Killing two birds with one stone in electronic manufacturing - we apologize to the flies and the fly swatter - is quite difficult. The more complicated the product, the higher the costs ... and the more reluctant management is to throw non-functioning goods in the bin - for 'recycling', of course.

The brave little tailor even managed more than two fliesItis really commendable when committed people such as biologist Yvonne Würz, PETA's zoo and circus specialist, stand up for the animals in this way and even want to adapt the language. In doing so, they discriminate somewhat, because their focus is more on cats and dogs and not on the mice and peeps that are massacred by cats.

The brave little tailor even managed more than two fliesItis really commendable when committed people such as biologist Yvonne Würz, PETA's zoo and circus specialist, stand up for the animals in this way and even want to adapt the language. In doing so, they discriminate somewhat, because their focus is more on cats and dogs and not on the mice and peeps that are massacred by cats.

A re-education of snakes, crocodiles and other predators and birds is probably still pending, because after all, does the crown of humanity have the right to dictate to animals what they should eat?

She is not alone in this, because in addition to asterisks in 'gendering', our highly revered gymnastics father Jahn and many others have already wanted to do something about language. Whether this is due to the human hubris [1] of being above nature, to necessity or simply out of boredom can be assessed differently in each case. If you follow an archaeologist like Mr. Jens Notroff, who cannot deduce any progress in human intelligence and character since the last 300,000 years from archaeological finds, then hubris at least appears to be unjustified.

After all, after the spear, bow and arrow and gunpowder (more Chinese than Berthold Schwarz [2]), we have now arrived in the electronic age, in which millions of hand-held phones record every event, mainly of course themselves against the spectacular backdrop.

Two birds - one stone

While repair may not be necessary in speech, it's hard to get by without it in electronic manufacturing, and as it gets more complicated, it's increasingly difficult to find and correct errors in production. As mentioned at the beginning, it is not so easy to kill two birds with one stone when it comes to recycling.

The fact that 1080P HD camera and video functions must now be available in many of these hand-held phones or computers makes production more complex and, of course, more expensive. The circuit boards alone for these devices are therefore no longer disposable items, as their bill of materials is ± $150.00, for higher-end smartphones ± $240.00 and for tablets already well over $300.00, not to mention the finished products, unless the production line finds so few faults that the investment in the costly repair process would be more expensive than disposing of the rare faulty product. Of course, the manufacturer/seller makes a very clear distinction between their own production and a failure at the customer's premises, because there it is usually only an incentive to buy a new toy for the child if he has dropped it for the third time. Unfortunately, when repairing complicated devices in the manufacturing process, you have to deal with more than just two problems (flies).

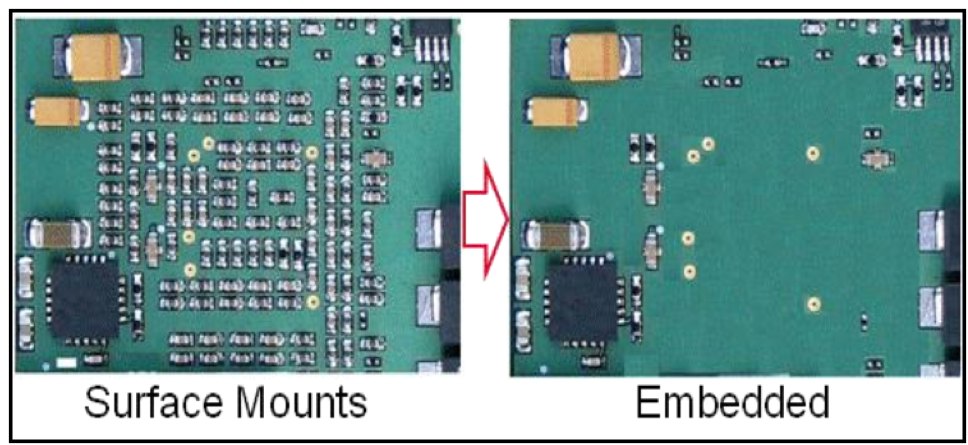

Example of sinking components into the circuit board

Example of sinking components into the circuit board

Lead-free solders cause headaches

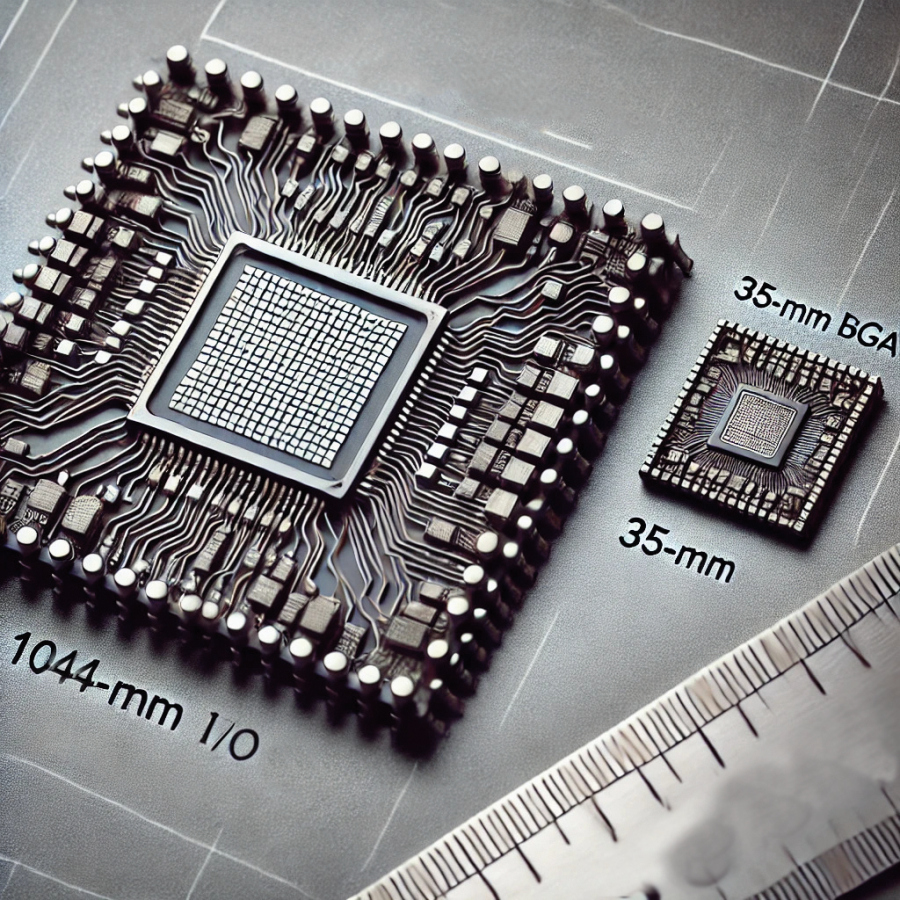

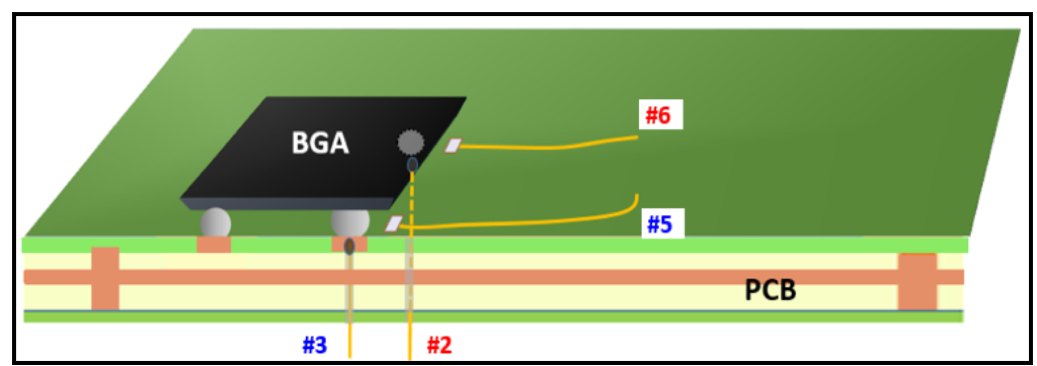

Lead-free solders, which place new demands on temperature profiles, are perhaps the most notable. This is certainly followed by the increase in the size of the components, which on top of that hide their solder joints underneath themselves and can therefore no longer be reached with a soldering iron. As heating plates, radiation or convection are then usually used, the tight placement of the components also means that stress on the closely adjacent components must be prevented. This is already causing headaches, because what information is needed and how do you find it? Do you have to measure the PCB, and if so, where? What about the other components? Do you measure on the component to be repaired, underneath it or even at one of its solder joints? This would usually not be possible without destroying the assembly. Hand-held devices also have to be shockproof (an iPhone is said to have survived a drop from 5000 m [3]), which means that the components have to be glued and encapsulated, a special challenge for the repair team who have to work their way to the soldered joints. In order to reach the solder joints, the conformal coating must first be removed, which can consist of a wide range of chemicals and must therefore be treated accordingly. In addition to solvents, mechanical methods can be used, such as sandblasting or scraping/sanding. Some can also be softened thermally and, as an exotic method, certain lasers are available that can (carefully) vaporize the material. Then comes the glue and finally the solder joints have to be melted in order to lift off the component without ruining the landing surfaces, which are usually leveled afterwards. If the component, which is certainly expensive, is to be reused, another process opens up, namely 'reballing', which is no easy task for large components. Placing and soldering a new component requires the entire process to be repeated in reverse. This is just as critical and the result must be verified by appropriate tests (electrical, X-ray). If everything works, then the product can be sold (at a reduced price?). If not, a second repair is usually not possible because there are regulations that limit the number of thermal excursions and for well thought-out reasons. But now the industry is letting more 'cats out of the bag' (or is it cutting open vegan calzones?) by wanting to solder with nanocopper [4] or even sinking the components into the inside of the circuit board. PCS (Printed Circuit Structure [5]) is perhaps the 'ultima ratio', should it become established.

Size comparison of a 114 mm BGA (10,000 I/O) with a 35 mm BGA

Size comparison of a 114 mm BGA (10,000 I/O) with a 35 mm BGA

Example of possible temperature measuring points

Example of possible temperature measuring points

References

[1] https://de.wikipedia.org/wiki/Hybris_(definition)

[2] https://de.wikipedia.org/wiki/Berthold_Schwarz

[3]https://www.welt.de/vermischtes/kurioses/article249424504/Noch-im-Flugmodus-Notgelandete-Boeing-737-iPhone-soll-Sturz-aus-5000-Metern-ueberstanden-haben.html

[4] https://pro-physik.de/nachrichten/exaktes-loeten-mit-nanoeffekten

[5] https://www.circuitinsight.com/pdf/printed_circuit_structures_ipc.pdf

Literature

Christiane Oelrich, 'Warum aus der Katze im Sack eine vegane Calzone werden soll', Die Welt, 05.01.2024.

www.forschung-und-wissen.de/nachrichten/psychologie/katze-im-sack-soll-vegane-calzone-werden-13378547 (Retrieved: 03.09.2024).

https://de.wikipedia.org/wiki/Friedrich_Ludwig_Jahn (Retrieved: 03.09.2024).

R. Trögel, 'Friedrich Ludwig Jahn und die deutschen Mundarten, Zeitschrift für Deutsche Mundarten', 17th year (1922), Franz Steiner Verlag.

Hikmat Chammas, 'Embedded Passive Technology', IPC APEX EXPO Conference Proceedings.

Brian Czaplicki, 'Advanced Rework Technology and Processes for Next Generation Large Area Arrays, 01005, PoP and QFN Devices'.

IPC APEX EXPO Conference Proceedings.

Peter Lu et al, 'Hot Air BGA Rework Process Improvement with a Touchless Temperature Dependent Live-Feedback Process', SMTA

Proceedings, www.circuitinsight.com/uploads/2/hot_air_bga_rework_process_improvement_touchless_temperature_smta.pdf (accessed: 03.09.2024).

Paul Wood, 'Rework Challenges for Smart Phones and Tablets', IPC APEX EXPO Conference Proceedings.