Whenever far-reaching decisions are made for mankind and industry, it becomes clear how little scientific groundwork decision-makers have done. The CFC ban was certainly the right decision. But it would have been better to consider the effects of substitutes.

It had long been clear that there was a correlation between the massive release of chlorofluorocarbons - known as Freon and other trade names - and the depletion of the ozone layer, which is essential for life on our planet. But it was a long time before the Montreal Protocol was agreed on September 16, 1987. The international treaty for the protection of the ozone layer called for the cessation of production of numerous substances that were and are held responsible for ozone depletion. The treaty came into force on January 1, 1989 and has since been amended and expanded in nine revisions.

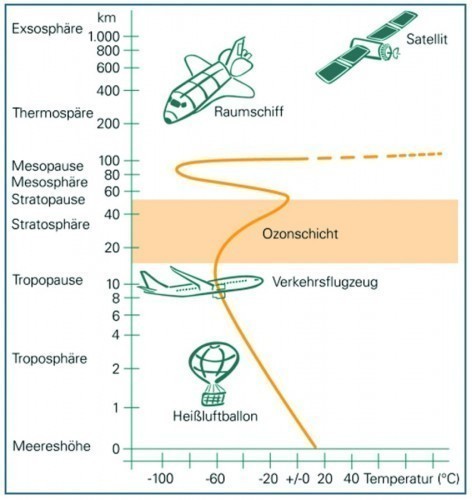

Fig. 2: The ozone layer is located in the stratosphere, between seven and 25 miles (11 and 40 km) above the earth's surface. It protects our planet from potentially harmful ultraviolet radiation. Source: Chemical Industry Fund 1995Ozoneis a so-called trace gas, which means that it only occurs in very low concentrations - only about three molecules of ozone can be found in 10 million atmospheric molecules, and the much-named 'layer', which is measured in Dobson units [DU], is only a few millimeters thick. Nevertheless, it acts as protection against harmful UV radiation from space. While the popular press has focused on skin cancer as the worst danger of the 'ozone hole', scientists are more concerned about plankton. In clear water, UV-B radiation can penetrate to a depth of over 10 meters.

Fig. 2: The ozone layer is located in the stratosphere, between seven and 25 miles (11 and 40 km) above the earth's surface. It protects our planet from potentially harmful ultraviolet radiation. Source: Chemical Industry Fund 1995Ozoneis a so-called trace gas, which means that it only occurs in very low concentrations - only about three molecules of ozone can be found in 10 million atmospheric molecules, and the much-named 'layer', which is measured in Dobson units [DU], is only a few millimeters thick. Nevertheless, it acts as protection against harmful UV radiation from space. While the popular press has focused on skin cancer as the worst danger of the 'ozone hole', scientists are more concerned about plankton. In clear water, UV-B radiation can penetrate to a depth of over 10 meters.

Due to their properties, CFCs have been used as refrigerants, aerosol propellants, for the production of foamed plastics such as expanded polystyrene or polyurethane foam and as solvents for dry cleaning and general degreasing purposes. In the electronics industry, manufactured circuit boards were washed with Freon or an azeotrope.

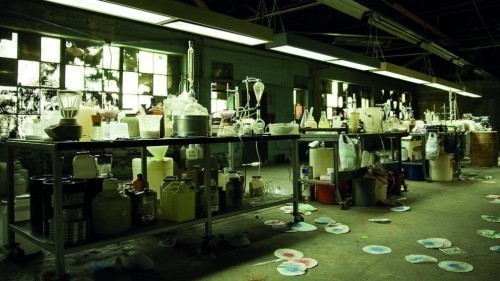

Freon also served drug manufacturers well in the production of methamphetamines [2]. Entire tanker loads were sent to so-called superlabs in South and Central America, for example.

Although a wide range of different chemicals are used to replace CFCs, a considerable number of companies simply replaced them with short-chain perfluoroalkyl carboxylic acids (scPFCAs), which do not degrade in the environment.

Fig. 3: Meth lab blown up in a million-dollar mansion in Ohio, USA (abcNews 19 April 2014)These are a group of synthetic chemicals known as perfluoroalkyl substances (PFASs), which also go by the not-so-joking name of 'forever chemicals'. The reason: they are difficult to destroy. PFAS are used in automotive, electrical and electronic applications as well as in the industrial processing and construction industries.

Fig. 3: Meth lab blown up in a million-dollar mansion in Ohio, USA (abcNews 19 April 2014)These are a group of synthetic chemicals known as perfluoroalkyl substances (PFASs), which also go by the not-so-joking name of 'forever chemicals'. The reason: they are difficult to destroy. PFAS are used in automotive, electrical and electronic applications as well as in the industrial processing and construction industries.

Due to their 'indestructibility', scPFCAs can travel long distances in the atmosphere and therefore often end up in lakes, rivers and wetlands, causing irreversible contamination and affecting the health of freshwater invertebrates, including insects, crustaceans and worms. It was also recognized that current drinking water treatment technologies could not remove them. Accordingly, scPFCAs have already been detected in human blood as well as in fruits, vegetables and other plants we consume.

This is extremely worrying as there are numerous potential adverse health effects: PFAS compounds correlate with cancer, liver damage, thyroid disease, reduced fertility, high cholesterol and hormone suppression.

Fig. 4: Researchers collect ice cores to study levels of CFC substitutes in the ArcticCoraYoung, an atmospheric chemist at York University, had found long-chain per- and polyfluoroalkyl substances (PFAS) in Arctic ice in a previous study. In her new research, she focused on shorter compounds. Her hypothesis was that the concentrations of these short-chain compounds had increased since the adoption of the Montreal Protocol. Young and Amila De Silva, a chemist at Environment and Climate Change Canada, reviewed annual concentrations of these compounds [specifically: trifluoroacetic acid (TFA), perfluorobutanoic acid (PFBA) and perfluoropropionic acid (PFPrA)] in ice cores (Devon Ice Cap in Nunavut, Canada) taken by glaciologist Alison Criscitiello of the University of Alberta.

Fig. 4: Researchers collect ice cores to study levels of CFC substitutes in the ArcticCoraYoung, an atmospheric chemist at York University, had found long-chain per- and polyfluoroalkyl substances (PFAS) in Arctic ice in a previous study. In her new research, she focused on shorter compounds. Her hypothesis was that the concentrations of these short-chain compounds had increased since the adoption of the Montreal Protocol. Young and Amila De Silva, a chemist at Environment and Climate Change Canada, reviewed annual concentrations of these compounds [specifically: trifluoroacetic acid (TFA), perfluorobutanoic acid (PFBA) and perfluoropropionic acid (PFPrA)] in ice cores (Devon Ice Cap in Nunavut, Canada) taken by glaciologist Alison Criscitiello of the University of Alberta.

The occurrence of all three compounds has increased since 1990. According to Young et al., for at least two of the compounds this has to do with the fact that they are increasingly being used as CFC substitutes.

Europe, at least, seems to have taken notice, as European countries have recently announced plans to phase out PFAS chemicals by 2030.

Another issue is 'renewable energy', which is intended to replace coal and oil as well as nuclear energy. Startled by images of wind turbine rotor blades in landfill sites, we scratch a little further at the image of the environmentally friendly and find out that apparently not everything is as 'green' as we like to portray. Let's leave aside the solar panels with their rare earths and their recovery and focus solely on windmills, which were already prominent in Don Quixote's time - although they were built somewhat differently to today's windmills.

Today, trucks transport the steel and other building materials. And since the power plants are only economical in windy locations, bulldozers and other heavy equipment first have to create access for foundation construction and erection cranes. Hardly feasible without diesel fuel.

Cement and steel are also not produced without energy (coal/oil) and a 5 megawatt turbine requires around 150 tons of steel for the reinforced concrete foundations alone. Another 250 tons are needed for the rotor hubs and nacelles (in which the gearbox and generator are housed) and 500 tons for the towers. We are neglecting the metal required for the masts, wires and transformers for the necessary high-voltage cables.

We could go on like this for a while. But let's turn to just one detail - the disposal of the rotor blades: although they might last for 20 years, they are replaced every ten years or so. As the approximately 60 m long blades, each weighing around 15 tons, consist of a combination of balsa or foam cores and glass fibre-reinforced epoxy or polyester resin outer laminations, they can hardly be reused cost-effectively. This is why they are buried in landfill sites. One blade requires between 23 and 34 cubic meters of landfill space: "The wind turbine blade will ultimately be there forever. Most landfills are considered a dry grave," says Bob Cappadona, Chief Operating Officer of the North American unit of Paris-based Veolia Environnement SA [3]. Maybe that will please some archaeologists later.

Finally, it must be admitted that a well-designed wind turbine can generate as much energy in less than a year as it took to build it. That leaves a productive 9 years until at least new rotor blades are due. And without oil and coal, they couldn't be built in the first place anyway.

About the person

Prof. Rahn is a globally active consultant in connection technology issues. His new book on 'Special Reflow Processes' was recently published by Leuze Verlag. He can be contacted at

Literature and notes:

K. Bourzac: CFC replacements are a source of persistent organic pollution in the Arctic - Analysis of ice cores shows increasing levels of three short-chain PFAS linked to CFC replacement chemicals, Most Popular in Environment, May 2, 2020

Geophys. Res. Lett. 2020, DOI: 10.1029/2020GL087535

https://spectrum.ieee.org/energy/renewables/to-get-wind-power-you-need-oil

References:

[1] Matthew 12:24 (Luther Bible 2017): according to Luke 11:15, Beelzebub is the chief of the devils

[2] www.justice.gov/archive/olp/methawareness

[3] At https://www.energieagentur.nrw/blogs/erneuerbare/beitraege/recycling-wie-werden-rotorblaetter-entsorgt it says, among other things: "Because the landfilling of GRP waste has been prohibited by law since 2005, storing the material is out of the question. Rotor blades are therefore shredded and the metal residues they contain are separated. The remaining waste has so far been used thermally as a fuel and sand substitute in the cement industry or incinerated in conventional waste incineration plants. However, this is only possible in small quantities due to the structure of the glass fibers and the complex chemical reactions in the incineration process, which put a strain on the filters and incineration lines. Meanwhile, a company in Bremen has developed an alternative solution and launched it on the market two years ago: "The composite materials of disused rotor blades are processed into a substitute fuel using a special process"