with air collectors or water-bearing systems also offer great potential, as some examples of implementation demonstrate. Another area of application in which a large number of systems have been implemented to date is vehicle cleaning. Some providers have declared the solarization of their sites to be part of their corporate strategy and are actively using this for marketing purposes. Solar heat is used here to heat the wash water and, in some cases, to keep the wash bays ice-free in winter using underfloor heating. However, there are also numerous examples of best practice in other sectors where a lot of cleaning is required. In the food industry in particular, with its high hygiene requirements, all production machines and rooms must be thoroughly cleaned at least once a day, which results in a considerable demand for hot water. Last but not least, in many companies the product itself is also cleaned, pre-treated in aqueous solutions or degreased. Electroplating and surface technology also offers very good opportunities for using solar process heat. Some companies in the sector have already recognized the great potential and invested in renewable heat.

Fig. 13: Breakdown of the installed collector area by sector

Fig. 13: Breakdown of the installed collector area by sector

According to estimates, there are well over 1,000 systems installed worldwide that reliably provide solar heat for industrial processes - with a strong upward trend. Large-scale solar systems (> 1,000m2 collector area) are being installed in Asia in particular. India, China and Mexico are global pioneers in this area.

Best-practice systems in surface technology

Huster Galvanik (Source: Ritter XL)Heinz Daurer & Söhne GmbH is a medium-sized electroplating company from the Karlsruhe area. Before the solar system was installed, two oil boilers were solely responsible for the heat supply. Thanks to the orientation of the roof of the production hall to the east and west, the solar yield can be distributed well throughout the day by using both halves of the roof. A total of 300m2 of CPC collectors have been installed which, together with a directly connected 15m3 buffer storage tank inside the building, supply several heat sinks at different temperature levels. In addition to the actual electroplating tanks, the air washer, the drying systems and the room heating are also supplied with solar heat. In the summer months, the boilers, which feed heat into the same buffer storage tank, can remain completely switched off on a large number of days. If there is insufficient irradiation, the collectors boost the return flow while the oil-fired boilers ensure the target temperature of 90 °C is reached.

Huster Galvanik (Source: Ritter XL)Heinz Daurer & Söhne GmbH is a medium-sized electroplating company from the Karlsruhe area. Before the solar system was installed, two oil boilers were solely responsible for the heat supply. Thanks to the orientation of the roof of the production hall to the east and west, the solar yield can be distributed well throughout the day by using both halves of the roof. A total of 300m2 of CPC collectors have been installed which, together with a directly connected 15m3 buffer storage tank inside the building, supply several heat sinks at different temperature levels. In addition to the actual electroplating tanks, the air washer, the drying systems and the room heating are also supplied with solar heat. In the summer months, the boilers, which feed heat into the same buffer storage tank, can remain completely switched off on a large number of days. If there is insufficient irradiation, the collectors boost the return flow while the oil-fired boilers ensure the target temperature of 90 °C is reached.

The example of Huster Galvanik shows that a solar thermal system can also provide heat efficiently without a storage tank. Here, the company and planners decided to integrate the solar system into the system in parallel with the boiler and dispense with the storage tank. Due to the often simultaneous occurrence of demand and solar radiation supply, a high solar coverage rate of 40 % can still be achieved. The high-quality CPC collectors with an area of 220m2 provide heat at 90 °C to heat the Galavanik baths. Despite the comparatively high temperature level, a specific yield of 430 kWh/(m2a) is achieved.

Autohaus Friedrich Hoffmann GmbH & Co KG (Source: Grammer Solar)In some paint shops, such as Autohaus Friedrich Hoffmann GmbH & Co KG in Sundern, solar heat is used directly for air preheating. Air collectors are increasingly being used here. At the Lethe company, which specializes in the treatment of ships and yachts, 1,400m3 of air per hour is heated by 40m2 of air collectors. The warm air is used in the painting process, among other things. Here, high air volume flows at moderate temperatures (approx. 22 to 24 °C) are required to remove the paint particles. Excess heat is fed directly into the room heating system.

Autohaus Friedrich Hoffmann GmbH & Co KG (Source: Grammer Solar)In some paint shops, such as Autohaus Friedrich Hoffmann GmbH & Co KG in Sundern, solar heat is used directly for air preheating. Air collectors are increasingly being used here. At the Lethe company, which specializes in the treatment of ships and yachts, 1,400m3 of air per hour is heated by 40m2 of air collectors. The warm air is used in the painting process, among other things. Here, high air volume flows at moderate temperatures (approx. 22 to 24 °C) are required to remove the paint particles. Excess heat is fed directly into the room heating system.

The Schulte paint center in Meppen also uses solar heat for the painting process (22,000m3/h at 24 °C). The heat is also used to dry the paint. To heat the air up to 70 °C, the 134m2 vacuum tube collectors provide 85 °C in an air-water heat exchanger. The overall system, which is completed by two 5m3 buffer storage tanks, provides 54 MWh of heat per year. This corresponds to a solar coverage of around 30 %.

Further information

In summary, it can be said that solar process heat has a very wide range of applications and is already being used in many companies today to lower energy costs and simultaneously reduce production-relatedCO2 emissions. The latter point can be particularly relevant for companies in the surface treatment industry, as companies in this sector usually have a high environmental impact. At the same time, investing in a solar thermal process heating system can also be counted towards the continuous improvement process (CIP) in accordance with DIN ISO 50001.

Schulte paint center (source: s power)

Schulte paint center (source: s power)

Basic information and background information on the use of solar heat in industry and commerce can be found on the aforementioned manufacturer-independent website www.solare-prozesswärme.info. In addition to the pre-planning tool presented here, current information on the German market and new best-practice systems from various sectors are regularly presented. Other relevant publications, such as sector-specific guidelines, are also available for download. A map with all implementations in Germany, including relevant information, will soon be available on the website. In addition to the technical aspects, planners and tradespeople involved will also be listed to make it easier for interested companies to find suitable project partners.

Literature

[1] ADAC, n.d., Proportion of roads in Germany in relation to the total area of the country in 2014, Statista, accessed May 7, 2019, available at https://de.statista.com/statistik/daten/studie/163401/umfrage/anteil-der-strassen-in-deutschland-an-der-gesamtflaeche/

[2] Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, Energy Policy 20 Years after Chernobyl, Documentation of the Conference Chernobyl 1986-2006: Experiences for the Future, Berlin, April 24-25, 2006

[3] Federal Ministry for Economic Affairs and Energy, Facts and Figures Energy Data, 2018

[4] Federal Ministry for Economic Affairs and Energy, Prozess wärme aus erneuerbaren Energien: Umsteigen und von Förderung profitieren, available at https://www.deutschland-machts-effizient.de/KAENEF/Redaktion/DE/Foerderprogramme/energieeffizienz-in-der-wirtschaft-modul-2-prozesswaerme.html, accessed on May 14, 2019

[5] Federal Network Agency, Federal Cartel Office, n.d., Gas prices* for commercial and industrial customers in Germany in the years 2008 to 2018 (in euro cents per kilowatt hour), Statista, available at https://de.statista.com/statistik/daten/studie/168528/umfrage/gaspreise-fuer-gewerbe-und-industriekunden-seit-2006/, accessed on May 14, 2019,

[6] Association of German Engineers, VDI 3988, Solar thermal process heat (green print), Beuth Verlag, Berlin, 2018