... for the production of corrosion-resistant micro-process engineering equipment using diffusion bonding

Tensile tests, discussion and conclusions / continued from Galvanotechnik 6/2024 Tensile tests

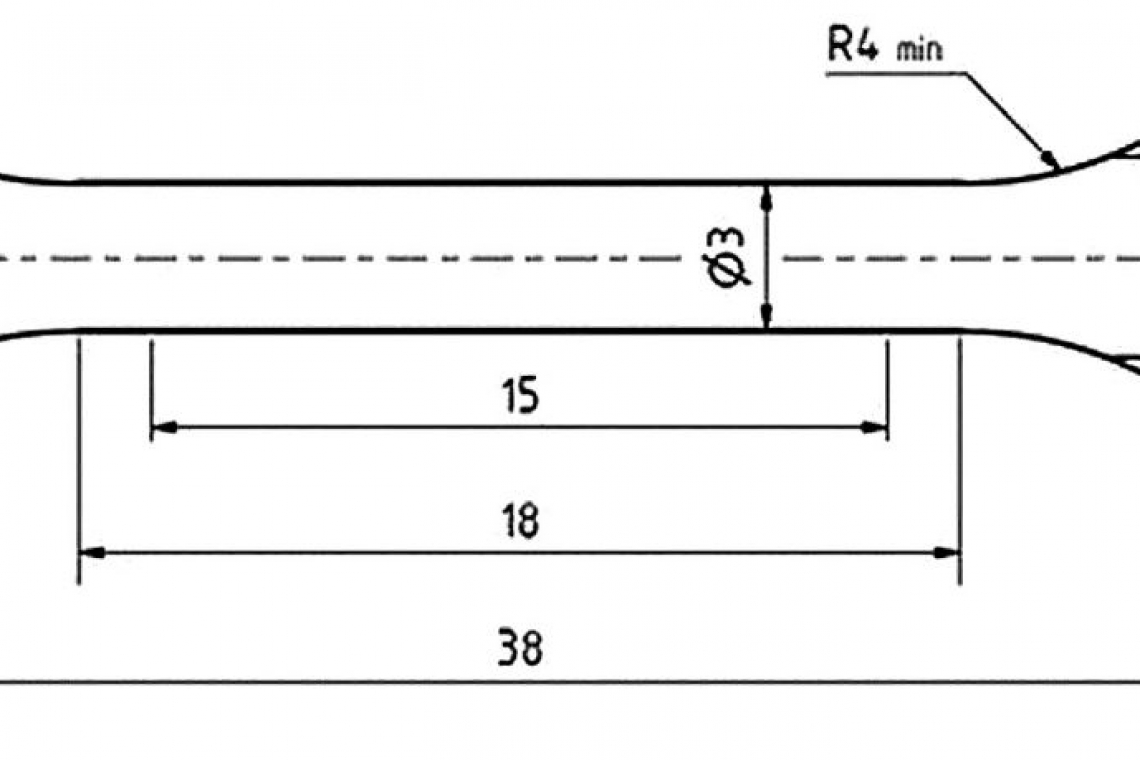

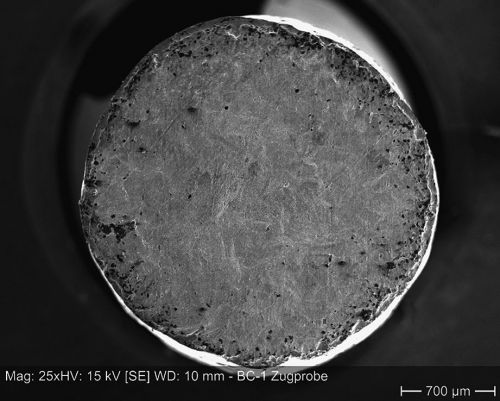

Round blanks were cut out of the diffusion bonding samples using wire erosion to produce tensile specimens. The area of the ten sheet layers was placed in the test length. The nominal diameter of the tensile specimens was 3 mm in order to better record differences in the joint quality and the effects of small defects on the mechanical properties (Fig. 3).

Five tensile tests were carried out for each condition. One set of tensile specimens of both materials was aged in 70% sulphuric acid at 100 °C for 1000 h in order to better quantify the corrosion attack and record the effects on the mechanical properties.

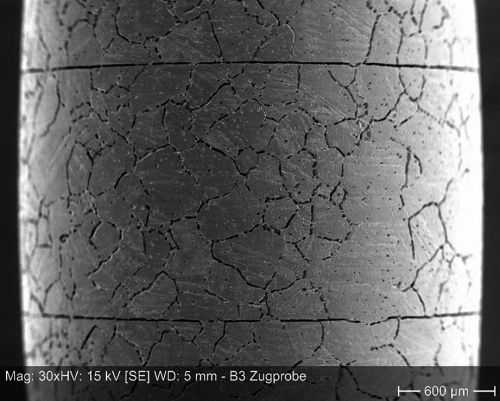

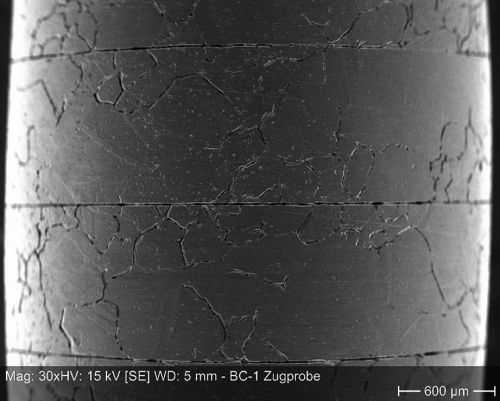

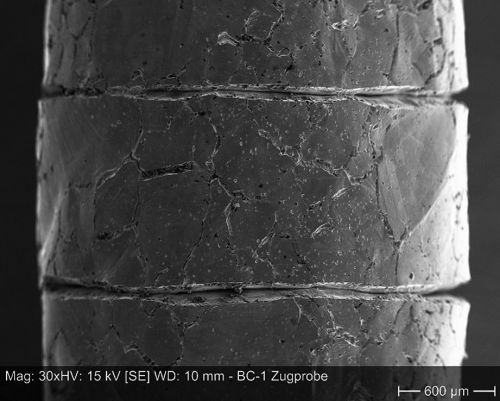

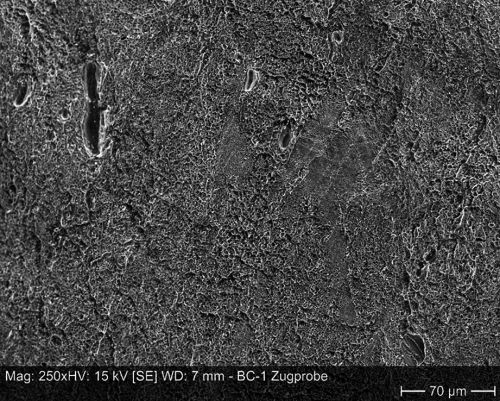

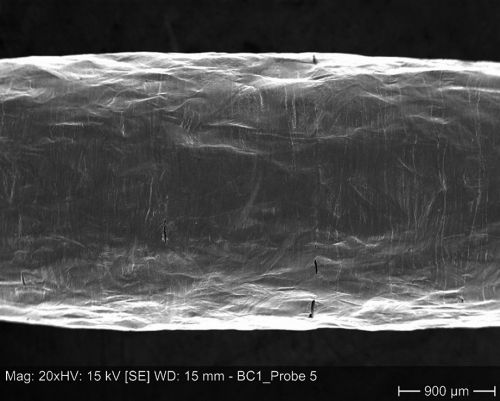

The different sheet thicknesses can be seen in the SEM images of the surfaces of the tensile specimens of both materials aged in sulphuric acid (Fig. 4) . In addition, the joining planes of the individual sheets stand out clearly. Despite the high joining temperature and long holding time, only rudimentary grain growth has taken place across the joining planes. The corrosion attack on the joining planes is significantly more pronounced than on the grain boundaries, which were, however, also developed. Grain sizes of around 500 µm are achieved. However, it is not possible to estimate the depth of corrosion attack on the joint planes on the basis of Figure 4.

Results of the tensile tests for Hastelloy B3 and analysis of the fracture surfaces

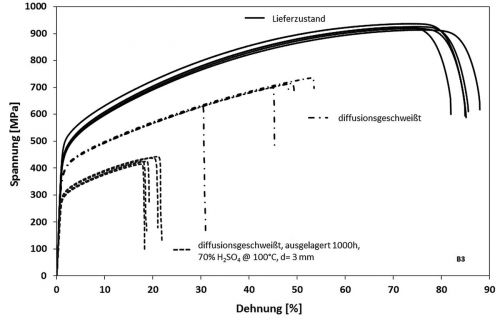

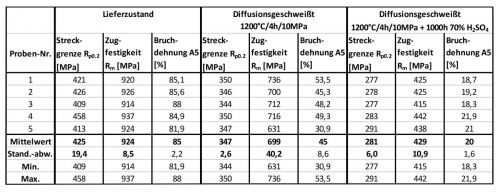

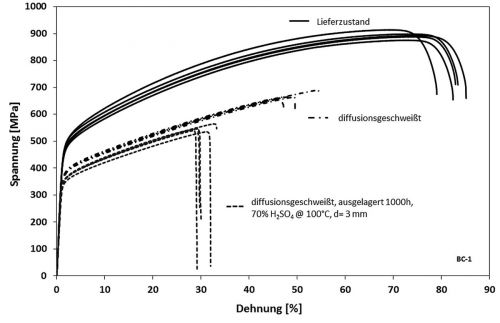

Table 8 shows values for equivalent yield strength, tensile strength and elongation at break for the delivery condition, diffusion-welded and diffusion-welded and aged for 1000 h at 100 °C in 70% sulphuric acid, including the associated standard deviations for five tensile specimens each. Figure 5 shows the progression of the measurement curves. The yield strength after diffusion bonding is significantly reduced compared to the delivery condition due to the heat treatment and grain growth. The drop in tensile strength and elongation at break must be taken into account when considering defects from diffusion bonding.

The curves for the diffusion-welded and sulphuric acid-aged states are shifted to significantly lower strength values.

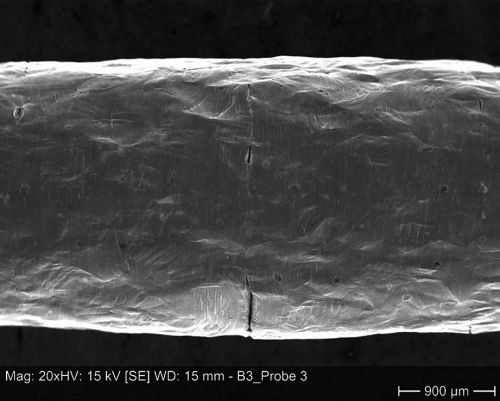

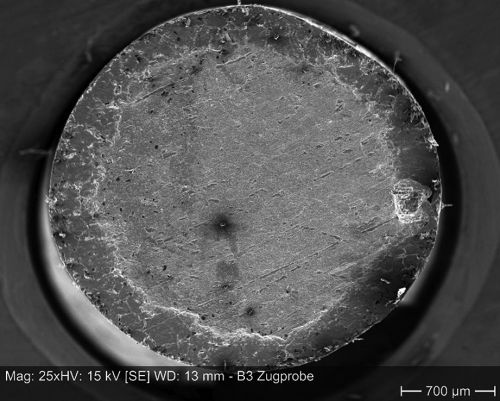

In the diffusion-welded state, the cross-section ( Figure 6) shows non-welded areas that cannot transmit any forces. The fracture surface is heavily deformed. Sliding bands are visible in non-welded areas. Partial tearing is visible on the surface area at joining planes. The resulting notch effect causes the significantly reduced elongation at break compared to the delivery condition and its strong scattering.

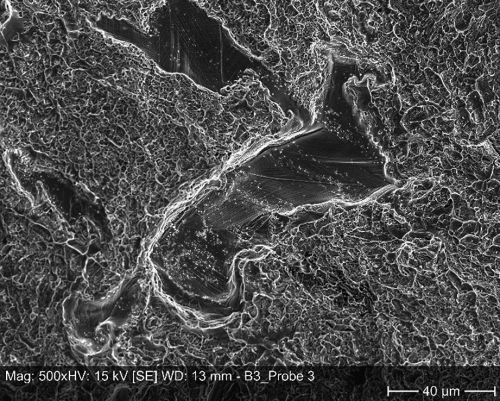

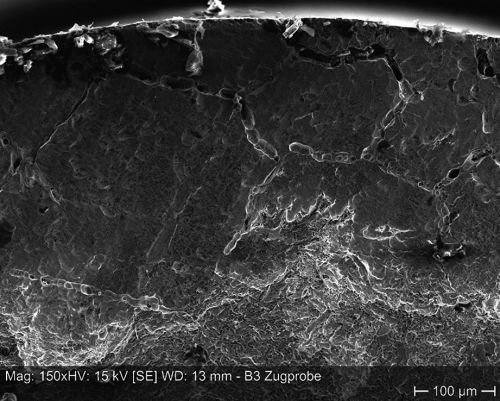

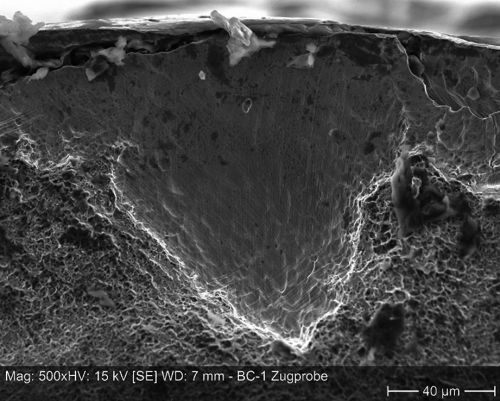

The effects described above are even more pronounced for tensile specimens aged in sulphuric acid (Fig. 7). Only here can it be seen that the corrosion attack depth in the joint planes is approx. 0.2 mm and considerably weakens the force-bearing specimen cross-section. As the test load is related to the nominal initial diameter of 3 mm, the stress curve appears to be shifted to significantly lower values. The elongation at break drops to values around 20 %. Smaller, non-welded areas are visible in the fracture surface. At former joining planes, the corrosion attack depth leads to localized expansion. Corroded grain boundaries also crack. The largest defect ultimately leads to fracture.

Fig. 7: Hastelloy B3 tensile specimen aged in 70% sulphuric acid at 100 °C for 1000 h after the tensile test. Top left: Joining plane with expanded corrosion gaps in the joining planes. Top right: Fracture surface of the joining plane in which the tensile specimen failed. The corrosion attack depth is clearly visible. Bottom left: Detail of the corrosion attack at the edge. Bottom right: Fracture surface detail - ductile failure with pronounced pitting structure, cross-section contains non-welded defects

Fig. 7: Hastelloy B3 tensile specimen aged in 70% sulphuric acid at 100 °C for 1000 h after the tensile test. Top left: Joining plane with expanded corrosion gaps in the joining planes. Top right: Fracture surface of the joining plane in which the tensile specimen failed. The corrosion attack depth is clearly visible. Bottom left: Detail of the corrosion attack at the edge. Bottom right: Fracture surface detail - ductile failure with pronounced pitting structure, cross-section contains non-welded defects

Results of the tensile tests for Hastelloy BC-1 and analysis of the fracture surfaces

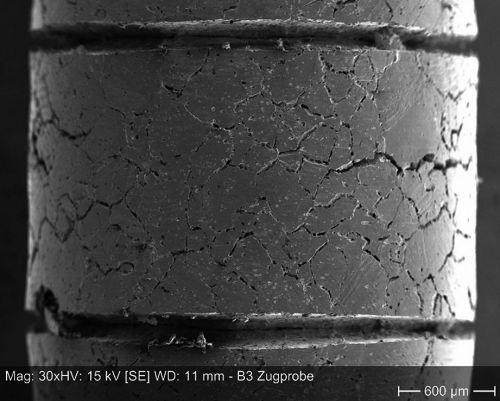

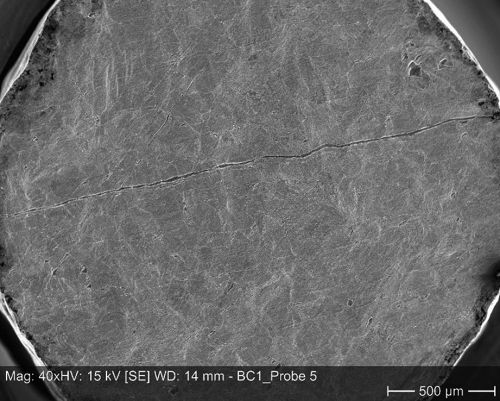

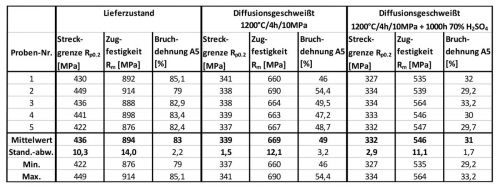

Table 9 shows the mechanical characteristic values for Hastelloy BC-1 in the same way. Here too, elongations at break of around 50 % are achieved for the diffusion-welded condition. Based on the analysis of the fracture surfaces, which show isolated non-welded areas (Fig. 9), this value must be considered in relation to the relatively low deformation of 2 % during diffusion bonding. It may still be possible to achieve improvements here. There are some noticeable differences compared to Hastelloy B3:

Tab. 9: Mechanical properties of Hastelloy BC-1 as supplied, diffusion welded and for diffusion welded tensile specimens aged in 70 % sulphuric acid for 1000 h at 100 °C

Tab. 9: Mechanical properties of Hastelloy BC-1 as supplied, diffusion welded and for diffusion welded tensile specimens aged in 70 % sulphuric acid for 1000 h at 100 °C

- The curves for diffusion-welded tensile specimens and those subsequently aged in sulphuric acid are at approximately the same level as those of the diffusion-welded specimens.

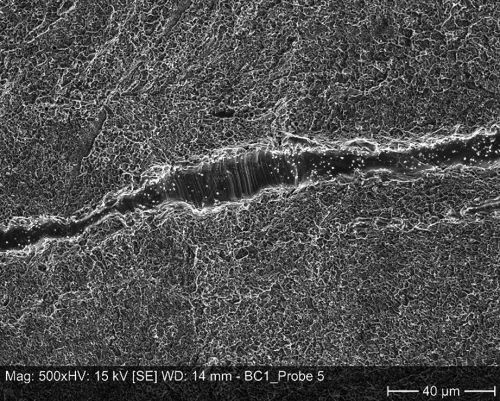

- -At 30 %, the elongation at break for tensile specimens aged in sulphuric acid is significantly higher than for Hastelloy B3. Figure 10 provides the reason for this: The corrosion attack depth is significantly lower than for Hastelloy B3. Nevertheless, the notch effect on the more heavily corroded joint planes also initiates the failure here.

Fig. 8: Tensile tests on Hastelloy BC-1 in various material states

Fig. 8: Tensile tests on Hastelloy BC-1 in various material states

Discussion and conclusions

The corrosion behavior of two nickel-based materials with a high molybdenum content was investigated in concentrated and 70% sulfuric acid. Initial diffusion bonding tests were also carried out.

In particular, only the tensile tests on tensile specimens aged in 70% sulphuric acid allow a distinction to be made between the corrosion behavior of the two materials and enable practical conclusions to be drawn about the service life of micro-process engineering equipment.

Fig. 9: Diffusion-welded Hastelloy BC-1 tensile specimen after the tensile test. Left: Heavily deformed surface with incipient failure due to cracking at joint planes.

Fig. 9: Diffusion-welded Hastelloy BC-1 tensile specimen after the tensile test. Left: Heavily deformed surface with incipient failure due to cracking at joint planes.

Compared to austenitic stainless 18/10 chromium-nickel steels, which can be diffusion welded with very good results from 1015 °C [9], a significantly higher joining temperature is required for these two materials with a high molybdenum content. This is probably due to the composition of the passive layer and its resistance.

No information was available on the surface condition of the sheets used. Grain growth across the joining planes was only observed to a limited extent. Possible causes may be the still too low deformation of 2 % during diffusion bonding or passive layers. The passive layer thickness is normally in the single-digit nanometer range. However, several hundred nanometers can also be achieved by hot rolling without changing the optical appearance of the surface. These thin oxide layers very effectively prevent the diffusion of atoms across the joining planes. A defined surface condition is therefore always desirable during diffusion bonding.

For practical reasons, the sheet metal surfaces were not ground, as this is not practicable for real components consisting of many sheet metal layers. The only feasible way to guarantee reproducible surface conditions is a commercial pickling treatment with agents containing hydrofluoric acid.

At 2 %, the deformation achieved during diffusion bonding of the samples for tensile specimen production was at the lower limit for achieving good material characteristics. The results of the preliminary tests also show how difficult it is to set a specific deformation via joining temperature and surface pressure. Deformation during diffusion bonding is also highly geometry-dependent.

The exposure of tensile specimens for 1000 h in 70 % sulphuric acid at 100 °C clearly showed that Hastelloy BC-1 is the more resistant material under these conditions. This could not be concluded from identical long-term corrosion tests on coupons of both materials.

Fig. 10: Hastelloy BC1 tensile specimen aged in 70% sulphuric acid at 100 °C for 1000 h after the tensile test. Top left: Shell surface with expanded corrosion gaps in the joint planes. Top right: Fracture surface of the joining plane in which the tensile specimen failed. Only slight corrosion attack depth recognizable. Bottom left: Detail - corrosion attack at the edge. Bottom right: Fracture surface - ductile fracture, dimple structure only slightly pronounced in places. Small, non-welded defects

Fig. 10: Hastelloy BC1 tensile specimen aged in 70% sulphuric acid at 100 °C for 1000 h after the tensile test. Top left: Shell surface with expanded corrosion gaps in the joint planes. Top right: Fracture surface of the joining plane in which the tensile specimen failed. Only slight corrosion attack depth recognizable. Bottom left: Detail - corrosion attack at the edge. Bottom right: Fracture surface - ductile fracture, dimple structure only slightly pronounced in places. Small, non-welded defects

The results achieved with regard to grain growth across the joint surfaces and the full surface of the joint are sufficient from a design point of view. Further optimization is required to guarantee high vacuum tightness.

Even elongation at break values of 20 % reliably prevent catastrophic component failure. Compared to the delivery condition or diffusion-welded without corrosion attack, the elongation at break of tensile specimens aged in 70% sulphuric acid at 100 °C for 1000 h is significantly reduced. The investigations are a valuable contribution to the design and service life assessment of micro-process engineering equipment made of these materials. The material Hastelloy BC-1 is clearly to be preferred by 70 % when used in sulphuric acid.

Grüneisen's rule states that a material has a linear expansion of approx. 2 % up to its melting point. Due to the high molybdenum content of Hastelloy B3 and BC-1, the thermal expansion coefficients of both austenitic materials are in the range of ferritic steels.

Literature

[9] T. Gietzelt; M. Walter; V. Toth; F. Messerschmidt; M. Blem: Comprehensive Study of the Influence of the Bonding Temperature and Contact Pressure Regimes during Diffusion Bonding on the Deformation and Mechanical Properties of AISI 304, Adv. Eng. Mater, 2021, accepted, DOI:10.1002/adem.202100188