Christoph Lehmann's astute remark refers to paradise and the fact that God put a tree there even though he knew that his creation would break the commandment and steal an apple. But what does that have to do with soldering?

By the way, there is nothing about an apple in the Bible. The Koran also only speaks of a 'fruit', so God had hardly planted an apple tree, but perhaps vines. Or did Eve even snack on figs? After all, it was a very draconian punishment - by human standards - for the loving God to chase the two fruit thieves out of paradise ... and that for trivial theft.

![Abb. 1: Adam und Eva [2] – beide fühlten sich völlig unschuldig an ihrem unsanften Abschied aus dem Paradies Abb. 1: Adam und Eva [2] – beide fühlten sich völlig unschuldig an ihrem unsanften Abschied aus dem Paradies](/images/stories/Abo-2022-12/plus-2022-12-031.jpg) Fig. 1: Adam and Eve [2] - both felt completely innocent of their rude departure from paradise

Fig. 1: Adam and Eve [2] - both felt completely innocent of their rude departure from paradise

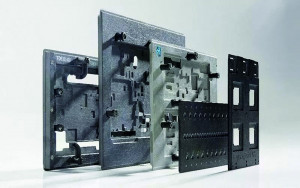

Soldering masks from Röchling, which are suitable for SMT, reflow and wave soldering processesItis hardly surprising that Adam did not necessarily blame himself for being thrown out. A similar phenomenon can be observed in soldering and especially in the prevalence of selective soldering. The EU and its RoHS directive are often blamed, as the higher temperatures caused by lead-free solder are not particularly good for some components. On the other hand, the soldering specialists on the line complain that the corresponding results come from a poor 'design' of the assembly. The design specialists, on the other hand, believe that the solderers simply cannot solder.

Soldering masks from Röchling, which are suitable for SMT, reflow and wave soldering processesItis hardly surprising that Adam did not necessarily blame himself for being thrown out. A similar phenomenon can be observed in soldering and especially in the prevalence of selective soldering. The EU and its RoHS directive are often blamed, as the higher temperatures caused by lead-free solder are not particularly good for some components. On the other hand, the soldering specialists on the line complain that the corresponding results come from a poor 'design' of the assembly. The design specialists, on the other hand, believe that the solderers simply cannot solder.

The marketers of selective soldering systems with their rosy promises contribute just as much to the questionable success as those managers who would rather sign a check for a series of systems than find out about the actual problems.

Selective soldering is not only a cost factor because it generates far more errors than a well-controlled wave soldering process or reflow production, but also because it introduces an additional production step (and often even several) with all the additional costs incurred due to the space required, necessary specialists and control steps.

It can be horrifying to come across rows of selective soldering systems in large-scale production facilities, all humming and buzzing. There is a wide range of methods used and why, from manual soldering to laser soldering.

In principle, some of the problems can already be tackled on the wave soldering system with masks (made of titanium?). This is not easy, but can prevent the purchase of another expensive system.

Selective soldering with mini waveAnobvious method is hand soldering, where you already have a wide choice. The traditional soldering iron is well known, hot air nozzles are no longer uncommon, and soldering tweezers and bar/bar soldering irons for melting two or more solder joints simultaneously have also found a market. Occasionally, someone tries infrared heating or even a laser on the parts still to be soldered.

Selective soldering with mini waveAnobvious method is hand soldering, where you already have a wide choice. The traditional soldering iron is well known, hot air nozzles are no longer uncommon, and soldering tweezers and bar/bar soldering irons for melting two or more solder joints simultaneously have also found a market. Occasionally, someone tries infrared heating or even a laser on the parts still to be soldered.

Hand soldering is very difficult to control and slow. Therefore, this step can only be taken in smaller productions.

Automating these basic methods is of course the logical next step. This can be done with robots, as is often seen in automotive supply companies, or with entire machine cells, with mini-wall, immersion systems, laser installations and hot air probably being the most common.

The fact that there are problems with all processes can be seen from the efforts of machine manufacturers to help users and offer them guidelines that should be taken into account in the design. Not only will this good advice be different for each type of system, but it is also a sign that the blame for the errors that are sure to occur is gladly rejected: "It's not our machine, it's your product!"

In hand soldering, the flux is usually supplied as a core in the wire. With machines, it must be applied 'selectively' before the soldering process, which is not easy with fully populated assemblies. Immersion baths, mini-waves and spraying processes are offered here before the PCB is heated. Pre-heating is usually necessary because otherwise distortions occur. This is because heating the PCB only locally leads to internal stresses.

Free of any guilt: Wilhelm Busch's youthful anti-heroes Max and Moritz

Free of any guilt: Wilhelm Busch's youthful anti-heroes Max and Moritz

Then everything is maneuvered precisely onto a mini surge or driven over it - in the hope that no other components are affected. The pictures in the machine manufacturers' publications usually only show the simplest constellations that even a fool could solder. What is required in reality often falls by the wayside, as this disturbs sales. But wouldn't it be more sales-promoting if you showed the customer that you can successfully master even the most difficult specifications?

Laser soldering, here at a laser power of 60 wattsThelaser soldering process depends on the type of solder to be used (wire, preform or paste). In the case of solder wire, the irradiation is carried out before the actual soldering process and the wire is then melted on the pad. This also helps to prevent the flux in the wire from splashing everywhere. This is much more difficult with preform or paste, and you have to work out how best to apply the energy. Diode lasers with wavelengths of around 800 nm or 980 nm and 50 to 100 watts are typically used here.

Laser soldering, here at a laser power of 60 wattsThelaser soldering process depends on the type of solder to be used (wire, preform or paste). In the case of solder wire, the irradiation is carried out before the actual soldering process and the wire is then melted on the pad. This also helps to prevent the flux in the wire from splashing everywhere. This is much more difficult with preform or paste, and you have to work out how best to apply the energy. Diode lasers with wavelengths of around 800 nm or 980 nm and 50 to 100 watts are typically used here.

No matter which method is used: One of the main problems is the residues on the assembly, which can be corrosive and conductive and therefore contribute to premature failure of the product. The smaller the components, the closer together they are and the lower the gaps, especially under the larger components, the more critical the contamination.

With the various selective methods, other fluxes and therefore other chemicals are often applied to the PCB, which differ from the original flux of the first soldering process. Not only does this make cleaning more complicated, because the solvent and the method must be adapted to the chemicals. The possibility of undesirable chemical reactions is also increased.

The allocation of blame thus becomes irrelevant, as is so often the case. To dwell on the religious, the devil is being cast out with Beelzebub here.

References

[1] Christoph Lehmann (1579-1639), German writer, school principal and town clerk in Speyer, from: Lehmann, Florilegum Politicum, Politischer Blumengarten, 1630

[2] Albrecht Dürer, Adam and Eve, two-part painting exhibited in the Museum del Prado (Madrid), the panels are considered the first autonomous nude depiction in the transalpine region

[3] Heinrich Christian Wilhelm Busch (1832-1908) Poet and illustrator who - alongside Lee Falk and Hal Foster - can probably be considered one of the forefathers of the genre 'comics' from Disney to Japanese manga

Literature

Gerjan Diepstraten: Design Improvements for Selective Soldering Assemblies[www.itweae.com/sites/default/files/technical-papers/GJD%20Paper%20-%20Design%20Improvements%20for%20Selective%20Soldering%20Assemblies%2012-9-2015.pdf]

Reid Henry: Practical Methods for Evaluating and Qualifying Selective Soldering Systems[https://rpsautomation.com/wp-content/uploads/2021/10/Practical-Methods-for-Evaluating-and-Qualifying-Selective-Soldering-Systems-1.pdf]

Omar García et al: Selective Reflow Rework Process, IPC Apex Expo Conference Proceedings[www.circuitinsight.com/pdf/selective_reflow_rework_process_ipc.pdf]

Xiang Wei et al: 'Partially-Activated' Flux Residue Influence on Surface Insulation Resistance of Electronic Assembly; SMTA Proceedings 2015, Rosemont, Il.[https://www.circuitinsight.com/pdf/partially_activated_flux_residue_influence_smta.pdf]

Image sources

www.roechling.com, www.kurtzersa.de, www.wolf-produktionssysteme.de