Dog lovers don't like to hear it, but some archaeologists are of the opinion that dogs were domesticated for their meat - which they believe is proven by cut marks on dog bones. Nevertheless, dogs were also buried in prehistoric times, but this has nothing to do with the saying.

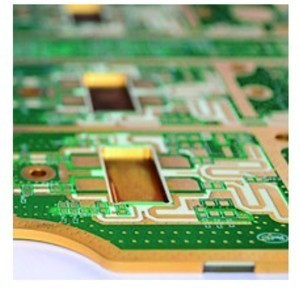

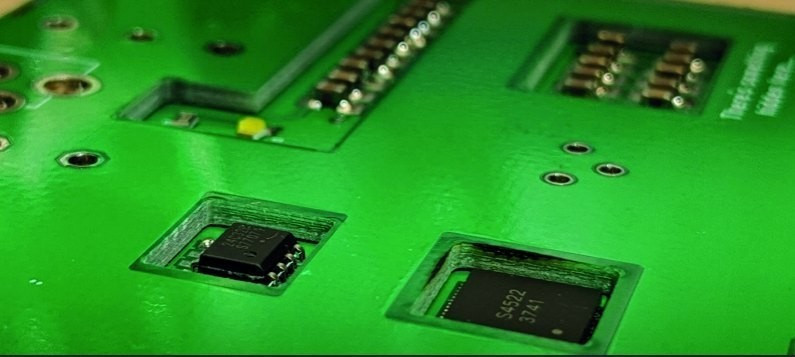

Fig. 2: Recess in a printed circuit board (Alcanta PCB)But let's not worry older ladies who fatten their furry friends on their laps, let's think about electronics, where people also start to bury things. The place where electronics bury chips is not the graveyard, but the circuit board.

Fig. 2: Recess in a printed circuit board (Alcanta PCB)But let's not worry older ladies who fatten their furry friends on their laps, let's think about electronics, where people also start to bury things. The place where electronics bury chips is not the graveyard, but the circuit board.

Of course, the first thing you ask yourself is why they do this - after all, it's not about the soul that needs to be saved in rituals. But there must be good reasons, because, as is so often the case, it makes the manufacture of the product more complicated. It is not just the printed circuit board that has to have new features, but the entire connection technology cycle is given special features.

The main motivation cited is that - especially when thicker components are recessed - the total thickness of the assembly can be reduced. Other arguments, such as better heat dissipation, shorter connection paths or even better durability, are also put forward. Some companies even see a reduction in the cost of the overall product as a possibility, even though production becomes more complicated and costly on several levels. But perhaps a higher degree of automation is being considered?

Recesses are increasingly required and it is now not uncommon to find such recesses with different dimensions and also in different inner layers. This makes it possible to use capacitors, transistors and even logic modules.

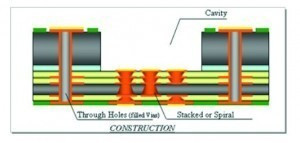

Fig. 3: Recesses in a printed circuit boardTheprocess is used for multilayer printed circuit boards and enables different shapes and layouts with several recesses at different depths.

Fig. 3: Recesses in a printed circuit boardTheprocess is used for multilayer printed circuit boards and enables different shapes and layouts with several recesses at different depths.

Most cavity boards are produced by the PCB manufacturer using a controlled depth routing process, which is carried out using special milling machines. Alternatively, cavities can also be produced using sequential lamination. Finally, of course, there is the most modern method, which uses special lasers that also allow the internal structure to be modeled.

As most of these recesses are filled with components that are still soldered, the process engineer is now faced with several problems. On the one hand, she has to provide the solder. Then there is the assembly and reflow soldering and finally, in many cases, cleaning before casting.

With the solder, you have the choice of either depositing it in the recess or applying it to the components before assembly - or possibly both.

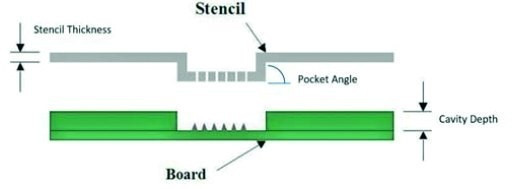

At first glance, it was thought that stencil printing was hardly feasible, but the good people have already come up with a lot of ideas and stencils with the right fit are already available from many suppliers.

It is obvious that the accuracy of customization is required here. The problem is exacerbated if several such recesses have to be covered with the same template. Cleverly manufactured templates, in which the insert is beveled or a certain amount of leeway is allowed, make balancing easier.

However, it quickly becomes clear that a normal squeegee cannot cope with this situation. Here, too, we have come up with a solution and segmented the squeegee. Cuts allow parts of the sheet to slide into the recess and still carry out the printing process. So all in all, it's not easy.

There are three other options. Pin transfer can bring solder into the depths of the PCB, a technique that has achieved good results in mass production but uses a paste that contains a lower proportion of metal. Dispensing in its various forms is slow, but could be a promising method if only a few points are covered. It is important to pay attention to the consistency of the paste, which should be somewhat thinner, and to choose a syringe that leaves deposits of the same size even after 10,000 points.

Fig. 4: Example of a stencil with corresponding LP

Fig. 4: Example of a stencil with corresponding LP

Fig. 5: Printing with a segmented squeegeeFinally, there is the much-discussed jetting. Even houses are now being sprayed with it, and why not paste heaps in the PCB? Here, too, it is important to use a system that works reliably. All too often, marketing promises are made that the system cannot then keep.

Fig. 5: Printing with a segmented squeegeeFinally, there is the much-discussed jetting. Even houses are now being sprayed with it, and why not paste heaps in the PCB? Here, too, it is important to use a system that works reliably. All too often, marketing promises are made that the system cannot then keep.

This somewhat extreme situation explains why assembly is more complex. Placing one or more components in the recesses requires 'dexterity'. Any twisting or correcting as well as too much pressure can smear the paste and ruin the subsequent soldering result. This is particularly important, as you also have your back to the wall if a repair process becomes necessary.

Depending on the type of component, either paste or flux can be applied to the component before it is placed and inserted. In the latter case, the balls must be able to melt during soldering, e.g. in the case of BGAs. Not all alloys on offer have melting points that can achieve this without damaging the component, another component or even the circuit board.

Flux is usually applied to the component with an immersion step, a method that is also feasible for certain pastes.

Fig. 6: This PCB contains a SOIC-8 and a QFN-60 package

Fig. 6: This PCB contains a SOIC-8 and a QFN-60 package

Finally, it remains to be determined whether everything has worked. Functional tests would be possible, but X-rays are probably required, especially during the development and introduction of such processes and then at least sporadically to ensure that the process runs within the set limits.

Literature and comments:

https://www.saw-leipzig.de/de/aktuelles/warum-der-hund-begraben-liegt-greiz

L.M. Snyder; W.E. Klippel: From Lerna to Kastro: further thoughts on dogs as food in ancient Greece, perceptions, prejudices and reinvestigations, British School at Athens Studies, Vol. 9, Zooarchaeology in Greece: Recent Advances (2003), Published By: British School at Athens

P. Vallabhajosyula et al: Reservoir Printing in Deep Cavities, SMTA Proceedings, SMTA International, Sep. 25-29, 2016, Rosemont, IL, USA

H. Grumm et al: The Potential of Stencil Technology - Choosing the Right Stencil Options to Maximize Yield and Earnings, SMTA Proceedings

W.O. Alger et al: Challenges of Manufacturing with Printed Circuit Board Cavities, IPC APEX EXPO Conference Proceedings

References:

[1] In the Middle Ages there was the term hunda, which means 'the booty' or 'the treasure'. In other words, the loot was actually buried. Over time, however, the word hunda fell out of use, but the phrase remained - but people reinterpreted it to refer to the dog

[2] https://ad.zh.ch/hier-liegt-der-hund-begraben