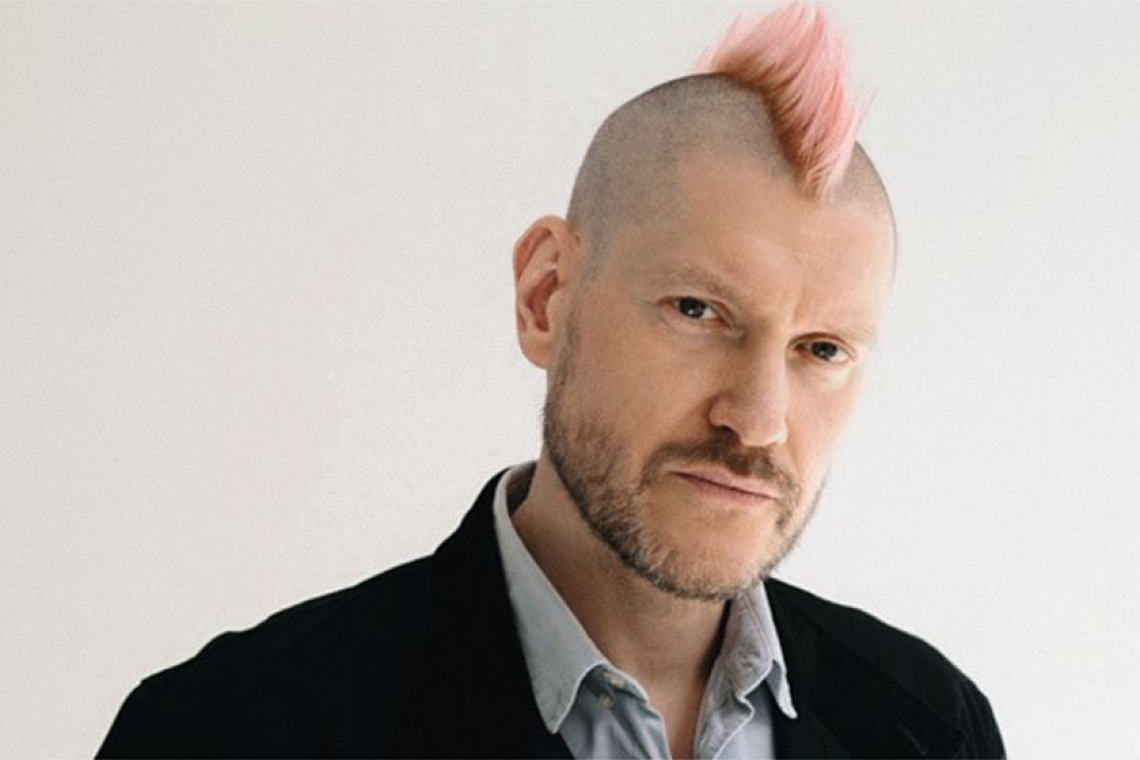

Automated machines, collaborative robots, 3D printing, artificial intelligence in data-driven process chains - the world of metalworking is changing rapidly. Recognizing development trends and maintaining an overview is a challenge. The crucial question remains as to how individual companies can correctly classify and profitably utilize what is on offer. For Dr. Markus Heering, Managing Director of EMO organizer VDW (German Machine Tool Builders' Association), EMO from 22-26 September 2025 is much more than just a trade fair. "As a platform for dialog between all international players in the industry - manufacturers and users alike - it is unique, because nowhere else will guests encounter so much international expertise as at the EMO," he says.

There is a need for modernization in almost every factory or production facility. Rising costs, energy and raw material prices as well as the new targets forCO2 emissions and the circular economy are the main drivers. Demanding applications such as in aerospace, medical technology or renewable energies require higher productivity and quality. The materials being processed are also changing. High-performance or coated materials are becoming thinner and lighter, stronger and more durable, and more resistant to corrosion and heat. Machining requires more specialist knowledge, which makes digital solutions and AI particularly worthwhile in times of increasing skills shortages.

The VDW cites automation, sustainability, digitalization and artificial intelligence as the most important development trends in metalworking. "Against the backdrop of high quality requirements and a shortage of skilled workers, automation is of central importance," emphasizes VDW Executive Director Heering. Automated production should enable both series production and cost-effective one-off production. Automation ranges from simple solutions such as pallet changers and handling systems to the use of robots and autonomous systems. The joint Cobot Area stand at EMO is explicitly dedicated to the possible applications of collaborative robots.

On the one hand, sustainability is about the measures that can be taken to reduce the energy and material consumption of machines and any ancillary and downstream processes. But it is also about the overall contribution that machines can make toCO2 reduction and sustainable industrial production. The Sustainability Area at EMO 2025 is a meeting place to experience modern solutions for sustainable production.

Digital solutions relating to the IoT (Internet of Things) and AI (Artificial Intelligence) will play a key role in making production more efficient in the future. More and more machines are being equipped with monitoring systems and sensors as standard to collect data. Digitally networked process chains create transparency. "Intelligent" machines can predict whether a failure is imminent and enable predictive maintenance.