Remote monitoring of the thermal status of electrical installations is very important so that automated infrastructure systems, for example, do not endanger the environment. The strategies at control cabinet and system level have parallels with microelectronics issues.

An unusual rise in temperature is often an early indicator of a fault and must be addressed before the system is damaged or, even worse, bursts into flames, possibly endangering assets or even people in the vicinity. Temperature rises can manifest themselves as individual 'hotspots' if assemblies or individual components are operating close to or above the safe temperature range, or if they are exposed to an elevated ambient temperature. In the first case, this could be due to a fault condition, e.g. a short circuit, or a system component, such as a transformer, running at full load for an extended period of time. The second case may be caused by the operating environment (prolonged exposure to intense sunlight) or a failure of cooling components or fans. Both cases pose a risk to the system and the environment.

Maintenance via the IoT

The aim of maintenance via the Internet of Things (IoT) is always to achieve zero downtime and rule out unforeseen device failures that could lead to serious accidents or unplanned system stops. To achieve this, the temperature of each panel in a factory and the ambient temperature must be carefully monitored using suitable sensor solutions. This type of real-time remote monitoring ensures that on-site visits are limited to what is absolutely necessary. Sometimes the fault can be rectified remotely, perhaps by reducing the power requirements of the system to allow key components to cool down. Other times, an on-site assessment by a technician may be required, for example to replace a faulty component or repair a short circuit.

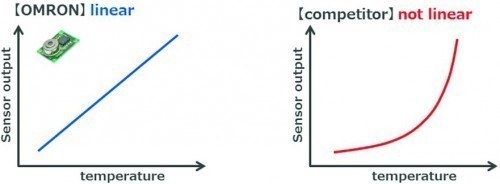

Fig. 2: If the sensor outputs the temperature directly, this is better than if signal processing is required firstTemperaturemonitoring of the entire cabinet in which the system is housed is essential, but clearly insufficient on its own: a component can run dangerously hot and be on the verge of breaking down or burning out without affecting the overall temperature of the system. On the other hand, attaching individual temperature sensors to each electrical component is completely impractical - a wiring harness can develop a focal point almost anywhere. New wide-angle thermal image sensors, which can detect hotspots in large system areas such as an entire panel surface, are an ideal starting point for truly effective remote thermal management of electrical systems. Complemented by ambient temperature sensors and air velocity sensors to check the proper functioning of cooling fans, they provide a complete IoT-based thermal monitoring and remote maintenance solution.

Fig. 2: If the sensor outputs the temperature directly, this is better than if signal processing is required firstTemperaturemonitoring of the entire cabinet in which the system is housed is essential, but clearly insufficient on its own: a component can run dangerously hot and be on the verge of breaking down or burning out without affecting the overall temperature of the system. On the other hand, attaching individual temperature sensors to each electrical component is completely impractical - a wiring harness can develop a focal point almost anywhere. New wide-angle thermal image sensors, which can detect hotspots in large system areas such as an entire panel surface, are an ideal starting point for truly effective remote thermal management of electrical systems. Complemented by ambient temperature sensors and air velocity sensors to check the proper functioning of cooling fans, they provide a complete IoT-based thermal monitoring and remote maintenance solution.

Wide-angle temperature sensors

New wide-angle infrared temperature sensors in a compact housing highlight hotspots throughout the field of view, bridging the gap between measuring the average temperature of the entire system and measuring the temperature of one or two selected points(Fig. 1).

"An unusual temperature increase is often an early indicator of a fault and must be addressed"

Fig. 3: The Omron 2JCIE measures seven sought-after environmental parameters in one compact unitTheD6T IR MEMS temperature sensor measures the surface temperature of the target object without contact using a thermopile that absorbs its radiated energy. With the built-in state-of-the-art MEMS thermopile, a customized sensor ASIC, signal processing microprocessor and algorithm in a tiny package, the D6T offers probably the highest signal-to-noise ratio (SNR) in the industry. This ensures clear, reliable measurements that can be easily interpreted by the system. A key benefit of the integrated signal processing microprocessor is its fully linear output(Fig. 2). By pre-processing the signal in the module, the D6T converts the sensor signal into a digital temperature output that acts as a direct interface to a microcontroller. This simplifies the system integrator's task, as alternative devices do not have a temperature output, so the designer must implement a signal processing algorithm to convert the output signal into a temperature value.

Fig. 3: The Omron 2JCIE measures seven sought-after environmental parameters in one compact unitTheD6T IR MEMS temperature sensor measures the surface temperature of the target object without contact using a thermopile that absorbs its radiated energy. With the built-in state-of-the-art MEMS thermopile, a customized sensor ASIC, signal processing microprocessor and algorithm in a tiny package, the D6T offers probably the highest signal-to-noise ratio (SNR) in the industry. This ensures clear, reliable measurements that can be easily interpreted by the system. A key benefit of the integrated signal processing microprocessor is its fully linear output(Fig. 2). By pre-processing the signal in the module, the D6T converts the sensor signal into a digital temperature output that acts as a direct interface to a microcontroller. This simplifies the system integrator's task, as alternative devices do not have a temperature output, so the designer must implement a signal processing algorithm to convert the output signal into a temperature value.

The space-saving design - the largest version with 32 x 32 elements measures only 14 x 8 x 8.93 mm - makes the D6T ideal for use in a panel or system. Its 90.0° x 90.0° field of view covers an area of 200 x 200 cm from a distance of one meter. In an ambient temperature range of -10 to 70 ºC, temperatures from 0 to 200 ºC can be measured without contact. Omron also has other IR sensors in its range for other requirements.

The ambient temperature

While such sensors identify specific hot spots, there is still a need to monitor the ambient temperature of the overall system. Compact multi-purpose environmental sensors make it very easy to provide a wide range of measurement functions with just one small sensor. These include temperature, humidity, air quality, light, air pressure, noise and acceleration. Sensors such as the Omron 2JCIE(Fig. 3) are able to monitor all these criteria and deliver the data via popular wireless and wired interfaces such as Bluetooth and USB. Despite its compact design, the 2JCIE has its own embedded memory for data logging to keep track of the environment.

Monitoring cooling systems

Fig. 4: The D6F-PH detects when wear and dirt deteriorates the performance of ventilation fansAnincrease in ambient temperature can of course also be due to deterioration or even failure of cooling systems such as fans. These, like any other component, need to be maintained and continuously monitored in real time to ensure that their performance does not drop below the required level due to wear and tear or dirt build-up in the air path. Suitable sensors for this task would be:

Fig. 4: The D6F-PH detects when wear and dirt deteriorates the performance of ventilation fansAnincrease in ambient temperature can of course also be due to deterioration or even failure of cooling systems such as fans. These, like any other component, need to be maintained and continuously monitored in real time to ensure that their performance does not drop below the required level due to wear and tear or dirt build-up in the air path. Suitable sensors for this task would be:

1. the D6F-PH digital pressure sensor(Fig. 4) for detecting airflow and clogged filters in heat recovery units. It measures the pressure difference between the inlet and outlet of the fan or filter and thus detects functional impairments and performance losses due to dirt blockages and alerts when cleaning or replacement is required.

2. a more compact alternative is the 2SMPB air pressure sensor. Omron's D6F-V improves efficiency by monitoring the exact air flow rate at which air is exhausted through the fan.

Look inside without opening a door

Author Fabrizio VitaliMaintenance engineersshould be able to carefully monitor the thermal status of an enclosure or panel in real time without having to open a door. This goal can be achieved by combining the three types of sensors described above. Wide-angle infrared sensors identify hotspots wherever they occur; ambient temperature sensors monitor the overall temperature of the enclosure; air flow meters prove that cooling fans are working correctly.

Author Fabrizio VitaliMaintenance engineersshould be able to carefully monitor the thermal status of an enclosure or panel in real time without having to open a door. This goal can be achieved by combining the three types of sensors described above. Wide-angle infrared sensors identify hotspots wherever they occur; ambient temperature sensors monitor the overall temperature of the enclosure; air flow meters prove that cooling fans are working correctly.

The real-time output of measurement data from these sensors can be analyzed with algorithms to reduce the technical skills required for the maintenance process and the results allow maintenance staff to identify and respond to faults in real time. By tracking temperature changes over time, it is also possible to make predictions that allow maintenance planning for maximum productivity when deploying service technicians and minimizing system downtime.