-Part 1 - Interactions between lubricants and steel surfaces and the resulting formation of friction- and wear-reducing tribochemical reaction layers are of fundamental importance for increasing efficiency. Coating tribological contact partners using physical vapor deposition (PVD) technology means that conventional steel/additive interactions cannot take place. An alternative to enable the formation of tribochemical reaction layers is the deposition of tribocatalytic coatings. Tribocatalytic elements such as Cu can interact with the lubricant.

Approach

The aim of the Cu modification of hard coatings is to convert the base oil molecules of the lubricant into layers of diamond-like carbon with a friction-reducing effect. To investigate the corresponding tribochemical interactions between the lubricant and the coating, (Cr,Al,W,Cu)N layers were deposited on the case-hardened steel 16MnCr5E using PVD hybrid technology. PVD hybrid technology combines direct current and high power pulse magnetron sputtering (dcMS/HPPMS). The tribological behavior of the coating was investigated in a pin-on-disc (PoD) tribometer. The synthetic, additive-free lubricant polyalphaolefin (PAO) was used as the lubricant. The tribocatalytic interactions were investigated using Raman spectroscopy. The influence of iron on the interactions was evaluated by varying the counter-body materials, 100Cr6 and Si3N4. At T = (23±5) °C and the use of a Si3N4 counter body, no catalytic interactions between coating and lubricant are detected. In contrast, at T = (90±5) °C and a 100Cr6 counterbody, increased carbon bonds are detected on the surface, indicating tribocatalytic interactions between the coating and PAO. In this study, a wear reduction was observed compared to a (Cr,Al)N reference coating. However, the observed tribo-induced reaction layer formation correlated with an increase in the coefficient of friction.

1 Introduction

Increasing environmental awareness and high energy costs are important development drivers in the design of industrial machinery and equipment and are driving efforts to increase the energy efficiency of such systems. However, an increase in energy efficiency goes hand in hand with increasing power densities on machine components and elements, resulting in higher wear rates and shorter service lives. For this reason, the reduction of friction and wear is of fundamental importance in many areas of industry. Over the past 40 years, hard coatings produced by physical vapor deposition (PVD) have been developed to reduce wear and are now state of the art in many applications. In addition to wear resistance, friction reduction through PVD coatings is also becoming increasingly important.

Conventionally, the interaction of steel surfaces of machine components with additives from lubricants causes the formation of friction- and wear-reducing tribochemical reaction layers, which contribute to the separation of the tribological contact partners [1]. By coating the interacting surfaces with wear-resistant inert coatings, however, such interactions are prevented. As a result, alternative approaches for the initiation of tribochemical reaction layer formation must be found and investigated. The modification of PVD coatings with tribochemically active elements, which can interact with the lubricant base oils and additives, offers great potential for enabling the formation of friction-reducing reaction layers in coated contacts as well.

In addition to the approach of modifying PVD coatings with triboactive elements such as W and Mo, which allow the formation of the solid lubricants WS2 and MoS2 through interaction with sulphur-containing additives [2], the modification of coatings with the tribocatalytically active element Cu also promises the possibility of forming friction-reducing reaction layers in tribological contact. The tribocatalytic effect of copper-containing PVD coatings was first investigated by Erdemir et al [3]. The modification of nanocrystalline MoN and VN coatings with Cu led to the formation of tribochemical carbon-based reaction coatings similar to amorphous carbon coatings, so-called diamond-like carbon (DLC) coatings, due to the interaction of Cu with the base oil of the lubricant polyalphaolefin (PAO) [3]. In experiments using a ball-on-disc tribometer, the formation of catalytically induced reaction layers correlated with the reduction of friction and wear in the lubricated steel/coating contact [3]. However, the formation of reaction layers due to catalytic interactions of PVD coatings with lubricants has been little studied. Against this background, the interactions between the coating system (Cr,Al,W,Cu)N and the unadditivated synthetic lubricant PAO were investigated in this study in order to demonstrate the potential formation of tribocatalytically induced and friction-reducing reaction layers. In addition to tribocatalytic interactions, the interaction between W from the coating and sulphur from the lubricant was also examined. This is possible because, despite the classification "additive-free", small amounts of sulphur are contained in the lubricant PAO for stabilization.

2 Procedure and investigation methods

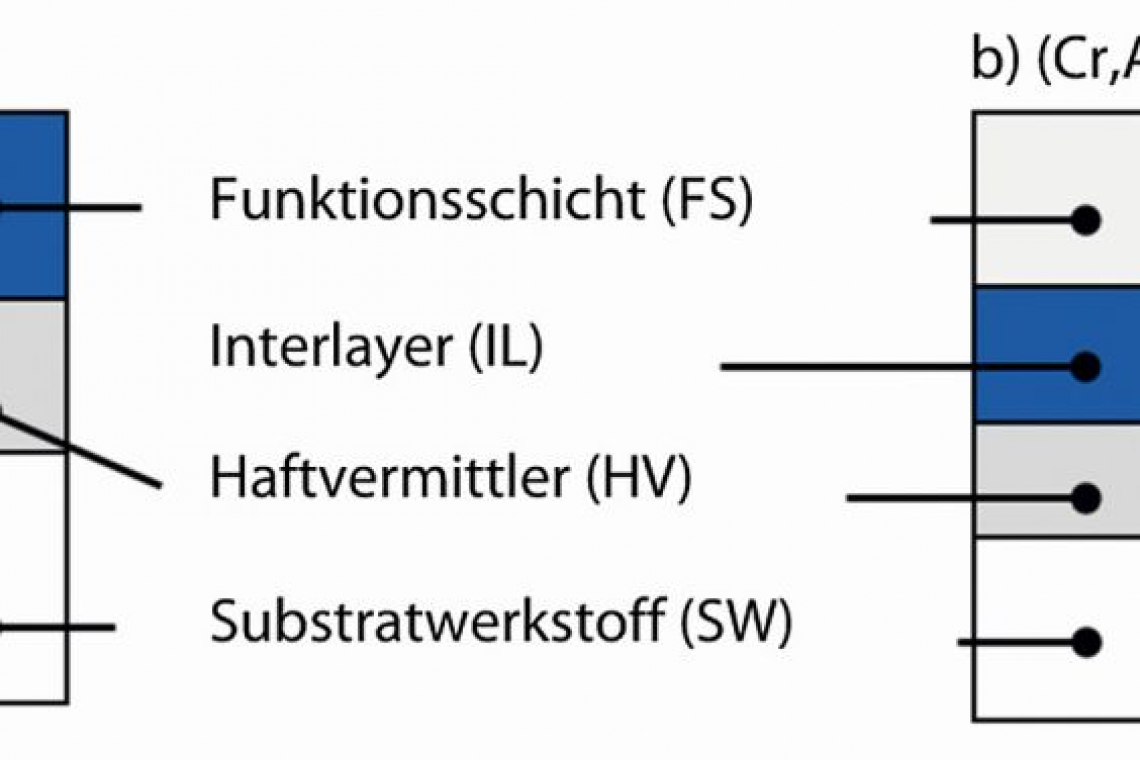

To investigate these relationships, a (Cr,Al,W,Cu)N coating was developed and deposited on the case-hardened steel 16MnCr5E (1.7131), hardness H = (60±2) HRC, using PVD hybrid technology - a combination of direct current and high power pulse magnetron sputtering (dcMS/HPPMS). The coating was produced using the CC800/9 HPPMS industrial coating system from CemeCon AG, Würselen, Germany, on polished round samples, Ø = 25 mm, h = 8 mm, Ra ≤ 0.02 µm. To synthesize the multilayer coating system shown in Figure 1, consisting of a (Cr,Al) adhesion promoter, HV, a (Cr,Al)N interlayer, IL, and the (Cr,Al,W,Cu)N functional layer, FS, the four dcMS and two HPPMS cathodes of the coating system were equipped with targets as shown in Table 1 .

| Process step | Target assignment | |||||

| dcMS1 | dcMS2 | dcMS3 | dcMS4 | HPPMS1 | HPPMS2 | |

| (Cr,Al) | Al | CrAl20 | CrAl20 | |||

| (Cr,Al)N | Al | CrAl20 | CrAl20 | |||

| (Cr,Al,W,Cu)N | Cu | W | CrAl20 | Al | CrAl20 | CrAl20 |

The number of cathodes used depended on the process step and the desired composition of the respective layer. Only the dcMS4 and both HPPMS cathodes were used for the production of the (Cr,Al) adhesion promoter, whereas all dcMS and HPPMS cathodes were used for the deposition of the (Cr,Al,W,Cu)N functional layer (Table 1). The designation CrAl20 indicates a Cr target in which 20 Al plugs are embedded. In order to be able to adjust the Cu content in the (Cr,Al,W,Cu)N functional layer within a moderate range of 10 at% ≤ xCu ≤ 30 at%, the dcMS3 cathode, which was equipped with an additional CrAl20 target, was used in addition to the cathodes used in the deposition of the (Cr,Al)N reference coating.

|

Process step |

|||

|

Process parameters [unit] |

(Cr,Al) |

(Cr,Al)N |

(Cr,Al,W,Cu)N |

|

UB,HPPMS [V] |

-100 |

-100 |

-100 |

|

ton [µs] |

40 |

40 |

40 |

|

f [Hz] |

500 |

500 |

500 |

|

[sccm] |

200 |

200 |

200 |

|

pN2 [mPa] |

- |

560 |

560 |

|

PdcMS1 [kW] |

- |

- |

0,5 |

|

PdcMS2 [kW] |

- |

- |

0,8 |

|

PdcMS3 [kW] |

- |

- |

3 |

|

PdcMS4 [kW] |

3 |

3 |

3 |

|

PHPPMS1 [kW] |

5 |

4 |

4 |

|

PHPPMS2 [kW] |

5 |

4 |

4 |

|

Legend: UB: bias voltage;ton: pulse duration; f: frequency; : argon gas flow; P: cathode power |

|||

The entire coating process was divided into four process phases: Heating, etching, coating and cooling. First, the heating power was set to PH = 1.5 kW for outgassing the vacuum chamber. The substrate surface was then etched for cleaning. To enable coating of the temperature-sensitive substrate material 16MnCr5E with a tempering temperature of T ≈ 180 °C, the heating was switched off during the etching and coating process. During the coating phase, the three-layer coating system was produced using the process parameters listed in Table 2. Finally, the coated substrates were cooled down to room temperature and the vacuum chamber was ventilated.

2.1 Analysis of the coating and composite properties

The topographical analysis of the coatings was carried out by confocal laser scanning microscopy (CLSM) using the VK-X210 microscope, Keyence, Neu-Isenburg, Germany. The line roughness of the coating was determined using the height-related data obtained from 50 line measurements in accordance with DIN EN ISO 4287. To analyze the coating morphology and thickness, transverse fractures of the coating composite were evaluated via scanning electron microscopy (SEM), ZEISS DSM 982 Gemini, Carl Zeiss AG, Oberkochen, Germany.

The chemical composition was analyzed using energy dispersive X-ray spectroscopy (EDX), Oxford Link ISIS, Oxford Instruments plc, Abingdon, England. With regard to the chemical composition of the deposited coatings, only the contents of the metallic components are given in the manuscript. The data do not correspond to stoichiometry, as local differences in composition may exist depending on the local phases present. The chemical compositions given therefore reflect the mean value from ten EDX measurements in each case.

The mechanical parameters of indentation hardness HIT and indentation modulus EIT were determined without mechanical post-processing of the coatings by means of nanoindentation using a Berkovich diamond. The TriboIndenter TI 950, Bruker Corporation, Billerica, Massachusetts, USA, was used. The indentation force was FInd = 10 mN. A total of 60 load-indentation depth profiles were recorded and evaluated. The method for calculating the indentation hardness HIT and indentation modulus EIT is based on the equations of Oliver and Pharr [4]. A constant Poisson's ratio of ν = 0.25 was assumed for the coating. Scratch tests based on DIN EN ISO 20502 were carried out to investigate the bond adhesion and optically evaluated via CLSM images to define the critical scratch loads Lc1, Lc2 and Lc3. The quantification of the bond strength in the composite (Cr,Al,W,Cu)N and 16MnCr5E was carried out using the HPG 200/2 scratch tester from the Gesellschaft für Fertigungstechnik und Entwicklung, Schmalkalden, Germany, at a constant scratch speed, vR = 10 mm/min, and a constant scratch load.

2.2 Investigation of the tribological behavior and tribocatalytic interactions between (Cr,Al,W,Cu)N and polyalphaolefin (PAO)

The tribological behavior of the (Cr,Al,W,Cu)N coating was investigated under continuous sliding conditions in a pin-on-disc (PoD) tribometer, CSM Instruments, Peseux, Switzerland, with an initial pressure of pH = 1,600 MPa, at a constant normal force of FN = 10 N, a radius of r = 5 mm, a relative velocity of v = 0.1 m/s and a running distance of s = 1,000 m at T = (23±5) °C and T = (90±5) °C. The base body was coated with (Cr,Al,W,Cu)N and polyalphaolefin (PAO). 16MnCr5E test specimens coated with (Cr,Al,W,Cu)N were used as the base specimens. Uncoated balls, Ø = 6 mm, made of 100Cr6 (1.3505) steel with a hardness of H = (60±2) HRC and ceramic balls, Ø = 6 mm, made of Si3N4 were used as mating specimens. The influence of iron on the tribocatalytic interactions was evaluated by varying the mating body material, 100Cr6 and Si3N4. The synthetic, additive-free lubricant PAO, ExxonMobil, Texas, USA, was used for the PoD tests. The analysis of the lubricant parameters density ρ, viscosity η and viscosity index VI was carried out at OELCHECK GmbH, Brannenburg, Germany (Table 3). Each combination of PoD test parameters was tested twice. A representative test result is shown in the results section. The results of the tribological tests of the (Cr,Al,W,Cu)N coating are compared below with those of a (Cr,Al)N reference coating, R, which was also produced using a hybrid process and the process parameters specified in Table 2. In the production of the reference coating, only the final synthesis of the functional layer was omitted and the duration for the production of the (Cr,Al)N layer was increased.

|

Lubricant |

Viscosity η [cSt] at T = 40 °C |

Viscosity η [cSt] at T = 100 °C |

Density ρ [kg/m3] at T = 15 °C |

Viscosity index VI [-] at T = 25 °C |

|

PAO |

63,3 |

10,5 |

0,85 |

156 |

The tribocatalytic interactions between coating and lubricant were investigated by Raman spectroscopy using the RENISHAW inVia REFLEX spectrometer, Renishaw GmbH, Pliezhausen, Germany. Raman spectroscopy was performed using a solid-state laser with a wavelength of λ = 532 nm. A grating with 1,800 lines per mm (l/mm) was selected. The Raman spectrometer was calibrated with a silicon reference sample before the measurements.

Literature

[1] H. Spikes: The History and Mechanisms of ZDDP, Tribology Letters 17 (2004) 469-489, https://doi.org/10.1023/B:TRIL.0000044495.26882.b5

[2] P.E. Hovsepian; P. Mandal; A.P. Ehiasarian; G. Sáfrán; R. Tietema; D. Doerwald: Friction and wear behavior of Mo-W doped carbon-based coating during boundary lubricated sliding, Appl. Surf. Sci. 366 (2016) 260-274, https://doi.org/10.1016/j.apsusc.2016.01.007

[3] A. Erdemir; G. Ramirez; O.L. Eryilmaz; B. Narayanan; Y. Liao; G. Kamath; S.K. Sankaranarayanan: Carbon-based tribofilms from lubricating oils, Nature 536 (7614) (2016) 67-71, DOI: 10.1038/nature18948

[4] W.C. Oliver; G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, Journal of Materials Research, 7, 6, (1992) 1564-1583, https://doi.org/10.1557/JMR.1992.1564

[5] J.C. Sánchez-López; A. Contreras; S. Domínguez-Meister; A. García-Luis; M. Brizuela: Tribological behavior at high temperature of hard CrAlN coatings doped with Y or Zr, Thin Solid Films 550 (2014) 413-420

[6] V. Korepanov; H. Hamaguchi; E. Osawa; V. Ermolenkov; I.K. Lednev; B.J.M. Etzold; O. Levinson; B. Zousma; C. PrakashEpperla; H.-C. Chang: Carbon structure in nanodiamonds elucidated from Raman spectroscopy, Carbon, 121 (2017) 322-329, https://doi.org/10.1016/j.carbon.2017.06.012

[7] B. Lafuente; R.T. Downs; H. Yang; N. Stone: The power of databases: the RRUFF project, in: T. Armbruster; R.M. Danisi: Highlights in Mineralogical Crystallography, (2015), W. De Gruyter, Berlin, Germany, 1-30, RRUFF ID R060514

[8] B. Lafuente; R.T. Downs; H. Yang; N. Stone: The power of databases: the RRUFF project, in: T. Armbruster; R.M. Danisi: Highlights in Mineralogical Crystallography, (2015), W. De Gruyter, Berlin, Germany, 1-30, RRUFF ID X050102

[9] A. Dychalska; P. Popielarski; W. Frankow; K. Fabisiak; K. Paprocki; M. Szybowicz: Study of CVD diamond layers with amorphous carbon admixture by Raman scattering spectroscopy, Material Science-Poland, 33, 4, (2015) 799-805, https://doi.org/10.1515/msp-2015-0067