The economic effects of the - highly controversial - billions in subsidies under the European Chips Act for new semiconductor factories in Saxony are finally becoming more tangible: according to a recent study, around €21.3 billion in additional value creation can be expected nationwide beyond these mega-fabs' own sales. And in 15 years at the latest, the state will have 'recouped' these subsidies through additional tax revenues and social savings, the researchers predict.

The new chip factories and expansions of TSMC/ESMC, Infineon, Jenoptik, X-Fab & Co. and their growing supplier industry will increase Saxony's economic output by around €12.6 billion from 2030. This will create around 24,200 new jobs in and around the fabs. These semiconductor investments will also make the regional economy more future and export-oriented. This was the result of the aforementioned study conducted by the Institute for Innovation and Technology (IIT) in Berlin for the Saxony Economic Development Corporation (WFS). "Dresden and the surrounding area will account for the lion's share of the growth effects," predicted study author Dr. Marc Bovenschulte during the presentation of the study. Within ten to 15 years, the approximately 7 billion euros in direct and indirect subsidies for the latest high-tech settlements and expansions should also pay for themselves - through additional tax revenue, levies and savings in social spending, the researcher estimated when asked by Plus.

It is quite conceivable that, after TSMC, the 'body and stomach suppliers' of the world market leader from Taiwan will also settle here in the future, as will chip design centers and circuit final assembly factories, most of which are still located in Asia today. All of this would lead to further growth spurts in "Silicon Saxony" that have not even been taken into account in the study. "At some point, the gravitational pull of Dresden as a microelectronics location will be so great that other players such as Nvidia or ARM will no longer be able to escape it," says Bovenschulte.

IIT researcher Marc Bovenschulte (center) hands over the study on the growth effects of the microelectronics industry in Saxony and Dresden to Saxony's Minister of Economic Affairs Martin Dulig (left) and WFS Managing Director Thomas Horn (right)

IIT researcher Marc Bovenschulte (center) hands over the study on the growth effects of the microelectronics industry in Saxony and Dresden to Saxony's Minister of Economic Affairs Martin Dulig (left) and WFS Managing Director Thomas Horn (right)

Saxony is working on a breakthrough for digital manufacturing networks

The Ceti Centre of Excellence in Dresden is also working on examples of digital collaboration and networked high automation based on 'Manufacturing-X' principlesBecausethe Chinese are increasingly putting the metaphorical gun to the chest of German SMEs that are spoiled by success, as they are flooding Europe's markets with ever better products at cheaper prices, an old major digitalization project for the industry is now getting a new boost: During the 'Hub disrupt' industry summit at the VW Manufaktur Dresden, engineers, software and other experts presented the first sample solutions for 'Manufacturing-X'. This represents a real "breakthrough" for this digital manufacturing network, according to Michael Kaiser from 'Smart Systems Hub Dresden', who organized the conference and the development of the application examples. The Dresden-based company now wants to roll out these concepts internationally via a new 'Open Smart Systems Hub Community'. In view of the strong competitive pressure that is no longer only felt by global corporations, but also by SMEs and small businesses, local companies will have little choice but to become much more digitally networked than before, emphasizes Alexander Jakschik from the eastern German section of the mechanical engineering association VDMA. "Global competition has changed, especially due to China," argues Jakschik. "We absolutely have to become more efficient and offer added value that the Chinese don't yet have." The 'Manufacturing-X' network aims to connect machine manufacturers, suppliers, spare parts producers and sellers of German industrial products in a highly efficient data ecosystem, ensuring greater efficiency and lower costs. Digital twins' are intended to make the entire value chain so transparent that everyone in the chain knows at all times where which component is currently "in the making", who worked on it and when, when it arrives at the factory or wholesaler - and who is responsible if there is a complaint afterwards. Decentrally organized and controlled data exchange is intended to ensure that each company protects its business secrets from others - such as suppliers from the Far East. However, because this major project has made little progress for years, Michael Kaiser and his hub team brought together experts from the business world and many creative minds. These specialists developed initial solutions in 'Thin[gk]athon' idea factories. A prototype production network was built around a company that offers on-demand mechanical engineering services, similar to a streaming video service. Digital suppliers from the Far East and Eastern Europe, spare parts suppliers from Saxony and national and international sales companies then docked onto this network. Instead of waiting for the big template solution for all applications, it has proven to make more sense to create a 'demo landscape' of concrete solutions from which everyone can pick the right 'Manufacturing-X' scenario, says Mirko Paul from the software company SAP, which has also developed several open-source computer programs for the 'Smart System Hub' project. "Around 80% of the demos created here can be reused in other companies, especially in SMEs," estimates the SAP expert.

The Ceti Centre of Excellence in Dresden is also working on examples of digital collaboration and networked high automation based on 'Manufacturing-X' principlesBecausethe Chinese are increasingly putting the metaphorical gun to the chest of German SMEs that are spoiled by success, as they are flooding Europe's markets with ever better products at cheaper prices, an old major digitalization project for the industry is now getting a new boost: During the 'Hub disrupt' industry summit at the VW Manufaktur Dresden, engineers, software and other experts presented the first sample solutions for 'Manufacturing-X'. This represents a real "breakthrough" for this digital manufacturing network, according to Michael Kaiser from 'Smart Systems Hub Dresden', who organized the conference and the development of the application examples. The Dresden-based company now wants to roll out these concepts internationally via a new 'Open Smart Systems Hub Community'. In view of the strong competitive pressure that is no longer only felt by global corporations, but also by SMEs and small businesses, local companies will have little choice but to become much more digitally networked than before, emphasizes Alexander Jakschik from the eastern German section of the mechanical engineering association VDMA. "Global competition has changed, especially due to China," argues Jakschik. "We absolutely have to become more efficient and offer added value that the Chinese don't yet have." The 'Manufacturing-X' network aims to connect machine manufacturers, suppliers, spare parts producers and sellers of German industrial products in a highly efficient data ecosystem, ensuring greater efficiency and lower costs. Digital twins' are intended to make the entire value chain so transparent that everyone in the chain knows at all times where which component is currently "in the making", who worked on it and when, when it arrives at the factory or wholesaler - and who is responsible if there is a complaint afterwards. Decentrally organized and controlled data exchange is intended to ensure that each company protects its business secrets from others - such as suppliers from the Far East. However, because this major project has made little progress for years, Michael Kaiser and his hub team brought together experts from the business world and many creative minds. These specialists developed initial solutions in 'Thin[gk]athon' idea factories. A prototype production network was built around a company that offers on-demand mechanical engineering services, similar to a streaming video service. Digital suppliers from the Far East and Eastern Europe, spare parts suppliers from Saxony and national and international sales companies then docked onto this network. Instead of waiting for the big template solution for all applications, it has proven to make more sense to create a 'demo landscape' of concrete solutions from which everyone can pick the right 'Manufacturing-X' scenario, says Mirko Paul from the software company SAP, which has also developed several open-source computer programs for the 'Smart System Hub' project. "Around 80% of the demos created here can be reused in other companies, especially in SMEs," estimates the SAP expert.

'Nova' is to become a kind of 'Android' of robotics

Christian PiechnickTheDresden University spin-off 'Wandelbots' has presented another building block for networked high automation: the new robot operating system "Nova". With this universal software, Wandelbots boss Christian Piechnick wants to make it easier for factories and craftsmen to plan, program and optimize the use of robots cheaply and easily. In his view, the manufacturer-independent operating system marks a "new departure in industrial automation. Just as Android revolutionized smartphones and Windows changed the PC world, Nova will make industrial robotics accessible to everyone and enable new types of commercialization for software developers." The idea is that, beyond the large, highly automated car and electronics factories, many SMEs and tradespeople are still finding it difficult to use robots in their businesses, even though the shortage of skilled workers and competitive pressure from Asia have long been pressing. Robots are not cheap, specialists are needed to prepare the use of the steel colleagues and to program the robots for their tasks, not to mention all kinds of permits. What's more, people and robots can come very close to each other, especially in older, rather labyrinthine workshops, where there are often systems from completely different manufacturers. Occupational safety precautions and preliminary investigations into where the robot arms will fit are therefore particularly important. And the Saxons now want to close these gaps in the market: As universal basic software, Nova is designed to get robots from Kuka, Epson, ABB, Kawasaki and other manufacturers up and running; according to Wandelbots, over 300 different models are supported. Knowledge of common programming languages such as Python and Javascript is sufficient to train the robots for their work tasks in the field. In this way, the Dresden-based company aims to significantly expand the circle of skilled workers who are suitable in principle for such automation projects.

Christian PiechnickTheDresden University spin-off 'Wandelbots' has presented another building block for networked high automation: the new robot operating system "Nova". With this universal software, Wandelbots boss Christian Piechnick wants to make it easier for factories and craftsmen to plan, program and optimize the use of robots cheaply and easily. In his view, the manufacturer-independent operating system marks a "new departure in industrial automation. Just as Android revolutionized smartphones and Windows changed the PC world, Nova will make industrial robotics accessible to everyone and enable new types of commercialization for software developers." The idea is that, beyond the large, highly automated car and electronics factories, many SMEs and tradespeople are still finding it difficult to use robots in their businesses, even though the shortage of skilled workers and competitive pressure from Asia have long been pressing. Robots are not cheap, specialists are needed to prepare the use of the steel colleagues and to program the robots for their tasks, not to mention all kinds of permits. What's more, people and robots can come very close to each other, especially in older, rather labyrinthine workshops, where there are often systems from completely different manufacturers. Occupational safety precautions and preliminary investigations into where the robot arms will fit are therefore particularly important. And the Saxons now want to close these gaps in the market: As universal basic software, Nova is designed to get robots from Kuka, Epson, ABB, Kawasaki and other manufacturers up and running; according to Wandelbots, over 300 different models are supported. Knowledge of common programming languages such as Python and Javascript is sufficient to train the robots for their work tasks in the field. In this way, the Dresden-based company aims to significantly expand the circle of skilled workers who are suitable in principle for such automation projects.

The Dresden-based company is also linking its operating system with the virtual 'Omniverse' worlds of the US microelectronics group Nvidia. This should make it easier for industrial and trade companies to simulate their future use with 'digital twins' in advance in a virtually simulated factory hall and discover weak points and optimization potential.

The Nova operating system from Wandelbots Dresden is designed to significantly simplify the programming and advance simulation of robot applications

The Nova operating system from Wandelbots Dresden is designed to significantly simplify the programming and advance simulation of robot applications

Saxony acquires its own AI supercomputer

In addition to robotics, ManufacturingX and other transformation components, advances in the key technology of artificial intelligence, where Europe still lags far behind the USA and China, play a central role in the new approach to flexible and networked high automation. This is unlikely to change any time soon for the 'big language models'. However, local companies are now making remarkable progress in the use of AI in industry. This is why Saxony is now acquiring its own AI supercomputer. The computer, which costs millions, is designed to perform up to 50 trill. floating point operations per second (= Exa-FLOPS), train AIs for institutes and companies and perform specific AI tasks. In classic supercomputer mode, it is expected to achieve 500 billion floating-point calculations per second (= petaFLOPS). Researchers from the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and the Munich-based computing technology supplier Partec estimate that the computer, named 'Elbjuwel', would be one of the most powerful AI computers in the world. "Unfortunately, up to 90% of the computing power required in Germany and Europe is currently not available in Europe, but has to be sourced primarily in America," explains Partec CEO Bernhard Frohwitter. This will soon change for Saxony thanks to the 'Elbjuwel': "A region that only ever computes via the cloud will never be able to exploit the full potential for development and industrial integration that arises when the supercomputer is available in its own country, even with the best of its own AI applications." "The planned platform should not only provide new impetus for the development of AI technologies, but also contribute to the training of specialists and support companies in overcoming the challenges of digitalization," promises HZDR Science Director Prof. Sebastian M. Schmidt. The 'Elbjuwel' will not only be available to Helmholtz researchers, but also to other scientists and companies in the Free State.

Leaftronic: Sheet design for eco PCBs

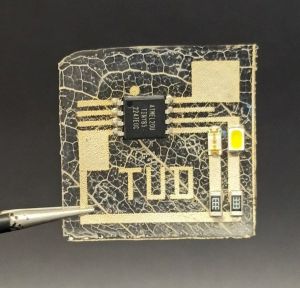

Leaftronic circuit board with circuit meanwhile, researchers at TU Dresden may have achieved an important breakthrough on the way to biodegradable yet long-term stable circuit boards: they have designed circuit boards based on tree leaves which, unlike classic plastic boards, are biodegradable yet stable and heat-resistant. The physicists and electronics engineers use circuit boards made from polymers, which normally break and melt too quickly in production processes when they are processed and fitted with circuits and electronic components. The scientists therefore stabilize such boards with fractal structures that resemble the veins of tree leaves. As a result, such eco PCBs can withstand higher temperatures and other stresses. They call this technology 'Leaftronic' ('leaftronics'). "When the devices have reached the end of their life cycle, the substrates can be easily decomposed in the soil or processed in biogas plants," says the university. This makes it possible to recover electronic components and valuable materials for recycling purposes. "This work points to a promising fusion of nature and technology," says Prof. Karl Leo from the Institute of Applied Physics (IAP), who led the research project. The concept offers "a sustainable path into the future in which we strive to reduce waste and combat climate change - an important step towards a circular economy in electronics".

Leaftronic circuit board with circuit meanwhile, researchers at TU Dresden may have achieved an important breakthrough on the way to biodegradable yet long-term stable circuit boards: they have designed circuit boards based on tree leaves which, unlike classic plastic boards, are biodegradable yet stable and heat-resistant. The physicists and electronics engineers use circuit boards made from polymers, which normally break and melt too quickly in production processes when they are processed and fitted with circuits and electronic components. The scientists therefore stabilize such boards with fractal structures that resemble the veins of tree leaves. As a result, such eco PCBs can withstand higher temperatures and other stresses. They call this technology 'Leaftronic' ('leaftronics'). "When the devices have reached the end of their life cycle, the substrates can be easily decomposed in the soil or processed in biogas plants," says the university. This makes it possible to recover electronic components and valuable materials for recycling purposes. "This work points to a promising fusion of nature and technology," says Prof. Karl Leo from the Institute of Applied Physics (IAP), who led the research project. The concept offers "a sustainable path into the future in which we strive to reduce waste and combat climate change - an important step towards a circular economy in electronics".

Sources

Saxony Economic Development Corporation, IIT, Smart Systems Hub, Mechanical Engineering Innovation Alliance, TU Dresden, HZDR, SMWK, Wandelbots, Oiger.de, VDMA