Atotech, the world's leading technology company in the field of specialty chemicals, equipment, software and services, is taking part in SurfaceTechnology for the second time this year from June 21 to 23, 2022 in Stuttgart. More than 200 exhibitors will present the most important trends in the surface industry to over 5,000 trade visitors over the three days of the trade fair. Atotech's experts will welcome interested visitors in Hall 1 at Stand C 33/30 at the "World of Surfaces" on the joint stand of the German Surface Technology Association (ZVO).

Surface coating with Zinni 220"We look forward to discussing the latest market trends in surface treatments with trade fair participants and presenting our new products and innovations to them," says Hartmut Rapp, Business Director at Atotech. "Atotech offers perfectly coordinated processes for every single step of the spectrum of decorative and functional surface finishing applications - from pre-treatment to final sealing." Atotech's product portfolio includes decorative coatings, anti-corrosion coatings, wear-resistant coatings and processes for the paint industry. Atotech's product highlights at SurfaceTechnology Germany are:

Surface coating with Zinni 220"We look forward to discussing the latest market trends in surface treatments with trade fair participants and presenting our new products and innovations to them," says Hartmut Rapp, Business Director at Atotech. "Atotech offers perfectly coordinated processes for every single step of the spectrum of decorative and functional surface finishing applications - from pre-treatment to final sealing." Atotech's product portfolio includes decorative coatings, anti-corrosion coatings, wear-resistant coatings and processes for the paint industry. Atotech's product highlights at SurfaceTechnology Germany are:

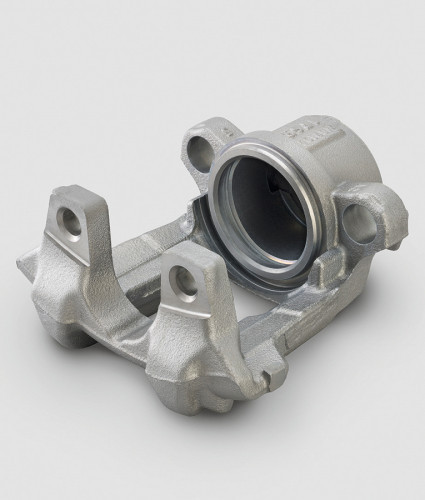

Zinni 220 - the most advanced acid zinc-nickel technology for outstanding corrosion protection: Zinni 220 is a highly innovative acid zinc-nickel process that combines outstanding corrosion protection with optimized coating and metal distribution and improved depth scattering. Zinni® 220 enables higher coating thicknesses with lower current density and optimum nickel incorporation rates of 12 to 15% compared to standard zinc-nickel processes. Depending on the requirements, Zinni® 220 can be adjusted as a glossy, semi-glossy or matt surface.

Zintek 200 + Zintek Top LV - a coating system for various OEM specifications: Atotech's Basecoat Zintek 200, together with the Topcoat Zintek Top LV, is an exceptional process combination for the automotive industry that meets several automotive OEM specifications at once. The zinc flake coating system meets the complex friction coefficient requirements for demanding multiple assembly as well as hot release behavior, even under different environmental conditions.

REACh-compliant solutions for decorative coating: Atotech offers Cr(VI)- and PFAS-free processes for the pre-treatment of plastics and decorative chrome plating of surfaces:

Covertron 600, Atotech's Cr(VI)-free plastic pretreatment process delivers equivalent performance and quality to conventional Cr(VI) processes.

TriChrome, Atotech's trivalent chromium process for decorative applications, is suitable for metal-based applications, plastic coatings and nickel-free intermediate layers. With their unique alloy properties, TriChrome processes offer a wide range of design possibilities with high corrosion resistance.

www.atotech.com / Hall 1, Stand C 33 /30