The Industrial Internet of Things (IIoT) offers fantastic prospects: Machine manufacturers could, for example, react more quickly to problems via remote access, save on travel costs and therefore offer service more cheaply, develop new business models or generate greater customer satisfaction. Plant operators, in turn, would benefit from higher plant availability, optimized processes and the associated energy savings as well as support from external experts and much more.

The practical implementation of IIoT has been slow. There are concerns among machine builders, plant operators and management alike. If these could be dispelled with easy-to-integrate yet secure solutions, a win-win situation would arise for everyone involved. How can this be achieved?

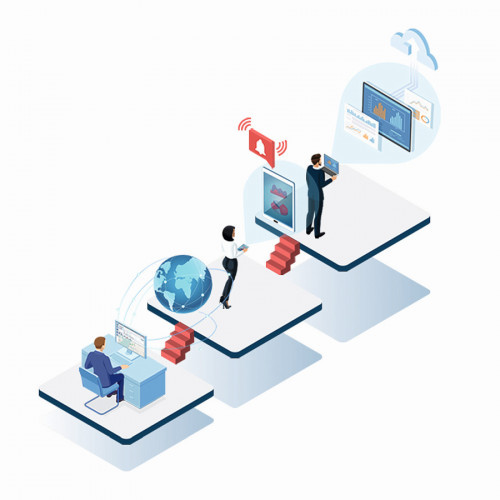

The Ewon remote maintenance solution from HMS helps machine builders and plant operators alike to get through the learning curve of digitalization projects fasterThesuccessful path to IIoT integration is: dream big, start pragmatically.

The Ewon remote maintenance solution from HMS helps machine builders and plant operators alike to get through the learning curve of digitalization projects fasterThesuccessful path to IIoT integration is: dream big, start pragmatically.

The area of tension in which machine manufacturers and plant operators find themselves with regard to digitalization can be easily explained using an everyday example: car drivers are generally not enthusiastic about providing the manufacturer with information about their driving habits or other user behaviour. Nevertheless, modern cars have an internet connection. This enables drivers to receive up-to-date traffic information such as traffic jam reports in real time, for example. The right vehicle app is usually included for newer models. It can be used, for example, to determine the location of the car, open and close windows and lock and unlock doors. Querying the fuel level or battery charge level and the associated remaining range is also a useful function. For electric cars, this is often combined with a display of the nearest charging station. Depending on the app, additional engine information such as acceleration, engine load, oil and water temperature can be called up. All in all, a useful feature that offers many advantages to vehicle users. Ultimately, it is the benefits that lead to users accepting that information about their usage and driving habits is transmitted to the manufacturers. They in turn use the information to further optimize their vehicles and better align them with user habits. Of course, it is important in all of this that data access is secure and that it is clearly regulated who is allowed to do what with which data.

Acceptance as a trailblazer for digitalization

In principle, what is becoming increasingly established in the automotive sector, especially with new vehicles, can also be implemented in automation. However, the implementation of digitalization in automation is still making slow progress. Many plant operators are skeptical when it comes to allowing machine builders to access machines within their plant. This is because they want to retain control over external access. Security concerns also continue to play a major role. According to the Microsoft study "IoT Signals" from October 2021, a third of all digitalization projects fail in the proof-of-concept phase because there is no clear strategy or expertise, the ROI is unclear and the focus is not on customer requirements.

What's more, cyber security is a relatively new topic for most machine manufacturers, and they still need to build up expertise in this area. Machine builders often only consider the possibility of remote access in the context of troubleshooting in order to gain insight into the machine in an emergency. Remote access to a machine is therefore usually only offered as an option for which the plant operator has to pay extra; or alternative solutions are used, such as a software connection with the laptop of a maintenance employee. This usually allows faults to be resolved at short notice, but it is not the basis for a service offering or a digitalization strategy.

The tension between end customer acceptance and service offerings from machine manufacturers can only be resolved if machine manufacturers rethink this and develop a vision for a structured service that offers users convincing benefits, as in the automotive example.

The task of machine manufacturers would be to increase user acceptance by taking a strategic approach to the issue of remote access, implementing reliable security procedures and focusing on the added value of remote access for the plant operator. For example, by developing new, well thought-out and - very importantly - user-oriented business models with clear rules on data usage. The machine manufacturer would benefit from remote access from the very first service case, because they can react without having to travel and create greater customer satisfaction.

The task of machine manufacturers would be to increase user acceptance by taking a strategic approach to the issue of remote access, implementing reliable security procedures and focusing on the added value of remote access for the plant operator. For example, by developing new, well thought-out and - very importantly - user-oriented business models with clear rules on data usage. The machine manufacturer would benefit from remote access from the very first service case, because they can react without having to travel and create greater customer satisfaction.

First step: connect the system

IIoT cannot simply be implemented on the side. The first step on the way to achieving this goal is to establish connectivity in a plant. According to a study by the Arc Advisory Group, 63% of all routine maintenance work can also be carried out remotely. However, the majority of industrial plants are not yet designed for remote access, although the benefits of remote access are quickly apparent to plant operators. They benefit from faster troubleshooting, which improves system availability, and have a direct line to the machine expert. At the same time, the machine manufacturer has lower costs for service calls, as service technicians have to travel less. The latter in turn improves their work-life balance and contributes to greater employee satisfaction at the machine manufacturer.

Although the advantages are obvious, it is not easy for machine builders to convince plant operators of the benefits of remote access. Security concerns are a major hurdle. It is a challenge for machine builders to explain why remote access is secure, what security standards are in place and how they have been implemented. As remote access was usually only offered as an option in the past, additional persuasion is required here. Thierry Bieber supports customers at HMS in the implementation of digitization strategies. He explains: "Customers who have integrated our Ewon solution for remote access into their machines as standard and strategically set up remote access service have been able to significantly increase user acceptance." The solution must support high security standards as a basic requirement. With the Ewon solution from HMS, the plant operator still has the option of enabling the remote connection for remote access himself via a "key switch" directly on the machine. The investment in the required remote maintenance router pays for itself with the first service call on site. This means that both sides benefit equally from remote access.

Second step: Increase service performance and involve customers

Once the first step has been taken and remote access to the system has been set up, others can follow. As remote access is usually only used by machine manufacturers in the event of a fault, it is only activated when necessary. However, the aim would be to involve the plant operator more closely and offer them a service that generates further added value for them. This is because machine networking also offers numerous benefits to the plant operator, their production manager or maintenance staff. As part of an improved service offering, the machine manufacturer could activate access rights for these stakeholders so that they can gain an overview of the machine status themselves in order to be able to react better and faster to current conditions. Regardless of whether they are currently in the plant or not. No extensive user rights would have to be set up for this. In this scenario, for example, it would be sufficient to grant the plant operator and their employees read-only access.

Further conceivable steps would be to initially only query relevant machine data locally for the plant operator in order to monitor machine key performance indicators (KPIs) or to send alarms and notifications in the event of deviations from the target values. As the machine data remains within the system in this case, no complex connection to an IIoT platform is required. User acceptance is generally higher with such solutions, as the entry hurdle for the plant operator is relatively low. All of this makes it possible to continuously increase efficiency and customer satisfaction, proactively respond to user needs and increase the competitiveness of machine builders and plant operators alike.

Clear the way for digitalization

The first two steps form the basis for standardized machine networking. This allows plant operators to gain initial experience with structured service offerings based on remote access. If machine networking is implemented with an open solution that also offers interfaces for connecting to common cloud platforms, the way is clear for further digitalization topics such as asset optimization and predictive maintenance.

Bieber sums up: "Because digitalization is best introduced gradually, it generally makes sense to set up small pilot projects first and then gradually add other areas. This gradually changes the role of the mechanical engineer. They are no longer just trouble shooters who are called out when problems occur, but are now able to make forecasts via remote diagnostics, e.g. on the service life of components." At the same time, his response times in the event of a problem are shorter because the time-consuming journey is no longer necessary. The machine builder can also provide support with process optimization. All of this makes the plant operator's work easier because they can hand over some of their maintenance tasks to external hands, who can intervene more quickly and in a more targeted manner thanks to their expertise.

If digitalization is implemented step by step for an entire plant, this brings further benefits that please plant operators and management alike: unplanned plant downtimes can be significantly reduced. This saves a lot of money and increases productivity at the same time. Operators are now able to work more directly with external experts from the respective machine manufacturers when carrying out maintenance work. At the same time, many tasks can be outsourced completely and maintenance staff can focus on activities that only they can do. In the course of such a digitalization process, the business areas of machine manufacturers and plant operators inevitably shift a little, but everyone involved benefits from the advantages of the new IIoT solution.

Reaching the goal faster with the right partner

From HMS's point of view, remote access paves the way towards digitalization. The communication experts at HMS have extensive market knowledge and support customers in the step-by-step implementation of their digitalization strategy. Under the Ewon brand, HMS offers a solution with which remote access to machines can be easily standardized by both machine builders and plant operators. Machine builders can thus offer their customers structured service offerings with significant added value compared to conventional troubleshooting. With the Ewon solution, plant operators retain control over remote access at all times and know what is happening in their plant. As both sides benefit, acceptance of remote access increases and drives forward standard machine networking. The Ewon solution from HMS helps both sides to get through the learning curve of digitalization projects faster, which ultimately improves the competitiveness of all players.

The experts for industrial communication

HMS Networks is one of the leading companies in the field of industrial information and communication technology (ICT). Its products are marketed under the brands Anybus, Ewon, Intesis and Ixxat. The company's aim is to create maximum flexibility for users when connecting devices and systems to the many different industrial networks. The experts for industrial communication help their customers to save development costs and at the same time always be at the cutting edge of technology. HMS is listed on the NASDAQ OMX Nordic Stock Exchange in Stockholm. The company is headquartered in Halmstad/Sweden. Industrial remote maintenance solutions are offered under the Ewon brand(www.ewon.biz).