The term "sustainability" has become a socio-political issue. This article clarifies from the perspective of a consultant to the chemical industry whether it is a new standard or just hype. Of course, there should be no talk of hype when developing sustainable solutions. However, guidance is needed, as the term sustainability is not something that is precisely defined. Rather, sustainable solutions should advance science, industry and society.

A look at the targets set by countries shows the development and increasing relevance of the topic. The European Union has set itself the goal of becoming climate-neutral by 2050. This means that greenhouse gas emissions in the EU are to be reduced to such an extent that they do not exceed the amount that natural sinks can absorb. The EU also has the interim target of reducing greenhouse gas emissions by at least 55% by 2030 compared to the reference year 1990.

Targets and interim targets differ

China has announced its intention to become climate-neutral by 2060 and not only wants to significantly reduce its greenhouse gas emissions, but may also use negative emission technologies. By 2030, China aims to peakCO2 emissions and increase the share of non-fossil energy sources in the energy mix. Under the administration of President Joe Biden, the USA has announced the goal of becoming climate-neutral by 2050. The exact reduction target for 2030 was announced in April 2021: to reduce greenhouse gas emissions by 50-52 percent compared to the reference year 2005.

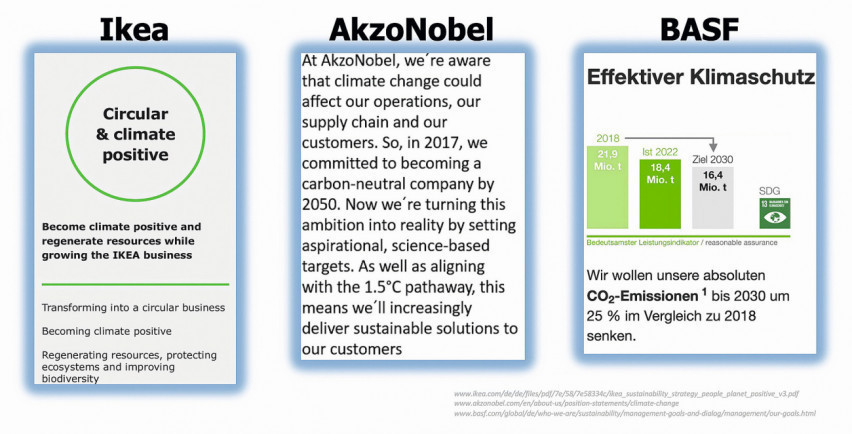

The proportion of countries that have committed to net zero emissions has risen from less than 10 percent to 95 percent in terms of global emissions. Globally active companies are also pursuing several sustainability goals. IKEA, for example, has set itself the goal of being climate-positive by 2030. The company wants to make its own operations and the entire supply chain more sustainable in order to achieve this. The company is increasingly focusing on renewable energy and investing in wind farms and solar energy. IKEA is also striving to use its resources more efficiently. AkzoNobel also has ambitious sustainability goals. The company aims to be climate neutral by 2050. The company is striving to reduce itsCO2 emissions along the entire value chain and increase the use of renewable energy. Another very important goal of the company is efficient water management in order to reduce water consumption and maintain water quality.

Many countries are even aiming for net zero emissions

A third example is BASF, which, like AkzoNobel, is pursuing the goal of being climate-neutral by 2050 and plans to reduce itsCO2 emissions by 25 percent by 2030 compared to 2018. The company is also committed to the responsible use of water and the protection of biodiversity (Figure 2). Fig. 2: Three companies, three goals: IKEA, Akzo Nobel and BASF define the path to climate neutrality

Fig. 2: Three companies, three goals: IKEA, Akzo Nobel and BASF define the path to climate neutrality

All three of these companies are pursuing the goal of a circular economy and want to develop products that last longer and are also repairable and recyclable. The companies also want to reduce their waste.

The three examples show that the industry is striving to become more sustainable and achieve climate neutrality. Issues such as a circular economy, recycling, waste reduction and efficient water management are also present and important for the leading companies.

BlackRock, the world's largest asset management company, which manages more than 10 trillion dollars, is also aware of its responsibility. In recent years, the company has taken increased action in the area of sustainability - it aims to tackle climate change sustainably through its investments. As a major shareholder in many companies, BlackRock takes its responsibility to make an impact at a corporate level. The firm is committed to ensuring that its holdings implement sustainable corporate governance and ESG disclosure. BlackRock emphasizes the importance of independent and competent boards and transparent management. BlackRock is also committed to encouraging companies to disclose their climate risks and adopt sustainable business practices.

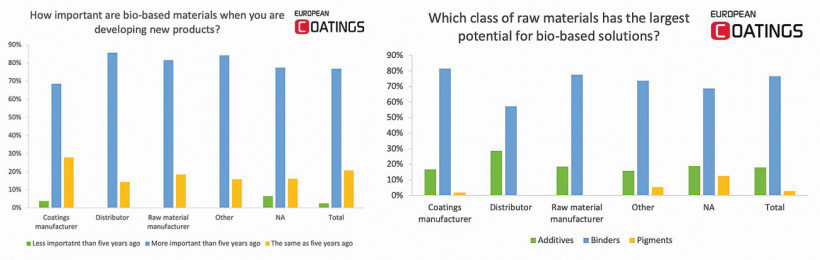

The increasing importance of bio-based raw materials is impressively demonstrated by a study by European Coatings (Figure 1). In chart 1 on the left, European Coatings shows how market participants assess bio-based raw materials; practically all of them see the increasing importance of a new class of raw materials. Chart 1: The left-hand side shows the market's assessment of bio-based raw materials. The right-hand side shows the raw materials that are most likely to be replaced by bio-based materials

Chart 1: The left-hand side shows the market's assessment of bio-based raw materials. The right-hand side shows the raw materials that are most likely to be replaced by bio-based materials

This leads to the following questions:

- How do you define sustainable raw materials?

- Are we talking about molecules that are based on mass balance in their production; are they possibly recycled materials; are they possibly based on depolymerized macromolecules?

- What is biobased and how should proof of biobasedness be provided?

- Are they self-declarations; do they require accelerated mass spectrometry to show the C14 content?

- What bio-content must a raw material or product have in order to be called bio-based?

Definition of the terms green, bio or sustainable urgently needed

In the other part of the European Coatings survey (Figure 1, right), participants were asked about the class of raw materials that has the greatest potential in terms of biobasedness. It is not very surprising that binders were mentioned in unison, followed by additives - in both cases, these are organic compounds. Above all, it is important to provide guidance. In addition to the industry, the scientific community, associations and politicians are also called upon to do this. This is the only way to ensure fair competition without consumers being misled.

Modern paint and varnish formulations

In the past, aqueous polymer dispersions with high glass transition temperatures (Tg) were often used to formulate aqueous emulsion paints and varnishes. The resulting minimum film forming temperatures (MFT) were also high. In order to be able to use the binders at colder temperatures close to 0 °C, coalescing agents (i.e. solvents) had to be used. Today, thanks to the internal plasticization of polymers and sophisticated technology, usually referred to as core-shell or power-feed, coalescing agents are used less and less. The use of alkylphenol ethoxylates, ammonia during neutralization and formaldehyde is usually dispensed with. Due to the efficient reaction process and the pure monomers, the last monomer molecules are also incorporated into the polymer chain so that the content of free residual monomers and volatile organic substances is very low.

In the past, the strong biocidal properties of aqueous dispersions have sometimes caused allergies. The industry is trying to dispense with allergens and replace them with other substances or dispense with them completely and - where possible - switch to preservative-free systems.

The use of high-performance components in paints and varnishes not only brings qualitative advantages: The sustainability of coatings that contain higher-performance components also benefits. You can imagine it like this: If an optimally post-treated titanium dioxide particle is well wetted by a high-performance binder, this results in a better contrast ratio and better abrasion, or a better gloss of the coating, even if less titanium dioxide and less binder are used. This is sustainable.

The voices of consumers and manufacturers

Today's consumers are well informed, they are open to new sustainable solutions and they are aware that we all have to contribute to the development. As the term organic can be very elastic, consumers are asking for a frame of reference: "How much organic does a product have to be in order to be called organic?" It is interpreted individually, sometimes the definitions are not consistent.

Producers seem to have specific ideas: If they mean "organic-based", they aim for at least 50 percent organic content in the raw material. This is also due to the fact that only a few substances can currently be synthesized 100% bio-based.

Users are open to bio-based products

Until recently, customers said that the raw materials should not have a price premium compared to petro-based substances. This is gradually changing. In the meantime, 20 percent higher prices are being accepted for bio-based raw materials. It cannot be ruled out that the accepted figure will be higher in the near future. In general, it can be observed that end consumers and product distributors are increasingly concerned with the issue of sustainable development and are open to new approaches.

In the discussion, we must not ignore the often used argument of "plate instead of tank". It is important that the underlying raw materials tend to come from bio-based waste and that nothing has to be grown separately for this purpose.

Interesting applications for bio-based binders: The applications of more sustainable binders have a wide range of uses and are used in practically all areas in which petrochemical binders are currently used. There is particularly great interest in the furniture industry, in the production of floor coatings and in the development of modern architectural paints. The interest of the furniture coatings industry is not surprising; IKEA has formulated several goals that should lead to more sustainable production. The supply industry is striving to meet these targets, which means that the entire supply chain is intensively researching bio-based solutions.

The OEM coatings, textile coatings and printing inks sectors are also working intensively on sustainable solutions. Other market segments that are interested in sustainable solutions are the construction chemicals and paper industries.

Bio-based building blocks on the market

The automotive industry has been working with very stable methacrylates such as isobornyl methacrylate for years. Durability, weather resistance and gloss retention are just some of the monomer's positive properties. Its special feature: it is obtained from isoborneol, i.e. from a native substance of bio-based origin. Although it has been on the market for years, users are finding new applications, especially when biobasedness is required. 2-octyl acrylate is arousing great interest on the market. The bio-based monomer has the potential to replace the petro-based 2-ethylhexyl acrylate. It remains to be said: If desired, emulsion polymerization can already be used to produce binders that are predominantly based on bioresources. Application technology shows that there are no disadvantages compared to petro-based polymers.

Bio-based materials must not have any functional deficiencies either

The acrylate or methacrylate acid esters are only 72 percent bio-based at most. This is due to the fact that the acrylic or methacrylic acid used to produce these monomers is based on petro-based chemicals. It is important to emphasize that promising efforts are underway to produce the two acids from biomaterials. It is only a matter of time before a commercially viable process is available. Another building block is succinic acid, which can be produced by fermentation from carbohydrates, in particular from starch and various oligosaccharides. The natural occurrence of succinic acid in the metabolism is used to specifically employ microorganisms that can produce it. There are now plants that are used for technical applications in biotechnological succinic acid production.

BASF offers 1,4-butanediol (BDO) from renewable raw materials. Bioproduction is based on a patented process developed by the California-based company Genomatica. In a fermentation process, the renewable dextrose is converted into a mixture of substances from which the 1,4-butanediol is isolated.

The innovative and new pentamethylene diisocyanate (PDI) from Covestro consists of 70 percent carbon, which is obtained from biomass without directly competing with food production. PDI offers manufacturers a hardener component based on renewable raw materials and an improved carbon footprint, which is a key differentiator. - to be continued -