This lion is very suspicious of the spiked animal with its shy look and of course has a good reason for it. Sophia Loren's wry look [2] has also made the rounds of the world's press, but is such a quick glance still enough to spot errors in the electronics industry these days?

The entire industry is suffering from a shortage of skilled workers, which is probably also the reason for the recent waves of immigration. In the electronics industry in particular, individual companies are chasing skilled workers away from each other, so that constant turnover is causing increasing problems even on the production lines. This situation even exists in populous countries such as China. In Shenzhen, for example, more than 180,000 people work in a few square kilometers and managers are faced with a fluctuation of up to five percent per month. The neighboring company only needs to put a few more RMB on the table and the change is complete.

Middle managers are also complaining about this. In Western countries, young people crowd into lectures on economics and law while shying away from the strenuous studies of science and technical professions.

While there are still 400 students in the beginners' mathematics lectures, this is reduced to 80 in the second semester, 10 of whom may eventually pass their diploma and one of whom may be admitted to a doctoral thesis. A shy look at the websites of the various universities shows the lack of doctorates in the scientific subjects.

Of course, the incentive of temporary academic contracts is not exactly sensational either, so it is not surprising that fewer and fewer talented scientists are embarking on academic careers.

![Abb. 2: Studienabgänge 2016 in wissenschaftlichen Fächern je Land [3] Abb. 2: Studienabgänge 2016 in wissenschaftlichen Fächern je Land [3]](/images/stories/Abo-2021-07/plus-2021-07-0034.jpg) Fig. 2: Degrees in 2016 in scientific subjects per country [3]

Fig. 2: Degrees in 2016 in scientific subjects per country [3]

In electronics, the problem is further dramatized by rapid progress. The pressure that arises when, as with 5G technology, components become huge or, on the other hand, tiny and competition between individual companies and power blocs escalates requires enormous flexibility, as the impact on the entire economy will be remarkable.

Such a shortage of skilled labor can be mitigated either by increased and improved training with appropriate incentives or by more and more technology in manufacturing, where precisely this 5G technology will play a significant role.

![Abb. 3: Dimensionen elektronischer Bauteile [4] Abb. 3: Dimensionen elektronischer Bauteile [4]](/images/stories/Abo-2021-07/plus-2021-07-0035.jpg) Fig. 3: Dimensions of electronic components [4]

Fig. 3: Dimensions of electronic components [4]

While artificial intelligence first ventured into operations based purely on dexterity, it is now setting its sights on far more ambitious goals. Both very large and very small components can no longer be placed by hand. So precise and fast machines are used. But these also have to be controlled and so the question arises as to where and how to monitor their skills.

It is a truism that the later an error is discovered, the more expensive it is to rectify, using a multiplier of ten per production step as a rule of thumb. It is therefore most expensive if the error makes it to the customer.

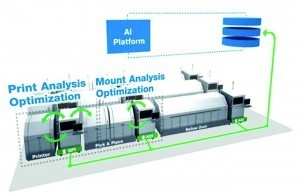

Fig. 4: Use of AI on an SM production lineThis meansthat the process engineer has to make decisions that lead to higher investments. However, she will only receive the money for this if she can prove that costs will be reduced and quality will increase in the long term. This applies in particular to the yield, i.e. the error rate in the individual production steps.

Fig. 4: Use of AI on an SM production lineThis meansthat the process engineer has to make decisions that lead to higher investments. However, she will only receive the money for this if she can prove that costs will be reduced and quality will increase in the long term. This applies in particular to the yield, i.e. the error rate in the individual production steps.

Checks after paste printing and placement are fairly obvious. However, it is usually left to specialists to find errors, which is very subjective, as one inspector may see an error here while another is satisfied. What constitutes a 'fault' may even be difficult to define.

The use of artificial intelligence, i.e. learning algorithms as they have long been known in mathematics and are now being enthusiastically adopted by programmers, can be introduced in many ways. Setting a target for what is desirable - as with the use of a 'golden circuit board' in paste printing - seems simple.

It is much more difficult to use a statistical feedback loop that collects data on the end product and correlates it with the print result. Given the amount of data that can be accumulated in mass production, this is actually a difficult but feasible task. However, the selection of the parameters to be controlled on the machine alone requires an essential understanding of the process. There is the machine, the stencil, cleaning cycles, paste specifications, monitoring systems and much more.

Similar mind games can then be played with the assembly. However, everything suffers from a few points that have to do with training. Programmers are not mathematicians or statisticians and certainly not soldering experts. This makes it difficult to select and use the right mathematical models and statistical methods. In addition, there are also the definitions of a 'good print image' for the paste and the 'correct positioning' in the x-y and z directions as well as the twisting φ and lack of coplanarity during assembly.

Fig. 5: Some of the new components on the tip of a ballpoint penThecurrent monitoring systems - including X-ray - still have very high alpha and beta errors, i.e. incorrectly detected or overlooked errors. Reducing both at the same time would now be a task for AI. Whether it will be able to replace a well-trained engineer in the foreseeable future depends, among other things, on the commitment of the best theoreticians and programmers during development. This brings us back to the basic situation in industry and electronic manufacturing: there is a lack of well-trained specialists and the complaints of gurus such as Erik Brynjolfsson and Andrew McAfee seem to fall on deaf ears with politicians. An important point here is also the promotion of basic research and not application in order to serve industry. However, policy makers are steering more and more students towards graduating with a Bachelor's degree rather than a Master's degree (or, in the past, the more prestigious Diploma) or a PhD.

Fig. 5: Some of the new components on the tip of a ballpoint penThecurrent monitoring systems - including X-ray - still have very high alpha and beta errors, i.e. incorrectly detected or overlooked errors. Reducing both at the same time would now be a task for AI. Whether it will be able to replace a well-trained engineer in the foreseeable future depends, among other things, on the commitment of the best theoreticians and programmers during development. This brings us back to the basic situation in industry and electronic manufacturing: there is a lack of well-trained specialists and the complaints of gurus such as Erik Brynjolfsson and Andrew McAfee seem to fall on deaf ears with politicians. An important point here is also the promotion of basic research and not application in order to serve industry. However, policy makers are steering more and more students towards graduating with a Bachelor's degree rather than a Master's degree (or, in the past, the more prestigious Diploma) or a PhD.

Typical of this is the lament of Australian universities [5], who feel they have lost Aus$2 billion due to the virus epidemic in China, rather than turning a blind eye to the failure to train capable graduates.

References

[1] Middle Low German schēl 'crooked(eyed)'

[2] https://en.wikipedia.org/wiki/Jayne_Mansfield%E2%80%93Sophia_Loren_photo

[3] https://www.nextbigfuture.com/2017/08/future-tech-dominance-china-outnumber-usa-stem-grads-8-to-1-and-by-2030-15-to-1.html

[4] https://www.electronics-notes.com/articles/electronic_components/surface-mount-technology-smd-smt/packages.php

[5] ASM Assembly Systems GmbH

Literature:

J. Yuh et al: Combing Automated Advanced Process Control with Feedback to Revolutionize the Printed Circuit Board Assembly Process, Proceedings of SMTA International, 2018, Rosemont, IL, USA

https://www.newpointdeview.com/pro-en/intercultural-compentence/high-employee-turnover-in-china-not-matter-of-money/

D. Zogbi: The Next Generation in Passive Electronic Components, TTI MarketEye

Bernstein; A. Raman: The Great Decoupling: An Interview with Erik Brynjolfsson and Andrew McAfee, Harvard Business Review, June 2015

About the person

Prof. Rahn is a globally active consultant

on interconnect technology issues.

His new book on 'Special Reflow Processes' was recently published by Leuze Verlag. He can be contacted at