HISTORY[S] OF ELECTROPLATING

A coating with a major impact on the electroplating industry and society

According to the literature, the introduction of galvanic chrome plating as a commercial process can be dated to around 1924, the year in which Liebreich's patent [1] - a key patent for galvanic chrome plating - gave this electroplating process a decisive boost. At almost the same time, a patent was filed in the USA by Fink [2], which was similar to Liebreich's patent in terms of its legal effect. This year, we can therefore look back on a 100-year history of galvanic chrome plating, which was revolutionary for the electroplating industry in many respects. Chromium deposition brought electroplating technology into the twentieth century at breakneck speed. Up to this point, electroplating practice had been more of an art than a science, which had hardly changed for decades and, as a small trade, was mainly concerned with silver plating of cutlery, gold plating of jewelry and nickel plating of small fittings. Now electroplating companies were forced to apply scientific methods not only to electroplating but also to other aspects of the technology such as cleaning, power supply, health and safety, waste water management, plant design and a host of other issues. All these problems had to be solved as soon as electroplating moved from small workshops into the world of mass production, especially in the emerging automotive industry [3].

Fig. 2: Chrome-plated single-lever mixer in a bathroom (Photo: stock.adobe.com/Iryna_I)With bright chrome plating, black chrome plating and so-called hard chrome plating, chrome electroplating helped the electroplating industry to conquer large markets worldwide.

Fig. 2: Chrome-plated single-lever mixer in a bathroom (Photo: stock.adobe.com/Iryna_I)With bright chrome plating, black chrome plating and so-called hard chrome plating, chrome electroplating helped the electroplating industry to conquer large markets worldwide.

Decorative chrome plating with layer thicknesses of 0.2 - 0.8 μm revolutionized the visual appearance of everyday objects in many areas. Soon it was impossible to look around without seeing chrome-plated objects. Flashing chrome surfaces on motor vehicles dominated the streetscape of large cities (Fig. 1), chrome and glass made banks and stores really stand out, no household was complete without chrome in the kitchen, bathroom (Fig. 2.) and living room, chrome-plated objects in offices, and countless instruments used by scientists, technicians and doctors could not do without chrome coatings.

However, this success story of decorative surface coatings with their bluish, shiny, hard, corrosion-resistant and non-tarnishing chrome layers - initially referred to as "metal cosmetics" - was not to last, as will be discussed later.

Metallic chromium was discovered by Louis-Nicolas Vauquelin in 1798, without it having any practical significance at the time. The very first beginnings of chrome plating date back to the 19th century, although proper chrome plating was not even conceivable at that time due to a lack of suitable power sources. Interestingly, the first attempts at chromium plating were made in the 1840s using trivalent chromium solutions, albeit with little success [3]. The basis for decorative chrome plating was not laid until the aforementioned patented results of Liebreich and Fink. In his book "Das Verchromungsverfahren" [4] published in 1926, Pfanhauser emphatically pointed out the high hardness of chrome plating layers and listed a number of areas of application where this hardness could be utilized. He mentioned the chrome plating of various types of tools, turbine blades for water and steam turbines, press molds, stamping dies, etc. The first practical utilization of the hardness of chrome plating for purely technical purposes was the bright chrome plating of copper gravure cylinders, which were thus given a multiple service life (Fig. 3). The hardness of the chrome coatings is naturally only effective if the coatings are sufficiently thick. It was not until 1938 that the conditions of hard chrome plating were properly recognized and could be used in practice [5]. Then, however, there was a tremendous upswing in this field and technical hard chrome plating, or rather thick chrome plating, opened up a completely new field of application for electroplating in addition to the previous areas of application of embellishment and corrosion protection in the field of machine and apparatus construction.

Chrome was a new metal for electroplating engineers in every respect. In the case of chromium, for example, the metal is present as a complex anion in its highest valence state. Even from today's perspective, it must be said that chrome plating only has disadvantages in its handling compared to other electroplating processes, such as its hexavalent form, low equivalent weight and extraordinarily low current yield. These three factors alone mean that the energy consumption of chrome plating is orders of magnitude higher than that of other galvanic metal deposition processes. Chromium plating works with high current densities and therefore requires very powerful current sources and large cable cross-sections. The chromium(VI) electrolytes are aggressive and highly corrosive. Since, due to the low current yield, a strong development of hydrogen leads to bath fogging during electrolysis, precautions must be taken to prevent this. The use of chromium in thin layers and the resulting short electroplating time mean that rinsing losses are disproportionately high and appropriate water treatment is necessary [5].

Fig. 3: Chrome-plated gravure cylinder with engraving (Photo: Stuttgart Media University)

Fig. 3: Chrome-plated gravure cylinder with engraving (Photo: Stuttgart Media University)

In view of this considerable degree of inadequacy of galvanic chrome plating, any other process would have had to fail. If chrome plating was nevertheless able to establish itself to such an extent, it was because the disadvantages of this process were obviously more than outweighed by the advantages of the product [5].

In the USA, the use of galvanic chrome plating began around 1925, almost simultaneously with the start of industrial automobile construction by companies such as General Motors and Ford [6]. In Germany, the shortage economy in the years of the Second World War also contributed to the further development of hard chrome plating, as hard chrome plating not only made it possible to significantly extend the service life of many devices, but in many cases also to replace the hard-to-obtain special steels with hard chrome plating of normal tool steel. Very often, it turned out that such a "replacement" delivered perfectly adequate results, so that hard chrome plating not only held its own after the war, but also continued to spread. Very often, hard chrome plating on normal steel was not only cheaper, but also more advantageous from a technical point of view than complete hard chrome plating on special steels [5].

The ever-increasing demands placed on decorative and corrosion-protective nickel-chromium and copper-nickel-chromium coatings by the automotive industry and its quality assurance tests triggered a wealth of research and development projects in chrome electroplating. The aim of the innovations in bright nickel plating, chrome plating, automated plant technology and much more was to constantly improve the decorative appearance, while at the same time protecting them from corrosion in the increasingly aggressive industrial climate caused by growing industrialization, and finally to meet the demands of constantly evolving industrial series production. The decorative corrosion-protective multi-coatings Ni-Cr and Cu-Ni-Cr, with all their problems, became the dominant topic of electroplating technology in research, development and production for a long time. The adoption and application of double nickel plating and micro-cracked chrome plating by American specialist companies also led to a lively discussion in Germany not only about the corrosion protection of Ni-Cr and Cu-Ni-Cr, but also about corrosion protection by electroplated layers in general. As the thin layers deposited by electroplating are not free of pores and cracks, the protection could only be partially based on a barrier effect. It was quickly recognized that corrosion reactions take place between the individual layers, so that coating systems had to be developed that optimally protected the base material against the respective atmospheric stresses. One of the most important findings, accelerated by the short-term corrosion tests (e.g. the so-called Kesternich test), was that chromium layers on mechanically polished matt nickel layers provided better protection against corrosion than those deposited on bright nickel. Of particular importance was the sulphur content, which was in the range of 0.04 to 0.08% by weight and higher in bright nickel, whereas the matt nickel generally contained only 0.01% by weight (6). The higher potential difference between the less noble bright nickel and the more noble chromium caused stronger corrosion currents and accelerated corrosion of the nickel layer, which could eat through to the base material. This realization led to the development of the "double nickel" process, in which the first nickel layer consists of matt or semi-bright nickel with a low sulphur content, on which a bright nickel layer and finally the chromium is deposited in a micro-cracked form. The improved corrosion protection effect of micro-cracked chrome compared to macrocracked chrome is due to the fact that a much larger nickel surface and therefore a much larger anodic surface is exposed. In addition, the micro-cracked chrome layer leads to better wettability, e.g. for oil, which was an advantage for use with lubricants.

Paradoxically, the decline in decorative chrome use began at a time when the process of decorative Ni-Cr deposition was enjoying unprecedented growth. This growth coincided with the development of reliable bright nickel electrolytes with their organic bright additive systems, which made large-scale, automated Ni-Cr deposition possible. The automotive industry, particularly in the USA, embraced chrome plating and large-scale chrome plating on cars became fashionable. But even at the same time, newer cars with heavily corroded coatings were a common sight, and voices were raised about how this didn't happen in the old days of polished, matte nickel coatings. To deflect attention from the serious corrosion problems, the suppliers of the extremely expensive organic bright nickel additives argued that the corrosion conditions had only worsened, that matt nickel was pure nostalgia and that the polishing of the matt nickel coatings was no longer necessary with bright nickel. It was practically five minutes to twelve when the causes of the increased corrosion caused by bright nickel were recognized. But by then, designers in the automotive industry had already begun to look for alternatives, such as the use of anodized aluminium or stainless steel. The long time that had elapsed for research into the causes of corrosion had in the meantime led to major damage to the image of the electroplating industry, although an explanation and technical solutions could now be offered [5].

From the second half of the 1970s, decorative Cu-Ni-Cr coating began to lose importance, particularly in the automotive industry. The slogan there was "save fuel/km", i.e. saving weight was the order of the day. Metal bumpers and hubcaps fell victim to this trend. It was possible to save on steel here, the corrosion protection of which could only be guaranteed with electroplating processes such as copper plating, nickel plating and chrome plating [6]. These high-turnover parts were replaced by hard rubber or plastics on various types of carriages. The reasons may have been of a fashionable nature or due to increased safety awareness and a reduction in production and repair costs [7]. The interior of the vehicles was not spared during the thorough rationalization process. The fact that the automobile had increasingly become a commodity rather than a luxury item for society certainly also played a role, so that designers replaced the chrome-plated components with cheaper painted plastic [8].

Another consequence of the "chrome-free" period in the automotive industry was that the large electroplating plants operated by car manufacturers in Germany and in most European industrialized countries were completely or partially abandoned and their orders shifted to contract electroplating companies, which, together with the electroplating companies, drove further development [8]. After the end of the "chrome-free" period, which reached its peak between 1988 and 1990 [8], more chrome parts began to be fitted to new models in order to increase their visual appeal. However, with the availability of various alternatives, manufacturers of higher quality products no longer wanted to see the ubiquitous and inexpensive chrome coatings on their products.

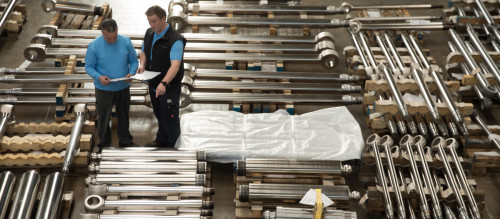

In contrast to decorative chrome plating, the importance of hard chrome plating with its higher layer thicknesses of 25 - 50 μm and its outstanding properties such as high hardness (800 - 1000 HV), high corrosion protection, high wear resistance, non-stick properties and high temperature resistance up to 800 °C continued to grow (Fig. 4). There are too many hard chrome applications to even come close to listing them all here. Examples of applications include the rebuilding of worn components, hydraulic cylinders, cylinder liners, exhaust valves for combustion engines, plastic injection molds, cutting tools and chrome coatings on broaching tools to release chips. However, with the advent of PVD and CVD processes for hard material coating, hard chrome plating has become a strong competitor in a number of application areas.

Fig 4: Hard chrome-plated rotationally symmetrical parts for cranes and excavators as well as the hydraulic and roller industry at Thoma Metallveredlung in Heimertingen (Photo: Thoma Metallveredlung)

Fig 4: Hard chrome-plated rotationally symmetrical parts for cranes and excavators as well as the hydraulic and roller industry at Thoma Metallveredlung in Heimertingen (Photo: Thoma Metallveredlung)

Chromium(III) electrolytes have been on the market since the seventies of the last century. For a long time, these processes were unable to gain a significant market share in the automotive industry in Europe [9]. Driven by the European chemicals legislation REACh, which requires chemical and process suppliers as well as coaters to replace chromium(VI)-based processes, the development of chromium deposition from electrolytes with trivalent chromium has now become a focus of scientific and technical galvanochromium deposition. The main reasons for the industry's increasing interest in trivalent chromium deposition are, in addition to the REACh requirement, the general interest in environmentally friendly processes and the OEMs' desire for individualization (color) and improved corrosion properties [9]. The requirements of OEMs for coating systems that can withstand corrosion in the very different global climate zones have grown and can significantly improve the corrosion resistance of classic coating systems for certain stresses (e.g. so-called Russian corrosion) with chromium (III) coatings.

Chromium coatings deposited from chromium (III) electrolytes differ in color from coatings produced by conventional chromium (VI) processes. However, special sulphate-based electrolytes already come very close to the color of classic chromium coatings. Specific mineral compounds based on nickel(II), tin(II), manganese(II) and, in particular, organic, mostly sulphur-containing electrolyte additives such as carbamates, methionine and thiodiethanol can be used to influence various factors such as layer thickness, layer distribution, color, gloss, hardness, pore density and wettability. The implementation of chromium (III) processes in existing plant technology is complex. Chromium (III)-based electrolytes have a much more complex structure than chromium (VI) electrolytes, which are characterized by a comparatively simple structure and which still dominate electroplating today.

" Driven by REACh, chrome plating with chromium(III) has become the focus of electroplating "

The fact that regulatory processes have a strong impact on electroplating production is nothing new. However, chemical suppliers and coating companies that have dedicated themselves to chrome electroplating from classic electrolyte systems have been subject to particularly stringent requirements for a number of years.

Almost in time for the 100th anniversary of chromium electroplating, a court annulment of the chromium trioxide authorization granted in 2020 once again caused great discomfort, as all the industry's efforts to review reports as well as measurements, notifications, investments, etc. have suddenly become obsolete [10]. Even companies that were prepared to make substitutions or individual authorizations have to fear losing their operating license, at least temporarily - a unique occurrence in the long history of chromium electroplating. Ultimately, however, the current burdensome regulatory situation will be just another page in the great electroplating history book.

Literature

[1] Liebreich, E. : DRP 448526, (1924)

[2] Fink, C.G. : USAP 1581 188, (1925)

[3] Silman, H. : Chromium Plating - Past, Present and Future, Interfinish (1984), 140-146

[4] Pfanhauser,W. Das Verchromungsverfahren, Leipzig-Vienna, Eigen-Verlag, (1926)

[5] Krämer, O.P., Weiner, R., Fett, M. : Die Geschichte der Galvanotechnik, Egon Leuze Verlag, (1959)

[6] Heymann, K. : Galvanotechnik im Strukturwandel, Metall 41 (1987), 282-283

[7] Jelinek, T.W., Lausmann, G.A. : Die Geschichte der Galvanotechnik, Egon Leuze Verlag, (2014)

[8] Bogenschütz, A.F. : Galvanotechnik - An industry with a future?, Galvanotechnik 74 (1983), 4, 387-392

[9] Pofalla, R. : Chromium III applications, ZVOreport (2014) 4, 44-45

[10] Zimmer, M.M. : Can we still be saved?, ZVOreport (2023) 4, 3