Bosch Manufacturing Solutions uses fully automated solutions for the efficient handling of selective galvanic coatings such as chrome plating, nickel plating of spark plug housings and anodizing of brake force distributors. At the heart of the systems is a reactor or rack concept adapted to the respective component, which masks the parts of the component that are not to be coated and thus enables high-precision, selective coating. The reversible cassette technology and the fully automatic rack electroplating system offer high production output and coating accuracy. The systems for anodizing brake force distributors operate on the basis of independent process modules that offer fast set-up with minimal production loss and high throughput with variable quantities.

Bosch Manufacturing Solutions Chemical Coating

Bosch Manufacturing Solutions offers a variety of electroplating technologies that enable components to be coated effectively and precisely. The portfolio includes painting, anodizing, conventional electroplating and, in particular, selective coating. With painting, surfaces can be coated multifunctionally, while the anodizing of aluminium components offers excellent wear and corrosion protection. With electroplating, all commercially available coating systems as well as special coatings can be applied.

The use of coating reactors with an integrated orifice enables high-precision, selective coating with a high deposition rate. A coating reactor for electroplating contains an anode, an electrolyte distributor and flow guide for a defined flow to the workpiece as well as a holder for the workpiece with an aperture or seal to limit the area to be coated. The reactor is opened for loading and unloading by means of automatic gripper handling. Selective electroplating is explained using the example of flowbox technology and the reversible cassette chrome plating system. Bosch Manufacturing Solutions also develops systems for rack-based electroplating for high-quality applications. One example of this is the coating system for spark plug housings, which is described below. The concept of reactor coating is also applied to anodizing coating and is presented here using the anodizing of brake force distributors as an example.

Plant technology

The plant technology at Bosch Manufacturing Solutions is fully automated and meets the highest standards and requirements to ensure efficient and high-quality coating of components. The coating systems can be set up in conventional factory halls, as the hazardous material area is encapsulated and the exhaust air is cleaned via droplet separators or exhaust air scrubbers.

Integrated supply technology and measurement technology ensure that the coating processes run smoothly and enable continuous monitoring of the process parameters. Bosch Manufacturing Solutions generally specializes in individual products or product groups, which means that tailor-made coating solutions can be implemented for different components. The electroplating systems comply with the applicable electroplating standards DIN EN 17059 and meet the requirements of the AwSV (German Ordinance on Installations for the Handling of Substances Hazardous to Water) and the WHG (German Water Resources Act). In addition to fulfilling the legal requirements, our systems have increased fire protection and safety technology thanks to redundant systems.

Selective chrome plating with Flowbox and reversible cassette technology

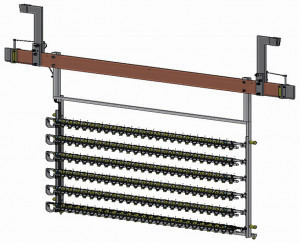

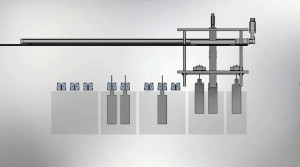

Fig. 1: Reversible cassette and FlowboxTheFlowbox reversible cassette technology is an innovative system technology at Bosch Manufacturing Solutions that was specially developed for the selective coating of components [1, 2]. The flowbox is a plastic body containing 104 individual reactors, each with an anode and a supply line for the electrolyte. The components are held on a magnetic double-sided reversible cassette and positioned in the coating aperture. Thanks to the individual anodes connected to individual rectifiers, it is possible to set the coating current for each component individually and thus achieve a high coating accuracy of +/- 3 µm with process reliability. Due to the very good flow conditions, a high deposition rate of up to 3 µm/min can be achieved during hard chrome plating.

Fig. 1: Reversible cassette and FlowboxTheFlowbox reversible cassette technology is an innovative system technology at Bosch Manufacturing Solutions that was specially developed for the selective coating of components [1, 2]. The flowbox is a plastic body containing 104 individual reactors, each with an anode and a supply line for the electrolyte. The components are held on a magnetic double-sided reversible cassette and positioned in the coating aperture. Thanks to the individual anodes connected to individual rectifiers, it is possible to set the coating current for each component individually and thus achieve a high coating accuracy of +/- 3 µm with process reliability. Due to the very good flow conditions, a high deposition rate of up to 3 µm/min can be achieved during hard chrome plating.

The double-sided turning cassette enables the components to be loaded and unloaded during the coating process. The components are held on the magnetic plate of the turning cassette, positioned in the flow box and run through the coating process on the underside of the turning cassette, while the coated workpieces are first pre-rinsed on the top side of the turning cassette and then transported on by the handling system before the next batch is placed on the turning cassette. Once the coating process is complete, the cassette with the components is automatically turned over so that the next batch can be coated on the other side. This continuous process enables a high throughput rate and uniform coating of the components (Fig. 1).

Another advantage is the integrated rinsing function. This allows the components to be pre-rinsed on the turning cassette after coating in order to reduce the carry-over of electrolyte and prevent electrolyte drying.

Bosch Manufacturing Solutions' flowbox reversible cassette technology is a pioneering solution for the selective coating of components and offers an efficient and precise way to realize high-quality surface coatings in industrial production. With this technology, Bosch Manufacturing Solutions customers can benefit from improved production performance, reduced scrap rates and increased product quality.

The reversible cassette chrome plating system (WVA)

The WVA is a system with fully automated handling for the partial hard chrome plating of gasoline injection valve components, which is based on flowbox turning cassette technology. One system contains four flowboxes and turning cassettes in an encapsulated process area to achieve a controlled environment and protection of people and the environment. This system is characterized by the fact that two different types of workpieces can be coated simultaneously (Fig. 2).

Fig. 2: Workpiece carrier with chrome-plated workpieces

Fig. 2: Workpiece carrier with chrome-plated workpieces

104 components per workpiece carrier are fed into the system and transported on a belt system to a transfer position. There, 52 workpieces are picked up by an automatic collet handling system and transferred in two passes to the turning cassette of the process module, where they are coated. The coated workpieces are picked up from the turning cassette by a gripper handling system and placed back on the workpiece carriers. From there, the workpieces first pass through a four-stage rinsing cascade and then vacuum drying. The integrated cleaning technology ensures that the limit value of 0.1 mg/cm2 for the chromate concentration on the component surface is reliably maintained. This is followed by a coating thickness measurement with X-ray fluorescence measuring devices in three automatic measuring stations. Based on the measured coating thickness values, workpieces whose coating is outside the tolerance are automatically ejected. A turning station is integrated to enable coating on both sides. When the workpieces are removed, they undergo a visual inspection and are then passed on to the next production step (Fig. 3 and 4).

Fig. 3: Layout of a turning cassette chrome plating system

Fig. 3: Layout of a turning cassette chrome plating system

The inline 100 % coating thickness measurement makes it possible to automatically detect any deviations and adjust the process parameters accordingly. This ensures a consistently high quality of the coating. The cycle time per component is around 0.9 seconds, so that a high production output of around 25 million chrome platings per year is achieved.

The high-speed nickel-plating system for spark plug housings

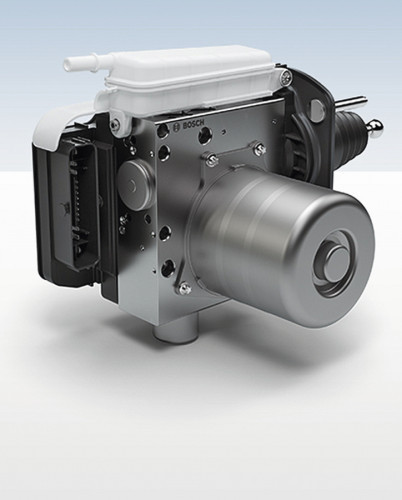

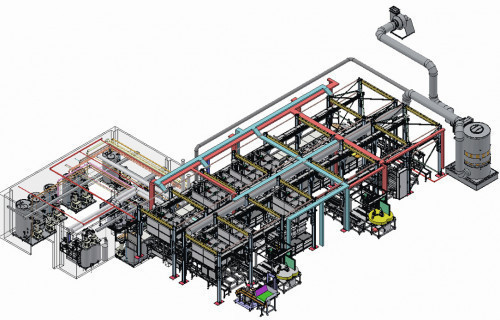

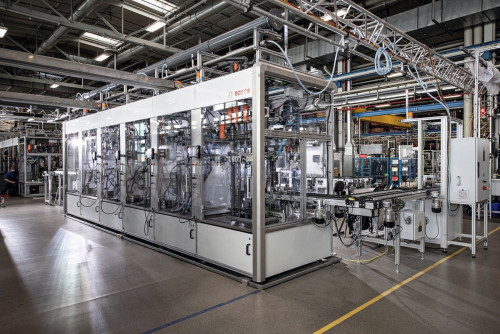

The fully automatic system technology for nickel-plating spark plug housings enables partial nickel-plating with internal coating of around 15 million spark plug housings per year in a bath electroplating process, occupying an area of around 300m2.

Fig. 4: Exterior view of the HSNP system with a view of the process tanks

Fig. 4: Exterior view of the HSNP system with a view of the process tanks

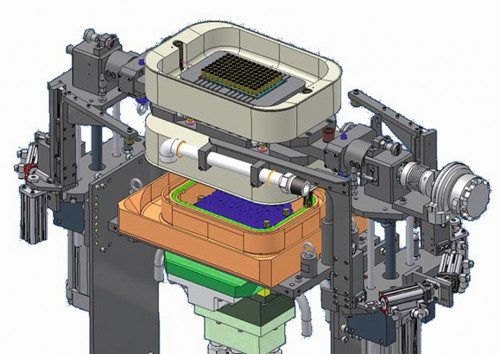

Fig. 5: The CAD view shows the high-speed nickel system on which Bosch spark plugs with a ground electrode made of nickel material and nickel-plated housing are manufactured

Fig. 5: The CAD view shows the high-speed nickel system on which Bosch spark plugs with a ground electrode made of nickel material and nickel-plated housing are manufactured

On the one hand, the simultaneous coating of different steels is a challenge, as the ground electrode is a high-nickel material that can only be coated at the same time as the steel spark plug housing through appropriate pre-treatment steps in a specially developed process. On the other hand, a selective partial coating of the inside is achieved by the ground electrode protruding into the inner area of the spark plug housing, thus improving the corrosion resistance of the product [3] (Fig. 4 and 5).

High-performance handling technology for spark plug coating

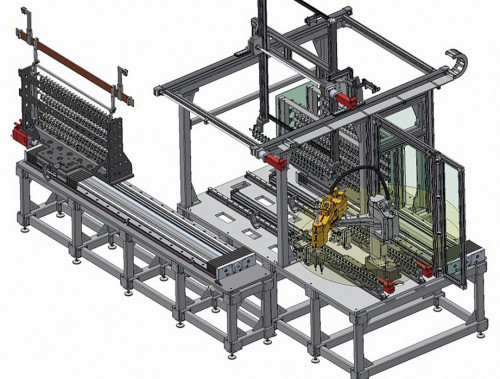

The system is loaded with spark plug housings as bulk material via a stepped lift conveyor, linear axis systems and a robot unit, which grips the components precisely and places them in the correct position. An inline contact inspection ensures the quality of the components and an NOK ejection system removes defective components. The cycle time per component is around 2.0 seconds. More than 20 component variants are available for partial nickel plating with internal coating of the spark plug housings (Fig. 6 and 7).

The product carrier structure consists of a base frame and six removable strips. One rail can hold 24 workpieces, resulting in a total of 144 components per product carrier (rack). The base frame has a product window of 1200 x 700 mm. The handling technology for spark plug coating includes various aspects that ensure efficient and precise execution of the coating process (Fig. 8).

A 2-fold gripper system with a 5-axis robot is used to load the strips, which are then placed on the rack and contacted there. The product carriers are automatically moved from station to station by trolleys. The carriage system enables the product carriers to be transported through the individual processing stations of the spark plug coating process. The speed of the carriage system is 40 m/min, with a load capacity of 300 kg.

The carrier changeover times are around 20 seconds and the absolute measuring system ensures a high accuracy of +/- 1.0 mm. Automated component handling and precise positioning ensure high production output. The triple carriage can move three racks at the same time, which is a very efficient solution for transporting the racks, enabling high throughput. A gathering and spreading system of the triple carriage compensates for the different distances between the racks during transfer and ensures precise positioning of the racks in the process baths (Fig. 9, 10 and 11). After coating, the spark plug housings are inductively dried and unloaded into plastic crates in a stripping station that is almost identical to the pick-and-place station, so that the coated housings can be further processed as bulk material.

Anodizing system for anodizing brake force distributors

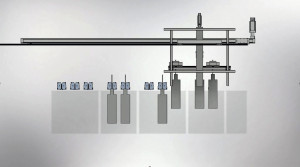

Brake force distributors require a selective anodizing layer as corrosion protection. Selective anodizing is a major advantage here, as no anodizing layer is required or is an obstacle on the remaining component surface. With selective anodizing, high deposition rates are possible with good flow and potential conditions (Fig. 12).

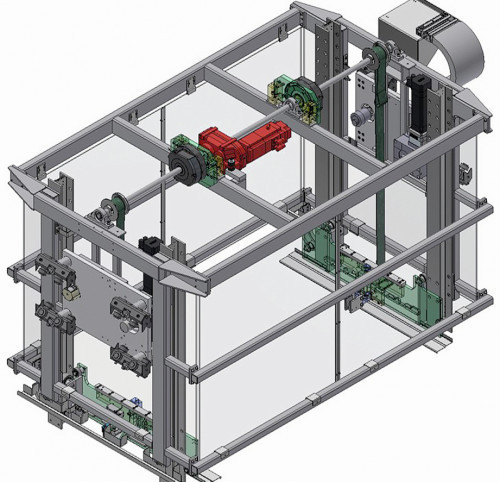

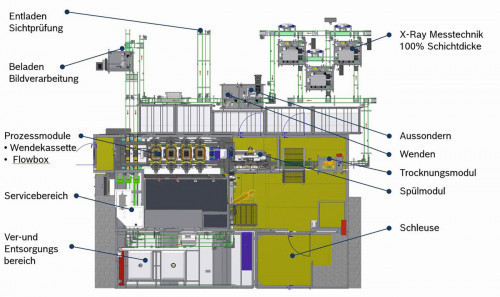

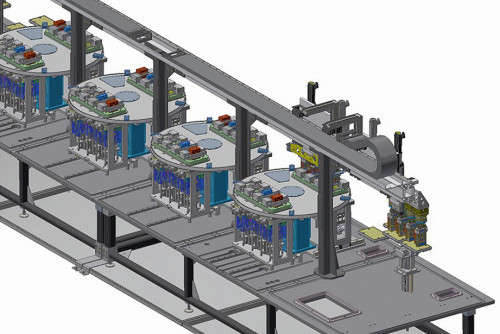

The system technology for anodizing brake force distributors enables partial anodizing in large series in closed process modules. The system is fully automated and enables the anodizing of over 1.8 million brake force distributors per year. It is equipped with four independent process modules that enable automatic handling and retooling of the individual modules during operation (Fig. 13).

Data is tracked in the anodizing system via intelligent type data management with inheritance. In addition, there is comprehensive process monitoring of the relevant parameters and the data is logged and archived in a central database. As a result, the system technology enables reliable quality assurance and process optimization.

Fig.13: Fully automatic anodizing system for brake force distributors

Fig.13: Fully automatic anodizing system for brake force distributors

Handling technology for selective anodizing

The system coats over eight component variants and can transport up to four components simultaneously in a 4-fold gripper system. The process is fed via a rotary table. The cycle time per component is 12 seconds. An important aspect of the handling technology is the tracking of goods by scanning data matrix codes (DMC). Each component is provided with an individual code that contains all relevant information and is tracked throughout the entire coating process. This ensures complete traceability. The anodizing station is equipped with rotary tables that enable the components to be positioned quickly and precisely. A portal axis with a path of approx. 6000 mm and a stroke of approx. 400 mm ensures efficient movement of the components and a high speed of over 40 m/min. The absolute measuring systems guarantee a high accuracy of +/- 0.3 mm to ensure precise positioning of the workpieces. Automatic collision detection on the z-axis prevents possible damage to the components and ensures trouble-free operation of the system.

The transport system for selective anodizing is divided into three areas in which different handling solutions are used:

Loading station:

In the loading station, the workpieces are manually inserted into the 2-fold product carriers. The product carriers are transported by a belt system and a measuring device determines the component height. Components that do not correspond to the set-up type are stopped.

The product carrier structure is designed so that the components can be positioned safely and stably to ensure consistent coating quality. At the same time, the product carrier is suitable for the different component types without retooling.

Anodizing station:

The anodizing station consists of four separately controllable individual modules, each with four coating reactors and two transfer stations at both ends of the system. Within the individual module, handling takes place via a rotary table, which moves the workpieces between an anodizing position and a loading and unloading position, which also enables rinsing. Within the system, the workpieces are transported by a 4-fold gripper system. In the transfer station, the workpieces are removed from the workpiece carriers by the gripper system and transported after the component-specific DMC has been recorded (Fig. 14).

Fig. 14: Rotary tables with coating nests in the fully automatic anodizing system

Fig. 14: Rotary tables with coating nests in the fully automatic anodizing system

Washing and unloading:

At the end of the anodizing station, the workpieces are placed in washing frames by the gripper system. These are guided by a belt system through a washing and drying system and finally arrive at an unloading station, where the workpieces are removed and fed to the next step in the production chain.

The transport system and the product carrier structure are integrated into the overall concept of the system in order to achieve high production output and efficiency. Precise control of the transport system enables coating times to be optimized and component throughput times to be reduced.

Summary

The article presented efficient handling technology for electroplating solutions such as selective chrome plating, nickel plating of spark plug housings and selective anodizing of brake force distributors. Overall, with this technologically advanced system technology, Bosch Manufacturing Solutions offers a reliable way to implement high-quality surface coatings in industrial production, resulting in improved production performance, reduced scrap rates and increased product quality. With a broad portfolio of electroplating technologies and customized solutions, Bosch Manufacturing Solutions is a strong global partner for companies in the field of special machine construction.

The article is based on a presentation at the Ulmer Gespräch at the end of May 2023.

Photos: Bosch Manufacturing Solutions

INFO

Bosch Manufacturing Solutions

As a global supplier in the field of special machine construction, Bosch Manufacturing Solutions specializes in manufacturing equipment and automation solutions. With nine locations and around 1,800 employees, Bosch Manufacturing Solutions is a strong global partner for companies in various industries. The company offers customized assembly and testing systems, advanced manufacturing processes and digital solutions along the entire product life cycle. Through a combination of innovative technologies, extensive expertise and a broad portfolio, Bosch Manufacturing Solutions enables its customers to achieve an efficient and high-quality value stream.

Literature

[1] Bauer, H.; Lingner, M. Handling device for a coating process, coating apparatus and method for handling at least one workpiece during a coating process (DE 10 2012 207 136 A1), German Patent and Trade Mark Office, (2012)

[2] Pilaski, M.; Röttgen, M.; Lingner, M.; Felsch, T.; Bergmann, T.; Baumgärtner, L.; Bubrin, M.: Injector component with coating, injector and device for coating (WO 2018/091723 A2), German Patent and Trade Mark Office, (2015)

[3] Pilaski, M.; Kraus, R.; Nölscher, H.; Rathgeber, S.; Petersen, G.; Bergmann, T.; Bubrin, M.; Hirte, T.; Gries, B.; Hölzl, C.R.: Spark plug housing with corrosion protection on the inside as well as spark plug and manufacturing process, German Patent and Trade Mark Office, (2019)