After many years of work on alternatives to cadmium, which is classified as toxic and has been used successfully for decades in the aerospace industry for coating corrosion-sensitive steel components, it was possible to realize an alloy deposition with ZnNi, which has excellent properties, especially on ultra-high-strength steels (Rm > 2000 MPa) and is also characterized by low human toxicity and better environmental properties.

To qualify the coating, the following possible candidates were first selected

- ZnNi

- ZnFe

- ZnCo

- Aluminum ceramic coatings (Sermetel®, Ceral®)

- Zinc flake

- Electrodeposited Aluminum

- Ion Vapor Deposited Aluminum

- Tin-Zinc

Zinc-Nickel selected. The properties of LHE cadmium (LHE = Low Hydrogen Embrittlement) then had to be critically examined in accordance with the following criteria:

- Simple galvanic process

- Good adhesion to steel

- Low layer corrosion with partial self-healing

self-healing effect due to chromating

- Self-lubricating properties

- Repair by pad electroplating possible

- Can be painted over with good adhesion

In addition to these characteristics and processes, ZnNi also had to be transferred and investigated:

- Investigations into H-kinetics

- Fatigue influences

- Corrosion-induced hydrogen embrittlement

(re-embrittlement)

- Coating morphology

- Coating pairings (mating surfaces) against

Hard chrome, nickel or HVOF (high velocity oxy-fuel spraying, here WCCoCr)

- Paint adhesion

- Mech. Machinability/assembly influences (e.g. bushings)

For this purpose, various test specimen geometries were used, mainly made from the main structural steel for high-strength applications 300M. Characteristics are:

- Low alloyed quenched and tempered steel according to works standard

- Remelted under vacuum

(VIM+VAR or 2 VAR)

- Maximum strength: 1930-2070 MPa

- Alloy composition: 0.40-0.43 C; 0.60-0.90 Mn; 1.45-1.80 Si; 0.70-0.95 Cr; 1.65-2.00 Ni; 0.30-0.50 Mo; 0.05-0.10 V; max 0.20 Cu; max 0.01 (P + S)

- Tempering temperature 300 °C

|

Test |

Criterion |

|

Adhesion LHE-ZnNi to substrate |

Pipe sleeve without flaking |

|

Adhesion of primer to LHE-ZnNi |

Cross-cut 0-1 |

|

HE: Creep rupture test acc. to ASTM F519 |

200 h without fracture |

|

Re-embrittlement |

≥ 50 % incr. stepload ASTM |

|

SSN (salt spray test) |

336 h without red rust |

|

Sliding friction thread |

f < 0,3 |

|

Abatement factor (reduction factor for fatigue) |

1.0 like LHE-Cd |

|

Repair (brush plating) without postbaking creep rupture |

ASTM F519 |

|

Decoating and recoat creep rupture |

ASTM F519 |

|

Resting potential / surface morphology |

Similar to LHE-Cd |

|

Layer transitions: HVOF/LHE-ZnNi + lacquer Chem. Ni/LHE-ZnNi + xylan |

336 h without red rust |

|

Resistance measurement |

≤ 10 m Ω |

|

Stone chip resistance ("C") |

DIN EN ISO 20567-1 without red rust |

|

Convertibility on large Fw components |

Device, current parameters ... |

|

Coating thickness distribution |

≥10 μm, complex geometries |

|

Bushing assembly on coated LG parts |

Feasibility, process reliability |

|

Climate change test |

White / red rust |

|

De-icing agent Aviform L50 (ZnNi vs. Cd) |

Resistance |

The test parameters are shown in Table 1. The test methods used for hydrogen embrittlement are methods according to ASTM F 519 (defined tensioning of rings with 200h exposure and loading of notched tensile specimens for 200h below 75 % notched tensile strength) and ASTM F 326-17 (testing of hydrogen permeability in a Lawrence gauge). As the latter method, which originated from Cd layer testing, was not yet ready for use at the time, a new test method was developed and patented. In principle, high-frequency acoustic emissions caused by microstructural damage to the material as a result of diffused hydrogen are measured under creep rupture test conditions.

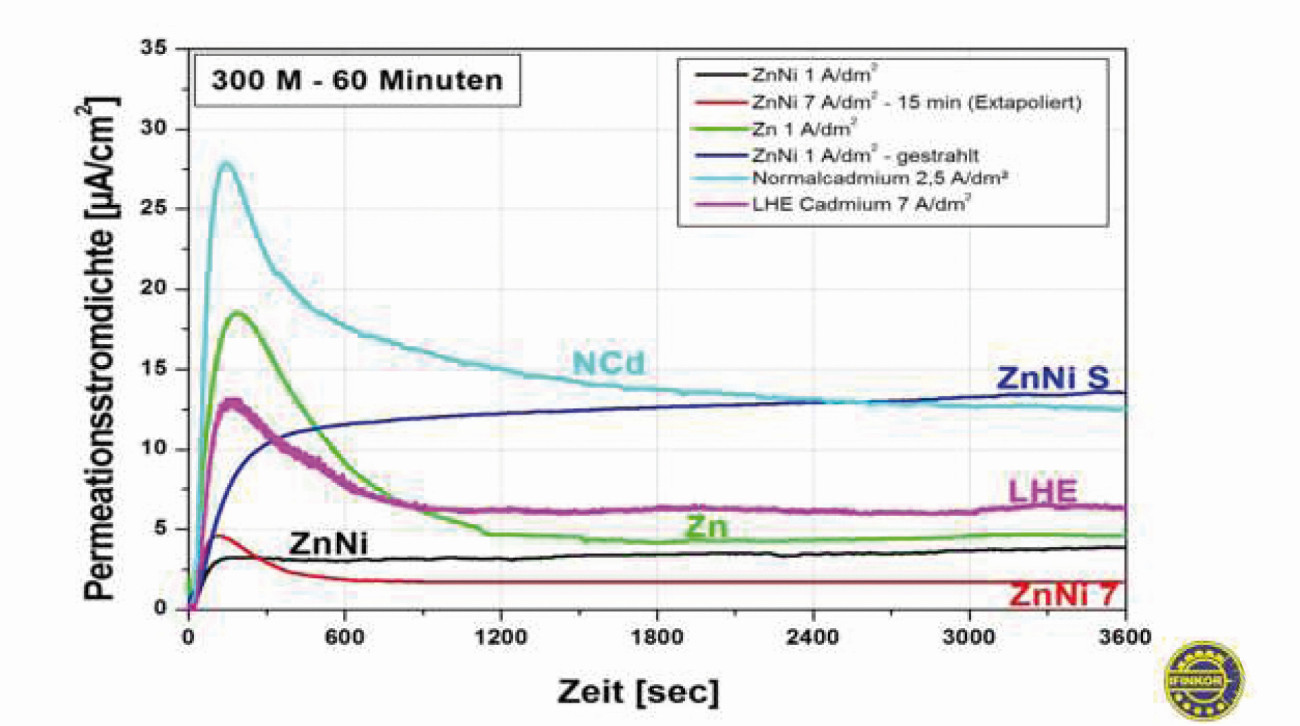

A further investigation focused on hydrogen kinetics and permeation measurement (Fig. 1). It can be seen here that ZnNi, with a current density of 7 A/dm², is characterized by a very low permeation current density, especially in comparison with LHE-Cd.

Fig. 1: Comparative H-permeation measurements

Fig. 1: Comparative H-permeation measurements

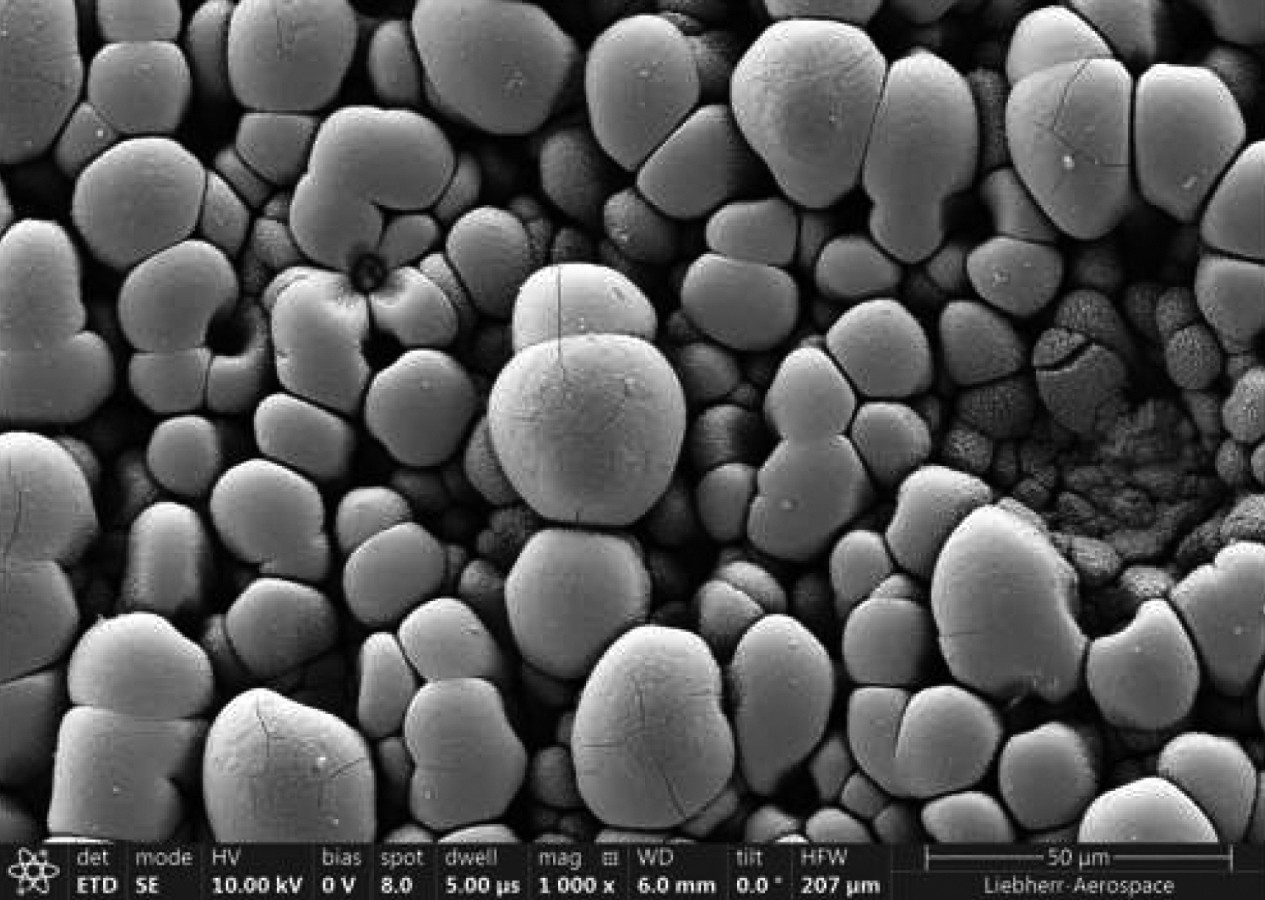

Another criterion is the surface morphology of the deposited layer on the substrate (Fig. 2). The desired bud-like (cauliflower) structure with pores and cracks, which positively influences the hydrogen outgassing behavior, can be seen very instructive here.

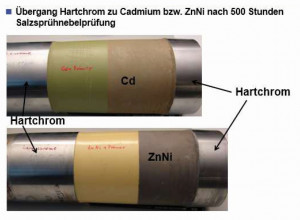

Fig. 3: Corrosion behavior of layer transitions A special characteristic of aeronautical details is the very careful and sensible design configuration that is geared towards maximum safety. This also and especially applies to the coating of surfaces in order to ensure long-term protection, service life, wear resistance and repairability of expensive components. Particular attention must therefore be paid to the mating surfaces for multiple and partial coatings (Fig. 3).

Fig. 3: Corrosion behavior of layer transitions A special characteristic of aeronautical details is the very careful and sensible design configuration that is geared towards maximum safety. This also and especially applies to the coating of surfaces in order to ensure long-term protection, service life, wear resistance and repairability of expensive components. Particular attention must therefore be paid to the mating surfaces for multiple and partial coatings (Fig. 3).

At the time of development, no usable hard chrome alternative was available, so that the Cr/Cd with Cr/ZnNi and Cd/primer coating and ZnNi/primer coating transitions had to be investigated. The investigation also focused on the Chem. Ni (40 μm)/ZnNi/primer coating and HVOF/ZnNi/primer coating transition, Chem. Ni and HVOF could be used in part as a Cr alternative. It was found that even after 1000 h SSN, no corrosion was visible (Fig. 4a and b).

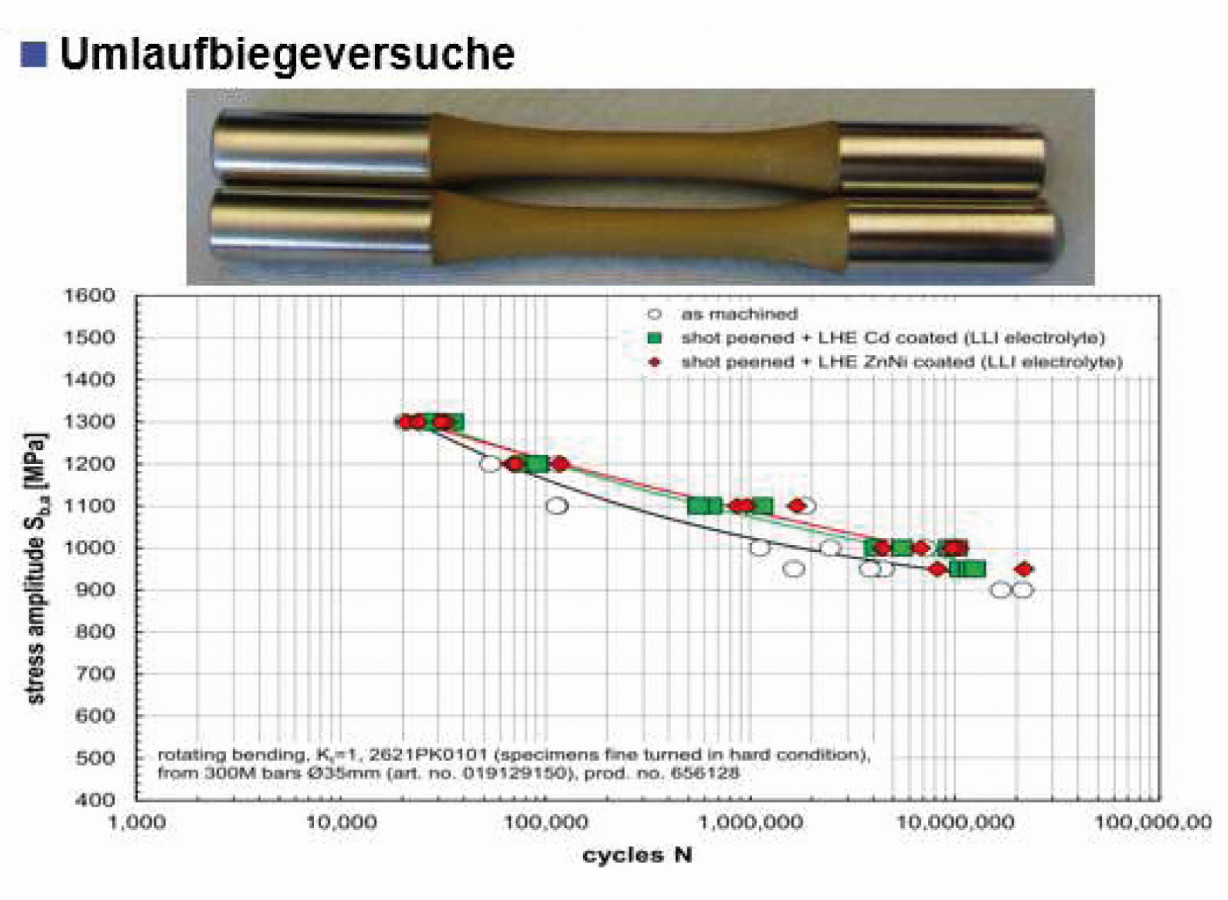

Other points of investigation were the fatigue behavior of the coated materials (Fig. 5). A comparison shows that there is no difference between LHE-Cd and LHE-ZnNi.

Fig. 5: Influence of the treatment process on the material fatigue behavior

Fig. 5: Influence of the treatment process on the material fatigue behavior

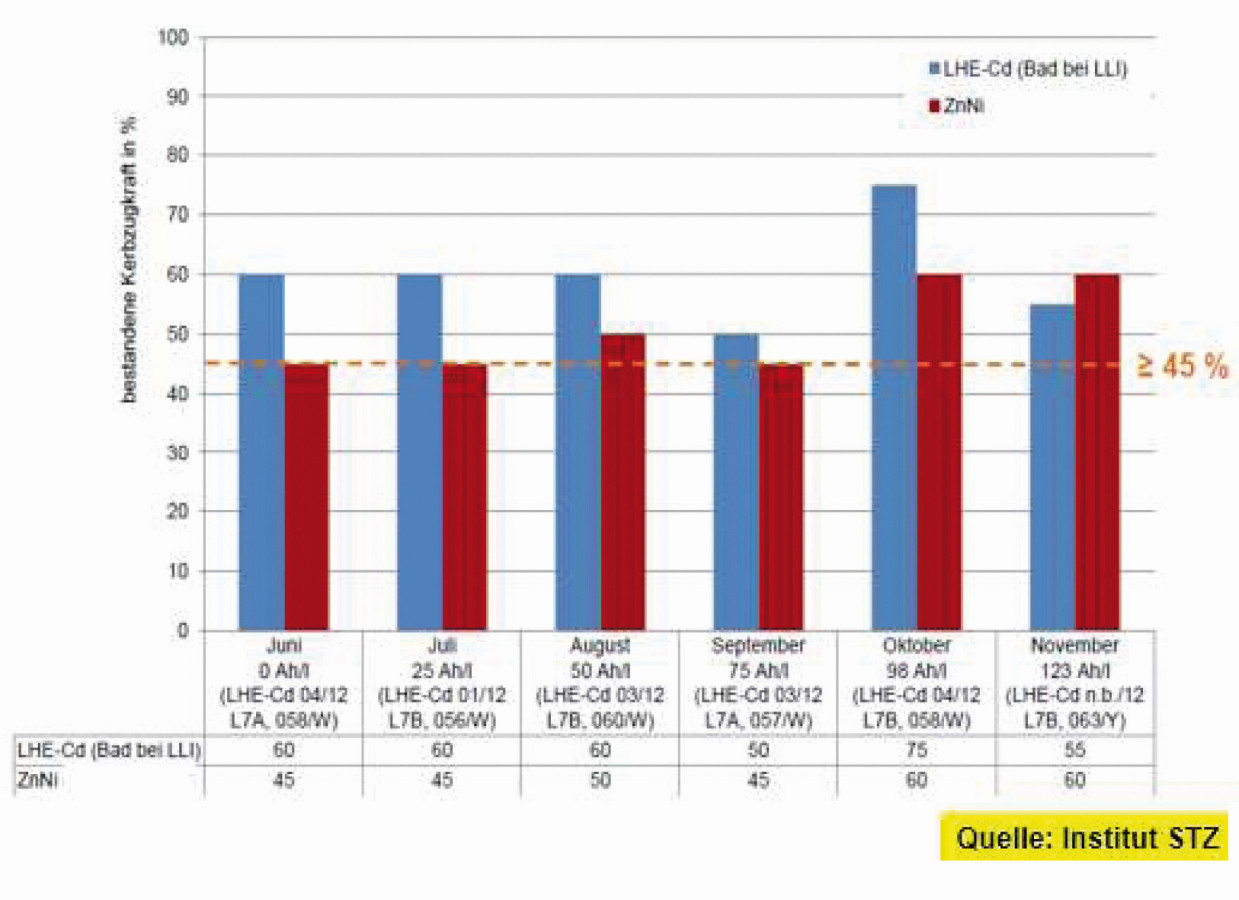

A special point in connection with corrosion and hydrogen embrittlement is the so-called re-embrittlement element. This describes the influence of layer corrosion on the hydrogen embrittlement behavior of ultra-high-strength aviation steels. For this purpose, a coated notched tensile specimen is exposed to a breaking load of 45 % in a 3.5 % NaCl solution for 24 h after it has withstood 200 h in air at 75 % Rm without breaking.

The load is then increased incrementally by 5 %/h. The last value before fracture is the characteristic value.

Figure 6 shows that the limit value for qualification was reached in every case, but also that Cd still shows a slightly better performance.

Fig. 6: Re-embrittlement behavior LHE-Cd /ZnNi

Fig. 6: Re-embrittlement behavior LHE-Cd /ZnNi

Following these complex investigations, the process was implemented in series production by verification on real large components as part of the industrialization process.