- Part 3 - Aluminum alloys: Extrusion and casting

The versatile light metal aluminum can be processed into components in various manufacturing processes. These include processing using the extrusion process or the production of cast plates and ready-to-form cast parts. Aluminum alloys are usually used for this.

Manufacturing process - extrusion of aluminum

The extrusion process is a continuous process in which aluminum or aluminum alloys are pressed through a die to produce complex cross-sectional profiles. This technique enables the efficient production of high-quality components for a wide range of applications, from the automotive industry to construction and electronics.

The basics of extrusion

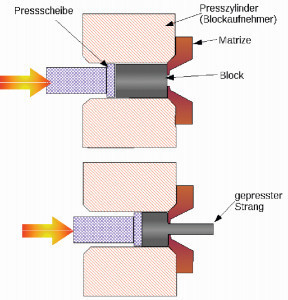

Extrusion is a forming process in which an extrusion billet (also known as a press billet) is pressed or drawn through a special tool form (die) to produce an elongated, often complex aluminum profile. The aluminum is plastically deformed to achieve the desired shape and dimensions. Typically, aluminum alloys with good extrudability are used, as these alloys have an optimal combination of formability, strength and corrosion resistance. Fig. 1: Graphic representation of the extrusion process

Fig. 1: Graphic representation of the extrusion process

Extrusion process sequence (Fig. 1)

- Preparation of the extrusion billet: The process begins with the selection and preparation of the extrusion billet, which is usually made of extruded aluminum. The extrusion billet is heated to operating temperature in order to increase its malleability.

- Inserting the extrusion billet: The heated extrusion billet is inserted into the extrusion press, where it is positioned between the die and the moving plunger.

- Extrusion press: The plunger moves in the direction of the die gap, exerting pressure on the extrusion billet. The preheated extrusion billet is pressed through a die that has the desired profile. The die is made of hardened steel and contains a hollow chamber that corresponds to the desired cross-section of the end product. During the pressing process, the aluminum is forced through the die, giving it the desired shape.

- Cooling and hardening: After extrusion, the extruded aluminium profiles are passed through cooling devices to stabilize their shape or they are left to cool in the air. Depending on the alloy and application, further heat treatment processes can be carried out to improve the mechanical properties of the material.

- Post-processing: The extruded profiles can be further processed as required, for example by cutting, drilling, milling or bending, to achieve the final shape and dimensions.

Advantages of aluminum extrusion

- Design freedom: extruded aluminum profiles can be produced in almost any desired shape, giving designers great freedom in the design of products.

- Material utilization: Extrusion allows aluminum to be efficiently formed into complex shapes, minimizing material waste.

- Weight reduction: Aluminum profiles are significantly lighter compared to steel profiles with the same strength, leading to weight savings in applications such as the automotive industry.

- Cost efficiency: Extrusion technology allows mass production of profiles in a short time, which leads to a reduction in costs.

Extruded profiles (Fig.2) offer a wide range of applications due to their customizable shapes and sizes. They are often preferred for their high load-bearing capacity, corrosion resistance and design flexibility.

Fig. 2: Extruded aluminum profiles for use in automotiveconstructionThere areapplications

Fig. 2: Extruded aluminum profiles for use in automotiveconstructionThere areapplications

in the construction industry...

- Window frames and door frames

- Facade cladding

- Railings and stair handrails

- Sun protection slats

- Partition wall systems

In transportation...

- Bicycle frames and handlebars

- Car body structures

- Trailer and truck bodies

- Rail vehicle interiors

In electronics and electrical engineering...

- Housings for electronic devices

- Control cabinet profiles

- Heat sinks for power electronics

- Support systems for cables and cabling

For furniture and furnishings...

- Furniture frames and structures

- Shelving and storage solutions

- Shopfitting and display systems

For lighting...

- LED profile housings for lighting applications

- Spotlight housings and lamp profiles

For sports and leisure equipment...

- Ski and snowboard frames

- Bicycle frames and components

- Tent poles

For industrial applications...

- Conveyor belt profiles

- Assembly systems for machines and plants

- Production and logistics racks

In medical technology...

- Medical device holders and structures

- Examination tables and couches

In the solar energy sector...

- Frames for solar modules

- Mounting systems for solar installations

In the marine and shipping industry...

- Ship components and structural parts

- Masts and support structures for boats

As well as in automation and robotics...

- Robot structural parts

- Conveyor belt guides

Conclusion

The extrusion process is a key component of aluminum processing, enabling the production of versatile and robust profiles for a wide range of applications. Its ability to produce complex shapes with high precision has made it an indispensable technology in various industries ranging from construction to automotive and electronics. The continuous development of alloys and process technologies will undoubtedly lead to new innovations and applications of the extrusion process in aluminum processing.

Manufacturing process - aluminum casting

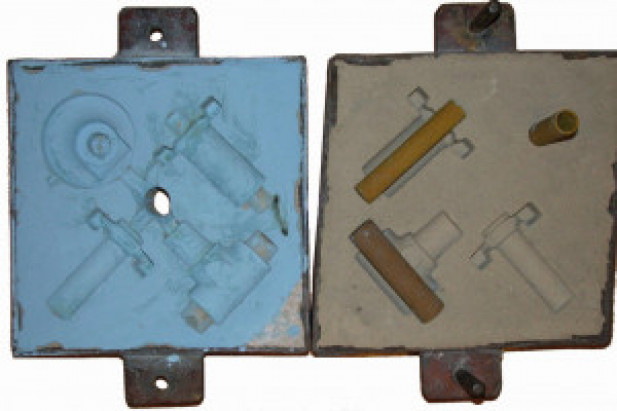

Aluminum casting is another manufacturing method that is used in various industries due to the versatile properties of aluminum alloys. The manufacturing processes of sand casting, gravity die casting and die casting are specifically selected depending on the application, requirements, quantities and complexity of components. Fig. 3: Upper and lower box of a sand casting mold, filled with cores on the right, which later form the cavities in the mold

Fig. 3: Upper and lower box of a sand casting mold, filled with cores on the right, which later form the cavities in the mold

Sand casting (Fig. 3)

Sand casting is one of the oldest casting processes and is also used for aluminum. In this process, a negative of the mold to be cast is made from sand. First, a model or pattern of the desired part is created. This model is embedded in molding sand to create a negative mold. The mold is then opened, the model removed and the cavity created is filled with liquid aluminum alloy. After solidification, the mold is opened and the cast part is removed. Sand casting is suitable for complex molds and small to medium production quantities.

The process in detail

- Pattern making: The sand casting process begins with the creation of a pattern or sample of the desired part. This pattern can be made from wood, plastic, metal or another suitable material. The pattern serves as a positive image of the final product and is used to make the mold for the casting.

- Mold making: The mold into which the molten aluminum is poured is made from molding sand. Molding sand consists of a mixture of sand, binders and often additives, which can be mixed in to achieve certain properties. The molding sand is filled into mold boxes, which form the negative of the part. There are two mold halves: the upper and lower mold halves.

- Mold closure and core placement: The two mold halves are joined together to close the mold. Before closing the mold, cores can be inserted to form internal cavities or complex internal structures of the part. The cores are made from sand or other materials and placed in the mold boxes.

- Casting: Once the mold is closed and the cores are placed, the liquid aluminum alloy is poured into the mold. This is done by pouring in the liquid metal using a casting ladle or crucible. The alloy flows into the mold through pouring channels and hoppers and fills the cavities defined by the mold and cores.

- Solidification and cooling: Once the molten aluminum has filled the mold, it begins to cool and solidify rapidly. During this process, the metallic structure of the part is formed. The cooling rate and heat dissipation influence the mechanical properties and microstructure of the cast part.

- Demoulding and finishing: Once the aluminum has completely solidified, the mould is opened. The cast part, often referred to as a casting, is carefully removed from the mold. At this point, additional finishing steps may be required to remove excess sand or flash. This may include grinding, cutting or other finishing steps to achieve the desired surface finish.

- Recycling the molding sand: The molding sand can be reused after the casting process. It is cleaned of the casting burrs and excess material and can then be used again for mold production. This contributes to the sustainability of the sand casting process.

Overall, the sand casting process enables the production of parts with complex geometries and individual requirements. The versatility of this process makes it a preferred choice for prototypes, small batches and parts where molding flexibility is required.

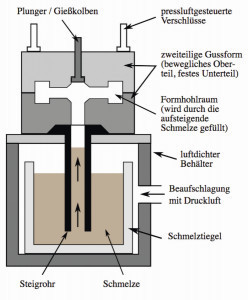

Permanent mold casting

Permanent mold casting, also known as permanent mold casting, uses a reusable mold (die) made of steel or cast iron. The mold is coated to prevent the aluminum from sticking. The mold is closed and liquid aluminum is injected into the mold under pressure. The rapid cooling results in parts with a high surface quality. This process is suitable for medium to large production quantities and parts with precise dimensions.

The gravity die casting process in detail (Fig. 4) Fig. 4: Low-pressure die casting is a variant of gravity die casting. The molten metal enters the die through a riser pipe as soon as the bath level is pressurized. The technique favors dense and pore-free casting, e.g. for aluminum wheels for automobiles

Fig. 4: Low-pressure die casting is a variant of gravity die casting. The molten metal enters the die through a riser pipe as soon as the bath level is pressurized. The technique favors dense and pore-free casting, e.g. for aluminum wheels for automobiles

- Preparing the mold: The mold is a reusable metal mold made of steel or cast iron. It consists of two halves that are carefully machined to achieve the desired shape of the end product. The surfaces of the mold halves are often coated to prevent the molten metal from sticking and to extend the life of the mold.

- Preheating the mold: Before the casting process, the mold is preheated to a certain temperature. This helps to ensure uniform solidification of the molten metal and prevents cracks or distortion in the cast part.

- Closing the mold: The two halves of the mold are closed to form the cavity into which the molten aluminum is poured. The halves are closed with a suitable force and secured by bolts or hydraulic systems.

- Pouring: Liquid aluminum is injected into the mold. This is often done under pressure to force the metal into the smallest details of the mold and ensure precise shaping. Pressure is maintained during the casting process to force the metal into the mould and minimize any air pockets.

- Solidification and cooling: After casting, the molten aluminum begins to solidify quickly in the mold. The rapid solidification results in parts with tight tolerances and a high surface quality. Cooling is supported by the heat dissipation of the mold.

- Demoulding: As soon as the aluminum has solidified completely, the mould is opened and the finished part, also known as a casting, is removed. Demolding can be automated or manual, depending on the size and complexity of the part.

- Post-processing: After the casting process, additional post-processing steps may be required depending on the requirements of the end product. This may include removing burrs, cutting excess material or finishing the surface to achieve the desired quality.

- Mold maintenance: The mold is subject to wear and tear over time. Regular maintenance, cleaning and repairs are required to maintain the quality of the molded parts. In some cases, the mold can also be recoated or repaired to extend its life.

The permanent mold casting process enables the efficient production of high-quality aluminum parts with precise dimensions and surface finishes. This process is used in industries such as automotive, electronics, aerospace and others where high production volumes and precision are required.

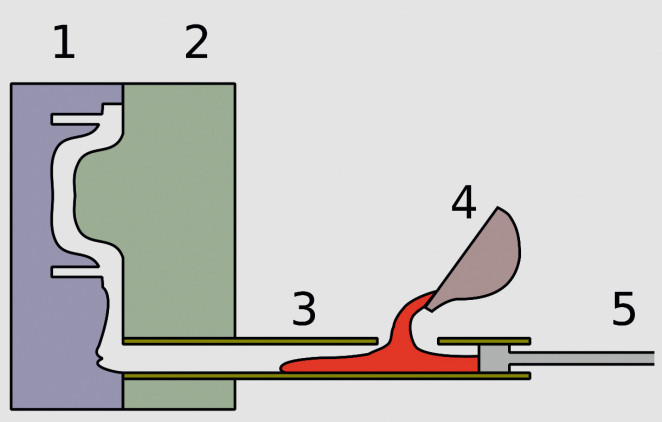

Die casting

Die casting is a high-pressure casting process in which liquid aluminum is injected into a mold under high pressure. The mold, also known as a die, is often made of steel and enables the production of complex and thin-walled parts with tight tolerances. The process is particularly suitable for high production volumes and is used in the automotive industry, electronics and many other sectors. This process is characterized by its high precision, fast cycle times and the ability to produce thin-walled parts. Fig. 5: The die casting process. Schematic of a cold chamber die casting machine: 1=die casting mold half, 2=stationary mold half, 3=cold chamber, 4=lamella, 5=die casting plunger

Fig. 5: The die casting process. Schematic of a cold chamber die casting machine: 1=die casting mold half, 2=stationary mold half, 3=cold chamber, 4=lamella, 5=die casting plunger

The die casting process in detail (Fig. 5)

- Mold production: The mold, also known as the die or tool, is made of high-strength steel. The die consists of two halves - the fixed die half and the movable die half - which are precisely machined to produce the desired shape of the end product. Cooling channels are provided in the die to aid rapid cooling of the cast metal.

- Closing the die: The movable die half is opened and the fixed die half is closed. The cavities formed by the two mold halves correspond to the negative shape of the desired part.

- Injecting the molten metal: Liquid aluminum is fed into a die casting machine, which melts the metal and keeps it at a precise temperature. The molten metal is then injected into the closed mold under high pressure. This pressure makes it possible to press the metal into every corner of the mold and create complex geometries.

- Solidification and cooling: As soon as the metal has been poured into the mold, it begins to solidify. Cooling takes place through heat dissipation via the die. As the casting process is fast, the metal usually cools down in a few seconds and reaches its final shape.

- Opening the die: Once the metal has solidified, the movable half of the mold is opened. This allows access to the finished part, which is often referred to as a casting.

- Removal and finishing: The cast part is removed from the die. In some cases, burrs or excess may occur on the mold parting surfaces that need to be removed. These excesses can be removed by grinding, milling or other processing steps to achieve the desired surface finish.

- Reuse of the die: The die, also called a permanent mold, can be used for thousands of casting cycles before it is worn out. Regular maintenance, inspection and, if necessary, repairs are required to ensure the quality of the cast parts and extend the life of the die.

Fig. 6: Preparation of the aluminum melt in the BMW light metal foundry in Landshut

Fig. 6: Preparation of the aluminum melt in the BMW light metal foundry in Landshut

Applications of aluminum casting

The die casting process enables the production of parts with high precision, tight tolerances and thin-walled structures. This process is used in the automotive industry, electronics, medical technology and many other sectors where high quality and precision are required. The applications of aluminum casting range from consumer goods to industrial applications.

There are possible applications in the

Automotive industry...

- engine housings

- Gearbox housings

- Chassis parts

- Steering and suspension components

- Wheel hubs and brake calipers

In electronics...

- Cases for computers and laptops

- Smartphone housings

- Electrical connectors

- Heat sinks for power electronics

In the aerospace industry...

- Aircraft components such as wings, aircraft doors

- Aerospace structures and components

In the household appliances sector...

- Cookware such as pans and pots

- Coffee machines

- Electrical household appliances such as mixers, toasters

In sports and leisure equipment...

- Bicycle frames and components

- Fishing rods and reels

- Sports equipment such as golf clubs

In medical technology...

- Medical device housings

- Surgical instruments

- Prosthetic devices

In power generation...

- Wind turbine components

- Parts for solar energy systems

In the marine and shipping industry...

- Ship components and structural parts

- Yacht components

And in the art and design sector...

- Sculptures and works of art

- Designer furniture and accessories

Figure 7: Structural cast aluminum component with integrated strut support

Figure 7: Structural cast aluminum component with integrated strut support

The challenges

The production of aluminum castings requires precise control of casting temperature, pressure and cooling to achieve the desired mechanical properties and surface finish (Fig. 6). Selecting the right alloy also plays an important role, as different alloys have different properties. Challenges in aluminum casting include porosity, microstructure irregularities and distortion. These challenges require careful process control and quality monitoring.

Conclusion

Aluminum casting is a manufacturing process that serves a wide range of applications. Sand casting, permanent mold casting and die casting are the main processes, which are selected depending on the production quantity, precision and complexity of the part. The continuous development of aluminum alloys and casting technologies will contribute to aluminum casting playing an even more important role in various industries in the future.

Summary

The manufacturing processes described in the last issue and this issue allow aluminum to be used in a variety of ways in all industries. The properties of the light metal, which are controlled by the alloys and heat treatments, make this diversity possible. Aluminum has become an integral part of our daily lives. This starts with wrapping breakfast in aluminum foil and opening a beverage can and extends to using the car or public transport and leisure activities. The way in which components are manufactured is already taken into account during the planning phase. The focus is on the requirements for the aluminum alloy and the economic factor.

Various surface coatings contribute to optimally supporting the requirements of parts and components - both in the decorative area and in fulfilling certain technical properties. A targeted selection of the manufacturing process, material requirements and surface coatings makes it possible to produce high-quality components that are fully suitable for their area of application.