It would certainly be pleasing if it were so easy to recognize liars by their short legs or long noses. Many citizens would then find it easier to vote for the right candidate - someone who looks largely normal. Marketing in connection technology is not spared in this respect either, because talking a crooked thing straight is probably the main task in this profession.

Fig. 2: Edition of 'The Adventures of Pinocchio. Le Avventure di Pinocchio. Storia di un burattino), Carlo Collodi, Bemporad & Figlio, Florence 1902. Drawing by Carlo Chiostri and A. BonginiWhether it is simply a lack of knowledge, uncritical parroting or deliberate misleading remains to be seen, but it has already led to 'corrections' of such 'myths' becoming the subject of congresses.

Fig. 2: Edition of 'The Adventures of Pinocchio. Le Avventure di Pinocchio. Storia di un burattino), Carlo Collodi, Bemporad & Figlio, Florence 1902. Drawing by Carlo Chiostri and A. BonginiWhether it is simply a lack of knowledge, uncritical parroting or deliberate misleading remains to be seen, but it has already led to 'corrections' of such 'myths' becoming the subject of congresses.

This type of advertising is based on the assumption that the customer is even less informed, even less well educated and even more stupid than the salesperson.

Wetting

The first thing that probably bothers you is the recurring claim that lead-free solder wets worse than leaded solder.

- For one thing, there are many different leaded and lead-free solders and it would at least be prudent to differentiate between them.

- Secondly, even before the introduction of 'lead-free' and RoHS, attention was drawn to the fact that this is a question of temperature and a nice, if not really correct, term was chosen for it: homologous temperature.

According to this, the wettability of a tin alloy depends on the excess temperature above the melting point. A glance at the graph published at the time should make it clear to even the most unintelligent what this means. You only need to draw a horizontal line to see that the wetting force of SnAgCu at 265 °C, for example, corresponds to the wetting of SnPb at approx. 220 °C (melting point SnAgCu approx. 217 °C, i.e. 'excess temperature' = 48 K / melting point SnPb approx. 183 °C, i.e. 'excess temperature' = 37 K). A closer look even reveals that, at least according to this test series, SnAgCu wets better at 280 °C than SnPb at 240 °C. So at least one qualifying remark should be added to this statement. The problem of 'poorer wetting' with lead-free solders only arises due to the (inevitable) choice of lower excess temperatures and possibly unsuitable chemicals in the fluxes.

Capillarity

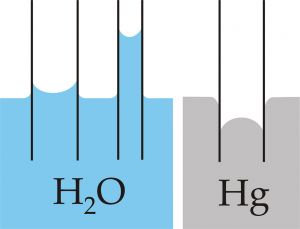

Then it seems that many people still cannot be convinced that solder is drawn into vias and not pressed into them. The surface tension of the various solders is so great that if the via is not wettable, the solder will remain at the entrance. This phenomenon is known from physics under the name 'capillarity'.

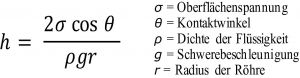

The head h of a liquid column is given by

Fig. 3: Rise height with wetting/non-wetting using the example of water/glass and mercury/glassFrom thisit follows that the better the wetting, the better the rise will be (contact angle small). As the radius of the DK appears in the denominator, it is inversely proportional to the rise height: i.e. the smaller, the higher, which is limited by the placement when soldering.

Fig. 3: Rise height with wetting/non-wetting using the example of water/glass and mercury/glassFrom thisit follows that the better the wetting, the better the rise will be (contact angle small). As the radius of the DK appears in the denominator, it is inversely proportional to the rise height: i.e. the smaller, the higher, which is limited by the placement when soldering.

Inspection

Since the American military once introduced the appearance of a solder joint as a criterion, most (?) quality managers are of the opinion that the quality of a solder joint in terms of its durability can be read from its appearance.

Study after study has shown that the appearance of the solder joint does not correlate with failure. On the one hand, there are too many types of stress, from vibration to impact to slow thermal cycling, where the different expansion coefficients come into play, to corrosive environmental conditions. So it seems to be largely irrelevant whether a solder joint is thick or thin, shiny or matt and whether everything is covered with copper or not, whereby bridges and open solder joints must of course be excluded.

If one wonders about this, the question then arises as to what really constitutes the 'quality' of a solder joint. After years of research, we still don't know. The interior seems to play a certain role, for example the thickness of the diffusion zone or certain impurities such as gold. It is not unlikely that external characteristics also allow conclusions to be drawn, but no one seems to have taken the trouble to identify these yet.

Perhaps it is also not clear that a statistical correlation does not constitute proof. It is often a good indication of where to start with your research. In the soldering industry, for example, it was found that certain end surfaces have a slightly longer life expectancy of solder joints with regard to certain stresses. Although a number of characteristics have been taken into account, no real explanation has yet been found.

Solder joints created in a good inert atmosphere also seem to last longer. In any case, this has been statistically proven several times. As the diffusion zone and other characteristics have not been found, an explanation is also still pending.

Full convection

There are neither pure radiation ovens (IR[3]) nor pure convection reflow systems. Neither is physically possible. Advertising such as at one of the 'productronic' exhibitions: "100 % convection" should scare off any patent attorney, because once again someone has invented a perpetual motion machine, which, if the patent examiners at the patent office are to be believed, is still happening all the time today.

This is actually less disturbing than the realization that engineers with a degree from a German university or technical college swallow such nonsense without protest.

Just to draw attention to it: All matter above absolute zero [0 K] radiates (not just IR) as a function of temperature. If the inside of a system is heated by convection, then the material radiates more and more. It is difficult to calculate how much it contributes, because extensive measurements would have to be made and none of the manufacturers go to this trouble. However, in principle, IR radiation also contributes to heating in convection ovens. Therefore, zero radiation would only be possible if the manufacturers cooled the inside of the system to 0 K - something that even the best physicists in their laboratories have not yet succeeded in doing.

After this enjoyable Beckmesserei [4], one could continue with an even greater number of points of criticism, but this is actually enough, because the intention of this short list is to encourage the esteemed gentlemen and ladies process engineers to think for themselves.

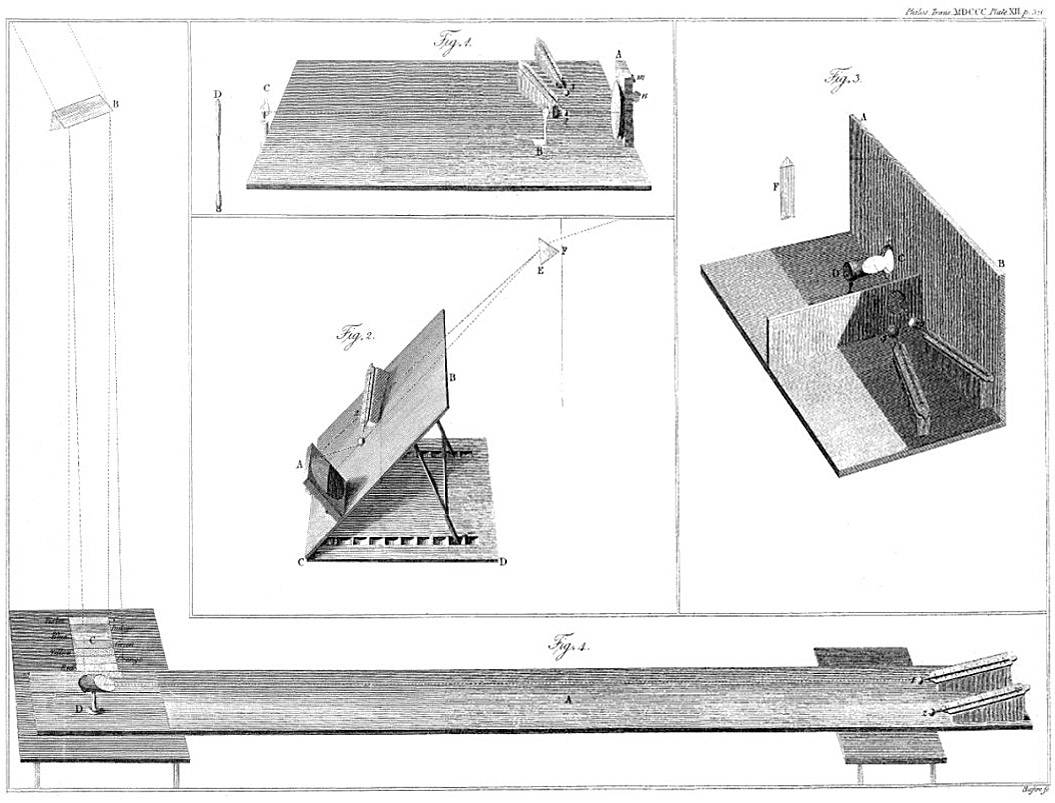

Fig. 4: Original experimental setup by Friedrich Wilhelm Herschel, drawing from 1800 (see reference, Herschel)

Fig. 4: Original experimental setup by Friedrich Wilhelm Herschel, drawing from 1800 (see reference, Herschel)

Literature

M. Dušek et al, 'Wettability in lead-free soldering: Effect of plasma treatment in dependence on flux type', Applied Surface Science, Volume 668,30.9.2024, www.sciencedirect.com/science/article/abs/pii/S0169433224011607 (accessed: 11.10.2024).

William Herschel LL. D. F. R. S., 'Experiments on the Solar, and on the Terrestrial Rays that Occasion Heat; With a Comparative View of the Laws to Which Light and Heat, or Rather the Rays Which Occasion Them, are Subject, in Order to Determine Whether They are the Same, or Different. Part I', Philosophical Transactions of the Royal Society of London, Vol. 90, London 1800, https://www.jstor.org/stable/107058 (accessed: 11.10.2024).

References

[1] Justus Georg Schottel(ius), 'Ausführliche Arbeit von der Teutschen HaubtSprache', 663 still as "Lügen haben kurze füsse".

[2]Carlo Collodi. Le avventure di Pinocchio.

[3] Discovered around 1800 by Friedrich Wilhelm Herschel (1738 - 1822), see literature.

[4] Nuremberg Meistersinger and scribe Sixtus Beckmesser (16th century) then in Richard Wagner's opera 'Die Meistersinger von Nürnberg' (1867).

![Abb.1: In Italien ist es wohl eher die lange Nase, die einen Lügner enttarnt[2]](/images/2024/11/15/plus-2024-11-036_large.jpg)