n environmentally friendly process from Ateco Tobler AG in Switzerland eliminates the rouging of stainless steel and thus ensures the required surface quality in processes in the pharmaceutical and food industries.

Stainless steel is by no means as robust as its colloquial name suggests. Stainless steel surfaces, especially in pharmaceutical, chemical, food and medical systems, require special attention both in new systems and after prolonged use in order to maintain the surface quality required for the processes. Contamination, foreign bodies and even hot water or pure steam impair the protective passive layer (chromium oxide-rich surface), the iron content of the surface increases and reddish-brown to black areas form. This phenomenon, known as rouging or blacking, can lead to particle detachment and impair the quality of the products.

A patented, environmentally friendly process that ensures cleaning, derouging and passivation without disposal problems now guarantees that the protective surface layer remains intact. Even when removing stubborn blacking, it replaces the aggressive stain with more compatible substances.

Stainless steel surfaces are preferred in industries where hygiene and corrosion resistance are important. The resistant material can withstand cleaning agents and disinfectants as well as steam jets, superheated steam and aggressive reagents in the system. However, stainless steel itself is not inert. Just as with anodized aluminium, the optimum protective effect is only achieved through a closed surface layer, in this case the passive layer, which is rich in chromium oxide. Unfortunately, this is not permanently stable and is not inherently sufficiently developed. It must therefore be recreated or refreshed for new installations and conversions or after a longer period of use. The specialists at Ateco Tobler AG Rheinfelden in Switzerland have now further improved their proven, environmentally friendly cleaning and derouging process with subsequent passivation, so that stubborn rouging can now also be removed under atmospheric oxygen. In collaboration with the Belgian company Technochim, a patented process has also been developed that can even remove blacking without aggressive pickling.

Chrome and protective coating in balance

Inert surfaces for aggressive media or hygiene applications must be finished as smoothly as possible and form a firmly adhering protective surface layer. In the case of stainless steel, this is a chemically inert, chromium oxide-rich top layer (passive layer) that protects the underlying matrix of iron and other alloy components. However, the chromium in the protective layer is in dynamic equilibrium with the base metal and the fluids processed in the system, so that even with pure water and temperatures above approx. 40 °C, the chromium content in the layer gradually decreases and the iron content increases. Heat accelerates this process. A red-brown rouging layer is formed (Fig. 1), which consists of iron oxides, in the case of rouging mainly of hematite, i.e. red-brown iron (II) oxide (Fe2O3) or in the case of so-called blacking mainly of magnetite (Fe3O4) (Fig. 2). The latter forms preferentially at high temperatures, e.g. under the influence of pure steam, and is very difficult to dissolve again due to its stable crystal structures. Particles can detach from the blacking and rouging layers and contaminate the system contents.

However, the surface protection is not only worn away during operation. Oil, grease or mineral and metallic contaminants can also permanently impair the formation of the passive layer in new systems or conversions and must therefore be removed before commissioning. Conventionally, for this so-called initial cleaning and passivation, the entire system, including all pipes, tanks and fittings, has been cleaned with lye and/or acids, any rouging caused by mineral acids etched off, rinsed and then passivated with oxidizing nitric acid. All materials must be certified and disposed of in an environmentally friendly manner at the end of the process, as the acids dissolve not only iron but also chromium and nickel. Ateco has now developed an environmentally friendly, pH-neutral alternative. This means that neither the reagent solutions nor the rinsing water have to be disposed of in a costly and time-consuming manner; discharge into a normal wastewater treatment plant is sufficient.

Environmentally and user-friendly treatments

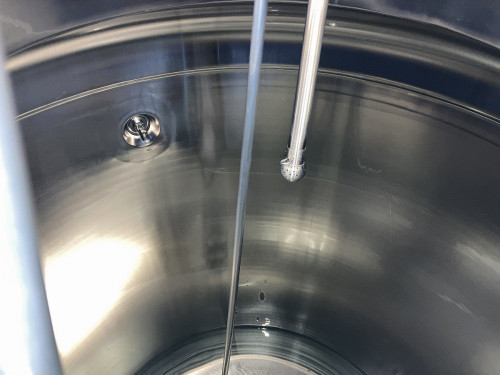

The individual steps, i.e. cleaning, rouging removal and passivation, can be combined as required, but produce the best results as a complete package. All reagents are certified pure chemicals and approved for all relevant certifications and validations in the food and pharmaceutical sectors. In addition to the cleaning chemicals, the conditions under which they are used are also important, i.e. the concentration of the cleaning agent, the temperature of the solution and the exposure time. The relevant parameters can be adjusted to the process contamination that occurs at the user's premises. Static, rotating and orbital spray heads are used to distribute the pre-rinse, the cleaning solution and for rinsing in order to wet the surfaces of large autoclaves, preparation, production and storage containers in a production-safe manner (Fig. 3). The sealing materials approved in the pharmaceutical industry are resistant to the cleaning solution and generally do not need to be replaced. The chemicals for cleaning, derouging and passivation are available in concentrate form so that the right solution can be prepared in each case. On request, the Swiss provider can also take on the complete cleaning of the system and prepare the corresponding certificates and reports. Experienced users can also carry out the work themselves; the necessary chemical certificates are included in the scope of delivery.

Fig. 3: Static, rotating and orbital spray heads can wet all surfaces, even in large autoclaves, preparation, production and storage tanks

Fig. 3: Static, rotating and orbital spray heads can wet all surfaces, even in large autoclaves, preparation, production and storage tanks

As the environmentally friendly agents only selectively remove the iron from the rouging layer, chrome, nickel etc. remain in the material matrix and do not contaminate the used solution. Whereas previous solutions for derouging still required all parts to be cleaned to be inerted, the new, improved formulation can also be used in a normal atmosphere, i.e. under the influence of oxygen, eliminating the need for the nitrogen rinsing that was previously required. This not only saves time and money, but also opens up completely new areas of application. Large containers such as spray drying towers, tanks or agitator vessels (Fig. 4) can now also be cleaned easily. The derouging set sustainably improves the surfaces even in systems and machines that are difficult or impossible to inert due to their function, such as stainless steel washing machines in laboratories and hospitals. This means that the passive layer can be restored to its original condition even in these applications.

Fig. 4: Even large containers or stainless steel washing machines can now be cleaned without inertization

Fig. 4: Even large containers or stainless steel washing machines can now be cleaned without inertization

The environmentally friendly and time-saving new derouging method offers a certified option for cleaning and re-passivating all stainless steel surfaces on your own or as a complete package. The clean surface significantly improves safety in the production process and prevents quality problems.

Powerful against iron oxide

Fig. 5: When derouging with Dirupure, water for cleaning is heated to the required temperature in an external tank, the liquid or solid components are added and dissolved

Fig. 5: When derouging with Dirupure, water for cleaning is heated to the required temperature in an external tank, the liquid or solid components are added and dissolved

Environmentally friendly solutions are already a good alternative as anti-rouging agents. However, they have so far been unable to do much against the altered crystal structure during blacking. In such cases, pickling with aggressive chemicals was the only option. With the new Dirupure LIQ +P in combination with Sodex LIQ +P and Technopass LIQ +P, this is now history. The three-stage process can completely remove even the most stubborn rouging/blacking layers. When derouging with Dirupure, water for cleaning is heated to the required temperature in an external tank, for example, and the liquid or solid components are added and dissolved (Fig. 5). The temperature of the cleaning solution must be kept constant for the entire duration of the process, up to a maximum of two hours. For deblacking, after cleaning with Sodex solution, the Dirupure chemicals are also pre-dissolved and heated externally in the second step. After at least 90 minutes of constant circulation, the surface is clean again. If the system does not allow circulation, it can also be repeatedly filled and drained to achieve the cleaning effect. Then rinse with water and passivate with Technopass solution. Here too, the system is premixed externally and then passivated again with a reaction time of approx. 120 minutes at around 90 °C.

All photos: Ateco

INFO

Ateco at a glance

Ateco Tobler AG has been active in the field of high-purity media since 2004. With extensive experience in the planning, qualification and validation of high-purity media systems and expertise in the treatment of high-quality stainless steel surfaces, it offers advice on the removal of rouging and passivation processes. The execution of orders with simultaneous documentation of the work carried out not only saves time and money, but also ensures that all standards are observed in complex cleaning processes.

Ateco also supplies high-quality cleaning products for in-house operations. Thanks to its central location in Switzerland, the company is flexible on the European market and can help customers solve their rouging problems quickly and easily.