Lightweight rollers made of carbon fiber reinforced plastic (CFRP) are increasingly replacing conventional steel or aluminum rollers in industry in order to reduce energy consumption and extend the service life of rollers, motors and bearings,

motors and bearings. Functional coatings such as non-stick coatings are required for rollers in various sectors of industry. The Fraunhofer Institute for Laser Technology (ILT) in Aachen and Rhenotherm Kunststoffbeschichtungs GmbH from Kempten are researching laser-based processes for producing highly functional non-stick coatings on CFRP rollers without causing thermal damage to the material. They are concentrating on wear-resistant non-stick coatings made of sol gels as well as those based on high-performance polymers such as polyether ether ketone (PEEK) and fluoropolymers.

Lightweight rollers made of CFRP are increasingly being used in industry as a replacement for conventional rollers made of steel or aluminum. Due to the weight savings, energy consumption in the application can be minimized and the service life of rollers, motors and bearings can be effectively increased. Functional coatings are often required for these lightweight rollers in order to improve the performance of the running surfaces. Such coatings can be non-stick coatings, for example, which are used in production facilities in the hygiene product manufacturing sector, the packaging industry and the automotive industry.

At present, however, non-stick coatings can only be applied to CFRP components to a limited extent. Wet-chemically applied sol-gel-based non-stick coatings must be thermally cured, e.g. using an oven process. However, the temperature required for this (200 - 300 °C) exceeds the maximum permissible temperature of the CFRP substrate (80 - 120 °C). Thermal curing at CFRP-compatible temperatures is therefore only insufficiently possible, resulting in inadequate coating functionality. Alternative non-stick coatings made of high-performance polymers such as fluoropolymers or PEEK must be melted after powder or spray application, sometimes at temperatures well above 250 °C. The required melting temperature exceeds the melting temperature of the CFRP substrate. In this case, the required melting temperature significantly exceeds the permissible temperature of the CFRP substrate, meaning that conventional production on CFRP components is only possible with polymers with very low melting or cross-linking temperatures (e.g. silicone). However, these are very soft and offer little protection against abrasion processes that occur in production facilities.

The Fraunhofer Institute for Laser Technology ILT is Europe's leading center for contract research and development in the field of laser technology. In the "Surface Technology and Mold Removal" department, the laser treatment of surfaces and functional layers has been developed together with renowned companies for more than 15 years. The "Thin Film Processing" group deals with the functionalization of thin films for wear and corrosion protection as well as for electronic, optical and structural applications.

Rhenotherm Kunststoffbeschichtungs GmbH is a service provider for the functional coating of industrial components and has more than 45 years of expertise in the development and application of coatings, mainly based on high-performance plastics such as the fluoropolymers known worldwide under the brand name Teflon. The main areas of application are non-stick coatings, dry lubrication, chemical corrosion protection and plasma coatings, a combination of thermally sprayed wear protection coatings and non-stick or traction coatings based on fluoropolymers or silicones. Using state-of-the-art plant technology and robotics, the components are coated precisely and optimized and equipped for their respective purpose.

The laser process, which is being jointly developed by the Fraunhofer ILT and Rhenotherm Kunststoffbeschichtungs GmbH, overcomes the disadvantages of conventional oven-based processing of non-stick coatings. The very localized energy input using laser radiation achieves the temperatures required for cross-linking/fusing in the coating and reduces the thermal load on the substrate material. The energy consumption for producing these coatings is lower than with an oven-based process, as only an area close to the surface is heated and not the entire component. In addition, the interaction time for processing the coatings can be significantly reduced compared to the oven process. As the laser is powered by electricity, climate-neutral production is possible thanks to the use of green electricity.

Several development steps are necessary to implement this project. Firstly, Rhenotherm is investigating the production of sol-gel and polymer-based dispersions that are suitable for processing using laser radiation.

For this purpose, the coating materials and the laser beam sources used must be adapted to each other. Depending on the coating material used and the laser wavelength, the laser radiation is absorbed to different degrees by the coating material. With a thick substrate, through which the incident radiation is absorbed, and a thin coating applied to it, there are three possibilities for the absorption of the radiation:

Coating-dominated absorption:

The absorption of the coating material is very high for the wavelength used. As a result, the optical penetration depth is significantly lower than the coating thickness. The radiant energy is therefore converted into heat in an area of the coating close to the surface. The rest of the coating material and the substrate surface are only heated via thermal conduction. Although the thermal influence on the substrate material is very low, there is a large temperature gradient in the coating, which can result in uneven coating properties or poor adhesion of the coating.

Substrate-dominated absorption:

The absorption of the coating material is very low for the wavelength used. The radiation that is not reflected by the coating is transmitted through the coating. The radiation is only converted into thermal energy on the substrate surface. This results in a high temperature at the interface between the substrate and the coating, which is utilized in joining processes, for example. However, there is a higher thermal load on the substrate material here. As the rest of the coating is also only heated via thermal conduction, this can lead to uneven coating properties.

Mixed absorption:

The absorption of the coating material is so high that the optical penetration depth is of the same order of magnitude as the coating thickness. This means that radiation is converted into heat over the entire coating thickness and possibly also on the substrate surface. This results in a lower temperature gradient in the coating than in the previously mentioned scenarios, which means that more uniform coating properties can be produced. The partial heating of the substrate surface can lead to higher adhesive strengths of the layers, but also to a higher thermal load than with coating-dominated absorption.

In all three absorption scenarios (Fig. 1), it is possible that the maximum permissible temperature of the substrate is briefly and locally exceeded. The range of influence and duration of this temperature increase depends on the absorption scenario and other laser parameters. For many substrate materials, no damage to the material occurs if the maximum permissible temperature is exceeded for a short time (< 1 s), as these temperatures were usually determined during processing using furnace processes and correspondingly long interaction times. Fig. 1: Possible absorption scenarios of laser radiation with the combination of a thick, absorbent substrate and thin coating

Fig. 1: Possible absorption scenarios of laser radiation with the combination of a thick, absorbent substrate and thin coating

In most cases, mixed energy deposition is preferred for the functionalization of layer systems due to the uniform layer properties, the higher adhesive strength and the comparatively low thermal load. If there is no wavelength of a laser suitable for the industry for which the coating material has the appropriate degree of absorption, it is possible to adapt the material. For example, laser absorbers (e.g. industrial carbon black) can be used, which achieve high absorption levels with lasers in the near-infrared range. The optical penetration depth can be influenced to a certain extent by adjusting the added quantity concentration.

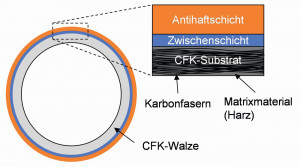

For the non-stick coating materials used here, the first step is to measure the optical properties of the coating materials as a function of wavelength using a spectrometer. Based on this, appropriate laser beam sources are selected and material adjustments are made. A laser in the near-infrared wavelength range is used for both the sol-gel and the polymer coating. After material adaptation, the optical penetration depth corresponds approximately to the thickness of the coating material. Fig. 2: Structure of the laser-processed coating system on a CFRP roller

Fig. 2: Structure of the laser-processed coating system on a CFRP roller

In addition to the development of non-stick coatings, Rhenotherm is also developing an intermediate layer that is applied between the non-stick layer and the CFRP component. On the one hand, the layer is intended to increase the adhesive strength of the non-stick coating on the CFRP roller and, on the other hand, the intermediate layer is intended to protect the CFRP from the laser radiation transmitted through the non-stick coating (Fig. 2).

Various material combinations are being tested for the development. The aim is to ensure that no radiation is transmitted through the intermediate layer. The layer thickness must be sufficiently thick to minimize the temperature on the CFRP surface.

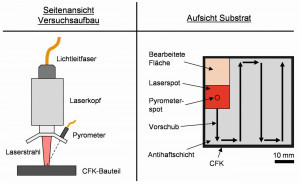

The intermediate layer is applied to the component by thermal spraying. The non-stick layer (sol-gel or polymer-based) is then applied to the component by spraying and processed using laser radiation (Fig. 3).

The "LDM6000" diode laser from Laserline GmbH with a wavelength of λ = 980 nm and a rectangular beam profile (14 mm x 14 mm) is used for laser processing. The laser beam is moved across the surface in a grid pattern to achieve flat processing. The thermal radiation of the coating is measured using the pyrometer "LPC04" from Dr. Mergenthaler GmbH in single-color mode and converted into a previously calibrated temperature (measuring wavelength λ = 1650-2000 nm). Based on this, the power of the laser is controlled by the pyrometer so that a previously defined temperature can be set within the laser spot during processing. This ensures uniform processing of the surface (Fig. 4). The laser process offers the possibility of fast and contactless processing of the coating.

Sol-gel-based non-stick coating

Sol-gel coatings are a promising technology for the production of thin to medium-thick coatings on various surfaces. They are based on sol-gel chemistry, in which a solution (sol) is converted into a gel, which is then applied to the surface and subsequently cross-linked to form a solid coating.

Sol-gel chemistry enables the production of coatings with a wide range of properties, such as high hardness, transparency, hydrophobicity or hydrophilicity. This makes them an attractive option for various applications, such as in optics, electronics, biomedicine or energy generation.

The production of sol-gel coatings takes place in several steps. First, a solution is prepared consisting of an organometallic precursor containing the desired material for the coating. This solution is then applied to the surface and converted into a gel by evaporating the solvent. The gel is then converted into a solid coating by heat treatment or irradiation with a light source.

The properties of the sol-gel coatings can be controlled by the choice of precursors and the variation of the manufacturing parameters. For example, the hardness of the coating can be increased by adding reinforcing materials such as nanoparticles and pigments. Transparency can be increased by choosing precursors with a low refractive index. Hydrophobicity or hydrophilicity can be controlled by the addition of surface modifiers.

Sol-gel coatings offer a number of advantages over conventional coating technologies. They enable the production of thin layers with high homogeneity and low porosity. They are also capable of coating complex shapes and structures, which makes them ideal for use on uneven surfaces.

The sol-gel coating used has a good non-stick effect even after application and drying. The aim of laser processing is therefore to harden the sol-gel coating without reducing the non-stick effect of the coating. In addition, the CFRP base material must not be damaged by the laser radiation.

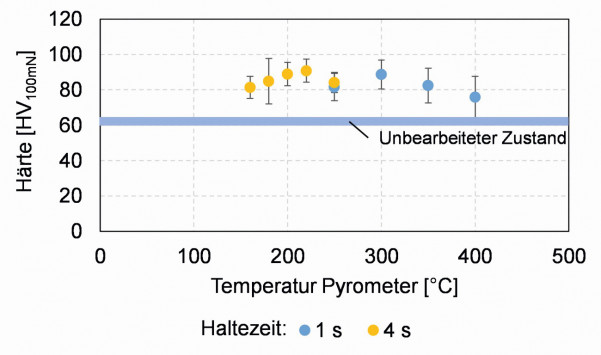

Various process parameters and processing strategies were investigated by the Fraunhofer ILT for the development of the laser process. The hardness of the sol-gel layers was measured before and after laser processing using the "Picodenter HM500" nanoindenter from Helmut Fischer GmbH. The indentation force is 100 mN.

Figure 5 shows the hardness of the sol-gel layers after laser processing as a function of the temperature controlled by the pyrometer and the holding time resulting from the variation of the feed rate. The hardness of the sol-gel layer in the unprocessed state is shown as a comparative value. Fig. 5: Hardness of the laser-processed sol-gel layers as a function of the pyrometer temperature and holding time

Fig. 5: Hardness of the laser-processed sol-gel layers as a function of the pyrometer temperature and holding time

For the holding time of 4 s, the hardness increases with increasing pyrometer temperature up to a value of 91 HV100mN at 220 °C. After that, the hardness increases with increasing pyrometer temperature. The hardness then decreases again with increasing temperature. With a holding time of 1 s, the hardness increases with increasing temperature up to a value of 89 HV100mN at a temperature of 300 °C. At higher temperatures, the hardness also decreases here.

In general, laser processing achieves an increase in hardness of up to 50 % compared to the unprocessed state on the surface of the non-stick coating. The results indicate that, depending on the holding time, there is an optimum temperature at which the coating achieves the greatest hardness. Up to this point, an increase in temperature leads to greater hardness. If the temperature is increased further, the hardness decreases again. This is presumably due to excessive energy input within a short time, which leads to insufficient cross-linking and thus to reduced hardness.

As the highest hardness is measured at higher temperatures for shorter holding times than for longer holding times, it can be assumed that the cause of the decrease in hardness is a diffusion-dominating effect, as it is dependent on both temperature and time.

The contact angle of the coating is measured using the "Mobile Surface Analyzer" from Krüss GmbH. The coating has a contact angle to water of 110° in both the uncured and cured state. This shows that it is possible to cure the material using laser radiation without reducing the non-stick properties.

The cross-section in Figure 6 shows that there is no damage to the CFRP fibers or the resin. This shows that the temperatures required to achieve the highest hardness in the layer (200-300 °C) can be achieved by laser processing without damaging the CFRP material. These temperatures cannot be achieved on CFRP using oven processes, as this destroys the resin. In addition to the possibility of using laser radiation to process coatings on temperature-sensitive components, laser radiation can shorten the processing time and reduce energy consumption compared to the oven process. Fig. 6: Cross-section of sample 252_RHL 23 sol-gel processed with laser radiation as a non-stick coating at 200x magnification

Fig. 6: Cross-section of sample 252_RHL 23 sol-gel processed with laser radiation as a non-stick coating at 200x magnification

Polymer-based non-stick coating

For the polymer-based non-stick coating, the layer is present as a particulate layer on the CFRP after application and drying. The polymer-based non-stick coating consists of a combination of PEEK and fluoropolymers. PEEK (polyether ether ketone) is a thermoplastic polymer that is used in many industrial applications due to its unique properties.

PEEK is characterized by its high temperature resistance, which means that it can be used at temperatures of up to 260 °C without losing its mechanical properties. This high heat resistance makes PEEK an ideal material for applications in the aerospace, automotive and electronics industries where high temperatures can occur.

In addition, PEEK has excellent chemical resistance to a wide range of chemicals, including acids, bases and solvents. This makes it a preferred material for applications where high chemical resistance is required, such as in the chemical industry or in medical technology.

Another advantage of PEEK is its high mechanical strength and rigidity. It has high tensile strength and flexural strength, making it an ideal material for applications where high load-bearing capacity is required. In addition, PEEK is also very dimensionally stable, which means that it retains its shape even under high loads. In this respect, PEEK was chosen as the main component of the coating in order to transfer the aforementioned outstanding properties to the CFRP substrate.

The aim of laser processing is to completely melt the layers. The aim is to achieve sufficient adhesive strength of the coating and to prevent thermal decomposition of the coating due to the laser radiation. The CFRP base material must also not be damaged by the laser radiation.

The material used has almost no absorption for the wavelength used. As described above, laser absorbers are added to the dispersion in different mass ratios. Laser experiments are then carried out by varying the feed rate. The processed layers are divided into the categories "partially melted layer", "completely melted layer" and "combustion". The adhesive strength of the completely melted layers is evaluated by means of a cross-cut test and a peel test.

Figure 7 shows the evaluation of the degree of melting of the processed coatings as a function of the absorber content and the feed rate. A constant power of 64 W is used for all tests. Fig. 7: Melting state of the polymer-based non-stick coatings melted by laser radiation as a function of the feed rate

Fig. 7: Melting state of the polymer-based non-stick coatings melted by laser radiation as a function of the feed rate

Completely melted coatings were produced for all laser absorber percentages tested. For the samples with 25 % absorber content, complete melting of the coating is achieved in a range of feed rates between 2.75 mm/s and 3.25 mm/s. With increasing absorber content, complete melting is already achieved at higher feed rates. At 25 % absorber content, complete melting begins at speeds < 3.25 mm/s and at an absorber content of 150 % already at < 8.75 mm/s. Similarly, the feed rate range at which complete melting is achieved increases with increasing absorber content. As a result, the speed range can be increased from 2.75 - 3.25 mm/s with an absorber proportion of 25 % to the speed range of 4.5 - 8.75 mm/s with an absorber proportion of 150 %. Overall, it can be shown that increasing the absorber concentration in the dispersion used enlarges the process window for laser processing.

Furthermore, it was found that increasing the absorber content also has a positive effect on the adhesive strength of the coatings. A cross-cut rating of GT2 to GT3 was determined for the samples with an absorber content of 25 %, a rating of GT1 to GT2 for the absorber content of 50 % and 75 % and a cross-cut rating of GT0 to GT1 for the absorber content of 100 % and 150 %.

Overall, it was possible to produce adherent and completely melted polymer layers on CFRP using laser radiation without separate preheating.

As with the sol-gel-based coatings, no damage to the CFRP base material was detected after laser processing, which demonstrated the feasibility of the process approach.

Figure 8 shows a completely melted polymer layer on a CFRP substrate including an adhesion layer.

The technology is currently being transferred to 3D components and the process is being scaled up to higher surface rates. The adaptations are being combined in a coating system suitable for industrial use. This work also includes a concept for applying a new non-stick coating to damaged rollers in order to increase the service life of the components. This is where another advantage of laser crosslinking comes into play, as partial decoating and recoating is also easily possible thanks to the sequential and very localized laser radiation. This means that mechanically damaged areas of the functional coating, such as scratches or worn areas, can be removed and repaired in a defined manner. This also contributes to sustainable industrial production and will be investigated in more detail as part of the project. At the same time, a life cycle analysis will be carried out to quantify the energy benefits of the process compared to conventional oven processes.

The holistic concept for coating application, processing and repair, in combination with energy-efficient and electricity-based processing methods, opens up the possibility of moving closer to a green industry.

Future areas of application for laser-sintered non-stick coatings on CFRP rollers include, for example, the production of films for the packaging industry and the lamination/converting of substrates with adhesives and other materials. The use of such roller bodies in the paper industry or in the production of labels and adhesive tapes is also conceivable. Fig. 8: Polymer-based non-stick layer on CFRP substrate including adhesion layer melted by laser radiation

Fig. 8: Polymer-based non-stick layer on CFRP substrate including adhesion layer melted by laser radiation

The project is funded by the Federal Ministry of Economics and Climate Protection BMWK as part of the Technology Transfer Program Lightweight Construction (TTP LB) and the Project Management Jülich PtJ (funding code: 03LB3051)