SMEs and institutes working hand in hand with the electronics industry - pioneering solutions for an ecological circular economy

Exhaust gas purifiers for semiconductor factories, self-decomposing shampoo sachets, high-temperature fuel cells for the hydrogen economy and flywheels for wind power lulls: Environmental technology has long since become an important economic and technological factor in Saxony.

Fig. 2: Laboratory test stand at Fraunhofer IKTS for separating heavy metals during sewage sludge incinerationThesesystems areoftenbased on known technology, but can only show their true efficiency potential with additional electronics.

Fig. 2: Laboratory test stand at Fraunhofer IKTS for separating heavy metals during sewage sludge incinerationThesesystems areoftenbased on known technology, but can only show their true efficiency potential with additional electronics.

There are now over 700 companies and institutes in the state with more than 17,000 employees and an annual turnover of over €3.7 billion in the environmental technology sector. In the state capital alone, over 360 players are involved in 'greentech', as environmental technology in the broader sense of the word is often referred to today.

"Saxon companies occupy a leading position, particularly in the lead markets of renewable energies, energy storage and the circular economy," according to an exposé by the Saxony Economic Development Corporation. "The industry benefits from Saxony's long tradition as an industrial location, especially for mechanical and plant engineering."

The Free State has been pursuing this path not only since the new traffic light government in Berlin called for an ecological renewal of the German economy. After all, the environmental technology roots here go back to the Middle Ages, when silver discoveries in the Ore Mountains attracted people from all over Germany to Saxony for the 'Berggeschrey'. Even then, this led to numerous innovations in processing, disposal and recycling. A word that is used inflationarily today also goes back to this line of tradition: in 1713, Freiberg's chief mining administrator Hans Carl von Carlowitz published the first book on the subject of 'sustainability'. The legacy of the GDR and the redevelopment projects of the post-reunification period gave this sector in the Free State another considerable boost in terms of experience, technological development and orders.

And the sector is still benefiting from this expertise accumulated over years and centuries. "The growth momentum of environmental technology is remarkable and exceeds that of other sectors of the economy," estimates the consulting firm Roland Berger in a study on 'Greentech - Made in Saxony'. The focus markets include Western Europe, Eastern Europe, North America and China. And in view of the energy, environmental and climate policy goals that Germany and many other countries around the world have set themselves, strong growth in environmental research, recycling technologies and their commercial exploitation can also be expected in the coming years.

Suprashming: On the trail of the frictionless engine

Fig. 3: Extremely hard carbon-based 'Diamor' coatings play a key role on the road to superlubrication. The IWS wants to add foreign atoms such as boron to these so that they combine with certain lubricant molecules and create ultra-lubricating interfaces during operation. This should reduce friction in the engine by around half compared to today'slevelsFraunhofer Institutes based in Dresden recently presented a series of innovations that promise greater environmental protection, economical use of resources and cost reductions in equal measure. For example, a team led by Dr. Volker Weihnacht from the Fraunhofer Institute for Material and Beam Technology (IWS) is working on virtually frictionless motors and gears as part of the joint projects 'Prometheus' and 'Chephren'. They combine carbon layers of diamond-like hardness, which they deposit in vacuum chambers under computer control, with new types of environmentally friendly lubricants. This enables them to create ultra-lubricating interfaces that drastically reduce friction in engines. In the next step, the engineers want to advance to so-called 'superlubrication' through improved layer qualities, plasma filters and dopants. This should enable virtually friction-free machines. The researchers are not only thinking of the classic combustion engine, but also the gearboxes and bearings of battery-powered cars and bicycles, as well as the drive chains of combine harvesters and the many moving components in machine tools.

Fig. 3: Extremely hard carbon-based 'Diamor' coatings play a key role on the road to superlubrication. The IWS wants to add foreign atoms such as boron to these so that they combine with certain lubricant molecules and create ultra-lubricating interfaces during operation. This should reduce friction in the engine by around half compared to today'slevelsFraunhofer Institutes based in Dresden recently presented a series of innovations that promise greater environmental protection, economical use of resources and cost reductions in equal measure. For example, a team led by Dr. Volker Weihnacht from the Fraunhofer Institute for Material and Beam Technology (IWS) is working on virtually frictionless motors and gears as part of the joint projects 'Prometheus' and 'Chephren'. They combine carbon layers of diamond-like hardness, which they deposit in vacuum chambers under computer control, with new types of environmentally friendly lubricants. This enables them to create ultra-lubricating interfaces that drastically reduce friction in engines. In the next step, the engineers want to advance to so-called 'superlubrication' through improved layer qualities, plasma filters and dopants. This should enable virtually friction-free machines. The researchers are not only thinking of the classic combustion engine, but also the gearboxes and bearings of battery-powered cars and bicycles, as well as the drive chains of combine harvesters and the many moving components in machine tools.

The super-lubricating 'Chephren' components should be ready for series production around the end of the decade. Interest from industry is already high. This can also be seen from the broad participation in the joint project. Among others, BMW, Wittenstein SE, VTD Vakuumtechnik Dresden, IWIS Munich and Fuchs Schmierstoffe from Mannheim are on board, as well as the Federal Ministry of Economics and Technology, which is providing funding.

The consistent use of 'super lubrication' in engines and gearboxes of cars, buses and trucks as well as in general mechanical engineering could reduce global carbon dioxide emissions by several hundred million tons per year. Wear damage as well as maintenance and lubricant costs would be significantly reduced. "Technological advances, particularly with extremely lubricious carbon layers, should finally make it possible to almost completely banish friction from technical systems," emphasizes Dr. Weihnacht.

IKTS: Combining closed-loop technologies in a factory complex

In so-called Laser-ArcTM systems, for example, a thin layer of 'tetrahedral amorphous' carbon, abbreviated ta-C, is created on piston rings. These layers are very hard and, after mechanical polishing, also very smoothGlobalecological effects are also expected by another Fraunhofer team from innovative factory and agricultural concepts that cleverly combine renewable energy sources, vertical farming and the latest electrochemical and filter-based water treatment technologies. State-of-the-art electronic control systems will be used. "With our technologies, we can finally link the water, energy and food sectors in a highly efficient way," says Dr. Burkhardt Faßauer, who heads the Department of Circular Technologies and Water at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden.

In so-called Laser-ArcTM systems, for example, a thin layer of 'tetrahedral amorphous' carbon, abbreviated ta-C, is created on piston rings. These layers are very hard and, after mechanical polishing, also very smoothGlobalecological effects are also expected by another Fraunhofer team from innovative factory and agricultural concepts that cleverly combine renewable energy sources, vertical farming and the latest electrochemical and filter-based water treatment technologies. State-of-the-art electronic control systems will be used. "With our technologies, we can finally link the water, energy and food sectors in a highly efficient way," says Dr. Burkhardt Faßauer, who heads the Department of Circular Technologies and Water at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden.

Properly treated, wastewater from municipalities and old mines in particular can become a source of raw materials, fertilizer and energy. Faßauer refers to estimates according to which around 87.5 TWh/a of energy, 1.8 million t/a of nitrogen and 275,000 t/a of phosphorus lie dormant in wastewater in the EU. However, a significant proportion of this has so far ended up largely unused in landfills or incineration plants. The energy content alone is equivalent to the annual production of a dozen large power plants.

By combining several technological approaches, some new and some familiar, the Fraunhofer researchers in Saxony are now aiming to recover some of these treasures in wastewater. These include fluidized bed combustion reactors that convert heavy metals in sewage sludge into gases at temperatures between 800 and 1000 °C and then separate them using heat-resistant ceramic filters. What remains is a concentrated phosphorus ash that can be further processed into fertilizer.

The Faßauer team also believes that the already well-known sewage sludge digestion process, which produces sewage gas, can be taken much further than before. Special plants could be used to better separate the various gas components in the sewage gas and operate combined heat and power plants with higher efficiency using the processed methane. The separatedCO2 could then be pumped into greenhouses to increase crop yields. If sewage sludge processors and greenhouses are located close to each other on the outskirts of the city, space-saving cultivation techniques such as vertical farming, in which greenhouses or cultivation containers are arranged vertically on top of each other, are also conceivable. In general, such concepts only develop their full potential when they are arranged close together in complex factories.

H2: Will alkaline, PEM or high-temperature electrolysis prevail?

Hot gas filter with ceramic filter elements for the recovery of valuable materials during sewage sludge incineration (pilot plant in Pirna by TU Dresden, LTC - Lufttechnik Crimmitschau GmbH and IKTS)The separated carbon dioxide from such new-generation recycling plants can also be used to produce synthetic fuel, for example, using Fischer-Tropsch synthesis - if the hydrogen required for this can be produced in a cost-effective and environmentally friendly way. The greentech industry and research in Saxony and Central Germany are also working intensively on this at the moment. This includes the 'HZwo' network in Chemnitz, the new hydrogen campus of Siemens and Fraunhofer in Görlitz, several projects of the universities of Dresden and Chemnitz as well as the Fraunhofer Institutes IWS and IKTS, the companies Linde and Sunfire in Dresden, FAE Elektrotechnik in Heidenau, Fuel Cell Powertrain Chemnitz and many others. And just a few months ago, Chemnitz acquired federal funding for a 'Hydrogen and Mobility Innovation Center' (HIC), which will focus primarily on the mobile use of hydrogen drives.

Hot gas filter with ceramic filter elements for the recovery of valuable materials during sewage sludge incineration (pilot plant in Pirna by TU Dresden, LTC - Lufttechnik Crimmitschau GmbH and IKTS)The separated carbon dioxide from such new-generation recycling plants can also be used to produce synthetic fuel, for example, using Fischer-Tropsch synthesis - if the hydrogen required for this can be produced in a cost-effective and environmentally friendly way. The greentech industry and research in Saxony and Central Germany are also working intensively on this at the moment. This includes the 'HZwo' network in Chemnitz, the new hydrogen campus of Siemens and Fraunhofer in Görlitz, several projects of the universities of Dresden and Chemnitz as well as the Fraunhofer Institutes IWS and IKTS, the companies Linde and Sunfire in Dresden, FAE Elektrotechnik in Heidenau, Fuel Cell Powertrain Chemnitz and many others. And just a few months ago, Chemnitz acquired federal funding for a 'Hydrogen and Mobility Innovation Center' (HIC), which will focus primarily on the mobile use of hydrogen drives.

An important focus for Saxony is expected to be on the development and construction of large-scale electrolysers. The players are pursuing all three basic technology paths: While Linde, for example, is currently designing one of Europe's largest PEM electrolysers in Leuna, Sunfire is concentrating on both older alkali technology and innovative high-temperature electrolysis (SOEC), which promises particularly high levels of efficiency but is still quite expensive.

Significant cost reductions for large electrolysers, as well as their counterparts, fuel cells, can be expected through new materials and process approaches. However, these key systems for the German and European hydrogen strategy are likely to become significantly cheaper primarily as a result of a move away from the manufacturing process that still dominates in many places - especially in stack production. The trend is towards accelerated automation of these assembly steps using 'Industry 4.0' methods and the massive use of sensors and robotics.

Moving away from manufacturing: reducing costs through automation

Electrolysis stack and synthetic fuel sample from Sunfire DresdenItis also worth taking a look at medium-sized companies: the special machine manufacturer Xenon, for example, which emerged from a department of the GDR computer combine Robotron in 1990, has launched an ambitious multi-year program with this focus: The engineers are working on high-speed running machines that assemble the reactor plate stacks for electrolysers and fuel cells at high speed and in a highly automated manner. "We see good opportunities here to come up with completely new solutions for stack assembly," assessed business unit developer Hartmut Freitag. The Saxons also refer to their experience with the post-automation of semiconductor factories and other technology companies, which has significantly improved their international competitiveness. Such experience from the electronics sector must now also be used in the plant industry for the scaling hydrogen economy.

Electrolysis stack and synthetic fuel sample from Sunfire DresdenItis also worth taking a look at medium-sized companies: the special machine manufacturer Xenon, for example, which emerged from a department of the GDR computer combine Robotron in 1990, has launched an ambitious multi-year program with this focus: The engineers are working on high-speed running machines that assemble the reactor plate stacks for electrolysers and fuel cells at high speed and in a highly automated manner. "We see good opportunities here to come up with completely new solutions for stack assembly," assessed business unit developer Hartmut Freitag. The Saxons also refer to their experience with the post-automation of semiconductor factories and other technology companies, which has significantly improved their international competitiveness. Such experience from the electronics sector must now also be used in the plant industry for the scaling hydrogen economy.

"We expect a strong surge in demand between 2027 and 2030," explains Freitag. This is when real high-speed vending machines will be needed. On the one hand, this is likely to be driven by the numerous large-scale electrolysers that are to be installed in Germany and Europe by the end of the decade. On the other hand, more commercial vehicles and possibly also hydrogen-powered cars are likely to come onto the market, which should also boost demand for stacks. "We are talking about very fast-cycling systems with particularly high positioning accuracy, camera recognition and a high degree of automation," explained Benjamin Reichelt, who coordinates the four-person development team for the stack project.

In addition to economic effects, ecological hopes are also pinned on the success of such projects: "Hydrogen technologies can make a major contribution to achieving climate neutrality in a modern, resource-conserving and at the same time value-adding society," according to a joint assessment by the Fraunhofer Institutes for Material and Beam Technology (IWS) in Dresden and for Machine Tools and Forming Technology (IWU) in Chemnitz. In the future, for example, emission-free car drives from fuel cells will be possible that cost hardly more than a 'combustion engine'. Technologically, Dr. Ulrike Beyer, head of the IWU hydrogen task force, sees a very similar pivotal point for this goal as the xenon engineers in Dresden: "We can only achieve this if we advance from the previous manufacturing operation to mass production."

Electricity-hydrogen-electricity buffer: efficiency still too low

Sunfire CEO Christian von Olshausen in front of an electrolysis plantItmight make sense to consider fuel cells and electrolysers, which are already closely related in technological terms, as a complex and to develop robot-supported high-throughput production approaches for both families of systems at the same time. Coupling the two systems offers the opportunity to at least partially solve another challenge of the energy transition. Hydrogen could serve as an energy buffer for the supply peaks and troughs ('dark doldrums') of solar and wind power plants. The concept of electrolytically producing hydrogen from water using surplus electricity from renewable energy sources and using it to generate electricity again when demand peaks has been around for some time. But the big breakthrough has yet to come. This is also due to the fact that the efficiency of this overall process from electricity to hydrogen and back again to electricity often only reached 30 to 50 % in older systems - and was therefore far below the efficiency of a large battery. However, modern high-temperature systems, on which Sunfire, Fraunhofer-IKTS and others in Bavaria are working, could increase this overall efficiency to over 65%. Engineers are now moving away from the concept of reversible systems, which use automatic control technology to switch back and forth between fuel cell and electrolyser operating modes, for reasons of efficiency. However, this does not generally speak against the coupling of optimized electrolysers and fuel cells in a hydrogen storage complex.

Sunfire CEO Christian von Olshausen in front of an electrolysis plantItmight make sense to consider fuel cells and electrolysers, which are already closely related in technological terms, as a complex and to develop robot-supported high-throughput production approaches for both families of systems at the same time. Coupling the two systems offers the opportunity to at least partially solve another challenge of the energy transition. Hydrogen could serve as an energy buffer for the supply peaks and troughs ('dark doldrums') of solar and wind power plants. The concept of electrolytically producing hydrogen from water using surplus electricity from renewable energy sources and using it to generate electricity again when demand peaks has been around for some time. But the big breakthrough has yet to come. This is also due to the fact that the efficiency of this overall process from electricity to hydrogen and back again to electricity often only reached 30 to 50 % in older systems - and was therefore far below the efficiency of a large battery. However, modern high-temperature systems, on which Sunfire, Fraunhofer-IKTS and others in Bavaria are working, could increase this overall efficiency to over 65%. Engineers are now moving away from the concept of reversible systems, which use automatic control technology to switch back and forth between fuel cell and electrolyser operating modes, for reasons of efficiency. However, this does not generally speak against the coupling of optimized electrolysers and fuel cells in a hydrogen storage complex.

Flywheel storage for the dark doldrums

From the middle of the decade, Xenon wants to gradually bring high-speed assembly systems for stacks of fuel cells and electrolysers onto the market: Xenon boss Tobias Reissmann (left) and business unit developer Hartmut FreitagConstructionmachinery engineers at TU Dresden are pursuing a completely different, actually well-known, but highly modernized energy buffer approach: together with partners from industry, they have built a 'rotational kinetic storage' (RKS) in Boxdorf in the Lusatian lignite mining region. This flywheel storage system can store half a megawatt hour of energy and release up to 500 kilowatts at peak times. According to the university, this storage system is therefore five times larger than the largest single flywheel storage system built to date. However, it is not yet a product ready for series production, but a demonstrator.

From the middle of the decade, Xenon wants to gradually bring high-speed assembly systems for stacks of fuel cells and electrolysers onto the market: Xenon boss Tobias Reissmann (left) and business unit developer Hartmut FreitagConstructionmachinery engineers at TU Dresden are pursuing a completely different, actually well-known, but highly modernized energy buffer approach: together with partners from industry, they have built a 'rotational kinetic storage' (RKS) in Boxdorf in the Lusatian lignite mining region. This flywheel storage system can store half a megawatt hour of energy and release up to 500 kilowatts at peak times. According to the university, this storage system is therefore five times larger than the largest single flywheel storage system built to date. However, it is not yet a product ready for series production, but a demonstrator.

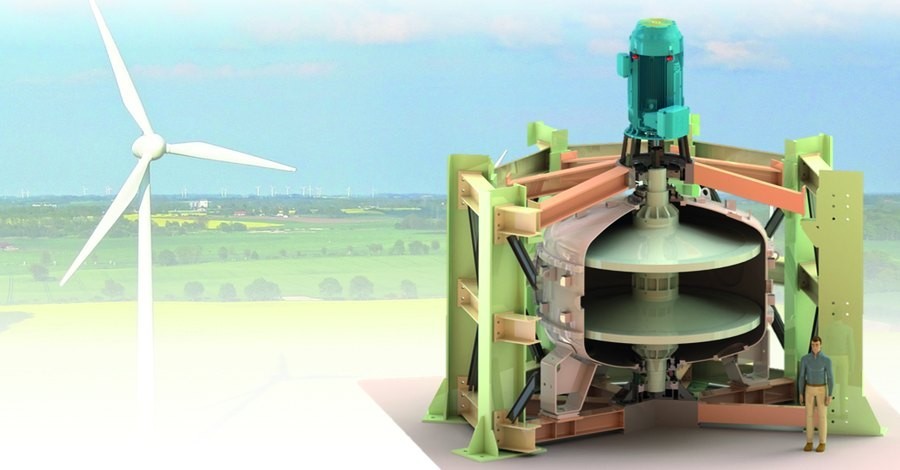

"The aim was to develop a long-lasting, dynamic and highly efficient energy storage system that can be installed directly next to a wind turbine, i.e. where the electricity is generated and transmitted with low losses," explained Dr. Thomas Breitenbach from the Endowed Chair of Construction Machinery. "To achieve this, it was necessary to place completely new demands on the storage system and push the boundaries of the technology." Experts from the fields of mechanical engineering, plant engineering, hydraulics, vacuum technology, electrical engineering and sensor technology are working together to adapt the mechanical and electronic capabilities of this system to the requirements of today's networks.

Packaging waste decomposes into sand in the sea

In addition to such energy technology innovations, engineers in Bavaria are also working on a completely different ecological problem that is awaiting a solution worldwide: we are talking about the mountains and floating islands of plastic that have piled up around the world or are drifting through the oceans. The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology (FEP) is pursuing a turbo recycling approach. The focus here is on the unfortunately widespread bad habit of throwing shampoo sachets and similar small plastic packaging either directly into the ocean from ships or carelessly onto the street. The next rainy season washes this waste into the next river and ultimately into the sea - where the packaging waste then adds to the floating islands of garbage. An FEP team led by Dr. John Fahlteich has therefore now developed shampoo sachets that turn into silicon oxides - ultimately sand - and biopolymers in seawater. "In the sea, this packaging decomposes by itself in less than six months," promises John Fahlteich.

Partial sectional view of the construction of the rotational kinetic storage unit with a human as a reference point

Partial sectional view of the construction of the rotational kinetic storage unit with a human as a reference point

Pyrolysis ships against floating islands of plastic waste

Produced from plastic waste: fuel mixture from the Biofabrik's pyrolysis container At the other end of the chain, namely the mountains and islands of waste, is where the 'Biofabrik' Dresden comes in: They have designed pyrolysis plants that use precise process control to convert foil bags, PET bottles and other civilization waste into oil, wax and other usable organic substances particularly efficiently. To do this, the reactors heat the plastics to just below the combustion point. There, the long polymer chains liquefy into shorter molecules. The resulting substances can then be processed into marine diesel, for example. The plants are intended to reduce waste dumps in emerging and developing countries and also provide secure sources of income for the local population. There are also plans to install mobile versions on ships in the future. These will then - possibly controlled by AI - 'eat up' the floating islands of plastic waste in the oceans. These highly automated floating recycling factories could then use the pyrolysis products to refill their own diesel tanks.

Produced from plastic waste: fuel mixture from the Biofabrik's pyrolysis container At the other end of the chain, namely the mountains and islands of waste, is where the 'Biofabrik' Dresden comes in: They have designed pyrolysis plants that use precise process control to convert foil bags, PET bottles and other civilization waste into oil, wax and other usable organic substances particularly efficiently. To do this, the reactors heat the plastics to just below the combustion point. There, the long polymer chains liquefy into shorter molecules. The resulting substances can then be processed into marine diesel, for example. The plants are intended to reduce waste dumps in emerging and developing countries and also provide secure sources of income for the local population. There are also plans to install mobile versions on ships in the future. These will then - possibly controlled by AI - 'eat up' the floating islands of plastic waste in the oceans. These highly automated floating recycling factories could then use the pyrolysis products to refill their own diesel tanks.

"Our vision is to develop sustainable and profitable business models," emphasizes the Bio-fabrik team. They are convinced that the removal of plastic waste from the earth does not have to be a permanently subsidized grant project, but can even be profitable. And the demand for this new-generation environmental technology is also considerable internationally, assures Biofabrik spokesperson Hendrik Oeser: "Since China has banned imports of plastic waste, the demand for other recycling options has been high worldwide."

Sources:

Saxony Economic Development Corporation,

Fraunhofer IWS, IKTS, FEP, IWU,

Biofabrik,

TU Dresden,

TU Chemnitz,

Oiger.de,

Saxon Ministry of Economic Affairs,

State Statistical Office Kamenz,

Xenon,

Sunfire