With a new vacuum distillation process from H2O GmbH, process water containing PFAS can be treated efficiently and sustainably. Per- and polyfluorinated alkyl substances (PFAS) are organofluorine compounds in which the hydrogen atoms have been partially (poly-) or completely (per-) replaced by fluorine atoms.

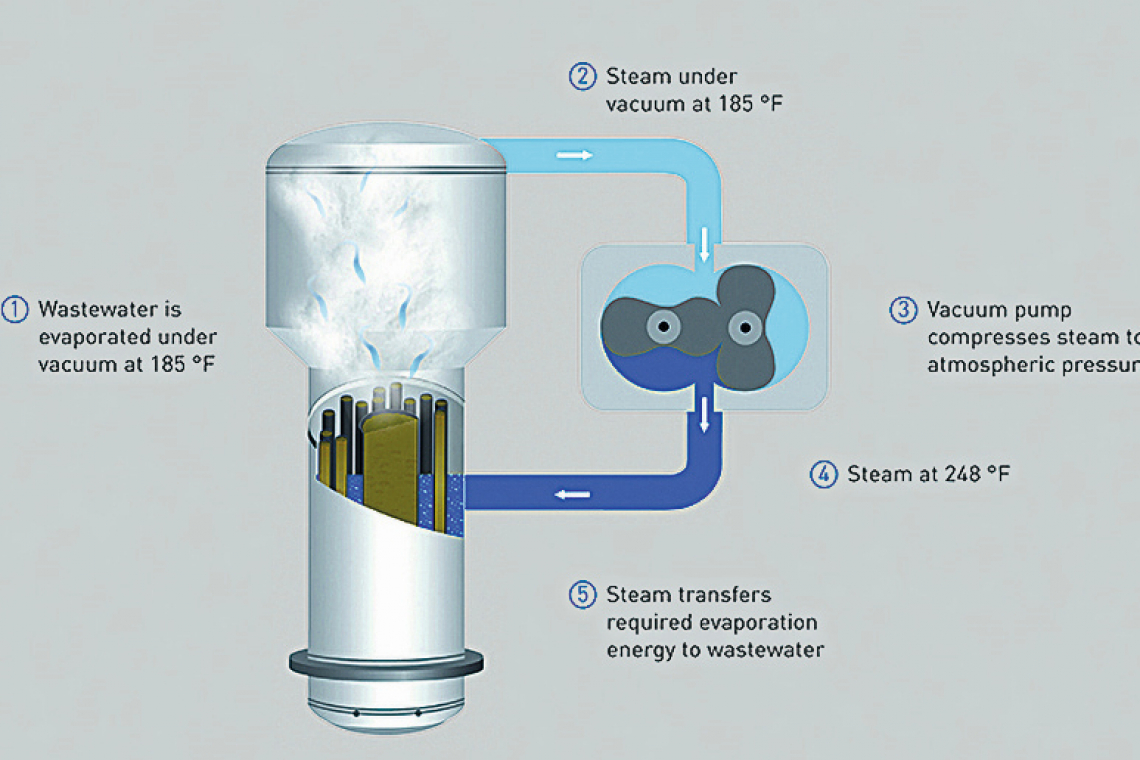

There are more than 10,000 synthetically produced chemicals that belong to this group. The effects of only a fraction of these on humans, animals and the environment have been sufficiently investigated. Treatment methods such as treatment with activated carbon, ion exchangers, membrane processes/reverse osmosis or oxidative processes for selected applications are suitable for the reliable and efficient treatment and circulation of PFAS-containing wastewater. However, due to the great variability of PFAS, complete separation cannot always be guaranteed for every compound. Vacuum distillation is based on the simple principle of separating substances according to boiling point differences - the industrial wastewater is evaporated. All substances with a higher boiling point than water remain in the evaporation residue. The process is particularly suitable for heavily contaminated wastewater. The distillate is PFAS- and salt-free and can subsequently be reused.