Electroplated dispersion layers are widely used in the contact systems of Siemens AG switchgear. After Siemens AG's Surface Technology Centre (TZO) in Berlin was closed, the concept of the complex electrochemical process and the electrolyte-specific plant technology was optimized.

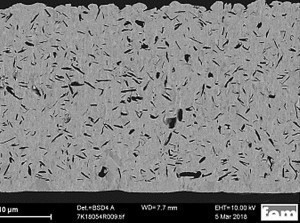

Fig. 1: Photograph of a cross-section of a silver graphite layer This Siemens-internal single-source technology has many years of expertise and was transferred to Pieper Oberflächentechnik Hermsdorf GmbH, which successfully implements the high requirements for the layer system and the layer itself.

Fig. 1: Photograph of a cross-section of a silver graphite layer This Siemens-internal single-source technology has many years of expertise and was transferred to Pieper Oberflächentechnik Hermsdorf GmbH, which successfully implements the high requirements for the layer system and the layer itself.

The use of silver as a contact material - especially for moving contacts in medium-voltage switchgear - is reaching its limits, particularly with regard to the abrasion resistance of silver. In order to increase the service life of silver-plated contact materials, Siemens worked with several institutes to develop two different dispersion layers: nanodiamond layers for increased wear resistance and silver graphite layers with a reduced coefficient of friction while maintaining the same contact properties, particularly with regard to electrical conductivity. The deposition of the silver graphite layers was protected in 1975 in a patent specification DE 2543082 for Siemens AG.

The challenge of both systems was and is to ensure a consistent and homogeneous layer quality, even under production conditions, as well as the meaningful evaluation of the deposited layers and their properties.

While the nanodiamond layers remained a niche product in industry and were used for small series, the patented silver graphite layer was established for broad application at Siemens AG's TZO Berlin and consequently transferred to series production. Compared to pure silver coatings, a defined installation rate of silver graphite colloids can reduce the coefficient of friction by up to 50 % and thus significantly increase the service life (Fig. 1 and 2).

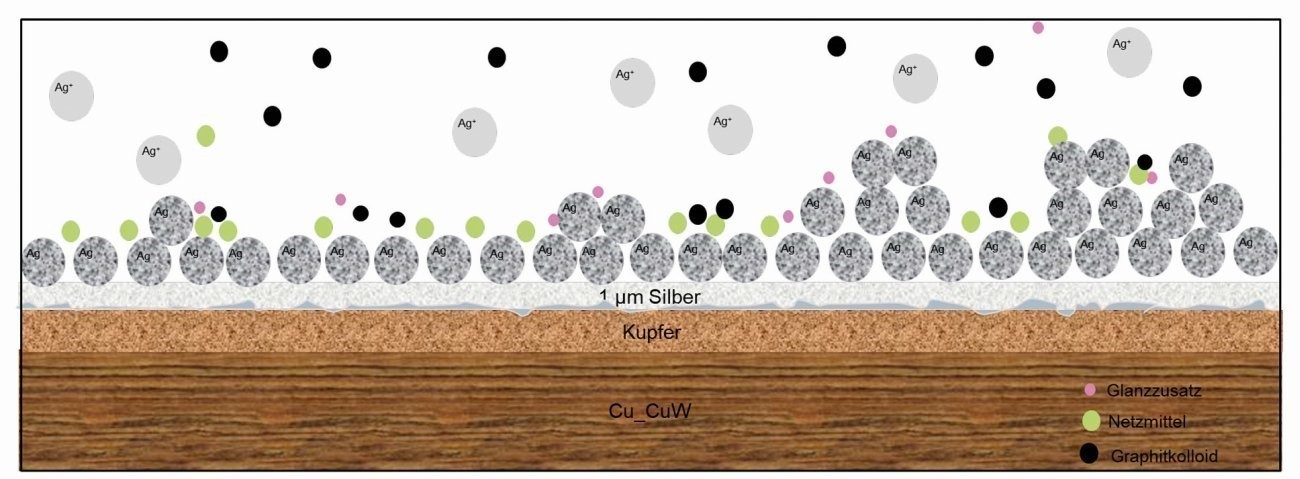

Fig. 2: SEM image of a silver graphite layer The silver graphite layers, which are usually more than 25 µm thick, are deposited from a colloidal graphite suspension, a cyanide base electrolyte with a defined surface tension and other organic additives that influence the growth of the crystallization nuclei. A graphite content of 0.9-1.5 wt% C (DIN 15936) of a defined natural graphite was identified as the optimum graphite content in the layer, which is homogeneously - but non-directionally - distributed in a metal matrix as a result of the interaction of the surface tension of the crystallization nuclei and a directional flow in order to set the corresponding optimum coefficient of friction for moving contacts. The crystallization nuclei are defined on the one hand by the organics, but also by the corresponding current density, the increase of which leads to a higher installation. As shown in patent specification 254082 (application 26.09.1975) as shown in Figure 3.

Fig. 2: SEM image of a silver graphite layer The silver graphite layers, which are usually more than 25 µm thick, are deposited from a colloidal graphite suspension, a cyanide base electrolyte with a defined surface tension and other organic additives that influence the growth of the crystallization nuclei. A graphite content of 0.9-1.5 wt% C (DIN 15936) of a defined natural graphite was identified as the optimum graphite content in the layer, which is homogeneously - but non-directionally - distributed in a metal matrix as a result of the interaction of the surface tension of the crystallization nuclei and a directional flow in order to set the corresponding optimum coefficient of friction for moving contacts. The crystallization nuclei are defined on the one hand by the organics, but also by the corresponding current density, the increase of which leads to a higher installation. As shown in patent specification 254082 (application 26.09.1975) as shown in Figure 3.

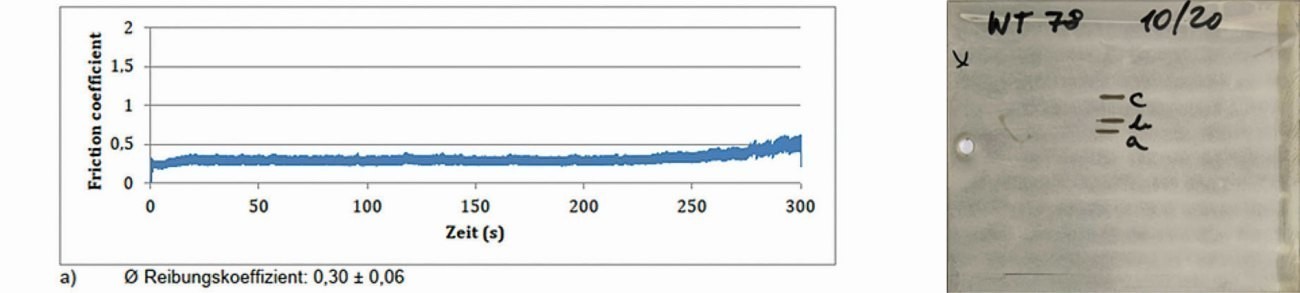

The friction coefficient of the deposited AgC layer is tested using a translational vibration and friction wear test rig SVT200 from Wazau. An in-process measurement method was developed by Siemens in order to create consistent measurement conditions and thus map the service life of moving contacts. The value is determined by taking the average of three measurements. The range of 0.2-0.6 was identified as optimal for the coefficient of friction.

In addition to the coefficient of friction and the wear rate, this measurement method can also be used to map process weaknesses such as uneven flow, system faults or bath ageing. An important factor for increasing the service life of the moving contact systems - in addition to a defined installation rate of silver graphite colloids - is the aforementioned micro and macro structure of the deposited silver layer. The homogeneous attachment of the graphite colloids to defined crystallization nuclei of the silver layer as well as the morphology and size of the individual natural colloids can significantly increase the coefficient of friction.

Fig. 3: Schematic representation of the graphite layer

Fig. 3: Schematic representation of the graphite layer

Ultimately, all process steps, from the activation of the surface and the coating system to the final step of compacting the surface, have a major influence on the service life of the subsequent switching systems. This can be seen in particular in the curve of the coefficient of friction, which very precisely depicts system weaknesses that could not be detected by the absolute value of the coefficient of friction (see Figs. 4 and 5).

Fig. 4: Ideal curve of the friction coefficient for silver dispersion layers (left) and sample sheet with the three measurement runs of the translational vibration and friction wear test

Fig. 4: Ideal curve of the friction coefficient for silver dispersion layers (left) and sample sheet with the three measurement runs of the translational vibration and friction wear test

Fig. 5: Last work step after coating, compaction of the silver graphite surface by a so-called ball polishing step in the round trough vibratorThemany years of experience and the electrolyte-specific expertise gained in this dispersion layer, especially in view of the decision to close the TZO Berlin of Siemens AG in autumn 2020, initially caused some headaches. Having to outsource this qualified and approved process was one of the particular challenges during the closure, as the silver graphite layer could not be replaced due to its special electrolyte-specific properties, neither by silver layers available on the market nor by comparable systems. To make matters even more difficult, it was not only necessary to find a supplier who was technically and qualitatively capable of taking on this large volume and providing professional support, but who also possessed a correspondingly high level of expertise in controlling this specific electrolyte. In addition, both the process and the plant technology not only had to be mirrored, but also adapted to the new supplier in terms of increased quality requirements.

Fig. 5: Last work step after coating, compaction of the silver graphite surface by a so-called ball polishing step in the round trough vibratorThemany years of experience and the electrolyte-specific expertise gained in this dispersion layer, especially in view of the decision to close the TZO Berlin of Siemens AG in autumn 2020, initially caused some headaches. Having to outsource this qualified and approved process was one of the particular challenges during the closure, as the silver graphite layer could not be replaced due to its special electrolyte-specific properties, neither by silver layers available on the market nor by comparable systems. To make matters even more difficult, it was not only necessary to find a supplier who was technically and qualitatively capable of taking on this large volume and providing professional support, but who also possessed a correspondingly high level of expertise in controlling this specific electrolyte. In addition, both the process and the plant technology not only had to be mirrored, but also adapted to the new supplier in terms of increased quality requirements.

In a lengthy process of selecting the best suppliers, Pieper Oberflächentechnik Hermsdorf GmbH was persuaded to take over this system as a single-source supplier. Pieper, whose majority of customers come from the electronics and automotive sectors, has been offering both silver and hard silver coating since 2001 and coats over 50,000m2 of surface per year with a total of 12,000 liters of silver and hard silver electrolytes.

It was precisely their continuous expertise in very demanding hard silver coating, which requires careful process and layer control, that led to the decision to transfer Siemens' internal and very complex AgC silver dispersion process to Pieper Oberflächentechnik Hermsdorf GmbH.

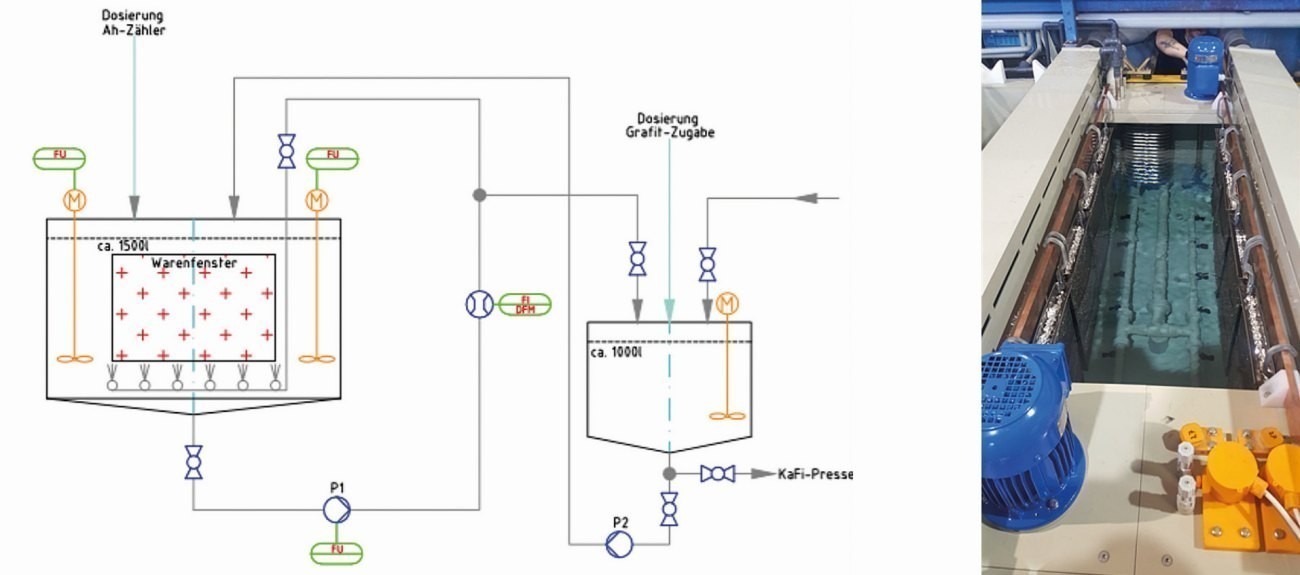

In cooperation with AST Anlagenbau GmbH, Siemens AG's previous system design was converted into an optimized system concept for this special electrolyte and integrated into the existing silver line in order to be able to take over Siemens' internal series production of the various components accordingly. The implementation of a uniform laminar flow of the suspension to a defined fabric window, variably changing anode and cathode ratios and the realization of a stable process control with a future smaller electrolyte volume with a changed exchange rate, initially led to some technically complex discussions, but finally resulted in a constructive fine-tuning(Fig. 6).

Fig. 6: New system concept with AgC tank and chamber filter press (l.). Heart of the silver dispersion deposition with solid anode solid

Fig. 6: New system concept with AgC tank and chamber filter press (l.). Heart of the silver dispersion deposition with solid anode solid

In this new system concept, the complexity of the heterogeneous mixture of substances also had to be taken into account in order to prevent sedimentation of the graphite colloids in particular. Both the tank and the corresponding flow conditions and the exchange rate of the electrolyte were optimized here in order to do justice to the modified system design. The use of natural graphite in particular results in continuous ageing of the grain distribution, which is intensified by the type of flow and the additional load on the drum coating. As already described, bath ageing has a negative effect on the service life, the coefficient of friction and the wear rate of the coating. This fundamental problem can only be solved by regular filtration of the electrolyte in a chamber filter press, which, in addition to the time-consuming, discontinuous depletion of the suspension, naturally also represents a process downtime (Fig. 7).

At the same time, an increase in the surface area of the graphite due to ageing or decomposition causes a change in the interaction with the organic additives, so that continuous monitoring of the additives in a narrow concentration range is essential. Despite the mirroring of the anode/cathode ratio, the small deviations in the filling level resulted in a new concentration range of the organic additives(Fig. 8).

Fig. 9: Silver graphite coating at Pieper before (l.) and after an ultrasound-enhanced rinsing step

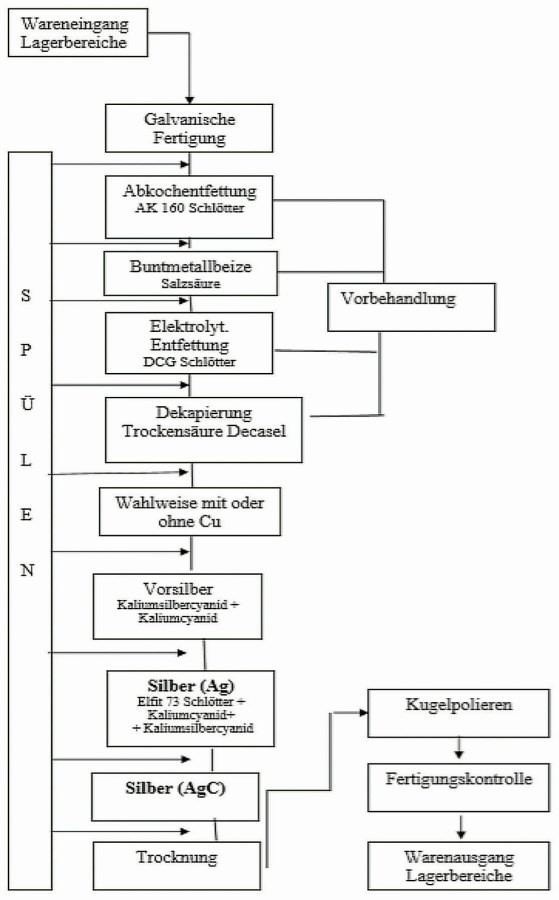

The consistent implementation of the system concept and the careful expansion of the silver line by extending the corresponding system segments, including the necessary rinsing steps(Fig. 9) right up to the final work step and the defined, coordinated process sequence(Fig. 10) for the contact components made of copper/copper alloys - optionally with or without an intermediate copper step - ultimately led to the rapid release of production for Siemens AG as well as for previous customers of TZO Berlin. Especially the variation of the different coating systems depending on customer requirements - either as barrel or rack coating - could be realized with this optimized mirroring and additional capacities could be gained.

Fig. 10: Coating process sequence for copper contact components

Fig. 10: Coating process sequence for copper contact components

This was the last process at TZO Berlin in September 2020 and thus the proverbial last bath was drained. The silver graphite dispersion coating - tribologically far superior to a silver coating - is successfully produced by Pieper Oberflächentechnik Hermsdorf GmbH based on the Siemens process with even higher requirements for the coating system and the coating itself, thus opening up space for further contact systems and developments.