The increasing use of electronic devices in all areas of life is driving up energy consumption. A large proportion of this energy is released into the environment in the form of heat. In Europe, around 1.2 exajoules are lost every year from IT infrastructures and data centers as well as devices such as smart devices. This heat below 80 °C is traditionally difficult to utilize due to poor thermodynamic efficiency and technological limitations.

There are very few materials capable of converting the heat into electrical energy, and none of them are compatible with current technology in semiconductor manufacturing facilities. However, a collaboration between Forschungszentrum Jülich and the IHP-Leibniz Institute for Innovative Microelectronics in Germany, together with the Universities of Pisa and Bologna in Italy and the University of Leeds in the UK, has now reached a milestone in the development of such a material that is suitable for energy harvesting on chips and compatible with the CMOS process of chip manufacturing.

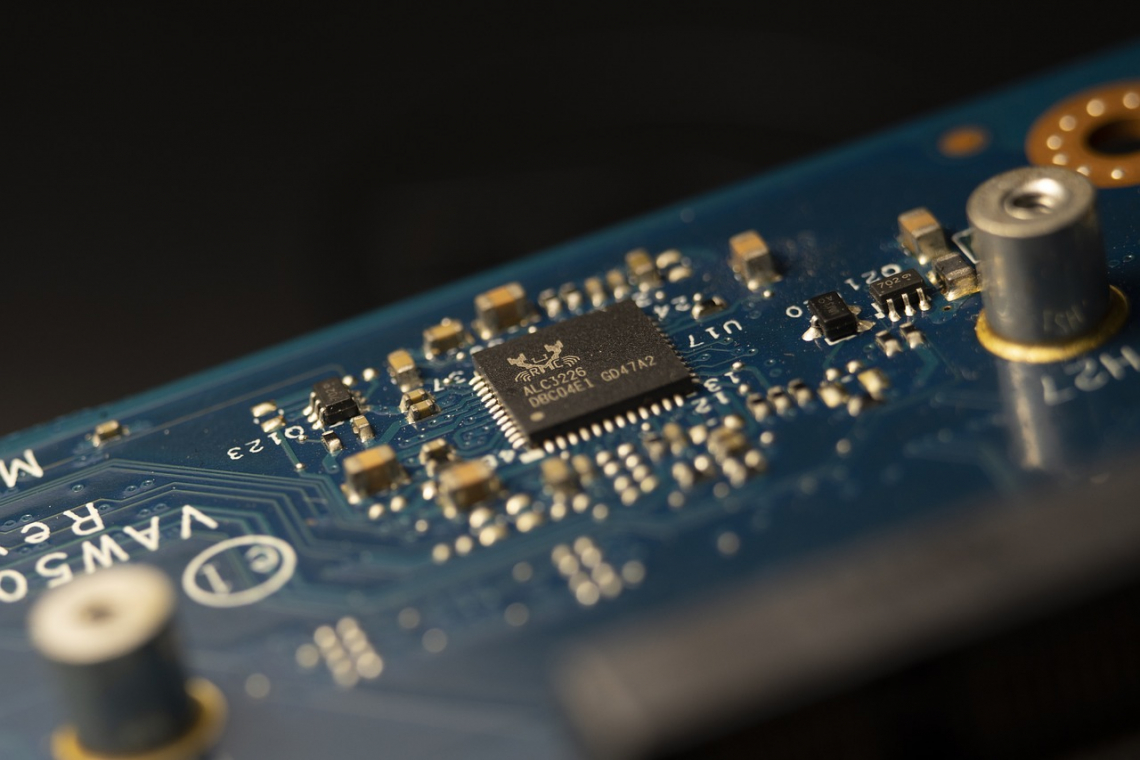

Adding tin to germanium significantly reduces thermal conductivity while maintaining electrical properties - an ideal combination for thermoelectric applications. The - experimentally confirmed - low thermal conductivity of the crystal lattice underlines the great potential of GeSn alloys as a thermoelectric material. Silicon-based microchips are integrated in order to convert the waste heat generated during operation back into electrical energy. This "energy harvesting" on the chip could significantly reduce the need for external cooling and electricity and thus increase the efficiency of electronic devices.