As a versatile energy carrier, hydrogen will play a key role in the long-term success of the energy transition.

Unfortunately, with an increasing proportion of hydrogen in natural gas networks and GDRM systems, the pulsation and vibration behavior in the pipelines changes due to the different sound velocities. The conversion of an existing natural gas system with regard to an increasing proportion of hydrogen should therefore be analyzed in terms of vibration as early as possible. Pulsation studies can be used to identify potential problems in advance. At the same time, continuous monitoring of the plant can significantly increase vibration safety. A new era of reciprocating compressors is thus developing for the storage and compression of hydrogen: while turbocompressors are subject to severe technical limitations, reciprocating compressors have clear advantages.

As part of the transition to sustainable energy sources, the use of hydrogen is increasingly being favored as a solution. Hydrogen is the chemical element with the lowest atomic mass. Under conditions that normally prevail on earth, it is not atomic hydrogen H that occurs, but molecular hydrogen H2 as an odorless gas (Fig. 1).

With the national hydrogen strategy, the German government is committed to a more diverse use of hydrogen [1]. Its use opens up great potential for reducing greenhouse gas emissions and should make a significant contribution to achieving climate targets in the future. The more than 500,000 kilometer long natural gas network and the existing natural gas storage facilities offer favorable transport and enormous storage possibilities [2]. However, numerous technical issues need to be clarified before this approach can be implemented. The following article deals specifically with the compression of hydrogen with existing compressor stations.

Compression of hydrogen with turbo compressors

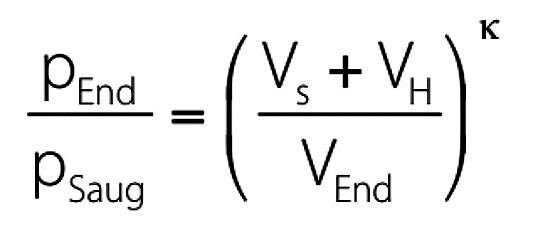

In the field of existing natural gas compressors, a basic distinction is made between turbo compressors (flow machines) and reciprocating compressors (positive displacement machines). However, the use of turbocompressors for hydrogen is not readily possible from a fluidic point of view. If one compares the basic properties of natural gas and hydrogen (see Table 1), in addition to the different density, the differences in the sound velocities are particularly noticeable.

Tab. 1: Comparison of pulsation-relevant material properties under the reference condition: Temperature 0 °C and 1 bar pressure

Tab. 1: Comparison of pulsation-relevant material properties under the reference condition: Temperature 0 °C and 1 bar pressure

Compression of hydrogen with a turbocompressor is only possible if the sound velocity triangles at the impeller inlet and outlet remain the same (Mach's similarity). For pure hydrogen, a four times higher throughput and a four times higher speed (circumferential speed) would therefore be required. This is hardly feasible for existing turbocompressor systems. For this reason, reciprocating compressors are favored for increasing the pressure of hydrogen.

Compression of hydrogen with reciprocating compressors

Compared to turbocompressors, the compression principle of reciprocating compressors allows them to be used almost independently of the pumped medium (Fig. 2). Nevertheless, when switching to a different pumped medium, the compressor, the pulsation dampers and the piping or storage system are confronted with completely different material properties. These have a significant influence on the pulsation behavior of the entire system and can therefore lead to a change in vibration behavior. The question arises as to what extent a natural gas compressor can be used for hydrogen from a dynamic point of view. A recommended approach is outlined below.

Fig. 2: Compression of hydrogen with reciprocating compressors (graphic: Kötter Consulting)

Fig. 2: Compression of hydrogen with reciprocating compressors (graphic: Kötter Consulting)

Pulsation-related aspects of reciprocating compressor systems

Fig. 3: Typical reciprocating compressor installation in 4-cylinder boxer arrangement with suction and pressure-side pulsation dampers for natural gas compression The reciprocating compressor (Fig. 3) can be used in various operating ranges at almost any pressure ratio due to its oscillating mode of operation. It is particularly impressive due to its robustness and excellent efficiency. However, the high maintenance costs and the dynamic forces, which can lead to increased vibrations, are disadvantageous.

Fig. 3: Typical reciprocating compressor installation in 4-cylinder boxer arrangement with suction and pressure-side pulsation dampers for natural gas compression The reciprocating compressor (Fig. 3) can be used in various operating ranges at almost any pressure ratio due to its oscillating mode of operation. It is particularly impressive due to its robustness and excellent efficiency. However, the high maintenance costs and the dynamic forces, which can lead to increased vibrations, are disadvantageous.

In order to avoid vibrations as early as the planning phase, calculations are carried out in advance in the form of pulsation studies, which provide information on the design and dimensioning of pulsation dampers, among other things. These are installed as close as possible to the cylinder flanges and enable an initial significant reduction in pressure pulsations.

Influences of hydrogen on the pulsation behavior of reciprocating compressors

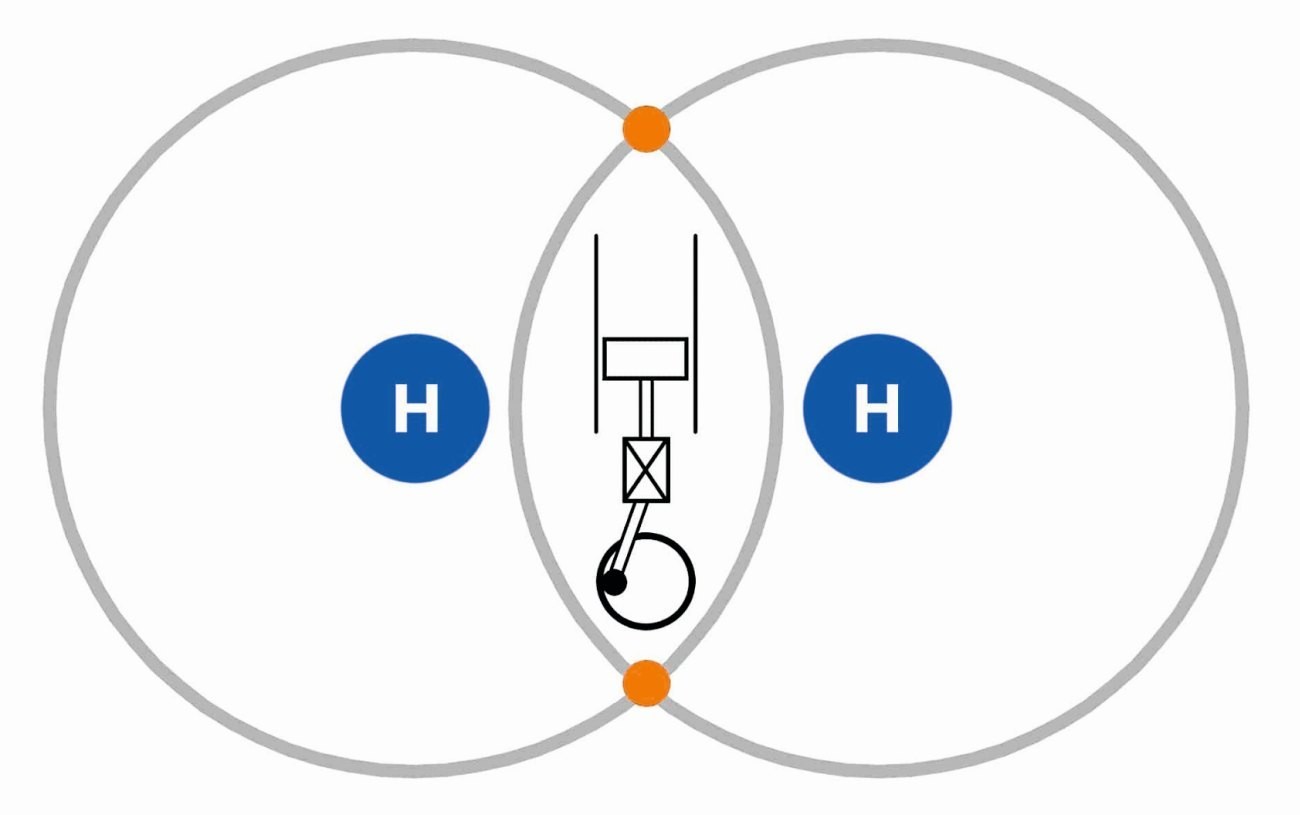

The use of hydrogen has numerous physical influences on the pulsation behavior of reciprocating compressors (Fig. 4). The compression process as well as the suction into and discharge from the working chamber can be assigned to the actual working principle of the compressor. The change in the acoustics of the pulsation damper and the influence on the piping acoustics in turn describe the resulting interaction of the compressor with the system.

Fig. 4: Influence of hydrogen on the pulsation behavior of reciprocating compressor systems

Fig. 4: Influence of hydrogen on the pulsation behavior of reciprocating compressor systems

Compression process

The main change during compression in the working chamber of any compressor is the significantly steeper increase in pressure depending on the chamber volume (Fig. 4 top left). This results from the substance-specific isentropic exponent. Due to the very rapid compression in the working chamber, an isentropic process can be assumed here. With the same chamber volume at the start of compression, the final pressure is reached significantly faster, which can be formally considered using the isentropic relationship equation <1

The equation clearly shows that with larger isentropic exponents and the same pressure ratio, the final pressure in the chamber volume is reached at an earlier point in time. This effect also occurs in the same way during the expansion after the end of the push-out. Switching to hydrogen therefore results in a larger volume flow compared to operation with natural gas. However, this effect is irrelevant if one considers the relationship between the two densities, which differ by a factor of around 9 depending on the state. This results in a significantly lower mass flow rate.

Suction / discharge

The changes during the actual compression in the working chamber also have an effect on the suction and discharge process. Figure 4 (top right) shows the discharge process on the discharge side based on the flow velocity as a function of the crank angle. It is clear that the compressor valves open slightly earlier when operating with hydrogen, as the final pressure is reached sooner. The same relationships apply on the intake side, whereby the acoustic excitation changes due to the intake or discharge process. These in turn have a significant influence on individual higher-harmonic components.

This effect has a positive influence on the pulsation level. The significantly lower sound impedance (product of sound velocity and density of the medium) leads to lower pressure fluctuations with constant velocity fluctuations. While the induced velocity fluctuations therefore remain at a similar level due to the similar volume flow, the induced pressure fluctuations are lower here.

Pulsation damper

The design of the pulsation damper is decisive for the vibration-related operating behavior of a reciprocating compressor system. They are therefore generally designed and manufactured individually for the respective process. A decisive influencing factor here is the sound velocity of the pumped medium. It is therefore essential to check what pulsation behavior occurs during operation with hydrogen.

Figure 4 (bottom left) shows an example of the damper effect for a high-quality pulsation damper in a two-chamber design with a "choke tube" in between. This design is often chosen for natural gas compressors. However, if the same compressor is now operated with hydrogen, the acoustic insertion loss shifts due to the higher speed of sound. As a result, the discharge frequency is now significantly less damped, which leads directly to increased vibrations.

Pipeline acoustics

The pulsations emerging from the pulsation damper then hit the piping system, in which so-called "acoustic resonances" can occur. Acoustic resonance always occurs when the length of an acoustic pipe section and the excitation frequency of an excitation source are in a specific ratio to each other, taking into account the speed of sound. In this context, a closed pipe branch is referred to as "acoustically closed", while a pipe connection at a container corresponds to an "acoustically open" end.

Figure 4 (bottom right) clearly shows that a variety of acoustic resonances can usually occur in pipe sections. The main difference between the position of the resonance frequency for natural gas and hydrogen is again due to the very different sound velocities. In addition, it can be seen that the damping elements (usually simple orifices or pulsation damper plates) installed to dampen acoustic resonances when planning existing systems have a significantly lower damping effect. As a result, resonance effects are more pronounced with hydrogen as the pumped fluid than with natural gas.

Formula symbol:

v (x, t) = flow velocity

p (x,t) = static pressure

ρ (x,t) = density

T (x,t) = temperature

κ = isentropic/polytropic exponent

R = specific gas constant

Z = real gas factor

μ = dynamic viscosity

INFO

Kötter Consulting Engineers:

Kötter Consulting Engineers is an independent consulting engineering firm specializing in noise and vibration technology. From consulting in the planning phase and support during commissioning to optimization measures or emergency interventions during operation, it develops solution concepts specifically in the areas of machines & systems, building physics & immission control and wind energy. The portfolio includes studies on machine dynamics and fluid mechanics, pulsation studies, technical acoustics, immission control, vibrations, wind energy and building physics.

From its two locations in Rheine and Berlin, the engineering office supports customer projects worldwide. Founded in 1978, Kötter Consulting Engineers now employs around 60 people.

Literature

[1] National hydrogen strategy of the German government for a more diverse application of hydrogen(https://www.bmu.de/download/nationale-wasserstoffstrategie/)

[2] Bick, D.S.; Schmüker, A.: H2 suitability of the long-distance gas network of the Open Grid Europe status, necessary adjustments and roadmap for implementation. Proceedings of the 34th Oldenburg Pipeline Forum