Soldering is still one of the most commonly used connection technologies in electronics production. Many years ago, lead began to be banned there, and thus from electronics as a whole. Has it disappeared completely? No. Is that a problem? - Well, this issue is perhaps problematic in a completely different way.

Until now, recycling in electronics has tended to be an unpopular or critical topic. Many people still remember the pictures and videos of components being desoldered over an open fire in Asia and Africa. ... not a nice topic - considering all the flame retardants and other critical substances. Lead was/is just one of many elements.

The most topical and explosive issue is the question of energy saving

The most topical and explosive issue is the question of energy saving

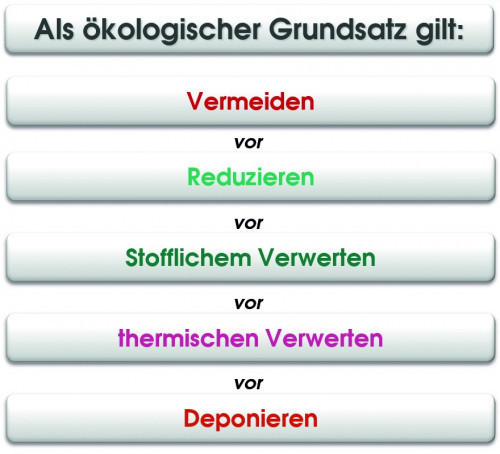

In Germany, reuse and recycling were considered very early on. At the beginning of the 1990s, there were a number of solutions and proposals. What remained was the guiding principle 'As long as there are enough precious metals in electronics, material recycling is worthwhile'. During a guided tour of various 'precious metal forges', it was possible to see how the gold, silver and platinum bars ended up disappearing into a high-security wing.

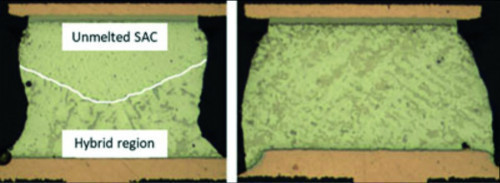

Cross-sectional image of a SAC-LTS hybrid compound (left) and a homogeneous LTS compound (center)

Cross-sectional image of a SAC-LTS hybrid compound (left) and a homogeneous LTS compound (center)

In the meantime, recycling behavior is changing. Other metals are also becoming increasingly expensive and therefore interesting for such recovery and return to the cycle (e.g. copper).

However, the most pressing current issue is the question of energy consumption and savings. So will the question of environmentally relevant factors in their weighting 'reinforce' the energy issue to such an extent that concerns about subsequent adverse health effects - in the event of improper use/disposal - no longer represent the primary and overriding criterion?

In this context, let's look at lead as an alloy - one of the most technically researched and mastered electronic materials: its processing is significantly more energy-efficient compared to current lead-free solders!

I would therefore like to pose a few questions at this point:

- So, with the inclusion of good recycling strategies, would a paradigm shift regarding lead in electronics and a return to lead-based soldering be conceivable?

- Would this be a possibility with closed loops? (I am having a conversation with environmental specialists who are working on the ROHS issue and WEEE).

- What would be the advantage or benefit of a return to leaded soldering?

- - an approx. 30 % energy saving (costs ↓)

- - A higher yield (costs ↓)

- - high process stability, even with smaller quantities (costs ↓)

- - lower error rates in further processing (costs ↓)

- This would mean that costs could also be reduced or would not explode as a result of the energy andCO2 savings.

- It would also mean that cost savings could be made on additives and base materials.

- For many applications, base materials with continuous operating temperatures of less than 100 °C are sufficient. However, the high soldering temperatures of the traditional lead-free solders have forced higher temperature resistances for these base materials. These are not actually necessary.

- E-mobility will reduce the demand for high-temperature materials that are or were used in combustion engines.

- So is there great potential here for saving energy and the associatedCO2 savings ?

- The question or dilemma now is what counts more: energy andCO2 savings or lead-free?

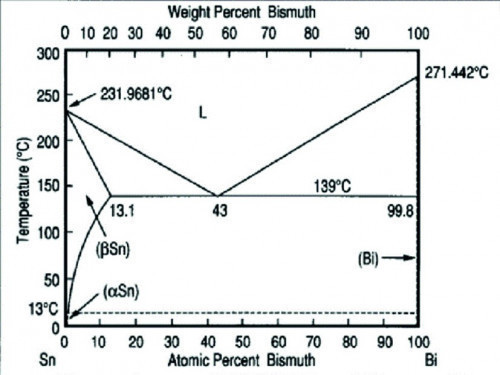

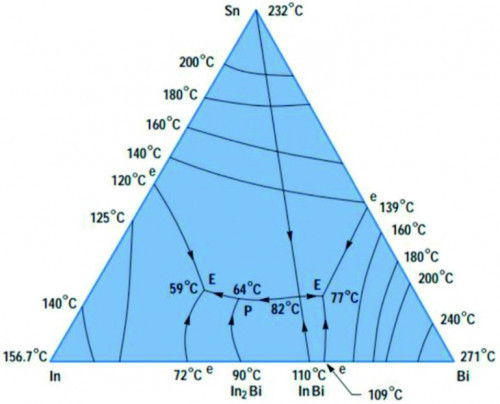

Alternative solders are being developed. Various international sources ([3, 4], see also Fig. 1, Fig. 2, Fig. 26) report on new developments based on bismuth/bismuth. It is interesting to note that large companies, such as Intel, are working intensively on this topic. Perhaps an indication of a new trend. In Germany, too, this topic has been under discussion for some time [1, 2]. If the return to lead-based soldering does not work out for most areas, at least the use of new, lower-melting solders would be a step forward. We should also look forward to the reports by Gustl Keller and Volker Tisken on SMTconnect in the next issues.

Because one thing is certain: energy will not become cheaper.

You can look at it that way. We can look forward to it.

Kind regards

Jan Kostelnik

Sources:

[1] K. Birkner: SnBiAg1 in der Serienfertigung (SnBiAg1 for serial production), DVS-Berichte 273, Fachtagung Weichlöten - Forschung & Praxis für die Elektronikfertigung; Hanau 2011

[2] M. Nowottnick; A. Novikov; J. Trodler: Possibilities and Limits of Bismuth Solders, P.195-200, SMTA International, Rosemont, IL, USA, Sep. 17 - 21, 2017

[3] Y. Liu et al: Low melting point solders based on Sn, Bi and In elements, Materials Today Advances, Elsevier, 29.10.2020

[4] N. Badwe et al: Sn-Bi Low-Temperature Homogeneous Solder Joint Microstructures, circuitsassembly.com, 21.01.2020.

[5] J. Kostelnik: Trends in AVT - from 3D printed copper structures to stretchable and conformable, 77th SAET working group in cooperation with the FED - Der Norden grüßt, 08.12.2021