eloxalwerk züri-oberland ag in Wetzikon ZH is an independent provider of all surface solutions for aluminium materials. The family business was founded in 2010 through a management buy-out from Elma Electronic AG.

In the meantime, Michael Läubli - already the second generation - has taken over the management of the company. As part of the replacement of the control system for the water treatment plant, the company decided to get down to business. The entire ion exchanger circulation system was to be replaced and the wastewater treatment plant adapted to the latest state of the art. After all, the highest quality demands are also placed on the technical conditions in the company.

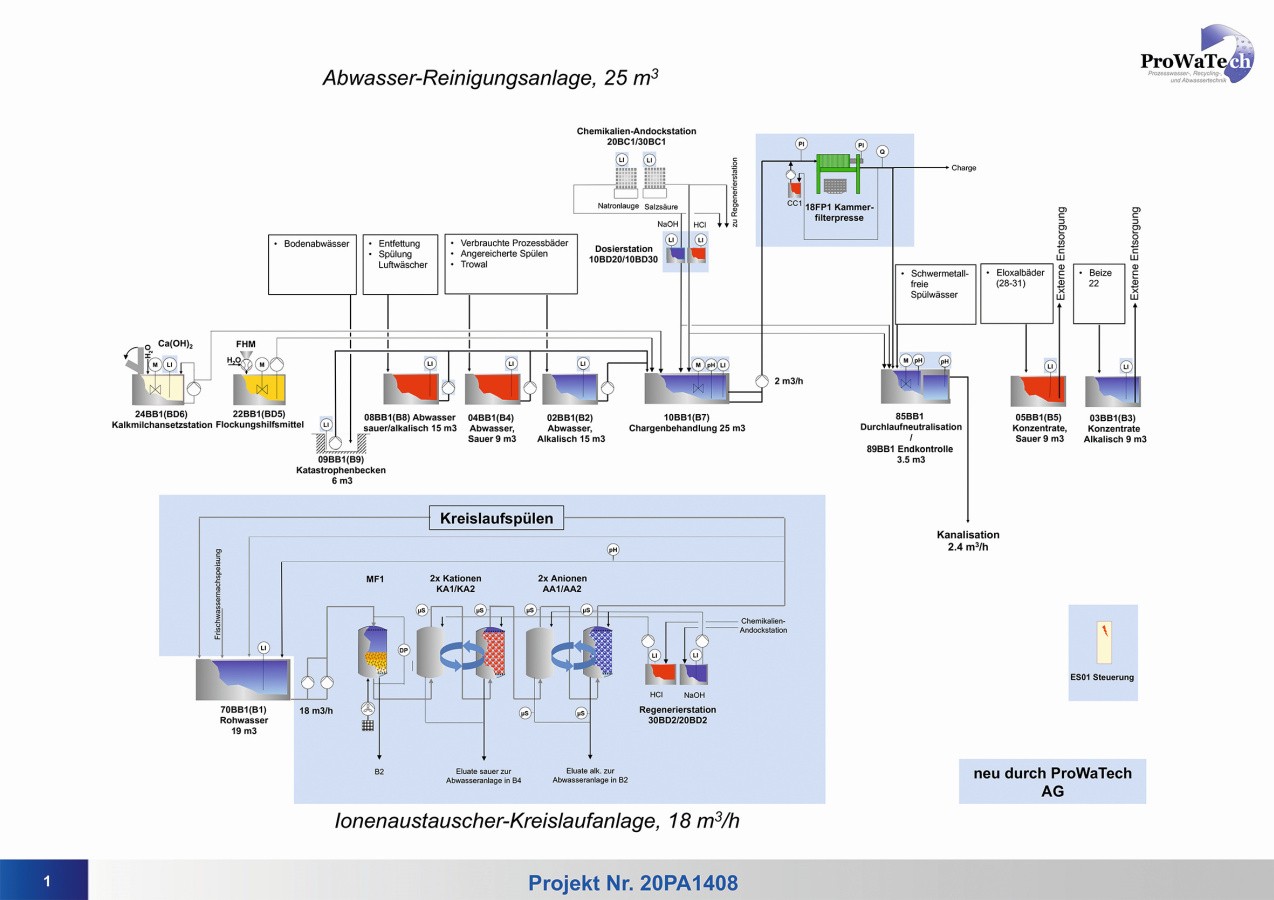

Figure 1: Process diagram as the basis for planning

Figure 1: Process diagram as the basis for planning

Initial situation

Figure 2: Basic image of the new visualization The company eloxalwerk züri-oberland ag operates a vertical rack machine in Wetzikon for pickling, anodizing, compacting and colouring aluminium. In addition to a variety of colors, vibratory finishing is also offered as a service.

Figure 2: Basic image of the new visualization The company eloxalwerk züri-oberland ag operates a vertical rack machine in Wetzikon for pickling, anodizing, compacting and colouring aluminium. In addition to a variety of colors, vibratory finishing is also offered as a service.

Recyclable rinsing water is recycled with the help of an ion exchanger, which saves valuable water. Non-recyclable and heavy metal-free rinsing water is neutralized and discharged into the sewage system. Rinse water and regenerates are treated in batches and the thin sludge is converted into a solid filter cake. The filtrate from the filter press is also neutralized before being discharged. The company has thus been operating environmentally friendly and high-quality water treatment processes for many years.

The task

The state of the art are advanced processes and facilities that help to limit emissions and thus protect the environment from negative influences. eloxalwerk züri-oberland ag has set itself the following tasks in the interests of continuous improvement and ensuring that its waste water system remains highly exemplary:

- Substitution of particularly hazardous substances

- Reduction of emissions through efficient use of chemicals

- Conserving resources by reducing the amount of fresh water required

- Increase process reliability and plant availability

- Higher automation and thus reduction of personnel costs

Planning phase

In collaboration with the engineers from Hauser + Walz GmbH, a detailed analysis of the current situation was carried out on site and compared with the best possible target situation. Once the proposed optimization measures had been defined, a project submission was prepared for approval under water protection legislation and presented to the Cantonal Office for Waste, Water, Energy and Air (AWEL) in Zurich. Following clarifications with the operator of the central wastewater treatment plant in Wetzikon, a new permit was issued by the AWEL and thus the go-ahead was given for the construction and operation of the new water treatment plant by ProWa-Tech AG.

The participation of eloxalwerk züri-oberland ag in the ÖKOPROFIT program of the Canton of Zurich (AWEL) had a positive influence on the approval process. ÖKOPROFIT (Ecological Project for Integrated Environmental Technology) is a practice-oriented program for improving resource efficiency in companies in the Canton of Zurich.

Catalog of measures

Michael Läubli in front of the new circulation system After the pre-treatment and anodizing electrolytes, flow measurement devices were installed in the slow-flow pre-sinks in order to reduce water consumption.

Michael Läubli in front of the new circulation system After the pre-treatment and anodizing electrolytes, flow measurement devices were installed in the slow-flow pre-sinks in order to reduce water consumption.

The company substitutes the use of hexavalent chromium for yellow chromating with a passivation containing hexafluorotitanate. The company has no longer used chromium trioxide since January 1, 2021, thus anticipating the ban on CrO3 in accordance with the Chemical Risk Reduction Ordinance from June 1, 2021.

The ion exchanger circulation system has been completely replaced. Thanks to countercurrent regeneration and series alternation, the need for regeneration chemicals and eluate production was reduced by 19 % compared to the existing ion exchanger system.

Additional measurements of turbidity, pH and conductivity values enable greater process reliability and monitoring. The new control and visualization system was equipped with a software tool so that the ProWaTech AG service technician can flexibly adjust the batch treatment program independently at any time during regular system maintenance with minimal time expenditure and without the help of software engineers.

The new filter press was equipped with an in-situ filter cloth cleaning system. A filter cloth cleaner is periodically pumped into the closed press via a storage tank and operated in a cycle. This avoids clogged filter cloths, the dry substance of the filter cake and the filtrate performance are constantly higher.

Basic pickling and acidic anodizing solutions are collected separately and recycled externally.

Implementation

The improvements to the plant technology and processes are in the details. One example is the technical design of the batch treatment. The reaction tank was equipped with a new polyethylene inlay, a tank spraying device (no incrustations in the tank) and measuring devices were installed on site (informative and easy to calibrate).

While most of us enjoyed the Christmas vacations - as far as the pandemic restrictions allowed - the very extensive conversion work was carried out in the period from December 21, 2010 to January 8, 2021. At no time was the timely commissioning of production affected.

A six-monthly maintenance service and short response times from the supplier in the event of system malfunctions will also ensure excellent availability of the entire water treatment plant at all times in the future.

Summary

Figure 3: New ion exchanger circulation systemConsideringthe tight schedule for the realization of the new plant components at the same installation site, starting with the commissioning on 23 July 2020 and ending with the commissioning on 11 January 2021, this was only possible thanks to the experienced project team of ProWaTech AG and the active support of eloxalwerk züri-oberland ag.

Figure 3: New ion exchanger circulation systemConsideringthe tight schedule for the realization of the new plant components at the same installation site, starting with the commissioning on 23 July 2020 and ending with the commissioning on 11 January 2021, this was only possible thanks to the experienced project team of ProWaTech AG and the active support of eloxalwerk züri-oberland ag.

Wastewater samples were taken from the final pH value control for one week under normal production operating conditions. The relevant metals including chromium, copper and zinc were analyzed using ICP-OES in a certified laboratory. The measured values of less than 0.1 mg/l were all well below the legal minimum requirements in accordance with the Water Protection Ordinance.

The experience of the first three months after the conversion shows that the sum of the measures has led to approximately a quarter less presence of the operating personnel for the wastewater treatment plant. The efforts are therefore not only a benefit for the environment.

Plant investments of around CHF 450,000.00 in times of COVID-19 testify to entrepreneurial courage and confidence. Ursi and Fredi Läubli can be proud to pass on their company to the next generation in top condition. They have made a significant contribution to protecting our environment.