Following the discussion of dirt layer structures, material-specific properties and the electrochemical surface cleaning process in Part 1 of this series, we will now take a closer look at the dirt layers. These usually occur as dirt films, i.e. they contain solvents. The moisture in the dirt promotes galvanic reactions. For the selection of the surface cleaning technology, the type of dirt is evaluated.

The object and its dirt film - a galvanic model

Dirt is classified according to its origin:

- Particles of the cutting tool (grinding paste, chips and chips of cutting edges, binders, etc.)

- Particles from the component (swarf, grinding dust, abrasion, casting skin, etc.)

- Dirt from the environment (oil mist, swarf, hall dust, fan dust, etc.)

- auxiliary materials from production (oils, greases, cooling lubricants, coolants, etc.).

A distinction is made according to the chemical composition of the dirt:

- Mineral oils

- Synthetic oils

- Organic oils and greases, drawing soaps

- Metallic chips

- Solid particles

- fibers

- Resinated waste oils and greases

- Waxes

- Inorganic particles such as rubber, plastics.

A distinction is made according to the aggregate state:

- Solid, hard particles, non-compressible materials

- Liquid contaminants with dissolved substances

- Pasty contaminants

- Condensed gases/vapors

A distinction is made according to the chemical and physical properties:

- Mechanical properties (adhesive, lubricating, abrasive, etc.)

- Chemical properties (polar/non-polar, organic/inorganic, saponifiable/non-saponifiable, basic/acidic/neutral, etc.)

- Electromagnetic properties (magnetic or magnetizable, statically chargeable, etc.)

- Thermal properties (temperature resistance, coefficient of expansion, flammability, combustibility, etc.)

- Viscous properties (surface tension, adhesion, etc.)

- Aero-/hydromechanical properties (particle size and particle shape, surface contours, cw values, etc.)

- Molecular properties (position in the PSE, electrical charges, molecular structures, etc.).

However, these classification criteria are not sufficient for selecting the optimum cleaning process. Based on tests and experience, the contaminants are described and assigned to a possible technology in groups.

From practical experience in dealing with water-soluble cleaning agents, a grouping as shown in Table 1 can be used:

|

No. No. |

No. Group |

|

1 |

Free of org. salts / replaces highly alkaline systems / particle and graphite removal |

|

2 |

Cold and high pressure sprayable (from 25 °C up to 700 bar net) |

|

3 |

Highly demulsifying / binds cooling lubricant |

|

4 |

Low-salt, salt-free, powerful cleaner before and after hardening process |

|

5 |

Highly alkaline, inhibited systems |

|

6 |

Highly alkaline systems, for extreme soiling, pickling |

|

7 |

Ready-to-use multi-metal cleaners as a solvent substitute / can be painted over |

|

8 |

Acidic and neutral metal cleaner (pickling), acidic plastic cleaner for PUR and GRP |

|

9 |

Alkaline plastic cleaner and alkaline metal cleaner |

|

10 |

Neutral cleaner with passivation |

|

11 |

For forged parts, removes traces of smears, demulsifying, passivating |

Table 1 and Table 2 on aqueous cleaners and the classification of component base materials in the periodic table of elements (PSE) show that component base materials have different electrical properties and that all foreign particles/dirt particles adhere to the component surface by charging. If it is possible to discharge or neutralize the component surface to the foreign/dirt particles on the component surface, it should be possible to mechanically remove the foreign/dirt particles with their mass from the component surface. The neutralization of the charges can be supported and controlled by low voltage and low current, as is well known in electroplating.

|

pH value |

Immersion |

Ultra- sonic |

Pressure flooding |

Spraying |

steel |

galvanized |

Stainless steel |

Aluminum |

Non-ferrous metal |

plastic |

demul- gating |

Corr. protection |

Temperature range |

Application conc. |

||

|

Product |

Product Description |

Process |

Compatibility |

in °C |

in % |

|||||||||||

|

HAKUPUR 324 |

Neutral cleaner, low salt |

9,8 |

yes |

yes |

yes |

yes |

yes |

yes |

yes |

conditional |

conditional |

yes |

yes |

yes |

35 - 80 °C |

2 - 5 % |

|

HAKUPUR 445 |

mildly alkaline cleaner |

10,3 |

yes |

yes |

yes |

yes |

yes |

conditional |

yes |

yes |

conditional |

yes |

partially |

yes |

35- 80 °C |

0,5 - 10 % |

|

HAKUPUR 448 |

Neutral cleaner, salt-free |

9,5 |

no |

conditionally |

yes |

yes |

yes |

yes |

yes |

yes |

yes |

yes |

very good |

Yes |

20 - 80 °C |

0,5 - 5 % |

|

HAKUPUR 270 |

Neutral cleaner, salt-free |

10,1 |

no |

conditionally |

yes |

yes |

yes |

conditional |

yes |

conditional |

conditional |

yes |

yes |

yes |

20 - 80 °C |

0,5 - 5 % |

|

HAKUPUR 196-8 |

alkaline cleaner, salt-free |

10,9 |

conditional |

yes |

yes |

yes |

yes |

no |

yes |

no |

yes no |

yes |

partially |

very good |

50 - 80 °C |

0,5 - 5 % |

|

HAKUPUR 50-706-3 |

alkaline cleaner |

13 |

no |

no |

yes |

yes |

yes |

yes |

yes |

yes |

conditional |

yes |

partially |

yes |

50 - 80 °C |

0,5 - 5 % |

|

HAKUPUR 50-706-2 |

alkaline cleaner |

13 |

yes |

yes |

no |

no |

yes |

yes |

yes |

yes |

no |

yes |

no |

yes no |

40 - 80 °C |

0,5 - 10 % |

|

HAKUPUR 56-70 |

Acidic cleaning conc. |

< 1 |

no |

no |

yes |

yes |

no |

no |

yes |

conditionally |

for whitening |

yes |

yes |

yes no |

20 - 60 °C |

2 - 4 % |

|

HAKUPUR 50-727-2 |

Strong alkaline cleaner |

> 13 |

no |

no |

yes |

yes |

yes |

no |

yes |

no |

yes no |

yes |

no |

yes |

30 - 80 °C |

0,5 - 5 % |

|

Decorrdal 20-1 |

Neutral desiccant |

6-7 |

Yes |

Yes |

yes |

yes |

yes |

yes |

yes |

conditional |

yes |

yes |

yes |

yes |

20 - 80 °C |

5 -1 0 % |

|

Decorrdal 35-52 |

Acidic system cleaner |

< 1 |

no |

no |

yes |

no |

no |

no |

20 - 80 °C |

5 - 10 % |

||||||

|

HAKUPUR 50-523 |

alkaline system cleaner |

> 14 |

yes |

no |

yes |

no |

conditionally |

conditional |

21 - 60 °C |

6 - 10 % |

||||||

It follows from these statements that the component surface must be reliably cleaned of foreign/dirt particles by a galvanic solution and/or a charged gas with mechanical energy and additional electrical charge by applying a defined DC voltage.

The galvanic model of this work can be summarized as follows:

At normal ambient temperature, at least two intrinsically electrically neutral materials are placed against each other over their entire surface in a conductive manner. Charge carriers are exchanged across the surface boundaries. The exchange ends when the electrical potential equilibrium is reached.

If the surfaces are separated from each other after a certain time, a surplus of charge carriers of the same quantity but with opposite polarity remains on each surface. I call this state "electrostatic charge". The time is determined by the base material and the foreign particle. More than a single discharge is not possible. Once the discharge has taken place, the process is complete.

This process has been demonstrated sufficiently often for electrically conductive materials and has also been confirmed for insulators. The result of this series is achieved in the developed technological cleaning process using dry steam and a technical system design is shown.

The task of surface cleaning

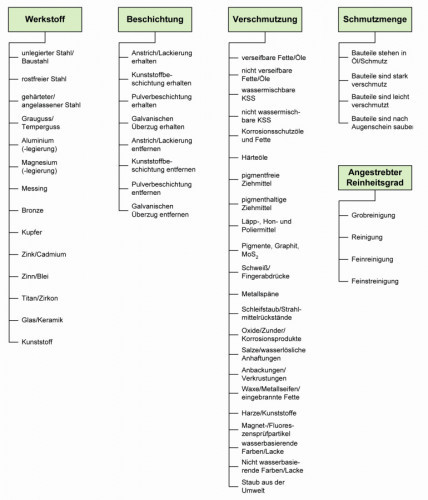

Fig. 1: Criteria for selecting cleaning agents There is no such thing as a clean and dry component surface. Every surface before cleaning has undefined adhering foreign particles. The cleaning process deliberately removes selected foreign particles and leaves behind a surface required for the subsequent processing step. The cleaning result is always a temporarily desired component surface, not a final processing state. Long-term intermediate storage before the final production process requires special passivation after surface cleaning, as oxygen and other oxidants always act on the component surface, the base material.

Fig. 1: Criteria for selecting cleaning agents There is no such thing as a clean and dry component surface. Every surface before cleaning has undefined adhering foreign particles. The cleaning process deliberately removes selected foreign particles and leaves behind a surface required for the subsequent processing step. The cleaning result is always a temporarily desired component surface, not a final processing state. Long-term intermediate storage before the final production process requires special passivation after surface cleaning, as oxygen and other oxidants always act on the component surface, the base material.

The questions of cleaning technology are always from which environment and from which physical-chemical process the component comes for cleaning.

The cleaning to be carried out in space and time determines the amount of automation, energy and media applications required.

The cleaned component always has a residual contamination in the form of a film of varying thickness and different physical-chemical composition. The quantity in volume, usually in ml or the mass in mg, provides important information about the nature of the film. The geometric dimensions of the foreign particles in the film are given in µm for length, in µm for width and in µm for thickness. Depending on the required, permissible design parameters of the foreign particles, the cleaning is assessed as successful or insufficient.

The chemical additives for aqueous cleaning are selected according to the criteria in Figure 1.

In the aqueous cleaning process, the cleaning medium is sprayed onto the component surface using nozzles. Flood injection baths after the first spray wash and before the spray rinse reach drill holes and undercuts and safely flush the foreign particles from the surface. The choice of nozzle shape and nozzle arrangement in the nozzle block aligned with the component surface determines the amount of cleaner on the component surface. The rules of hydraulics take effect. The angle of reflection and the breaking up of the water droplets into droplets and thus haze are important for the choice of design parameters. A model for the mode of action of the nozzles is described below.

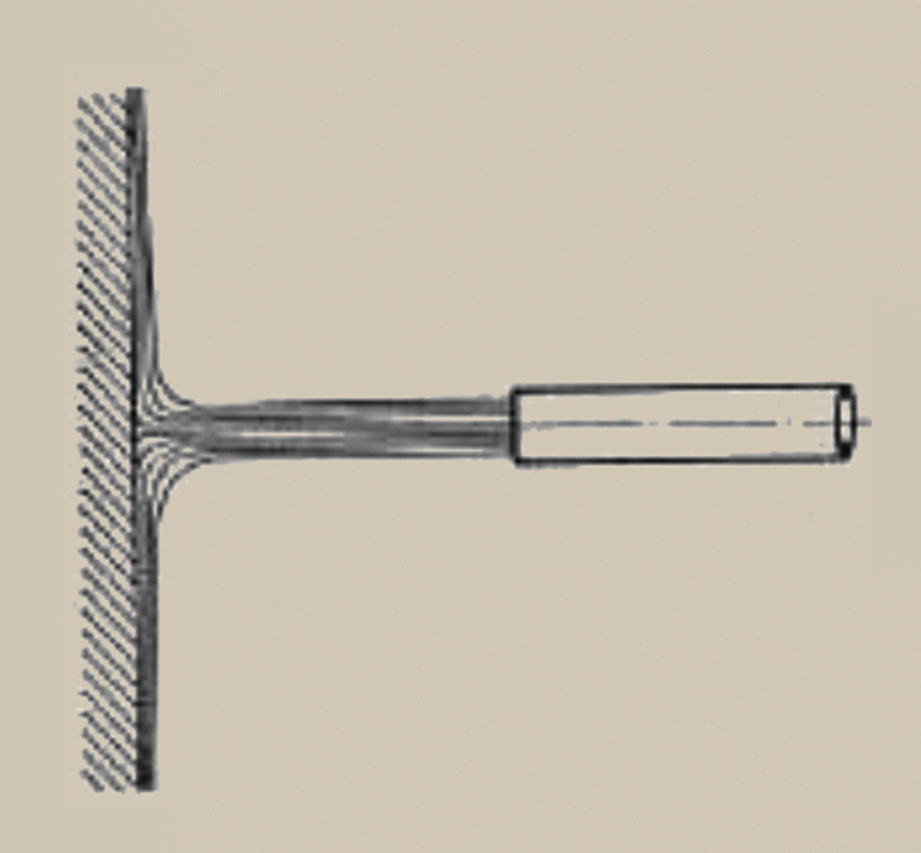

In Figure 2, the spray nozzle is shown as a full jet nozzle in its effect independent of the installation position. The effect of gravity is superimposed by the much greater pump energy. The medium flowing off the component surface, a liquid film with a thickness and a flow velocity, determines the removal of the dissolved foreign particles. The direction, the inclination of the nozzle axis to the component surface determines the flow direction and thus the volume on the respective component surface. The outlet volume from the nozzle and the size of the reflecting component surface, together with the relative speed of the nozzle to the component surface and the dwell time, result in the media film thickness and the media flow velocity.

Fig. 2: Free jet on a vertical plate

Fig. 2: Free jet on a vertical plate

The steam cools down as it exits the nozzle and on the cold component surface, it condenses and forms water droplets. These are evaporated by subsequent steam. The condensed water droplets thus discharge the surface and the foreign particles and suck the foreign particles from the surface. They are extracted towards the collection tank by the vapor extraction system.

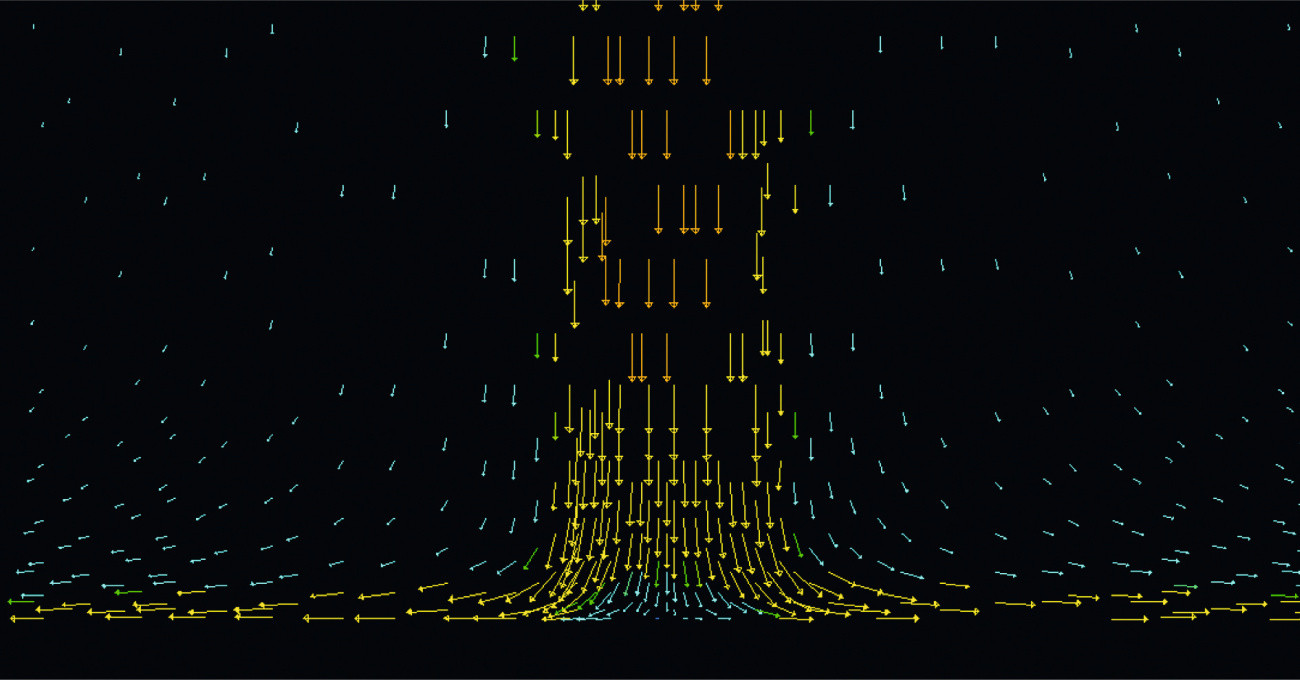

In Figure 3, the water molecules are distributed differently in the free jet. The yellow arrows show the water jet molecules in high abundance. The blue arrows show the diffuse water jet separated from the air. There are few water molecules in the center of the water jet.

Fig. 3: Distribution of the water in the jet and on the surface

Fig. 3: Distribution of the water in the jet and on the surface

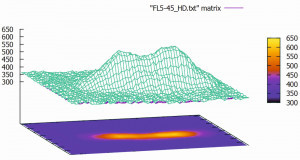

In Figure 4, the impact energies on the component surface are measured as a function of the water quantity and the impact forces from a flat nozzle with a 45° splay angle.

Fig. 4: Impact force on the component surfaceIfsuperheated steam instead of an aqueous solutionisapplied to the impact plate via a nozzle, mechanical transport is only possible by adding air from the environment. Due to the injection effect of the flowing hot steam, the air acts as a blowpipe in the direction of the component surface. Taking into account the reflection effects, the reflected vapor, a mixture of steam, water droplets, foreign particles and air, is extracted in the tests described in this series of articles. The area around the effective point of the nozzle on the surface remains without vapor, the hot steam remains in the water circuit of the cleaning system. The dissolved foreign particles are safely conveyed into the collection tank.

Fig. 4: Impact force on the component surfaceIfsuperheated steam instead of an aqueous solutionisapplied to the impact plate via a nozzle, mechanical transport is only possible by adding air from the environment. Due to the injection effect of the flowing hot steam, the air acts as a blowpipe in the direction of the component surface. Taking into account the reflection effects, the reflected vapor, a mixture of steam, water droplets, foreign particles and air, is extracted in the tests described in this series of articles. The area around the effective point of the nozzle on the surface remains without vapor, the hot steam remains in the water circuit of the cleaning system. The dissolved foreign particles are safely conveyed into the collection tank.

The cleaning result is determined using standardized procedures. These procedures are independent of the cleaning technology. They are determined by defining the test procedure for the respective component. The procedures are standardized, i.e. reproducible. The standards for these tests are ISO standard 16232/1-10 and the VDA 19 standard.

The content of Part 3 ranges from the weaknesses of previous surface cleaning methods to the definition of cleanliness and the separation of bonds between the surface and particles.