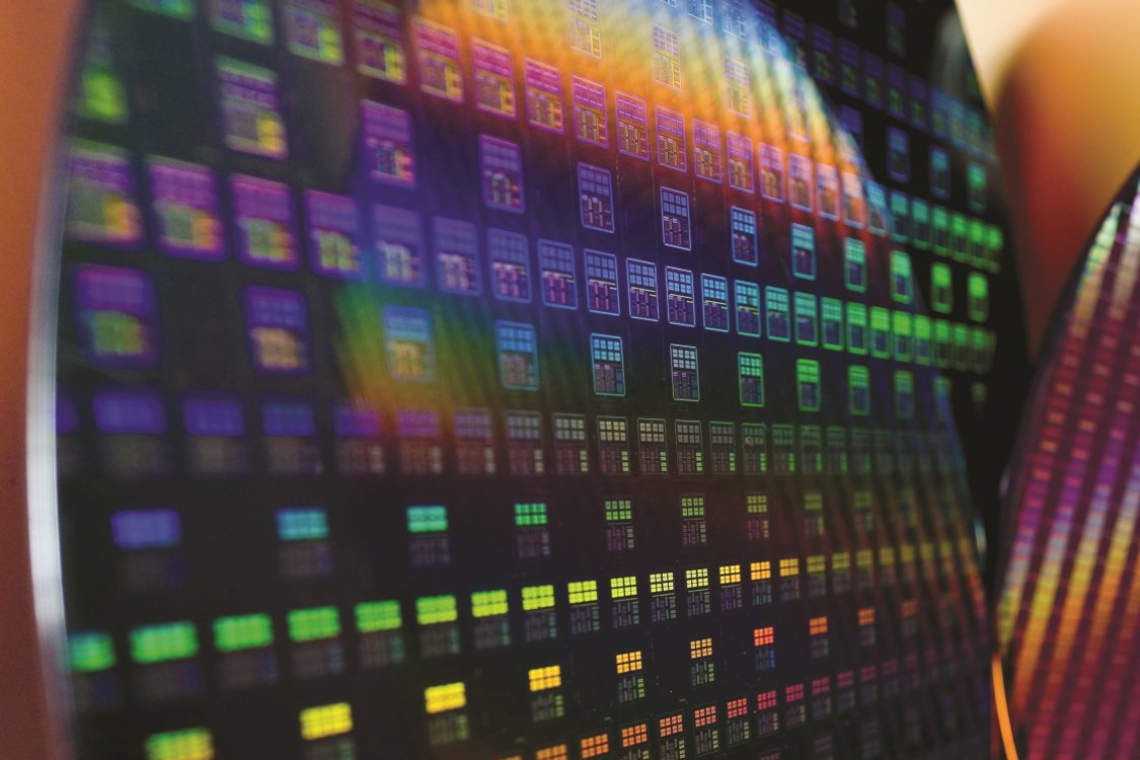

The investments in Saxony in a massive expansion of production and training capacities in microelectronics and related industries are becoming more concrete: TSMC and its European partners have heralded the start of construction for its Dresden mega chip factory, while the Free State, the state capital and the surrounding area are pushing ahead with their skilled worker program. And a cosmic application is set to ensure a boom in orders in Saxony's high-tech economy.

It was announced for a long time and celebrated in advance, but now the time has come: managers and politicians have driven the first spades into the ground in Dresden for Germany's most expensive chip factory: For €10 billion, a joint mega-fab is being built here by TSMC with the European semiconductor groups Bosch, Infineon and NXP. The state is paying half of the investment sum as aid. For 'Silicon Saxony' Managing Director Frank Bösenberg, this is money well spent: "This shows impressively that the measures of the EU Chips Act to strengthen the European semiconductor industry are taking effect and further consolidating Dresden as a central innovation and production hub in Europe." Meanwhile, a special gift from Brussels has sweetened the ground-breaking ceremony for the chip company TSMC's first mega-fab in Europe: on the same day, the EU Commission also officially allowed the German government to finance half of the 10 billion investment in Dresden with taxpayers' money. "This project will have a major impact on the entire business location of Saxony, far beyond Dresden" - Thomas Horn, Managing Director of 'Saxony Economic Development', is convinced of this. In particular, the state economic promoters hope that TSMC's regular suppliers from Taiwan and other countries will gradually move to Dresden in the wake of Megafab. "We would be delighted if numerous Taiwanese companies from both the microelectronics and other sectors set up their new European base here."

Fairness pact concluded

Because such large-scale subsidies are controversial, regional business representatives had already staked their claims around the TSMC fab at the Saxon State Chancellery in advance: representatives of SMEs and chip companies negotiated an agreement with the government in Dresden to ensure, among other things, that smaller companies and the surrounding communities also benefit from the large-scale settlement. Among other things, the deal provides for the large semiconductor companies to use their international appeal to recruit enough skilled workers from abroad - so that this pool is then just as sufficient for the carpentry shop and the small garage as it is for the large chip factory in 'Silicon Saxony'. A new advisory board is also intended to prevent TSMC, Infineon & Co. from fishing around too much in the same apprentice pools as craftsmen and SMEs. SMEs are also to be given equal access to the new training capacities that are being created in and around Dresden for the growing semiconductor industry.

Securing skilled workers for microelectronics

While concerns are mounting in Magdeburg and Saarland as to whether the chip factories announced by Intel and Wolfspeed will actually be built in the foreseeable future, Saxony is getting down to business: not only have Infineon and TSMC already started building their factories, but the skilled worker programs for the Saxon semiconductor industry announced by the Free State and the state capital are also taking shape. The city and state have now agreed on two investments in a large-scale apprentice training program with a total value of around €0.25 billion: For the theoretical part, a new 'Excellence Vocational School Center for Electrical Engineering' (Det) is being built in Dresden's Prohlis district at a cost of €127.5 million. This is set to start in the 2028/29 school year and will be designed for up to 2,200 prospective microtechnologists, mechatronics technicians, IT specialists, electronics technicians, electrical system fitters and information technology system electronics technicians. "Dresden is the leading microelectronics location in Europe and 'Silicon Saxony' continues to grow," said Saxony's Minister President Michael Kretschmer (CDU), explaining the state's rather unusual involvement in the direct construction costs for such a large vocational school. "This also increases the demand for well-trained specialists. With the construction of the new vocational school center, we are significantly increasing the training capacities for the future-oriented electrical engineering sector. This will benefit large semiconductor manufacturers and medium-sized companies alike." At the same time, a central training center for microelectronics in Saxony is being built in Radeberg near Dresden for the practical training part. It will cost around €120 million and will train up to 1,000 future mechatronics engineers and microtechnologists on industry-related equipment. This 'Saxon Training Center for Microelectronics' (Sam) will include an apprentice clean room factory, training rooms, laboratories and workshops. "We deliberately chose Radeberg as the location," explained Saxony's Minister of Economic Affairs Martin Dulig (SPD). "In doing so, we are ensuring that the positive effects of semiconductor development reach the Dresden region directly. The skilled trades and SMEs are an elementary component of Silicon Saxony. We are ensuring that they continue to benefit from the investments of global corporations. The microelectronics training cluster is a major building block for the demand for skilled workers." The background to these investments in education is the organic growth of the high-tech industries in 'Silicon Saxony', but also the recent establishment of TSMC: The Saxons had not only promised the Taiwanese billions in subsidies from the federal and state governments, but apparently also a steady flow of skilled workers for the new mega-fab in Dresden.

"Together with the Saxon state government, we are pursuing the goal of making Saxony the 'Taiwan hub' in Germany and Europe"

Thomas Horn

A new large vocational training center for electrical engineering is being built in Dresden-Prohlis

A new large vocational training center for electrical engineering is being built in Dresden-Prohlis

Zeiss buys litho division

Meanwhile, the equipment sector for chip factories is once again on the move: Zeiss is buying the chip exposure division of the Swiss technology group 'Ruag'. This includes the lithography technology production facilities in Zurich and Coswig in Saxony with a total of 200 employees. This was announced by the Zeiss microelectronics subsidiary 'Zeiss Semiconductor Manufacturing Technology' (SMT) in Oberkochen and Ruag International (alias 'Beyond Gravity') in Zurich. "Since 2001, we have continuously developed our expertise in lithography applications and established a successful partnership with our main customer Zeiss SMT," explained Ruag CEO André Wall. "The new owners will provide our lithography division with an ideal environment for the further development of the great expertise we have built up over the years." The transfer is also a logical step for Zeiss SMT CEO Christoph Hensche: "The Lithography Division of Ruag International has been an excellent and reliable partner in our supply chain over the last two decades," he emphasized. "The semiconductor market offers many opportunities for a prosperous future. Zeiss SMT is continuing on its growth path, which will be supported by this acquisition." The Swiss company took over the factory in Coswig from the Saxon company "HTS" in 2016. They wanted to move closer to the Dresden chip cluster.

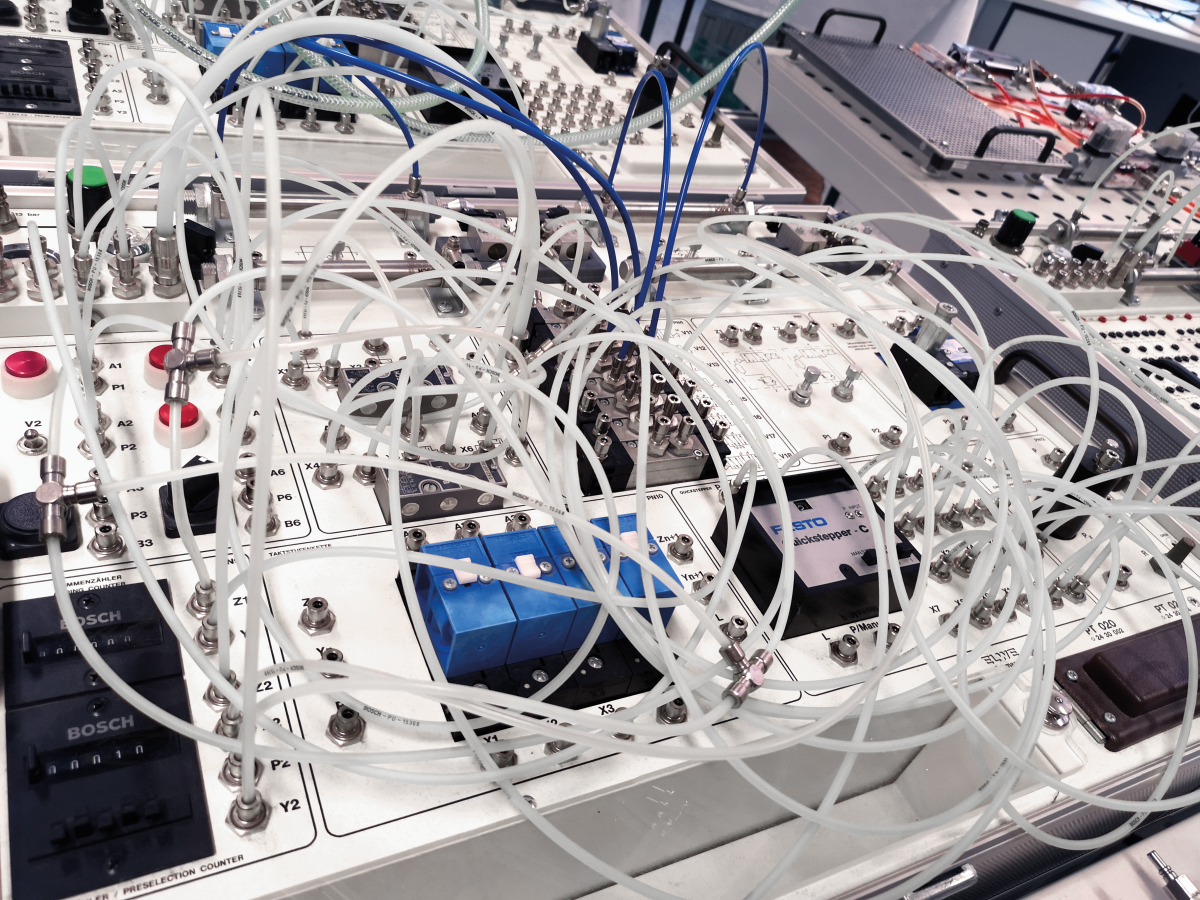

A look inside Ruag's litho division

A look inside Ruag's litho division

Saxony bids for Einstein telescope

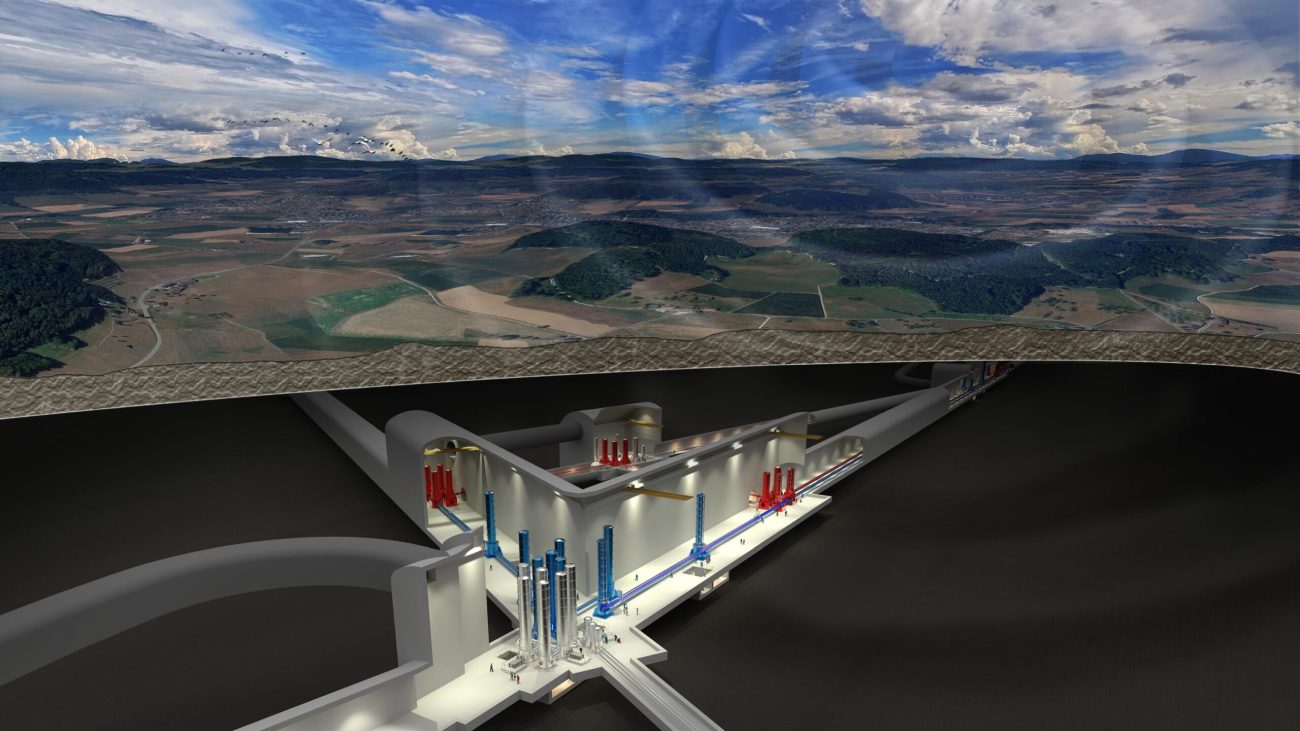

In the meantime, politicians and researchers in Saxony have decided on another major project that should provide a significant boost to the economy in the state: They want to bid for the planned Einstein telescope and build it in Lusatia. Astronomers want to use this large underground instrument to capture gravitational waves from space with unprecedented accuracy and combine them with radio telescope data in order to look into the 'nursery' of the universe. At first, this may sound like very distant worlds and a theory far removed from industry. However, the electronics industry in Saxony and throughout Germany is secretly expecting a boost in orders if this European super instrument is actually built in Lusatia - although the European Meuse-Rhine Region (EMR) and Sardinia are also bidding for this major European project. The Einstein Telescope will require a large number of completely new control, measurement and evaluation systems as well as sensors and complex detectors that will be unique in the world. This in turn could generate orders for the high-tech supply industry in the region for years to come - from circuit boards and special circuits to AI accelerators and special software. The huge underground triangular instrument is primarily intended for the 'German Center for Astrophysics' (DZA) being built in Görlitz. Lusatia was promised the money for this large-scale research center as compensation for the coal phase-out. "Both major projects, the DZA and the Einstein Telescope, are a perfect match in terms of content and would complement each other well as direct neighbors," explained Saxony's Science Minister Sebastian Gemkow (CDU). Underground gravitational telescopes usually consist of a triangular or two-legged cave system in which mirrors guide laser beams over long distances in different directions. Small differences in transit time can then provide indications of gravitational waves acting from space. These in turn arise, for example, when two ultra-heavy black holes orbit or merge or when other very massive objects interact.

This is how astrophysicists envision their underground Einstein telescope. The construction alone is likely to trigger a boom in orders and research in the electronics and equipment industry in the respective region.

This is how astrophysicists envision their underground Einstein telescope. The construction alone is likely to trigger a boom in orders and research in the electronics and equipment industry in the respective region.

The market potential is enormous

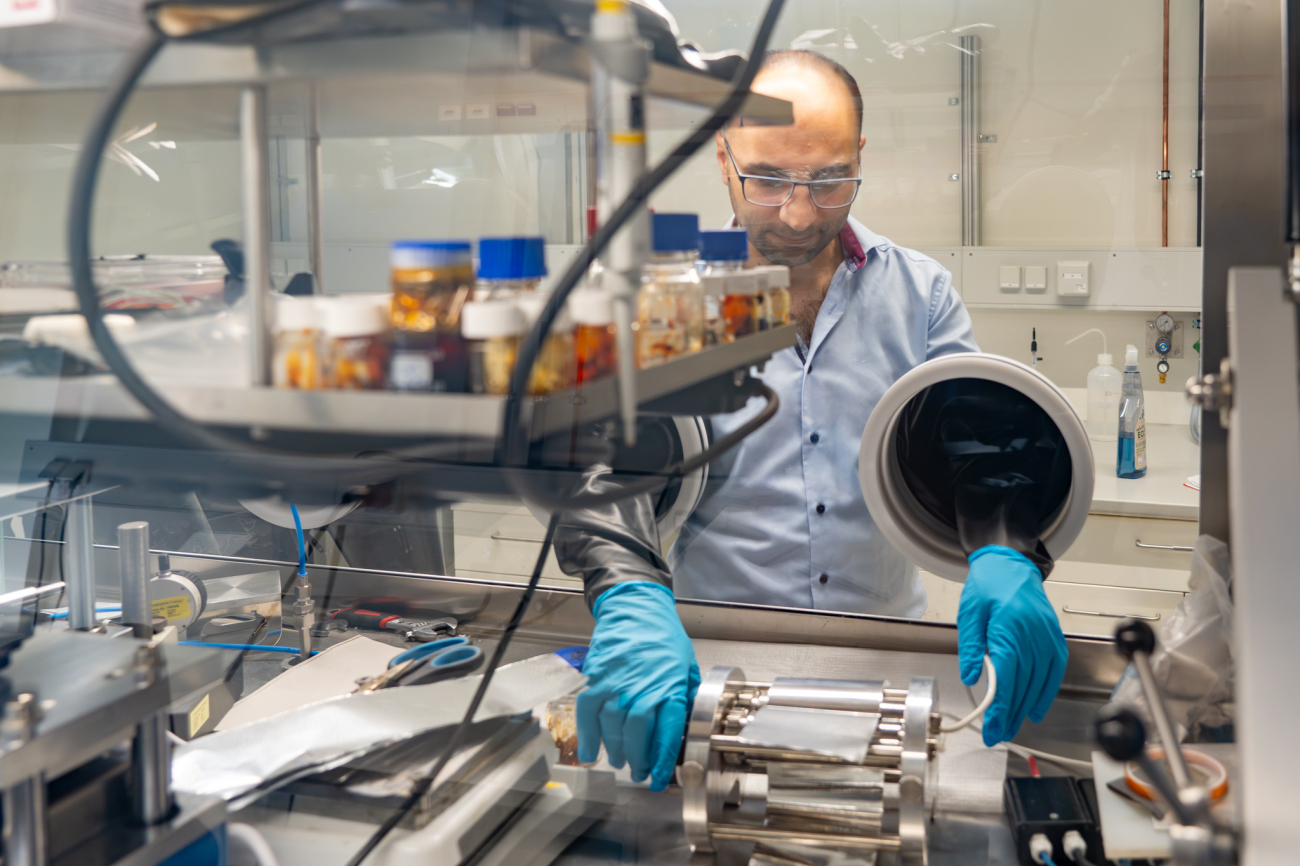

And another look at the other end of the high-tech cluster 'Silicon Saxony': while politicians and managers in Dresden and Görlitz are pushing ahead with new large-scale projects, researchers in Freiberg have developed a promising accumulator made of aluminum, carbon and solid polymer electrolytes. Compared to most of today's batteries, these energy storage devices are cheaper and more fireproof, and Germany would not have to import strategically scarce raw materials such as lithium. The Saxon Ministry of Science is now providing €0.25 million to enable the Freiberg Mining Academy to prepare this new battery technology for series production. Scientists and economic policymakers see great market potential in the aluminum-polymer solid-state batteries as stationary energy storage devices for houses with solar roofs. The Freiberg engineers use aluminum and graphite instead of lithium for their electrodes. However, the real highlight of their energy storage systems are the electrolytes in between, through which the charge carriers move back and forth: In lithium batteries, these are usually liquid solutions of hydrocarbons and lithium salt. In the Freiberg energy storage system, however, this task is performed by a honey-colored solid polymer. "This is a mixture of triethylamine hydrochloride and aluminum chloride, which together with polyamide form a solid network," explains project team member Oliver Schmidt. "Compared to traditional liquid electrolytes, this solid electrolyte offers numerous advantages: It cannot leak, is resistant to moisture and oxygen and reduces corrosion. It also replaces the usual separator layer, which makes the battery safer and more cost-effective to manufacture."

The battery consists of aluminum as the anode, graphite as the cathode and a novel polymer-based electrolyte developed at the university.

The battery consists of aluminum as the anode, graphite as the cathode and a novel polymer-based electrolyte developed at the university.

References

TSMC, Silicon Saxony, Saxony Economic Development Corporation, Saxon State Chancellery, Dresden Chamber of Industry and Commerce, Ruag, Oiger.de, Freiberg Mining Academy.